15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

104 |

Published by VMT at Mar 20 2024

104 |

Published by VMT at Mar 20 2024

Resolving Dimensional Deviation in CNC Machining Caused by Secondary Oxidation

In the manufacturing process of CNC machined parts, secondary oxidation is a common issue that may lead to dimensional deviations, significantly affecting product quality and customer satisfaction. It is crucial for CNC machining factories to address the problem of dimensional deviation caused by secondary oxidation. This article will delve into the causes of secondary oxidation, its impact, and the measures CNC machining factories should take to solve this issue, aiming to help improve product quality and ensure machining accuracy.

I. Causes and Impact of Secondary Oxidation:

Secondary oxidation typically occurs during the surface treatment process of CNC machined parts, especially in the processing of metal materials. The main causes include:

Material Issues: Certain metal materials are prone to oxidation reactions during processing, especially in high-temperature, high-humidity, or corrosive gas environments.

Improper Surface Treatment Process: The use of excessively concentrated oxidants, prolonged treatment times, or inadequate temperature control during the surface treatment process can lead to secondary oxidation.

Poor Storage and Transportation Conditions: Prolonged exposure to humid or oxygen-containing environments during storage and transportation can also result in secondary oxidation.

Secondary oxidation has a severe impact on the dimensional accuracy and surface quality of CNC machined parts. The formation of an oxide layer alters the part's dimensions, causing deviation issues. Additionally, the oxide layer may affect the surface roughness and gloss of the part, diminishing overall product quality.

II. Measures for CNC Machining Factories to Solve Dimensional Deviation Caused by Secondary Oxidation:

To address the problem of dimensional deviation caused by secondary oxidation, CNC machining factories can take the following measures:

Optimize Material Selection:

Choose materials with better anti-oxidation performance to reduce the likelihood of oxidation during processing.

For metals prone to oxidation, consider surface coating or pre-treatment methods to enhance their anti-oxidation capability.

Improve Surface Treatment Process:

Optimize the surface treatment process to ensure that parameters such as oxidant concentration, treatment time, and temperature are controlled within reasonable ranges.

Employ advanced surface treatment technologies like vacuum coating to enhance the anti-oxidation properties of the part's surface.

Strengthen Storage and Transportation Management:

Ensure a dry and well-ventilated storage environment to prevent prolonged exposure to humid or oxygen-rich conditions.

Implement protective measures during transportation, such as using sealed packaging and adding desiccants, to minimize the part's contact with oxygen.

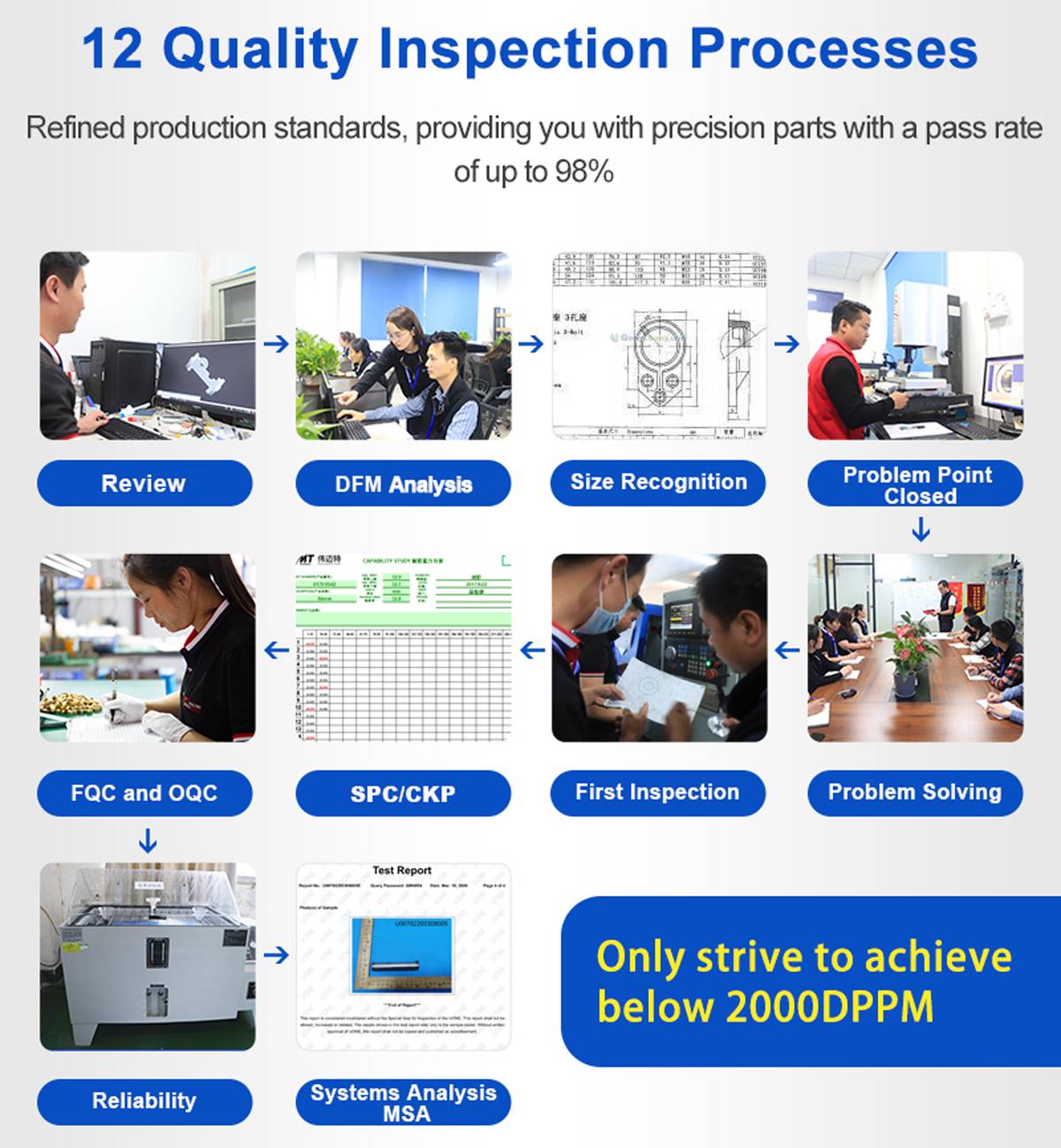

Strict Quality Control and Inspection:

Establish a comprehensive quality control system, monitoring each processing step rigorously.

Intensify dimensional and surface quality inspections to ensure products meet quality requirements.

Promptly analyze and address the causes of dimensional deviations.

Enhance Employee Training and Technical Support:

Provide training to raise awareness among employees about the issue of secondary oxidation and the importance of mitigating its effects.

Collaborate with surface treatment experts and research institutions to introduce advanced techniques and equipment, elevating the overall technical proficiency of the factory.

III. Case Analysis and Practical Experience:

To illustrate how to solve the problem of dimensional deviation caused by secondary oxidation, let's consider a real-world case:

A CNC machining factory encountered dimensional deviation issues in a batch of aluminum alloy parts. Analysis revealed that secondary oxidation during the surface treatment process was the root cause. The factory implemented the following measures:

Pre-Treatment of Aluminum Alloy:

Implemented an anodizing process to form a dense oxide film on the surface, enhancing the parts' anti-oxidation capability.

Optimized Surface Treatment Process:

Adjusted oxidant concentration, treatment time, and temperature, ensuring they were within optimal ranges.

Introduced vacuum coating technology to provide additional protection to the part's surface.

Improved Storage and Transportation Practices:

Enhanced management practices to maintain a dry storage environment and prevent exposure to oxygen during transportation.

As a result of these measures, the factory successfully resolved the dimensional deviation problem caused by secondary oxidation, improving overall product quality and customer satisfaction.

IV. Conclusion and Future Outlook:

Secondary oxidation poses a common and challenging issue in the CNC machining of parts. CNC machining factories must recognize its severity and implement effective measures to reduce its impact on product quality. By optimizing material selection, improving surface treatment processes, managing storage and transportation conditions, implementing strict quality control, and enhancing employee training, factories can significantly reduce the occurrence of secondary oxidation, thereby improving the accuracy and stability of CNC machined parts.

Looking ahead, with the continuous advancement of technology and the maturation of CNC machining techniques, we believe that CNC machining factories will achieve greater breakthroughs and progress in addressing issues like secondary oxidation. By introducing advanced processing equipment and surface treatment technologies, refining quality management systems, and fostering collaboration with other enterprises, factories can further elevate product quality and competitiveness, contributing to the continuous development of the CNC machining parts manufacturing industry.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!