14 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

662 |

Published by VMT at May 09 2024

662 |

Published by VMT at May 09 2024

With the rapid development of modern industry, die casting technology plays a crucial role in manufacturing. Zinc die casting, as an important branch of die casting technology, has been widely used in multiple fields due to its unique advantages. This article will provide a detailed analysis of the definition, material selection, advantages and disadvantages, applications of zinc die casting, as well as addressing common issues related to zinc alloy die casting parts, aiming to offer readers a comprehensive and in-depth understanding.

I. What is Zinc Die Casting?

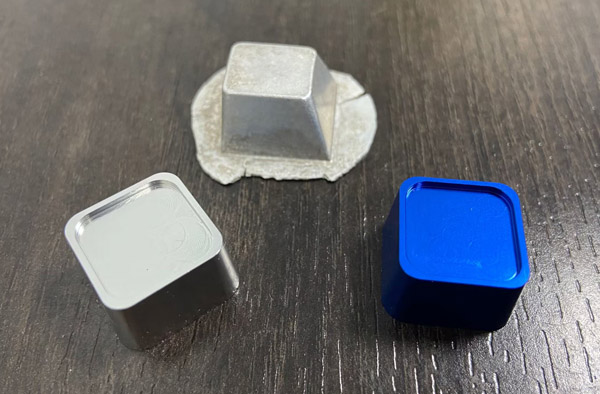

Zinc die casting is a process of injecting molten zinc alloy into molds under pressure, which solidifies and forms the desired shapes of parts or products after cooling. Zinc alloys, characterized by low melting point, good fluidity, and ease of processing, make zinc die casting an efficient and economical forming method. Through zinc die casting, parts with complex shapes and high precision can be produced to meet various industrial demands.

II. What other materials can undergo die casting?

In addition to zinc alloys, many other materials can also undergo die casting, such as aluminum alloys, magnesium alloys, copper alloys, etc. These materials have their own characteristics suitable for different application scenarios. For example, aluminum alloy die castings are lightweight and high strength, widely used in automotive, electronics, and other fields; magnesium alloy die castings have excellent heat dissipation and corrosion resistance, suitable for manufacturing products requiring good heat dissipation.

III. Advantages of Zinc Die Castings

High production efficiency: Zinc die casting process enables rapid and continuous production, greatly improving production efficiency.

High part accuracy: Zinc alloys have good fluidity and can fill fine structures of molds, ensuring the precision and consistency of parts.

Good surface quality: Zinc die castings have smooth surfaces without defects such as pores and shrinkage, with high aesthetics.

High material utilization: During the die casting process, zinc alloys can fully utilize the mold space, reducing material waste.

IV. Disadvantages of Zinc Die Castings

High mold costs: Zinc die casting requires specialized molds for production, resulting in high costs for mold manufacturing and maintenance.

Not suitable for large parts: Due to the relatively low strength and hardness of zinc alloys, the zinc die casting process has limitations in manufacturing large parts.

High requirements for operation skills: Zinc die casting process requires strict control of parameters such as temperature and pressure, demanding high operation skills.

V. Applications of Zinc Die Castings

Zinc die castings, with their unique advantages, have been widely used in various fields. For example, in the automotive industry, zinc die castings are used to manufacture engine parts, chassis components, etc.; in the household appliance sector, zinc die castings are used for manufacturing electrical enclosures, radiators, etc.; in the toy industry, zinc die castings, due to their smooth surface and aesthetic characteristics, are widely used in various toy components. In addition, zinc die castings are also widely applied in telecommunications, medical, aerospace, and other fields.

VI. Conclusion

In conclusion, zinc die casting, as an efficient and economical forming technology, has broad application prospects in the manufacturing industry. By thoroughly understanding the definition, material selection, advantages and disadvantages, and applications of zinc die casting, we can better leverage its advantages in industrial production and promote the sustainable development of the manufacturing industry.

VII. FAQ about Zinc Alloy Die Castings

Q: What causes the surface porosity of zinc alloy die castings?

A: The surface porosity of zinc alloy die castings may be caused by factors such as unreasonable mold design, poor exhaust, or incomplete removal of gases in the molten metal. This issue can be addressed by optimizing mold design, improving exhaust systems, or adjusting die casting process parameters.

Q: How to improve the strength of zinc alloy die castings?

A: Improving the strength of zinc alloy die castings can be achieved by selecting high-strength zinc alloy materials, optimizing part structure design, and adding heat treatment processes. Moreover, strict control of die casting process parameters is also essential to ensure part strength.

Q: How to avoid deformation of zinc alloy die castings during production?

A: To avoid deformation of zinc alloy die castings during production, attention should be paid to the following aspects: Firstly, ensure the accuracy and stability of the mold; secondly, control the temperature and pressure during the die casting process to prevent excessive temperature or pressure from causing part deformation; finally, perform appropriate post-treatments such as correction and aging to eliminate internal stresses and improve dimensional stability of parts.

By addressing the above questions, we can better understand and solve the issues that zinc alloy die castings may encounter during production, thereby improving production efficiency and product quality.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!