15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

169 |

Published by VMT at Nov 11 2023

169 |

Published by VMT at Nov 11 2023

CNC machining manufacturers meet customer customization needs in a variety of ways:

Perfect communication: Fully communicate with customers to understand their specific needs and customization requirements. Including product design requirements, dimensional specifications, material selection, surface treatment, delivery time, etc., to ensure that both parties have a consistent understanding of customization needs.

Professional technical support: CNC machining manufacturers should have a professional technical team with rich machining experience and knowledge. Utilizing cutting-edge CNC machines and software, complex custom designs can be created to meet customer-specific requirements. They can provide customers with technical consultation and advice, help customers choose appropriate processing techniques and materials, and conduct professional assessment and analysis of customization needs.

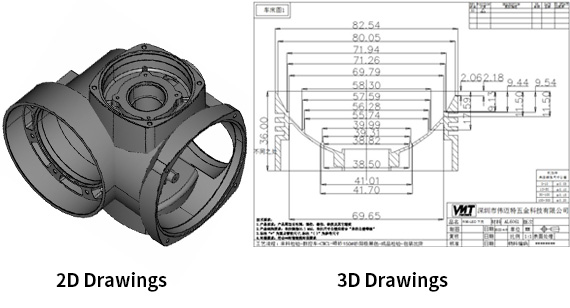

Customized design and electronic drawings: CNC machining manufacturers can customize designs according to customer needs and provide corresponding electronic drawings. This ensures that the dimensions and geometries during processing meet customer requirements and reduces communication errors.

Custom Programming: Customizing CNC programs to match unique part designs and specifications enables the production of highly customized assemblies.

Material Selection: Available in a variety of materials, giving customers options to meet their specific needs, whether aluminum, steel, plastic or other specialty materials.

Design expertise: Skilled engineers and technicians work with customers to interpret and refine design specifications to ensure custom requirements are met.

Prototyping and Sampling: Prototype samples or small batch production available, allowing customers to review and approve designs before mass production, ensuring accuracy and satisfaction.

Flexible manufacturing processes: Adaptable production methods allow designs or specifications to be changed during the manufacturing process to meet changing customer needs.

Flexible production capacity: CNC machining manufacturers should have flexible production capacity and be able to quickly adjust production according to customer needs to meet customization needs of different scales and batches. At the same time, they should also have the ability to achieve high-precision and high-quality processing to ensure the quality of customized parts.

Quality control and inspection: CNC machining manufacturers must conduct strict quality control and inspection throughout the entire production process to ensure that customized parts meet the quality standards required by customers. This can include procurement inspection of raw materials, monitoring of processing, pre-shipment inspection of finished products, etc.

After-sales service and support: CNC machining manufacturers must provide comprehensive after-sales service and support, including timely communication, solving technical problems, handling quality objections, etc. Customers may have different needs and changes during the customization process, and manufacturers need to respond proactively and provide corresponding support and solutions.

Through the above measures, CNC machining manufacturers can better meet customers' customized needs and provide customers with unique and complex customized parts and products, thereby enhancing customer satisfaction and loyalty.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!