15 years one-stop China custom CNC machining parts factory

175 |

Published by VMT at Apr 30 2025 | Reading Time:About 6 minutes

175 |

Published by VMT at Apr 30 2025 | Reading Time:About 6 minutes

When designing or sourcing precision plastic components, choosing the right material is often the most overlooked yet critical decision. Two of the most commonly compared engineering plastics—Delrin (POM-H) and UHMW (Ultra-High Molecular Weight Polyethylene)—are both popular for CNC machining but have dramatically different strengths. Select the wrong one, and you may face dimensional instability, part failure, or unexpected wear under real-world conditions.

Now imagine investing in production only to realize your selected plastic warps under heat or fails under load. That’s the risk when you don’t understand the core differences between these two materials. Each plastic—Delrin and UHMW—excels in specific applications, but only when matched correctly to the demands of your design and environment.

In this article, we’ll walk you through a clear, side-by-side comparison of Delrin vs. UHMW, backed by technical specifications and real-world applications. Whether you're producing Delrin CNC machined parts or UHMW CNC machined parts, you’ll get expert insights to help you choose the right material for high-performance results.

Delrin vs. UHMW: Delrin offers superior stiffness, dimensional stability, and precision, making it ideal for high-tolerance plastic CNC machined parts. UHMW, on the other hand, excels in abrasion resistance and low friction, making it perfect for wear-heavy applications. Your choice depends on whether you prioritize machinability and rigidity (Delrin) or durability and impact resistance (UHMW).

Selecting between Delrin and UHMW isn’t just about comparing datasheets—it’s about understanding how each plastic behaves under pressure, friction, heat, and load. In the following sections, we’ll dive deep into each material's unique properties, benefits, limitations, costs, and applications to help you confidently choose the best option for your CNC machining services. Let’s begin by understanding each material individually.

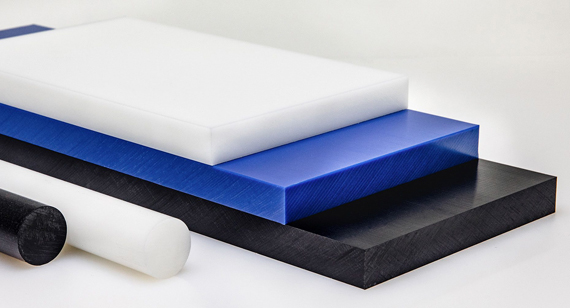

Ultra-High Molecular Weight Polyethylene (UHMW) is a type of thermoplastic known for its exceptional toughness, abrasion resistance, and low coefficient of friction. Its full name hints at its secret: UHMW has a very high molecular weight (usually 3 to 6 million g/mol), which contributes to its outstanding durability and wear properties. Despite being relatively soft compared to other engineering plastics, UHMW outperforms most materials in sliding or high-wear applications.

UHMW is widely used in industries such as material handling, food processing, medical equipment, and even military applications. One of its biggest advantages is its extreme resistance to abrasion—far superior to many metals and other plastics. It also resists moisture absorption, which makes it ideal for wet or corrosive environments. Because of its low surface energy, it also has excellent non-stick properties, preventing substances from adhering to its surface.

However, it’s worth noting that UHMW is not ideal for applications requiring tight tolerances or fine details. It can be challenging to machine with high precision due to its tendency to deform slightly under cutting forces. As a result, UHMW CNC machined parts are best suited for applications where toughness and impact resistance matter more than exact dimensions.

In short, UHMW is a go-to solution for high-wear environments where durability, chemical resistance, and low friction are essential—but it may fall short when high precision or thermal stability is required. That’s where its counterpart, Delrin, often takes the lead.

Delrin, also known as POM-H (Polyoxymethylene Homopolymer), is an engineering thermoplastic developed for high-precision parts that require stiffness, low friction, and excellent dimensional stability. It is one of the most commonly used materials for plastic CNC machined parts, especially when tight tolerances, low moisture absorption, and mechanical strength are essential. As a homopolymer form of POM, Delrin offers better crystallinity than copolymer POM, making it stronger and more rigid.

Delrin is produced through a polymerization process that results in chains of repeating formaldehyde units. This chemical structure gives Delrin its unique combination of mechanical and chemical properties. It is widely recognized for its high tensile strength, wear resistance, and low creep, even under long-term stress. These characteristics make it ideal for applications in industries like automotive, aerospace, industrial machinery, and medical devices.

Unlike UHMW, Delrin is more suitable for parts that demand high dimensional accuracy and repeatability. Delrin CNC machined parts can achieve sharp corners, clean threads, and smooth finishes without deformation—making it a preferred material in CNC machining factories for functional prototypes and end-use components. Additionally, Delrin can operate effectively at higher temperatures than UHMW, giving it another edge in demanding applications.

In summary, Delrin is a high-performance material that excels in structural integrity, machinability, and strength. If your project demands precision, durability, and a professional finish, Delrin is often the better option over softer, more impact-resistant plastics like UHMW.

Choosing the right plastic material can make or break the success of a CNC machining project. When it comes to high-performance thermoplastics, UHMW (Ultra-High-Molecular-Weight Polyethylene) and Delrin (POM-H) are two of the most widely used materials for plastic CNC machined parts. While both offer valuable characteristics, they serve very different engineering needs—so understanding the difference is essential for selecting the ideal solution.

UHMW CNC machined parts are prized for their superior impact resistance, self-lubricating surface, and excellent wear performance in abrasive environments. On the other hand, Delrin CNC machined parts are known for their rigidity, dimensional accuracy, and high tensile strength. The challenge many engineers and procurement specialists face is knowing when to use which material based on the project’s mechanical, thermal, and environmental demands.

Comparing UHMW and Delrin is especially important for applications in automotive, aerospace, industrial, and medical sectors where part failure is not an option. Whether you’re designing a bushing, gear, pump component, or protective equipment, understanding the differences in machinability, cost, heat resistance, and durability helps reduce design risk and save costs.

This side-by-side evaluation also benefits buyers looking for CNC machining services. Not all materials behave the same on the shop floor, and choosing the wrong one can result in higher rejection rates, longer lead times, or higher machining costs. CNC machining factories like VMT help bridge this gap, but informed material selection remains a key first step.

Keep reading to explore the unique properties of each material and find out which one is better suited for your CNC machining needs.

When choosing between UHMW and Delrin CNC machined parts, understanding their core material properties is essential. These two engineering plastics serve different mechanical and environmental functions despite both being top choices in plastic CNC machining parts. From impact resistance to dimensional stability, the physical, mechanical, and chemical characteristics of each plastic affect performance and suitability for specific applications. This section breaks down the unique properties of UHMW and Delrin to help you make an informed decision for your CNC machining services project.

UHMW Properties

Ultra-High-Molecular-Weight Polyethylene (UHMW) is a thermoplastic polymer recognized for its incredible wear resistance, low friction, and toughness. Often used where abrasion, impact, or chemical exposure is a concern, UHMW CNC machined parts are common in industrial conveyors, protective gear, and medical devices. Its long molecular chains offer enhanced strength and resistance without compromising machinability. UHMW is an excellent choice when parts are exposed to high impact, moisture, or require self-lubrication. Let’s take a deeper look into its specific chemical, mechanical, and physical properties.

Chemical Properties of UHMW

UHMW is chemically inert, making it ideal for harsh environments. It resists most acids, alkalis, and organic solvents, which means it can be used in chemical processing or food contact applications without degrading. Unlike many plastics, UHMW is odorless, tasteless, and FDA-compliant, often used in food, beverage, and pharmaceutical processing. It’s also resistant to corrosion, leaching, and bio-fouling, making it a preferred option in marine or wet environments. Its chemical stability ensures performance over time, even when exposed to cleaning agents, fuels, and disinfectants.

Mechanical Properties of UHMW

Mechanically, UHMW boasts exceptional impact strength—among the highest of all thermoplastics. It offers outstanding abrasion resistance, more than 15 times that of carbon steel in some cases. Its low coefficient of friction enables smooth sliding surfaces, which reduces wear on both the UHMW part and any contacting materials. However, UHMW has a lower tensile strength and rigidity compared to Delrin, which can limit its use in load-bearing or precision-fit applications. It’s ideal for wear strips, chute liners, and gears in high-impact or high-friction conditions.

Physical Properties of UHMW

UHMW has unique physical characteristics that contribute to its longevity and versatility. It exhibits very low water absorption (less than 0.01%), which helps maintain mechanical integrity in humid or wet environments. Its density is low (about 0.93–0.94 g/cm³), making it lightweight compared to many engineering plastics. UHMW maintains stability across a broad temperature range (from -150°C to about 80°C), and it’s naturally opaque white, though colored variants are available. One drawback is its poor UV resistance, which means it may degrade over time with prolonged sunlight exposure unless stabilized.

Delrin: Properties

Delrin, a brand name for acetal homopolymer (polyoxymethylene or POM), is renowned for its exceptional dimensional stability, rigidity, and strength. Compared to UHMW, Delrin CNC machined parts offer better precision, tighter tolerances, and higher load-bearing capabilities. It is often the preferred material when mechanical strength and low moisture absorption are critical. Due to its excellent balance of mechanical and chemical properties, Delrin is commonly used in gears, bushings, fuel system components, and medical or aerospace devices where accuracy and reliability matter. Below, we’ll break down Delrin’s properties in detail to help you determine its suitability for your plastic CNC machining parts needs.

Chemical Properties of Delrin

Delrin demonstrates superior toughness even at low temperatures (down to -40°C), making it ideal for components exposed to cold or fluctuating environments. It has high mechanical strength and rigidity, which helps maintain part integrity over time, even under stress. Delrin resists fatigue and mechanical wear, making it suitable for moving parts and repeated-use components. It is also resistant to impact and moisture, with low water absorption that ensures long-term dimensional stability. The material’s natural insulating properties make it safe for electrical applications, and it is chemically resistant to fuels, solvents, and neutral pH substances. Additionally, Delrin retains color and integrity well, resisting fading from heat and minor UV exposure.

Mechanical Properties of Delrin

Delrin offers excellent mechanical performance, particularly in applications that require strength, precision, and resistance to fatigue. It features:

These properties make Delrin CNC machined parts highly reliable, especially when tight tolerances, wear resistance, and load handling are required.

Thermal Properties of Delrin

Delrin maintains performance in a moderate temperature range and offers excellent thermal consistency for CNC machining:

Physical Properties of Delrin

Physically, Delrin is dense (~1.41 g/cm³), giving it a solid, high-quality feel. It has moderate UV resistance, although prolonged exposure to direct sunlight without stabilization may degrade the surface. Its opaque white (natural) appearance gives a clean and glossy finish that is both aesthetically pleasing and functional. Compared to UHMW, it is easier to polish and gives a more refined surface finish, making it ideal for visible components or assemblies that require low friction and smooth movement.

Electrical Properties of Delrin

Delrin’s excellent insulating properties make it reliable for electronic components. It offers:

Other Properties

When it comes to choosing the right plastic material for CNC machining services, understanding both the strengths and weaknesses of UHMW and Delrin is essential. While both offer exceptional performance in industrial applications, they serve different purposes based on mechanical properties, chemical resistance, and machining behavior. This section will help you evaluate the pros and cons of each to decide which material better suits your project requirements. Whether you're producing bushings, gears, wear plates, or other plastic CNC machined parts, knowing the capabilities and limitations of UHMW CNC machined parts versus Delrin CNC machined parts can help minimize production costs and improve performance.

UHMW Advantages

UHMW (Ultra-High Molecular Weight Polyethylene) stands out due to its excellent wear resistance, low friction surface, and high impact strength. It’s a preferred material in high-abrasion environments like conveyor systems, mining, and food processing. Key advantages include:

These benefits make UHMW CNC machined parts a cost-effective and long-lasting solution for heavy-duty and repetitive-use applications.

UHMW Disadvantages

Despite its advantages, UHMW also has certain limitations that restrict its use in some CNC machining projects:

Understanding these disadvantages ensures that you avoid material failure or costly post-machining fixes in sensitive designs.

Delrin Advantages

Delrin offers high strength, stiffness, and dimensional stability, making it an excellent alternative to metal in precision applications. Its advantages include:

These strengths make Delrin CNC machined parts highly suitable for industrial equipment, medical devices, and precision mechanisms.

Delrin Disadvantages

While Delrin excels in many areas, it is not suitable for all environments. Some disadvantages include:

Selecting Delrin means balancing its excellent mechanical properties against potential limitations in extreme chemical or environmental conditions.

Cost is a major factor in any manufacturing decision, especially when selecting between plastic CNC machined parts like UHMW and Delrin. While both materials offer excellent performance in specific applications, their pricing structures, machining behavior, and lifecycle costs differ significantly. Understanding the cost implications of each material can help you choose the most cost-effective option for your CNC machining project without compromising quality or performance.

When choosing between UHMW and Delrin for plastic CNC machined parts, cost is often a key deciding factor—especially for large-volume production or budget-sensitive projects. While both materials offer unique performance benefits, they come at very different price points. Understanding how each material’s cost aligns with your project requirements can help you avoid unnecessary overspending without sacrificing functionality or performance.

Delrin is generally more expensive than UHMW due to its higher precision, rigidity, and machining performance. UHMW offers better affordability for large, wear-resistant parts that don’t require tight tolerances.

Before selecting a material based solely on cost, it's essential to consider the full context: material price per unit, machining costs, yield rate, and expected part performance. The following comparison will guide you through key pricing differences and cost-related factors for Delrin vs. UHMW, helping you choose the right material for your application and budget.

Material Costs: UHMW vs. Delrin

In general, UHMW is more affordable than Delrin. Its raw material cost is typically lower due to its simpler polymer structure and broader availability. UHMW is often used in applications where cost savings and wear resistance are top priorities, such as in liners, guides, or protective pads. On the other hand, Delrin is considered a premium engineering plastic. It offers higher mechanical strength, greater dimensional stability, and better machinability—features that justify its higher price for precision parts.

Raw Material Price

UHMW is typically the more economical choice, with prices ranging from $2 to $5 per pound, depending on the form (sheet, rod, or tube) and supplier. It’s widely used in bulk applications where cost efficiency and abrasion resistance matter more than dimensional precision. Delrin, on the other hand, ranges from $6 to $12 per pound, primarily due to its enhanced mechanical properties, consistent manufacturing quality, and brand premium (Delrin is a registered trademark by DuPont, whereas UHMW is often available as a generic material).

Here’s a rough cost comparison:

Note that prices can fluctuate based on raw material markets, supplier, part geometry, and volume of your order. Also, the machining time and tool wear must be considered. UHMW’s lower rigidity means longer machining times and possible part deformation, increasing overall production costs. Conversely, Delrin machines faster, holds tight tolerances, and reduces finishing steps—resulting in lower labor and post-processing costs.

Machining Costs

Delrin CNC machined parts typically cost less to machine than UHMW, despite the higher raw material cost. Delrin cuts cleanly, generates less heat, and has low tool wear—reducing cycle times and tooling replacement costs. UHMW, being softer and more elastic, is prone to deformation during machining, which can lead to higher scrap rates, longer setup times, and the need for additional fixturing or post-processing—all of which add to the final cost.

Material Waste & Yield

Delrin’s dimensional stability allows for precise tolerances, reducing rework and improving material yield. UHMW, due to its lower stiffness and higher thermal expansion, can warp or shift during machining. This sometimes results in lower usable yield per sheet or rod, especially for complex parts with critical dimensions.

Volume Discounts & Availability

UHMW is widely produced and stocked in large volumes, offering better discounts for bulk orders. Delrin, particularly in specialty grades (such as FDA-approved or glass-filled), may have longer lead times and limited availability, impacting pricing flexibility.

Total Cost of Ownership

When evaluating Delrin vs. UHMW, consider long-term costs such as part longevity, maintenance, and replacement. Delrin’s superior wear resistance and rigidity may offer lower lifecycle costs in precision applications. UHMW, while cheaper initially, may require more frequent replacement in demanding conditions—raising total cost over time.

When evaluating cost, it's important to consider not just material pricing but the total cost of ownership:

In short, UHMW offers initial cost savings, making it suitable for bulk, low-precision parts. However, Delrin provides better long-term value in applications demanding precision, stability, and durability—justifying its higher upfront cost. For CNC machining factories aiming to deliver reliable, high-quality plastic CNC machined parts, the choice between UHMW CNC machined parts and Delrin CNC machined parts depends on striking the right balance between function and budget.

When choosing between UHMW and Delrin for CNC machining services, the differences between these two engineering plastics go far beyond price. Each material has distinct characteristics that make it suitable for specific applications in terms of processability, durability, dimensional stability, and resistance to heat. Understanding these key differences is crucial for designers, engineers, and procurement teams who want to get the best performance and value from their plastic CNC machined parts.

Processability

Delrin is widely favored in CNC machining factories because of its excellent dimensional stability and ease of machining. It holds tight tolerances, produces clean finishes, and doesn’t warp or deform easily under heat or pressure. This makes Delrin CNC machined parts ideal for high-precision applications in automotive, aerospace, and industrial settings.

In contrast, UHMW is more difficult to machine due to its low melting point and high elasticity. While it doesn’t chip or crack easily, it tends to deform during machining, requiring slower speeds and sharper tools. That said, UHMW CNC machined parts are excellent for applications where tolerance is less critical, but resistance to abrasion and impact is vital.

Durability

UHMW shines in applications requiring high impact resistance and extreme wear resistance. It performs well under continuous sliding contact and is often used for wear strips, conveyor guides, and abrasion-resistant liners. Its molecular structure makes it almost impossible to crack or shatter under pressure.

Delrin, on the other hand, offers a different kind of durability—specifically mechanical strength and fatigue resistance. It is stiffer, stronger, and more rigid than UHMW, allowing it to endure cyclic stress, pressure, and tension without breaking down. This makes Delrin better for load-bearing and mechanical parts like gears and bushings.

Heat Resistance

Delrin can withstand higher operating temperatures (up to ~96.9°C) compared to UHMW (maximum ~82°C). It also maintains its mechanical properties better under heat, which is critical in high-speed or friction-heavy environments. UHMW, while excellent in cold or abrasive conditions, can deform more easily when exposed to elevated temperatures.

Dimensional Stability

One of Delrin’s greatest advantages is its dimensional and geometric stability. It resists moisture absorption and thermal expansion, ensuring consistent part size and shape over time. UHMW, by contrast, has a higher coefficient of thermal expansion and can absorb more moisture, leading to dimensional changes that may affect precision assemblies.

In summary, Delrin is better for precision, heat resistance, and mechanical strength, while UHMW excels in impact resistance and cost-efficiency for wear-intensive environments. Both materials have their place in CNC machining services, and selecting the right one will depend on your performance requirements, environment, and budget.

Ultra-High Molecular Weight Polyethylene (UHMW) is often a go-to choice for applications requiring outstanding impact strength, chemical resistance, and low friction. But when it comes to CNC machining, this high-performance thermoplastic comes with both benefits and drawbacks. Understanding these can help manufacturers, engineers, and buyers determine whether UHMW CNC machined parts are the right fit for their project—and whether the trade-offs align with performance goals and budget requirements.

Advantages of CNC Machining with UHMW

One of the biggest advantages of CNC machining with UHMW is its exceptional resistance to wear and abrasion. This makes it an ideal choice for parts exposed to frequent sliding, impact, or friction—such as liners, guides, and bushings in conveyor and packaging systems. Its low coefficient of friction also minimizes heat buildup and reduces the need for lubrication, which is particularly valuable in food-grade or clean-room environments.

UHMW’s chemical resistance is another major selling point. It is highly resistant to a wide range of chemicals, including acids, solvents, and alkalis, which makes it an ideal material for use in corrosive environments such as wastewater treatment plants, chemical processing facilities, or marine equipment.

Its impact strength is virtually unmatched among thermoplastics, and it remains tough even at cryogenic temperatures. Furthermore, UHMW is FDA-approved for food contact in many grades, making it a practical option for food processing equipment where hygiene and safety are paramount.

From a cost perspective, UHMW is significantly more affordable than many other engineering plastics like Delrin or PEEK, offering an economical solution for large-scale, wear-prone components.

Limitations of CNC Machining with UHMW

Despite its strengths, UHMW presents several challenges in CNC machining. Most notably, its low melting point and high elasticity make it prone to deformation during machining. This means slower feed rates, sharper tools, and more cautious machining strategies are required—raising both the time and cost of production.

Another limitation is UHMW’s poor dimensional stability. It tends to expand or shrink in response to temperature and moisture changes, making it difficult to achieve or maintain tight tolerances. This limits its use in high-precision applications where exact fitting or repeated alignment is necessary.

UHMW also lacks the rigidity and mechanical strength of materials like Delrin. It can flex under load and is not ideal for parts that require structural strength, tight tolerances, or exact mechanical movements.

Finally, joining or bonding UHMW with adhesives or other materials is a significant challenge due to its non-stick, waxy surface. Specialized surface treatments or mechanical fastening are often required.

Overall, CNC machining with UHMW offers unmatched wear resistance, chemical durability, and affordability, but it does so at the expense of precision, rigidity, and processing ease. For industries that prioritize rugged, cost-effective parts over micron-level accuracy, UHMW CNC machined parts are a solid choice.

Choosing the right material for CNC machining is a decision that impacts everything—from performance and product lifespan to production cost and efficiency. Delrin, a brand of acetal resin, has earned its reputation for being a machinist-friendly plastic with superior mechanical properties. But how does it truly perform in CNC operations? And what should you watch out for? In this section, we’ll dive deep into the advantages and limitations of CNC machining with Delrin, helping engineers, procurement managers, and designers make smarter decisions when specifying materials for their plastic CNC machined parts.

Advantages of CNC Machining with Delrin

Delrin offers a powerful combination of machinability, mechanical strength, and dimensional accuracy, making it a top material choice for CNC machining factories producing high-performance plastic components.

Smooth Machining

Delrin is renowned for its excellent machinability. It cuts cleanly and consistently, generating smooth, burr-free surfaces without the need for extensive post-processing. Whether milling, turning, or drilling, machinists benefit from reduced tool wear, shorter cycle times, and superior part finish. Its low friction coefficient also contributes to smooth cutting, which makes it ideal for producing Delrin CNC machined parts that require tight tolerances and refined surfaces—such as gears, cams, and precision housings.

Dimensional Stability

A major advantage of Delrin is its exceptional dimensional stability. It maintains shape and precision even under mechanical stress or fluctuating temperatures, making it ideal for high-precision assemblies. Unlike softer plastics, Delrin resists warping and creep over time, which is critical in industries like automotive, aerospace, and electronics. For CNC machining services handling high-tolerance production, this stability ensures consistency in part quality from prototype to full-scale manufacturing.

Durable and Resilient

Delrin’s high tensile strength and rigidity give it the durability needed for mechanical components subjected to stress, pressure, or wear. It’s tough enough to absorb impact without cracking and performs reliably in dynamic environments. This makes it a dependable substitute for metal in many cases, particularly for bushings, bearings, and mechanical levers. Additionally, Delrin CNC machined parts offer longer service life compared to many other plastic alternatives, reducing replacement costs and downtime.

Heat Resistance

Delrin handles continuous operating temperatures between 80°C and 100°C, with some grades reaching higher thresholds. Its thermal resistance enables use in environments where heat build-up might degrade other plastics like UHMW. It also exhibits low thermal expansion, further supporting tight dimensional control. This property makes Delrin valuable in applications involving friction, such as sliding mechanisms or gear systems, where both heat and pressure are common.

Limitations of CNC Machining with Delrin

Despite its many strengths, Delrin does have limitations that must be considered during material selection.

First, it is not inherently UV-stable, and prolonged sunlight exposure can cause degradation unless UV-stabilized grades are used. Additionally, it struggles with chemical resistance to strong acids and alkalis, limiting its use in aggressive environments.

Bonding Delrin to other materials is also a challenge. Its low surface energy resists adhesives, making traditional gluing methods ineffective. Designers often need to rely on mechanical fastening solutions instead, which can complicate assembly.

Delrin can off-gas formaldehyde when overheated during machining. This requires strict safety protocols and adequate ventilation in CNC machining factories to ensure operator safety and product quality. Finally, cost can be a concern—Delrin is more expensive than many other plastics, including UHMW, making it less ideal for low-budget or high-volume disposable parts.

By understanding both the strengths and limitations of Delrin, product developers and manufacturers can make informed decisions that balance performance, cost, and application needs. For projects requiring high precision and consistent durability, Delrin CNC machined parts are an outstanding solution.

When designing precision components, selecting the right plastic material can significantly impact product performance and lifecycle. Both UHMW (Ultra High Molecular Weight Polyethylene) and Delrin (acetal homopolymer) offer a wide range of industrial benefits, but they shine in different applications. Understanding where each excels allows manufacturers and engineers to optimize their material choices based on function, environment, and regulatory requirements. In this section, we’ll compare where UHMW CNC machined parts and Delrin CNC machined parts are most effectively used—helping you match the right plastic to the right job.

UHMW Applications

UHMW is widely used in situations requiring low friction, high impact resistance, and outstanding wear properties. Its ability to perform in abrasive environments without cracking or chipping makes it invaluable across rugged industries.

UHMW is used in vehicle components that demand high wear resistance and noise dampening. It helps improve durability while reducing weight and cost.

Rock Climbing Equipment

Due to its exceptional toughness and low friction, UHMW plays a role in sports equipment requiring resistance to harsh environmental conditions and repeated impact.

Personal Protective Armor

UHMW is often used in ballistic and tactical protection due to its high energy absorption and light weight.

Its biocompatibility and low moisture absorption make UHMW ideal for long-term implants where wear and lubrication are key concerns.

Other Industries

UHMW is commonly found in food processing, bulk material handling, and packaging industries. Its FDA compliance, non-stick surface, and chemical resistance make it perfect for conveyor systems, machine guards, and cutting boards.

Delrin Applications

Delrin stands out in applications that require high stiffness, low friction, and excellent dimensional stability. It’s particularly valued in tight-tolerance precision parts that must hold up to mechanical stress, making it a go-to for plastic CNC machined parts in technical and safety-critical fields.

Delrin is widely used for components that require rigidity and creep resistance under mechanical load. Its ability to maintain tolerances even under vibration or temperature shifts makes it ideal for internal automotive systems.

Its strength, machinability, and chemical resistance suit it for non-implantable medical tools and devices that require precision.

Aerospace

Delrin’s high strength-to-weight ratio and ability to maintain dimensional accuracy under heat and load make it an aerospace favorite for various structural and mechanical parts.

Delrin works well in high-load and high-cycle machinery. Its resistance to deformation and fatigue makes it perfect for moving parts in industrial settings.

Other Industries

Delrin is also used in robotics, consumer electronics, and appliance manufacturing due to its formability, surface finish, and strength. It’s often the material of choice when transitioning from metal to plastic without sacrificing performance.

Curious about why so many customers choose VMT CNC Factory for their plastic CNC machined parts?

Choosing the right CNC machining partner is just as important as choosing the right material. At VMT, we specialize in delivering precision-crafted Delrin CNC machined parts and UHMW CNC machined parts that meet the highest standards of performance, durability, and consistency. With advanced equipment, deep industry knowledge, and a client-first mindset, we help you turn your plastic part concepts into functional, high-quality components that exceed expectations.

Advanced CNC Machining Capabilities for Plastics

VMT is equipped with high-speed, high-accuracy CNC machining centers that are specially calibrated for handling engineering plastics like Delrin and UHMW. These materials behave differently from metals—they can expand, warp, or deform under improper tooling or excessive heat. Our team understands these behaviors intimately, ensuring the material is machined with the correct parameters to preserve dimensional accuracy and structural integrity. Whether you need tight tolerances, smooth finishes, or complex geometries, VMT delivers consistent results with every order.

Expertise in Delrin and UHMW Material Handling

Not all CNC machining factories are experienced in working with performance plastics. At VMT, our engineers and machinists have years of hands-on experience with acetal (Delrin) and UHMW materials. We know how to optimize speeds, feeds, and coolant applications to avoid issues like surface melting, internal stress, or tool chatter. This translates to fewer reworks, faster lead times, and better part performance—especially for clients in aerospace, automotive, and medical fields.

Precision, Scalability, and Quality Assurance

Whether you're ordering a one-off prototype or need thousands of repeatable parts, VMT has the scalability and infrastructure to deliver. Every part is produced under rigorous quality control procedures—from raw material verification to in-process inspections and final measurements. We also offer full traceability and documentation for industries that require compliance, such as FDA or ISO-certified sectors. For high-volume orders, our CNC automation systems maximize repeatability and minimize production cost.

Customer-Centric Support and Collaboration

We don’t just produce parts—we collaborate with clients. Our engineers provide design for manufacturability (DFM) feedback, helping you identify cost-saving opportunities or material upgrades that won’t compromise function. We offer transparent quotes, fast turnaround, and global shipping support to keep your project moving smoothly from prototyping to full-scale production. Whether you're developing a new product line or need replacement parts quickly, VMT is here as your dependable CNC machining partner.

Looking to get started with your next Delrin CNC machined parts or UHMW CNC machined parts order? Contact VMT today to request a quote or consultation.

When choosing between Delrin and UHMW for your plastic components, it all comes down to understanding your specific application requirements. Both materials are widely used in CNC machining services thanks to their unique characteristics: Delrin offers higher dimensional stability, better machinability, and greater rigidity, while UHMW provides superior impact resistance, abrasion resistance, and excellent chemical inertness.

For high-precision components where tight tolerances, fine finishes, and stability are critical, Delrin CNC machined parts are often the ideal choice. In contrast, if your application demands extreme durability, impact resistance, and low friction in harsh environments, UHMW CNC machined parts offer a cost-effective and reliable solution.

At VMT, we bring deep expertise in plastic CNC machined parts, helping you select the right material and deliver components that meet stringent quality standards. Whether you're producing prototypes or full production runs, VMT stands out among CNC machining factories for our reliability, precision, and client-centered approach.

Let our team help you decide the best material for your application—because choosing the right plastic and the right CNC machining partner makes all the difference.

Which is stronger, Delrin or UHMW?

Delrin is stronger in terms of tensile strength and stiffness, making it better suited for high-precision parts. UHMW, however, excels in impact resistance and wear properties.

How to distinguish UHMW from Delrin?

UHMW has a waxy, slippery texture and is softer, while Delrin feels harder and machines more like a metal. Visually, Delrin is glossier and more rigid, while UHMW is more flexible.

Which plastic is stronger than UHMW?

Materials like PEEK and polycarbonate are generally stronger than UHMW in tensile strength and heat resistance, but UHMW remains a leader in impact resistance.

How do the properties of Delrin differ from UHMW?

Delrin offers higher dimensional stability, rigidity, and machinability, while UHMW provides better abrasion resistance, chemical resistance, and shock absorption.

What are the disadvantages of UHMW?

UHMW can be difficult to machine precisely, doesn’t bond well with adhesives, and has poor heat resistance compared to other plastics like Delrin.

Does Delrin absorb water?

Delrin absorbs very little water compared to other plastics, making it suitable for humid and wet environments.

What is another name for Delrin?

Delrin is a brand name for acetal homopolymer (POM-H), a type of polyoxymethylene manufactured by DuPont.

Are there any cheaper alternatives to Delrin?

Acetal copolymer (POM-C) is often used as a more cost-effective alternative to Delrin with similar properties, though it offers slightly lower strength and stiffness.

Why is Delrin so expensive?

Delrin is more expensive due to its high performance, tight tolerances, excellent machinability, and brand recognition from DuPont.

Does Delrin crack easily?

Delrin has good impact resistance but can crack under repeated flexing or in very low temperatures if not properly supported.

Does Delrin degrade over time?

Delrin is highly durable but can degrade when exposed to UV light for extended periods unless stabilized or coated.

Can you sand Delrin?

Yes, Delrin can be sanded, but care must be taken to avoid heat buildup that can melt the surface. Use light pressure and fine grit sandpaper.

Does Delrin shrink when it is cold?

Like most plastics, Delrin will contract slightly in cold temperatures but maintains good dimensional stability across a broad temperature range.

Can you bend Delrin with heat?

Delrin can be bent when heated above its forming temperature (~160°C), but excessive heat can cause warping or outgassing.

What is better than UHMW?

For high-strength or high-temperature applications, materials like PEEK or Delrin may be better suited, depending on your needs.

Is Delrin difficult to machine?

Delrin is one of the easiest engineering plastics to machine, offering clean chips, smooth finishes, and tight tolerances.

Is Delrin suitable for bushings?

Yes, Delrin is ideal for bushings due to its low friction, wear resistance, and dimensional accuracy.