15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

164 |

Published by VMT at Sep 30 2021

164 |

Published by VMT at Sep 30 2021

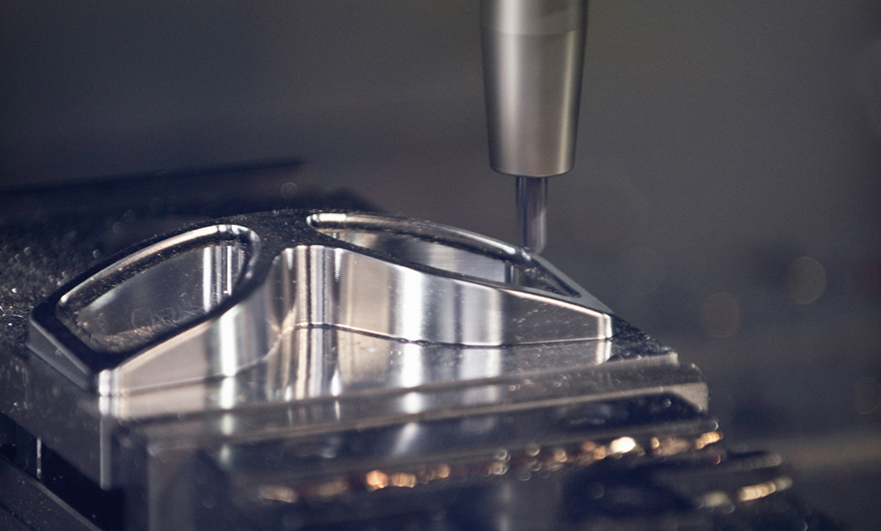

In CNC milling parts, you can always encounter all the problems of fillet, tapping, chamfering, setting, drilling, undercutting, etc. How to optimize, improve the design and reduce costs? This article will introduce you to the relevant skills and knowledge of CNC milling parts service.

vBefore we start, we need to understand the machining principles of CNC milling machines. The CNC milling machine is mainly for subtractive manufacturing. It fixes the CNC milling parts in a vise on the CNC workbench, and then processes the raw materials through the X, Y, and Z axes of the milling machine, and rotates the tool spindle at a very high speed for cutting Material and leave almost any desired shape. There are more advanced machines with additional functions and axes, but understanding a simple three-axis milling machine is an important first step in mastering manufacturing.

How to choose the tool type for CNC milling?

Understanding the most basic types of tools is to provide the knowledge needed to design better CNC milling parts.

1. The fillet end mill is similar to the flat end mill, it increases the tool strength by eliminating the thin tip, but the radius at the corner is very small. It is suitable for quickly removing material and leaving a small bottom radius on CNC milled parts.

2. The drill bit is only used to make vertical holes in CNC milling parts, so it is the tool with the shortest length and the largest diameter is the first choice.

3. The flat end mill is the most common end mill. It produces flat bottom cutting and can be used for material and finishing of vertical walls.

4. The ball end mill is suitable for 3D shapes with complex surfaces and larger bottom radius.

The actual end mill is a cantilever beam. For CNC milling parts of the same diameter, the length of the milling cutter doubles its deflection (deflection is when the force or non-uniform temperature changes, the axis of the rod is perpendicular to the axis The linear displacement or the linear displacement of the midplane of the plate and shell in the direction perpendicular to the midplane.) will increase eight times, which requires a significant slowdown in processing time. In other words, the diameter of an end mill with the same length will increase the deflection by 16 times. Two end mills apply the same force, but the end mill that is twice the length has more deflection than the other end mill.

Design Skills of CNC Milling Parts

The use of milling tools will run through the part design, so the designer should always consider the length of the end mill required to process the drawn shape.

1. If square corners must be used for CNC milling parts, use a fillet end mill to make the diameter of the fillet cut as large as possible.

2. Keep the height of the machine feature less than four times its width. Tall and thin features will vibrate significantly during processing, resulting in poor tolerances and surface finish. Try and add reinforcement where possible to reduce tall isolated features.

3. For threaded holes, through holes are always better than blind holes. Because it allows chips to be expelled from the cutting thread. The depth of the hole should not exceed three times the diameter. If this point is exceeded, in fact any increase is necessary because it becomes more difficult to manufacture and screw in the fastener.

4. For blind holes, always let the pilot drill exceed half of the thread diameter. It is very difficult to tap the thread all the way to the bottom of the hole, and the machine needs to change the tap type to achieve this.

5. Large diameter and short end mills will provide the fastest machining time to produce the most cost-effective CNC milling parts.

6. Understand the size of the tool you are using and always keep the internal fillet radius slightly larger. This prevents the tool from rapidly increasing the amount of material it cuts when it reaches the corner. If the tool diameter exactly matches the internal fillet, then when the tool enters the corner, it will suddenly switch to a large amount of cutting engagement, which may cause the tool to break. For example, if the tool used is an end mill with a diameter of 10 mm, fill the park corner a bit larger, for example, 6 mm.

7. Reducing the number of settings can improve the accuracy of CNC milling parts. Since the functions made in the same settings are almost as accurate as those made by CNC, this is very good. Since all tool paths must start with a vertical rotating tool, any feature on the side of the part requires the part to be removed from the vise and re-clamped. Re-clamping takes time and brings opportunities for error, because the part must be in the vise again for the program to continue cutting.

8. If a very high plane tolerance is required, please use a small boss with a reduced area. Especially on larger CNC milled parts, this only allows certain areas to require high tolerances. The rest can be put more loosely. In this way, machine components can be easily adjusted to meet the required tolerances.

9. Ensure that your finished CNC milling parts meet the ready-made raw material dimensions. Check the general size of your metal supplier. Always leave 3 mm under the part so that the device can grasp the part, and leave at least 1 mm on all sides. This will leave some material to be processed, so you will always get a finished surface that looks good and has accurate dimensions.

10. If you want the sharp edge to break on the CNC milled part, just point to it on the drawing and mark it as a broken edge. The machinist will deepen this edge and only model the chamfer when you really need a certain size. Keep the angle of the chamfer at 45 degrees, as this is a very common tool size. Just place it in a different position, you can use the same tool to make chamfers of different widths.

Summarize

CNC milling parts design and machining need to consider the cooperation of tools to create high-quality parts. When encountering problems such as fillet, tapping, chamfering, setting, drilling, undercutting, etc., practical operations are required to know whether it is suitable for use. Therefore, we will provide you with a reasonable and complete solution before processing, and we look forward to starting the next CNC milling part project for you.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!