15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

311 |

Published by VMT at Dec 05 2023

311 |

Published by VMT at Dec 05 2023

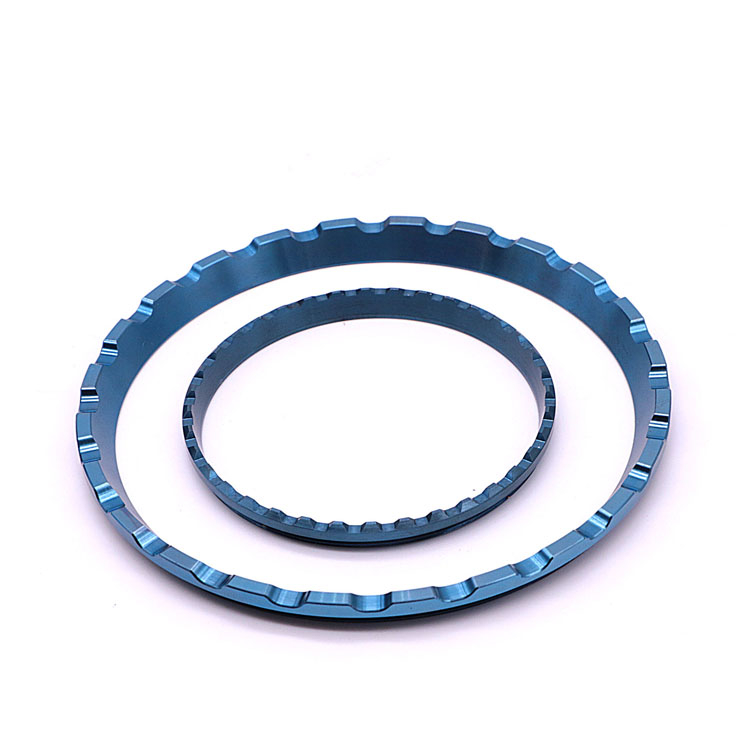

Surface Treatment Options for Titanium CNC Machined Parts: Enhancing Performance and Aesthetics

Titanium CNC machined parts, known for their exceptional strength and corrosion resistance, can benefit further from various surface treatments. These treatments not only enhance the aesthetic appeal but also improve the functional characteristics of titanium CNC components. Here are some surface treatment options suitable for titanium CNC machined parts:

Anodizing:

Anodizing forms a protective oxide layer on the titanium surface, improving corrosion resistance and adding color options. It enhances the material's durability and provides an attractive finish.

Passivation:

Passivation removes free iron from the surface of titanium, promoting corrosion resistance. It is particularly beneficial in applications where preventing rust and maintaining a clean appearance are crucial.

Polishing:

Polishing gives titanium CNC parts a smooth, reflective surface. This cosmetic treatment enhances the appearance of the components, making them suitable for high-end applications such as jewelry or aerospace CNC components.

Blasting:

Sandblasting or bead blasting creates a textured surface on titanium, imparting a matte finish. This treatment is often chosen for its aesthetic appeal and can also improve the material's resistance to scratches.

Electropolishing:

Electropolishing improves the surface finish of titanium by removing a thin layer of material, resulting in a smooth, shiny appearance. It also helps in minimizing micro-roughness and improving corrosion resistance.

Plasma Coating:

Plasma coating involves depositing a thin layer of a protective material on the titanium surface. This can enhance wear resistance, reduce friction, and provide additional protection against environmental elements.

PVD Coating (Physical Vapor Deposition):

PVD coatings, such as titanium nitride (TiN) or titanium carbonitride (TiCN), can be applied to titanium surfaces to improve hardness, reduce friction, and enhance wear resistance.

Laser Marking:

Laser marking allows for precise engraving of text, logos, or other identifiers onto the titanium surface. This is often used for branding purposes or for adding essential information to the component.

Ceramic Coating:

Ceramic coatings can provide a layer of protection against abrasion, wear, and corrosion. These coatings enhance the durability of titanium components in challenging environments.

Hydrographics (Water Transfer Printing):

Hydrographics allow for the application of intricate patterns or designs onto the titanium surface. This method provides a unique and customizable aesthetic finish.

Selecting the appropriate surface treatment for titanium CNC machined parts depends on the specific application, performance requirements, and desired aesthetics. These treatments not only protect the material but also open up possibilities for customization and innovation in various industries.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!