15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

110 |

Published by VMT at Feb 18 2024

110 |

Published by VMT at Feb 18 2024

Introduction:

In the manufacturing industry, CNC machined parts find widespread applications across various sectors, especially in fields requiring high precision and complex structures. However, due to diverse usage environments, many parts need to operate under harsh conditions such as high temperatures, low temperatures, exposure to UV radiation, and corrosive environments. This places higher demands on the weather resistance and corrosion resistance of CNC machined parts' surfaces. This article explores how to ensure the weather resistance and corrosion resistance of custom CNC machined parts surfaces.

I. Choosing Appropriate Materials:

Firstly, selecting materials with excellent weather resistance and corrosion resistance is crucial. For instance, stainless steel, aluminum alloys, and certain advanced plastics exhibit good corrosion resistance, while specific alloys and ceramic materials excel in high-temperature and UV resistance. When selecting materials, consideration should also be given to their performance in specific environments and compatibility with other materials.

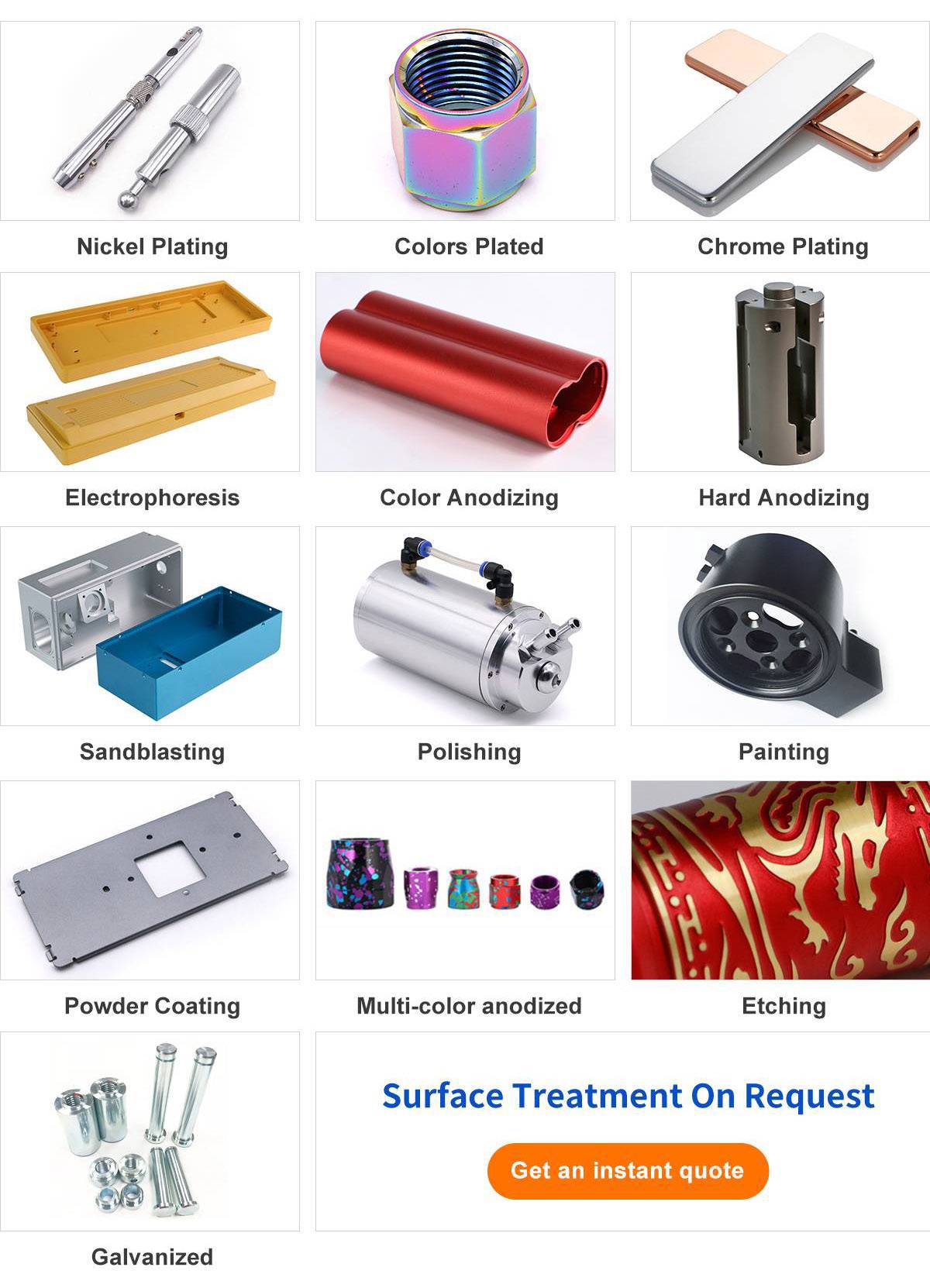

II. Significance of Surface Treatment:

Surface treatment is a key aspect of improving the weather resistance and corrosion resistance of CNC machined parts. Through surface treatment, the physical and chemical properties of the part's surface can be altered, enhancing its durability. Common surface treatment methods include coating, plating, and surface modification. For example, applying anti-corrosion coatings can effectively improve a part's corrosion resistance, and applying heat-insulating coatings can enhance resistance to high temperatures.

III. Control of Surface Treatment Processes:

Controlling surface treatment processes is crucial to ensuring weather resistance and corrosion resistance. Firstly, choose suitable surface treatment processes such as electroplating, chemical plating, or spraying. Secondly, control process parameters, such as temperature, pressure, time, and concentration, to ensure they are within optimal ranges. Additionally, regular maintenance and calibration of surface treatment equipment should be performed to ensure its proper functioning.

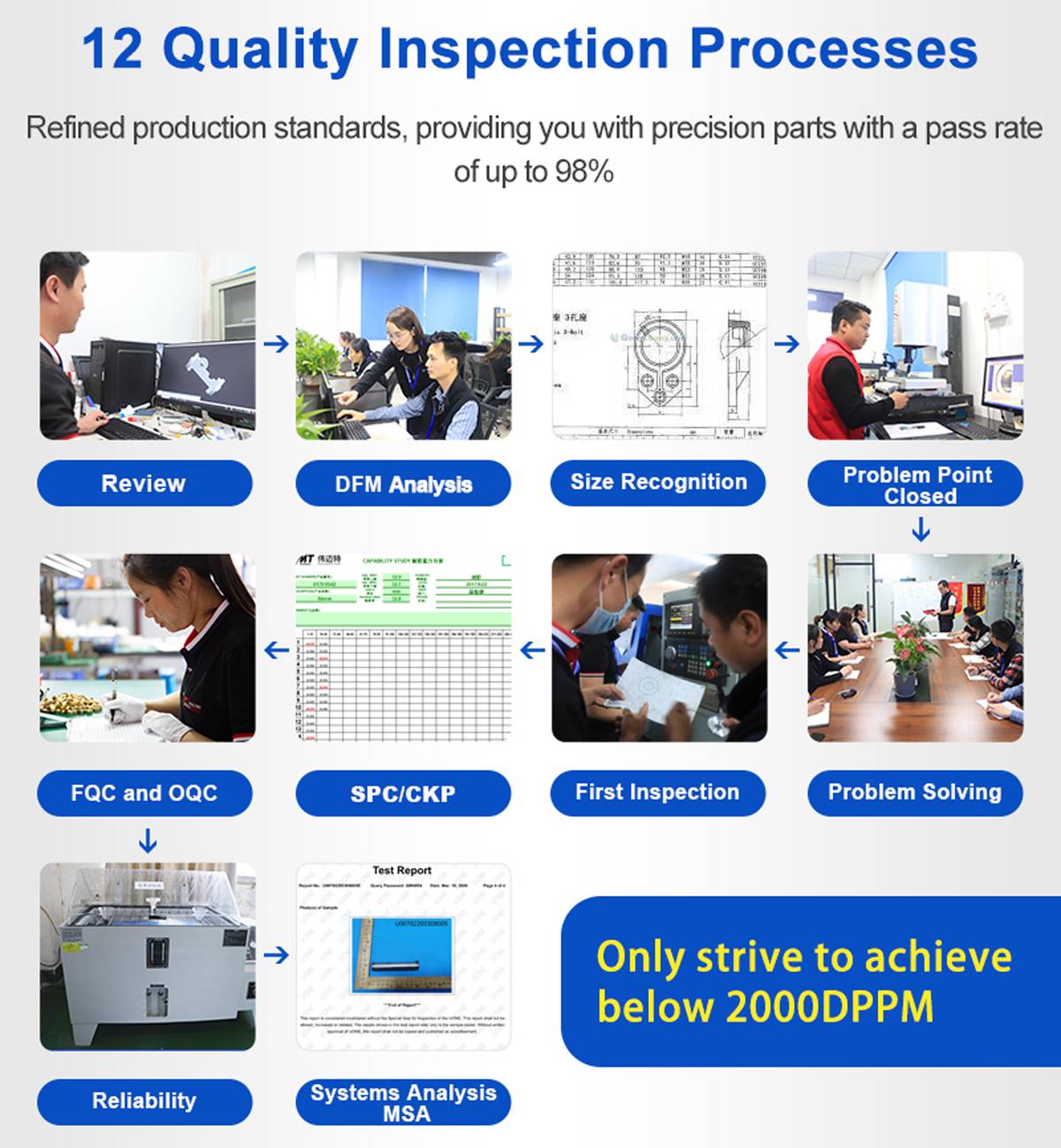

IV. Quality Inspection and Control:

Quality inspection and control are essential means to guarantee the weather resistance and corrosion resistance of CNC machined parts surfaces. Develop comprehensive quality inspection plans covering aspects like visual inspection, performance testing, and environmental adaptability testing. For critical elements, employ non-destructive testing techniques like X-ray testing or ultrasonic testing. Regular calibration and maintenance of inspection equipment are necessary to ensure the accuracy and reliability of inspection results. Non-conforming products should undergo traceability and rework, with analysis of the reasons and implementation of corrective measures.

V. Consideration of Environmental Factors:

During the design and manufacturing processes, the performance of parts in specific working environments should be considered. For example, parts used in marine environments require special attention to corrosion resistance, while those used in high-temperature environments need consideration for heat resistance and stability. Additionally, other environmental factors like humidity and UV exposure should be taken into account for their potential impact on the weather resistance and corrosion resistance of parts surfaces.

VI. Continuous Improvement and Innovation:

With continuous technological advancements, new materials and surface treatment techniques emerge. Companies should stay informed about industry trends and the latest technological developments, continuously introducing new technologies, processes, and materials to enhance the weather resistance and corrosion resistance of CNC machined parts. Simultaneously, ongoing improvement of existing processes and optimization should occur, reducing costs and increasing product competitiveness. Collaboration with research institutions and universities can further drive innovation and provide robust support for corporate advancement.

VII. Personnel Training and Qualifications:

The skills and experience of operational personnel are crucial for ensuring the weather resistance and corrosion resistance of CNC machined parts surfaces. Therefore, systematic training should be provided to familiarize operators with the characteristics and requirements of various materials and surface treatment processes. Additionally, ensuring that operators possess relevant qualifications and certifications is essential to guarantee they have the necessary skills and knowledge to execute tasks.

VIII. After-Sales Support and Services:

For delivered custom CNC machined parts, comprehensive after-sales support and services should be provided. This includes prompt responses and resolution of issues encountered by customers during usage, offering necessary maintenance and repair services, and collecting customer feedback for product and service quality improvement. Through high-quality after-sales support and services, companies can earn customer trust and establish a positive reputation.

Conclusion:

Ensuring the weather resistance and corrosion resistance of custom CNC machined parts surfaces requires a multi-faceted approach. From selecting suitable materials and surface treatment methods to rigorously controlling process parameters and implementing quality inspection and control; from considering environmental factors to continuous improvement and innovation; from personnel training and qualifications to providing quality after-sales support and services. By comprehensively applying these measures and continually optimizing and refining production processes, companies can provide customers with custom CNC machined parts exhibiting excellent weather resistance and corrosion resistance. This contributes to extending product lifespan, reducing maintenance costs, meeting customer needs, and, importantly, ensures market competitiveness and facilitates sustained growth.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!