15 years one-stop China custom CNC machining parts factory

80 |

Published by VMT at May 13 2025 | Reading Time:About 6 minutes

80 |

Published by VMT at May 13 2025 | Reading Time:About 6 minutes

Are you struggling to determine which machining method is best for your precision components—CNC Swiss machining or traditional CNC machining? You’re not alone. Many engineers, buyers, and manufacturers face this exact challenge when planning high-precision parts. Choosing the wrong method can lead to suboptimal tolerances, longer cycle times, or even unnecessary costs. But here’s the good news: once you understand the key differences between CNC Swiss machining and traditional CNC machining, selecting the right method becomes a strategic advantage. In this article, we’ll break it all down, clearly and professionally, so you can make informed decisions that save time and money while boosting product quality.

The main difference between CNC Swiss machining and traditional CNC machining lies in how the material is supported and moved: Swiss machines move the bar stock through a sliding headstock, improving stability for small, high-precision parts, while traditional CNC machines keep the workpiece stationary. Swiss machining is ideal for complex, long, small-diameter components requiring tight tolerances.

Understanding the fundamental difference between CNC Swiss machining and traditional CNC machining is just the beginning. To make the most informed decision, it's important to explore how each process operates, their respective advantages, and what types of components they’re best suited for. Let’s begin by defining each method before diving into their core differences.

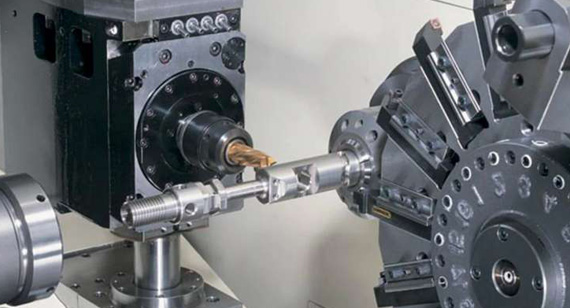

CNC Swiss machining is a highly precise subtractive manufacturing process that originated in the Swiss watchmaking industry. It uses a specialized type of lathe known as a Swiss-type lathe, which operates differently from traditional lathes. The defining feature of Swiss machining is the sliding headstock mechanism. Instead of holding the workpiece stationary while the tools move, the Swiss machine feeds the material through a guide bushing. The cutting tools remain close to the point of contact, drastically reducing deflection and vibration. This setup provides exceptional accuracy, especially for slender or complex parts.

Swiss machining is known for producing small-diameter, high-precision components that demand tight tolerances—often within ±0.0002 inches. This makes it ideal for industries such as medical, aerospace, electronics, and defense, where micro-components are standard. Swiss-type machines can perform multiple operations in a single cycle, such as turning, milling, drilling, knurling, and threading, without transferring the part between machines. This leads to reduced setup time, enhanced consistency, and faster throughput.

CNC Swiss machining is especially beneficial for producing long, thin parts or those with complex geometries. If your project involves components with deep cuts, intricate shapes, or tight tolerances—especially in high volumes—Swiss machining is often the best choice. For example, many CNC Swiss machining parts include surgical screws, valve stems, electronic pins, and miniature shafts.

For manufacturers looking for precise, repeatable, and efficient production, CNC Swiss machining offers unparalleled advantages. At VMT, we provide advanced CNC Swiss machining services tailored to your project’s unique specifications.

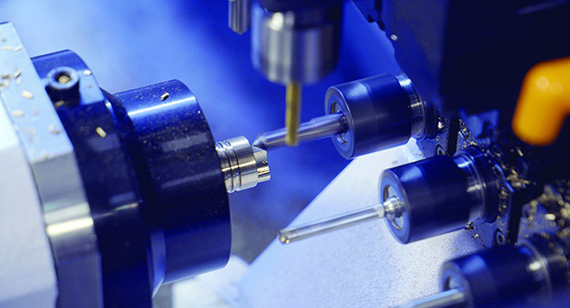

Traditional CNC machining is a versatile and widely adopted manufacturing process used to create a broad range of precision parts. At its core, CNC (Computer Numerical Control) machining uses pre-programmed software to automate and control machine tools like lathes, mills, routers, and grinders. In traditional CNC setups, the workpiece remains stationary or is held in a rotating spindle while various tools move around it to remove material and shape the final part.

Unlike CNC Swiss machining, which uses a sliding headstock and guide bushing, traditional CNC machines rely on a fixed workholding method. This makes them better suited for medium-to-large parts or components that are shorter and more rigid. The setup allows for complex operations involving multiple axes (3, 4, or even 5-axis machining), giving engineers tremendous flexibility in creating complex geometries, detailed features, and smooth finishes.

Traditional CNC machining is highly effective for prototyping, low-to-medium volume production, and parts that do not require extreme precision on very small scales. Common parts made with this method include brackets, casings, custom fixtures, enclosures, structural components, and various industrial equipment parts.

Because of its broad capabilities, traditional CNC machining is commonly used in industries such as automotive, aerospace, industrial manufacturing, and medical device production. VMT offers a full range of CNC machining services using state-of-the-art equipment in our CNC machining factories. Our team helps customers produce both standard and custom components with tight tolerances, exceptional surface finishes, and dependable turnaround times.

Although both CNC Swiss machining and traditional CNC machining serve similar goals—precision, repeatability, and automation—they operate under fundamentally different principles. These differences affect everything from part size and complexity to cycle time, tooling, and ideal applications. Choosing between these two methods depends on your project’s unique requirements. Below, we compare their key attributes to help you make the right decision.

1. Spindle Box Motion

In CNC Swiss machining, the bar stock moves longitudinally through a sliding headstock, while the cutting tool remains stationary near the guide bushing. This configuration reduces material deflection and enables extremely precise machining, especially for long, thin parts. In contrast, traditional CNC machines hold the material in place (or rotate it in the case of lathes), and the cutting tools move across it. This setup is ideal for rigid parts but may lead to chatter or vibration with slender geometries.

2. Workpiece Support and Stability

CNC Swiss machines provide continuous support to the material through a guide bushing located near the cutting tool. This ensures high stability, making Swiss machining optimal for producing parts with small diameters or extended lengths. Traditional CNC machines, on the other hand, grip the workpiece using chucks or vises without the support of a guide bushing, which may result in deflection when machining long or narrow features.

3. Machining Axes and Complexity

Traditional CNC machining typically uses 3-axis, 4-axis, or 5-axis configurations, offering immense flexibility for intricate part geometries and multi-face operations. CNC Swiss machining usually includes 5 to 8 axes and enables multi-tasking (e.g., turning, milling, and drilling in one setup), but is generally limited to smaller parts. Swiss machines are engineered for high-volume, complex micro-components, while traditional machines excel at larger, multi-dimensional parts.

4. Ideal Part Size and Geometry

CNC Swiss machining excels at manufacturing small-diameter, long, and slender parts—typically less than 1.25 inches in diameter and several inches long. The sliding headstock and guide bushing design offer superior support, allowing for high-precision machining of parts that would otherwise deflect or chatter on traditional machines. Typical geometries include shafts, pins, surgical screws, and connectors.

Traditional CNC machining, however, is more suitable for parts with larger diameters, bulkier structures, and more complex 3D shapes. It can handle thicker raw materials and produce broader component types—from flat plates and brackets to deep cavities and angled features. This makes traditional CNC the go-to solution for parts that are short, wide, or heavy, such as housings, enclosures, and mechanical frames.

5. Coolant Use

In CNC Swiss machining, coolant plays a crucial role due to the close tool-part engagement and high-speed, high-precision operations. The coolant keeps the cutting area clean, dissipates heat, and extends tool life. Many Swiss machines are equipped with high-pressure coolant systems (up to 2,000 psi) that help maintain dimensional accuracy by reducing thermal distortion.

While traditional CNC machines also rely on coolant systems, they often use lower pressure and are less dependent on precision coolant delivery. Coolant is still essential in traditional setups to reduce tool wear and improve surface finishes, but it’s not as critical for dimensional stability as it is in Swiss machining. In high-volume Swiss operations, using the right coolant system can significantly impact production quality and part consistency.

6. Insert and Tool Specifications

Tooling in CNC Swiss machining is highly specialized. Swiss machines use compact, modular tool holders that allow for rapid tool changes and high-density tool setups. Many tools are capable of both front and back operations, enabling multi-tasking without changing fixtures. Inserts are often designed for micromachining with coatings tailored for high-speed, tight-tolerance work.

Traditional CNC machining, by comparison, uses larger and more versatile tool holders and inserts. While still capable of great precision, traditional tools are optimized for a broader range of operations and materials. They may not achieve the same fine tolerances as Swiss tooling but offer greater flexibility when working on various part sizes and types.

7. Cycle Time and Production Efficiency

CNC Swiss machining is known for its exceptional production efficiency, particularly in high-volume manufacturing. By enabling simultaneous operations—such as turning, milling, drilling, and backworking—Swiss machines can complete complex parts in a single setup without the need for secondary processing. This dramatically reduces cycle times and labor costs. In fact, Swiss machining often achieves up to 30–50% shorter production cycles compared to traditional CNC methods for the same part types.

Additionally, Swiss machines are designed for unattended or "lights-out" production, where machines run for extended periods with minimal human intervention. This capability boosts throughput and minimizes idle time, making Swiss machining ideal for mass production of small, intricate components like medical screws or electronic contacts.

Traditional CNC machining, while highly flexible and capable of producing larger or more complex-shaped parts, generally has longer cycle times. This is especially true when a part requires multiple setups, manual repositioning, or transfer between machines for secondary operations. For low-to-medium production runs, traditional CNC machines still offer reliable performance, but they may not match the speed or efficiency of Swiss machining in micro-part production.

8. Automation and Material Handling

CNC Swiss machines are often equipped with automatic bar feeders that allow continuous material loading for extended production runs. These systems can process long bars of raw material with minimal manual intervention, enhancing automation and reducing downtime. Some advanced Swiss machines also feature automatic part catchers and chip conveyors, further streamlining the workflow.

Traditional CNC machining centers typically rely more on manual material handling unless integrated into automated cells. While robotic loaders and pallet changers are available, they are not as inherently built into the workflow as with Swiss systems. As a result, traditional machines may require more labor input and supervision between runs or for setup changes.

If you're seeking a solution that supports automated, high-speed production with minimal downtime, Swiss machining is often the better fit. For flexible, varied jobs or larger components, traditional CNC machining provides the necessary adaptability.

9. Tolerances and Surface Finish

One of the defining strengths of CNC Swiss machining is its ability to achieve extremely tight tolerances and excellent surface finishes. Thanks to the sliding headstock and guide bushing design, the workpiece is always supported close to the cutting tool, minimizing deflection and vibration. This configuration allows Swiss machines to routinely hold tolerances within ±0.0002 inches (±5 microns), which is ideal for high-precision industries like medical device manufacturing, aerospace, and microelectronics.

In addition to precision, Swiss machines produce exceptionally clean and smooth surface finishes. The combination of stable cutting conditions, high spindle speeds, and fine tooling results in parts that often require no secondary finishing. This makes Swiss machining a go-to method for components that must meet both dimensional accuracy and aesthetic or functional surface quality standards.

Traditional CNC machining, while highly capable, generally holds tolerances in the ±0.001 to ±0.005 inch range, depending on the setup, tooling, and machine rigidity. It is more than sufficient for a wide variety of industrial and commercial applications, including automotive components, structural parts, and mechanical assemblies. However, achieving Swiss-level precision may require specialized tools, more refined setups, or secondary processes such as grinding or polishing.

If your project demands ultra-tight tolerances or pristine finishes in high volumes, CNC Swiss machining is often the superior choice. For parts with larger features or less stringent precision requirements, traditional CNC machining remains a cost-effective and reliable solution.

10. Cost and Setup Time

Cost and setup time are two of the most important factors when deciding between CNC Swiss machining and traditional CNC machining—especially for manufacturers evaluating long-term production strategies or prototyping plans.

CNC Swiss machining typically requires a higher initial investment in both machine cost and setup. Because Swiss machines are highly specialized and designed for tight-tolerance, high-volume production, the programming, tooling, and bar feeder setup can take more time and expertise. However, once the machine is set up, the unit cost per part drops significantly—particularly for large production runs. The process becomes highly efficient, with minimized waste, reduced operator intervention, and virtually no need for secondary operations.

On the other hand, traditional CNC machining usually involves a lower setup cost and faster changeovers, especially for prototyping or low-to-mid volume batches. Traditional CNC machines are easier to program for diverse geometries and offer more flexibility when producing different parts with the same machine. For short runs or parts with complex 3D features, traditional CNC is often more cost-effective and adaptable.

However, because traditional CNC machines may require multiple operations or setups for the same part that a Swiss machine could handle in one pass, total production time and costs can add up for high-volume jobs. In such cases, Swiss machining becomes more economical despite its higher upfront setup.

In summary:

11. Applications

The types of components suited to CNC Swiss machining vs. traditional CNC machining are often the most decisive factor in choosing between the two processes. Their distinct capabilities naturally align with different industrial applications.

CNC Swiss machining is ideally suited for producing small, intricate, high-precision parts in large volumes. Industries like medical, aerospace, defense, consumer electronics, and automotive frequently rely on Swiss machining to manufacture critical components such as:

Because Swiss machines can handle tight tolerances, complex features, and thin, long geometries in a single operation, they are the gold standard for producing micro-mechanical parts that must meet strict regulatory or performance requirements.

In contrast, traditional CNC machining is a versatile solution across a wider range of part sizes and complexities. Its flexibility in handling various shapes, materials, and dimensions makes it ideal for:

Traditional CNC machining is commonly used in industrial equipment, aerospace, automotive, medical device prototyping, consumer goods, and optics.

Ultimately, if you're manufacturing long, slender, high-precision parts in bulk, CNC Swiss machining is typically the best option. But if you need larger or more geometrically complex parts with flexible quantities, traditional CNC machining is often more suitable.

Choosing between CNC Swiss machining vs. traditional CNC machining involves evaluating the specific needs of your project—precision, complexity, volume, material, and budget. While both technologies offer exceptional capabilities, they each come with distinct advantages and limitations. Understanding the pros and cons of each approach can help you make the most informed decision for your CNC machining parts needs.

Pros and Cons of CNC Swiss Machining

Pros:

High Precision & Tight Tolerances

Swiss machining is unmatched in producing intricate components with tolerances as tight as ±0.0002 inches. This is essential for industries like medical devices, aerospace, and microelectronics.

Efficient for Long, Small-Diameter Parts

The guide bushing stabilizes long workpieces, making it perfect for manufacturing narrow, cylindrical parts without deflection.

High-Speed & Lights-Out Production

CNC Swiss machines support simultaneous operations (turning, drilling, milling) and continuous bar feeding, significantly reducing cycle times and enabling 24/7 production.

Reduced Secondary Operations

The precision and clean finish often eliminate the need for grinding, polishing, or other post-processing.

Cons:

Higher Setup Time & Cost

Programming and tooling are more complex, which increases initial setup time and requires skilled operators.

Less Versatile for Large or Irregular Parts

Swiss machines are optimized for small, symmetrical components and are less suited for large or geometrically complex parts.

Higher Equipment Investment

Swiss lathes are generally more expensive to purchase and maintain compared to standard CNC machines.

Pros and Cons of Traditional CNC Machining

Pros:

Highly Versatile

Traditional CNC machining can handle a wide variety of part sizes, shapes, and materials—from aluminum housings to steel engine blocks.

Lower Setup Time for Prototypes & Short Runs

It's faster and more cost-effective to program for short runs, making it ideal for prototyping and low-volume production.

Capable of Complex Geometries

Multi-axis CNC machines can execute detailed 3D contours, pockets, and undercuts that Swiss machines may struggle with.

Widely Available & Familiar Technology

Traditional CNC machines are standard in most machining shops, making it easier to source parts or manufacturing partners.

Cons:

Longer Cycle Times

Compared to Swiss machining, traditional methods often require multiple setups or machines, especially for intricate parts.

Lower Precision for Small, Long Parts

Without a guide bushing, small-diameter or long components are more prone to deflection and reduced accuracy.

May Require Secondary Operations

Some parts may need additional finishing or handling, increasing labor and cost.

Both machining types are critical in modern manufacturing. Swiss machining excels in high-volume, small, precision parts, while traditional CNC machining shines in flexibility, part size range, and geometric complexity.

Certainly! Here is a clear and professional comparison table outlining the pros and cons of CNC Swiss machining vs. traditional CNC machining:

| Criteria |

CNC Swiss Machining |

Traditional CNC Machining |

| Precision & Tolerances |

Extremely high; up to ±0.0002 inches — ideal for micro parts | High, but typically within ±0.001 to ±0.005 inches |

| Best for Part Size |

Small-diameter, long, cylindrical parts | Medium to large parts with varied shapes |

| Cycle Time & Efficiency |

Shorter cycle time; ideal for high-volume production | Longer cycle time; may require multiple setups |

| Secondary Operations Needed |

Often unnecessary due to excellent finish and precision | Sometimes needed, depending on surface finish and tolerance |

| Setup Time & Complexity |

Higher setup time and more complex programming | Faster setup, especially for short runs or prototypes |

| Flexibility |

Limited to small, symmetrical parts | Highly versatile for a broad range of geometries and materials |

| Machine Cost |

Higher cost of equipment and tooling | Lower machine and maintenance costs |

| Production Type |

Ideal for long-run production of precision components | Suitable for short to medium runs, prototyping, and general production |

| Common Industries |

Medical, aerospace, electronics, defense, precision automotive parts | Automotive, aerospace, industrial, mold making, custom components |

| Skill Requirements |

Requires highly skilled operators and programming expertise | Easier for general machinists to program and operate |

Understanding where CNC Swiss machining vs. traditional CNC machining excels helps manufacturers make the right choice for specific project needs. While both technologies are rooted in precision and efficiency, the parts they produce and the industries they serve can differ significantly. Below, we explore how each method is applied across real-world manufacturing scenarios.

Applications of CNC Swiss Machining

CNC Swiss machining is the preferred method for producing high-volume, small-diameter, tight-tolerance parts, particularly those that require precise concentricity and clean surface finishes. Its ability to perform multiple operations in a single cycle makes it indispensable in high-precision industries:

Swiss machines are widely used to manufacture orthopedic screws, dental implants, surgical pins, and catheter components. Their ability to meet stringent regulatory tolerances makes them ideal for life-critical devices.

Aerospace Components

Lightweight, high-strength aerospace parts such as miniature fasteners, connectors, and valve components are commonly produced on Swiss machines.

Consumer Electronics Components

Precision parts used in smartphones, wearables, and audio devices—including shafts, bushings, and hardware—are manufactured efficiently with Swiss machining.

Defense Product Components

Applications include micro-mechanical firearm components, high-tolerance fasteners, and secure electronics enclosures.

Swiss machining is used to create fuel injection nozzles, sensor pins, and small mechanical parts where precision affects performance.

These industries favor Swiss machining for its speed, accuracy, and the ability to eliminate secondary processes, saving both time and cost over large production volumes.

Applications of Traditional CNC Machining

Traditional CNC machining is known for its versatility, handling a broad range of materials, part sizes, and shapes. It is frequently used for both prototyping and full-scale production in the following areas:

Engraving and Decorating

CNC routers and mills produce fine engravings on metals, plastics, and wood for signage, branding, and decorative parts.

Component Manufacturing

From custom brackets and flanges to structural frames, traditional CNC machining handles medium-to-large components across countless industries.

Automotive Component Manufacturing

Parts such as engine blocks, transmission housings, and brake components are frequently machined using multi-axis CNC equipment.

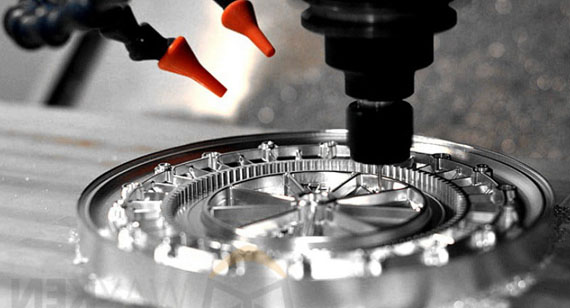

Mold Manufacturing

Injection molds, die cast tools, and press mold bases require high rigidity and complex 3D geometries—tasks traditional CNC machines handle well.

Aerospace Component Manufacturing

Large turbine components, bulkheads, and structural elements are often machined using 5-axis CNC milling or turning.

Automated Production Lines

Fixtures, jigs, end-effectors, and mounting brackets for robotics and conveyors are routinely made with traditional CNC methods.

Part Finishing and Modification

Post-casting or forging, parts may require precision milling or drilling—applications where traditional CNC excels.

Medical Device Components

Traditional CNC is used for surgical instrument handles, orthopedic tools, and prototypes for custom medical solutions.

Consumer Electronics Components and Housings

Metal casings, internal support structures, and EMI shielding elements are machined for devices like laptops and monitors.

CNC machining is used to fabricate lens housings and precision adjustment frames in the optics industry.

Industrial Equipment

Custom machine parts, pumps, flanges, and housings in heavy-duty applications rely on traditional CNC for durability and performance.

In short, CNC Swiss machining shines in micro-part production for high-precision, high-volume industries, while traditional CNC machining is better suited for larger, more complex, or varied parts across a broader range of industries.

Choosing between CNC Swiss machining vs. traditional CNC machining isn’t always straightforward. Your decision should depend on part specifications, production volume, tolerance requirements, and budget. Both technologies have unique strengths and limitations, so the key is aligning the right method with the right job. Let’s explore the factors that help determine the best fit for your manufacturing needs.

Which to Choose: A Comparative Guide

| Factor |

Choose CNC Swiss Machining If... |

Choose Traditional CNC Machining If... |

| Part Size |

Your parts are small, slender, and precision-critical | Your parts are medium to large with broader dimensional ranges |

| Tolerances |

You require ultra-tight tolerances (±0.0002”) and fine finishes | You need standard tolerances or can tolerate secondary operations |

| Production Volume |

You're running high-volume production of identical components |

You need low- to medium-volume runs or frequent design changes |

| Cycle Time |

You need faster cycle times and fewer secondary operations | You can accommodate longer cycle times and post-processing |

| Material Handling |

You want to reduce manual handling and improve automation | You need flexibility in workholding or multi-face machining |

| Budget & Setup |

You can invest in higher machine/tooling costs for long-term efficiency | You need a cost-effective solution for prototyping or smaller batches |

| Part Geometry |

The part is symmetrical or cylindrical in nature | The part has complex 3D contours, varying thicknesses, or multiple faces |

Summary

If you're manufacturing precision micro-components, such as medical pins, aerospace fasteners, or electronic hardware, and need tight tolerances, short cycle times, and consistent automation, CNC Swiss machining is the clear winner. On the other hand, if your project involves larger parts, complex geometries, or diverse materials, and especially if you're prototyping or doing low-volume runs, then traditional CNC machining is likely the better choice.

Ultimately, the ideal method depends on your application, budget, and production goals. In some cases, combining both technologies yields the best results—using Swiss machining for high-precision inserts and traditional CNC for housing or supporting structures.

Looking for an in-depth comparison of CNC milling vs. turning or want to learn about other machining methods like turret lathes or CNC grinding? Explore our related content:

While the comparison of CNC Swiss machining vs. traditional CNC machining covers many common use cases, modern manufacturing involves a broader set of techniques. Understanding other key machining processes like CNC milling, CNC turning, and turret machining can help you select the most efficient and cost-effective solution for your specific parts. Let’s explore how each of these methods expands your production capabilities.

CNC Milling: Achieving Precision

What is CNC Milling?

CNC milling is a subtractive manufacturing process where a rotating cutting tool moves along multiple axes to remove material from a stationary workpiece. Unlike turning operations, milling is ideal for creating complex, prismatic, or non-cylindrical parts.

Advantages of CNC Milling

CNC milling is valued for its precision, versatility, and adaptability. Here's how it enhances your machining strategy:

If your parts are larger, flat, or complex in shape, and you require intricate detailing, CNC milling should be part of your strategy.

CNC Turning: Where Symmetry Meets Speed

What is CNC Turning?

In CNC turning, the workpiece rotates while a stationary cutting tool removes material. It’s best suited for round or cylindrical parts, such as shafts, rods, and bushings.

Advantages of CNC Turning

For components that are round, tubular, or require tight concentric tolerances, CNC turning is often the most efficient process.

Turret Machining: Maximizing Turning Efficiency

Turret lathes are enhanced turning machines equipped with multiple tool stations that allow automatic tool changes during a single operation. When integrated with CNC control, turret machining enables faster cycle times and better automation — especially for medium to large batch runs.

If you're producing a variety of operations on turned parts and need higher efficiency, turret machines offer the best of both CNC turning and automation.

Interested in learning how these methods compare to CNC Swiss machining or when to use each? Check out these deep dives:

Your Trusted CNC Machining Partner for Precision Parts

At VMT, we understand that choosing between CNC Swiss machining vs. traditional CNC machining can be challenging. That’s why we offer a comprehensive range of CNC machining services to support your specific production goals — whether you're manufacturing high-precision micro components or robust, complex assemblies.

With over a decade of experience, VMT has grown into one of the most reliable CNC machining factories, specializing in Swiss machining, CNC turning, CNC milling, and custom part fabrication. We serve industries like medical, aerospace, electronics, automotive, and industrial equipment, delivering consistent quality and performance every time.

Why Choose VMT for CNC Swiss and Traditional Machining?

Full-Service Capabilities

Tight Tolerance Machining

Material Versatility

Surface Finishing & Quality Assurance

Responsive Engineering Support

Get Your CNC Machining Project Started Today

Whether you need high-volume CNC Swiss machining for tiny electronic components or traditional CNC machining for large aerospace structures, VMT is the one-stop solution. Our in-house expertise, modern equipment, and commitment to customer success make us the ideal partner for your precision machining needs.

Ready to get a quote or discuss your project? Contact VMT today to explore how our CNC machining services can benefit your production line.

Choosing between CNC Swiss machining and traditional CNC machining ultimately comes down to the specific requirements of your project — part size, tolerance, complexity, production volume, and material. CNC Swiss machining excels in producing small, high-precision components with tight tolerances and high efficiency, making it ideal for sectors like medical devices, aerospace, and electronics. On the other hand, traditional CNC machining offers greater flexibility for larger parts, complex geometries, and a wide range of machining operations such as milling, turning, and drilling.

Throughout this article, we've examined the key differences, pros and cons, and application scenarios of both methods, helping you better understand which solution best fits your needs. We've also highlighted other complementary machining technologies like CNC milling, turning, and turret machining, which further expand your manufacturing capabilities.

If you're still unsure which process is best for your application, the experienced team at VMT is ready to help. With advanced equipment, deep technical expertise, and a full suite of CNC machining services, we can provide you with optimized solutions for everything from prototype development to mass production.

For expert support, competitive pricing, and unmatched precision, contact VMT — your trusted CNC machining factory for both Swiss and traditional CNC machining parts.

Can Swiss machines perform milling operations?

Yes, modern CNC Swiss machines can perform milling in addition to turning. They are equipped with live tooling and multi-axis capabilities, allowing for complex machining operations such as drilling, slotting, and cross-milling — all in one setup.

What are the limitations on the types of parts that can be manufactured by Swiss machines?

Swiss machines are optimized for small, slender, and high-precision parts, typically less than 1.25 inches in diameter. They're less suitable for large or bulky components due to limited work envelope size and bar stock capacity.

Can traditional CNC machines achieve the same level of precision as Swiss machines?

While traditional CNC machining can offer tight tolerances, CNC Swiss machining typically delivers greater precision for long, narrow parts. This is due to the guide bushing system that supports the workpiece close to the cutting tool, minimizing deflection.

Can Swiss machines handle secondary operations such as knurling and threading?

Yes. Swiss-type lathes can handle knurling, threading, engraving, cross-drilling, and even complex contouring without transferring the part to another machine, reducing cycle time and improving accuracy.

How do maintenance requirements differ between the two machine types?

Swiss machines require more frequent maintenance due to their high-speed operations and complex tooling systems. Traditional CNC machines, while simpler, also need regular upkeep — particularly for tool alignment, spindle calibration, and lubrication systems.

What is the difference between CNC machining and Swiss machining?

CNC machining is a general term for computer-controlled subtractive manufacturing. Swiss machining is a specialized form of CNC turning where the workpiece moves while being supported by a guide bushing, allowing for extremely tight tolerances on long, thin parts.

How does CNC machining differ from traditional machining?

Traditional machining often involves manual or semi-automated equipment, while CNC machining is fully computer-controlled, offering greater repeatability, efficiency, and complexity in part production.

What is the difference between Swiss turning and CNC turning?

Swiss turning involves a moving workpiece supported close to the cutting tool, ideal for slender components. CNC turning uses a fixed spindle and rotating workpiece, suitable for a wider range of part sizes and shapes.

What is the difference between a Swiss lathe and a regular lathe?

A Swiss lathe uses a sliding headstock and guide bushing for maximum support and precision during machining. A regular lathe holds the workpiece in a fixed chuck, making it better suited for shorter or larger-diameter parts.

What are the 5 most common types of CNC machine tools?

The five most common types include:

What is Swiss machining?

Swiss machining is a precision CNC turning process where the workpiece moves along the Z-axis while being supported close to the tool by a guide bushing. It's ideal for small-diameter, high-tolerance parts used in industries like medical, aerospace, and electronics.

What are the advantages of CNC over traditional machining?

CNC machining offers greater precision, automation, repeatability, and efficiency. It reduces human error, supports complex geometries, and is suitable for high-volume production, unlike manual machining, which is slower and less consistent.

Which country is best for CNC machining?

Several countries lead in CNC technology, including Germany, Japan, the United States, and China. For cost-efficiency and scale, China is one of the most competitive markets. VMT, based in China, offers world-class CNC machining services at global standards.