15 years one-stop China custom CNC machining parts factory

Home / Resources / Material / Brass CNC Machining /

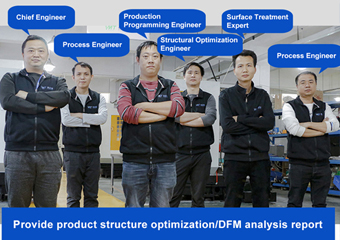

Professional Custom Alloy Brass CNC Machining Team

24/7 CNC Machining Facility with Samples Ready in 7-10 Days

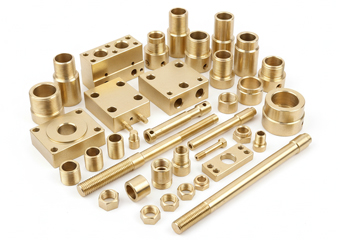

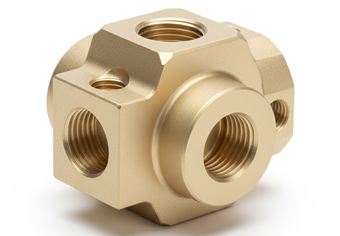

Why choose brass? Because it combines excellent machinability, outstanding electrical conductivity, corrosion resistance, and natural antibacterial properties. Our professional brass CNC machining team can efficiently and precisely turn these advantages into real value for your products. Whether it’s complex valve components, wear-resistant gears, or highly conductive electronic connectors, we provide stable, reliable, and cost-effective custom mass production solutions.

VMT specializes in producing high-precision, complex-structure brass CNC machined parts. Certified with ISO9001 and IATF16949, we offer one-stop services from prototyping to mass production. With advanced CNC equipment and a professional team, we manufacture high-strength, corrosion-resistant brass parts with guaranteed precision and consistency. We provide CNC milling, turning, and other machining services, offering flexible quotations based on project stages to meet strict tolerance requirements and ensure fast delivery. By continuously optimizing our processes, we meet your diverse production needs and provide strong support for your project's success.

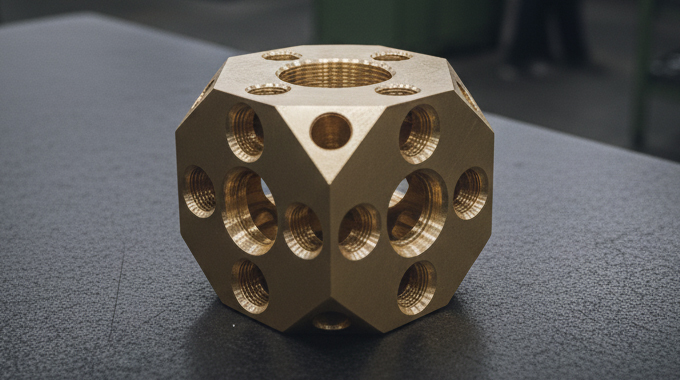

Brass CNC Machined Prototypes

From brass prototype development to mass production, we leverage our mature rapid precision machining capabilities to provide fast, accurate, and cost-effective brass CNC prototype solutions to over 1,000 clients. Equipped with 100 advanced machines and a professional team of more than 12 engineers, we offer manufacturability analysis and form dedicated prototyping teams, supporting 24-hour CNC prototype machining. Through 12 strict quality inspection processes and professional testing equipment, we ensure every prototype part achieves excellent dimensional accuracy and functionality, making it ideal for conductivity testing, wear verification, and assembly checks. Each part fully meets design requirements and comes with an authoritative inspection report. Choose us to ensure your product flows smoothly from concept to validation.

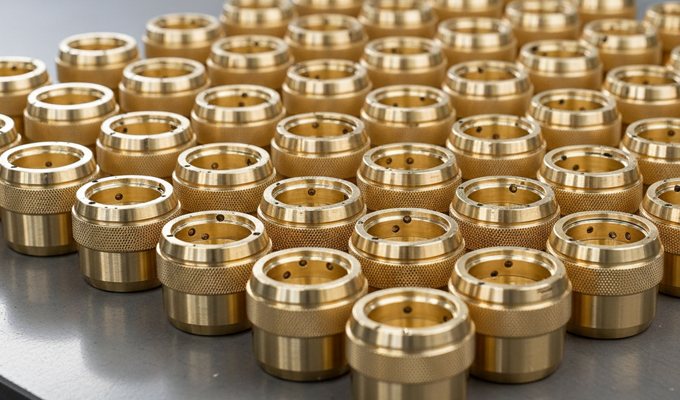

High-Volume Custom CNC Machined Brass Parts Manufacturing

When your project moves from prototype validation to large-scale production, we provide cost-effective, efficient, and stable solutions for mass customization of brass parts. Professional engineering DFM analysis reduces costs from the design stage, and a rich material inventory (such as Brass C260, Brass C360, etc.) lowers raw material procurement costs and lead times. We implement full-process statistical process control (SPC) along with strict quality procedures, including first-article inspection, in-process inspection, and final inspection, ensuring that the critical dimensions and performance of the 1st part and the 10,000th part are highly consistent, guaranteeing smooth production and assembly. If you complete CNC brass part validation with VMT, you can seamlessly transition to mass production. We ensure a high level of consistency in process, quality, and data from prototype to volume production, greatly shortening your production cycle and reducing the technical and management risks associated with switching suppliers.

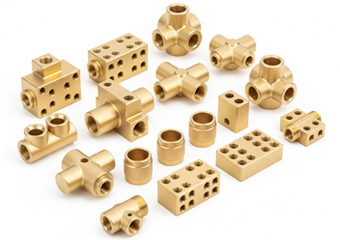

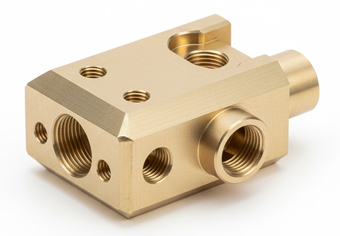

Custom Brass CNC Machining Parts

Brass is an ideal engineering material with excellent electrical conductivity, corrosion resistance, and outstanding machinability. With natural antibacterial properties and low cost, it is widely used in electronic connectors, plumbing valves, wear-resistant gears, and daily consumer products, making it an economical choice for efficient precision manufacturing. Leveraging our professional CNC milling, CNC turning, and 5-axis CNC machining capabilities, we provide customized high-precision brass CNC parts services, from rapid prototypes to mass production.

VMT Provides Brass Materials: Brass C23000, Brass C26000, Brass C27200, Brass C28000, Brass C36000, Brass C38500, Brass C46400, Brass C68700, etc.

Advantages of Brass

Brass offers a combination of excellent machinability, corrosion resistance, and aesthetic appeal, making it one of the most popular materials for custom CNC machining parts.

Price: $$$

Delivery Time: < 10 days

Wall Thickness: 0.75 mm

Tolerance: ±0.005 in. (±0.125 mm)

Maximum Part Size: 200 x 80 x 100 cm

Disadvantages of Brass

While brass is versatile, it has some limitations that should be considered before production:

Brass H85 | C23000 | CuZn15 | CZ101 | 85Cu–15Zn

C23000 brass, also known as Red Brass or 85-15 Brass, offers excellent corrosion resistance, formability, and warm golden color. It's ideal for CNC machining, forging, and deep drawing processes. Commonly used in plumbing fittings, decorative hardware, electrical connectors, and musical instruments.

Yield Strength (MPa): 105–275 MPa

Tensile Strength (MPa): 275–420 MPa

Fatigue Strength (MPa): ~120 MPa

Elongation at Break (%): 30–50 %

Hardness (Brinell): 60–110 HB

Density (g/cm³): 8.83 g/cm³

Melting Point (°C): 900–940°C

Brass H70 | C26000 | CuZn30 | C2600 | CZ106 | CuZn30 | 70Cu–30Zn

C26000 brass, also known as Cartridge Brass (70-30 Brass), provides excellent ductility, corrosion resistance, and cold workability. It's ideal for CNC machining, stamping, and deep drawing. Commonly used in cartridge cases, radiator cores, connectors, and decorative hardware across various industries.

Yield strength (MPa): 95–250 MPa

Tensile strength (MPa): 315–460 MPa

Fatigue strength (MPa): ~125 MPa

Elongation at break (%): 30–60%

Hardness (Brinell): 55–110 HB

Density (g/cm³): 8.53 g/cm³

Melting Point (°C): 920–950°C

Brass H68 | CuZn32 | CuZn33 | CZ107 | CuZn33 | 68Cu–32Zn

CuZn32 brass, also known as Yellow Brass or Alloy 68, offers excellent formability, corrosion resistance, and thermal conductivity. It is ideal for CNC machining, deep drawing, and bending processes. Commonly used in tubes, radiator components, electrical connectors, and decorative fittings.

Yield strength (MPa): 150–300 MPa

Tensile strength (MPa): 350–500 MPa

Fatigue strength (MPa): ~120 MPa

Elongation at break (%): 30–50%

Hardness (Brinkel): 70–120 HB

Density (g/cm³): 8.53 g/cm³

Melting Point (°C): 900–940°C

Brass H65 | CuZn35 | CuZn36 | CZ108 | CuZn36 | 65Cu–35Zn

H65 brass (CuZn35), also known as Yellow Brass, offers excellent corrosion resistance, high ductility, and good machinability. It is suitable for CNC machining, deep drawing, and stamping and commonly used for radiator fins, hardware fittings, plumbing components, and decorative parts.

Yield strength (MPa): 160–310 MPa

Tensile strength (MPa): 360–520 MPa

Fatigue strength (MPa): ~125 MPa

Elongation at break (%): 25–45%

Hardness (Brinkel): 75–125 HB

Density (g/cm³): 8.50 g/cm³

Melting Point (°C): 910–940°C

Brass H62 | C27200 | CuZn37 | C2700 | CuZn37 | CZ109 | CuZn37 | 62Cu–38Zn

H62 brass (C27200), also known as Yellow Brass or 62-38 Brass, offers excellent corrosion resistance, high ductility, and good machinability. Ideal for CNC machining, deep drawing, and bending, it’s widely used in valves, fittings, fasteners, radiator components, and decorative hardware.

Yield strength (MPa): 200–310 MPa

Tensile strength (MPa): 380–500 MPa

Fatigue strength (MPa): ~130 MPa

Elongation at break (%): 30–50%

Hardness (Brinell): 75–125 HB

Density (g/cm³): 8.50 g/cm³

Melting Point (°C): 900–940°C

Brass H59 | C28000 | CuZn40 | C2801 | CuZn40 | CZ111 | CuZn40 | 59Cu–41Zn

H59 brass (C28000), also known as Muntz Metal or 60-40 Brass, offers good corrosion resistance, high strength, and moderate machinability. It is suitable for CNC machining, forging, and stamping, commonly used in marine hardware, valves, fasteners, and structural components.

Yield strength (MPa): 210–320 MPa

Tensile strength (MPa): 400–520 MPa

Fatigue strength (MPa): ~130 MPa

Elongation at break (%): 25–40%

Hardness (Brinell): 80–130 HB

Density (g/cm³): 8.5 g/cm³

Melting Point (°C): 900–940°C

Brass HPb59-1 | C36000 | CuZn39Pb1 | C3604 | CuZn39Pb1 | CZ124 | CuZn39Pb1 | 59Cu–39Zn–1Pb

HPb59-1 | C36000 Brass is known as free-cutting brass or lead brass. It offers excellent machinability, high strength, and good corrosion resistance. Ideal for CNC machining, turning, and automatic lathing. Commonly used in valves, connectors, fittings, gears, and electrical components across multiple industries.

Yield strength (MPa): 200–350 MPa

Tensile strength (MPa): 350–500 MPa

Fatigue strength (MPa): ~105 MPa

Elongation at break (%): 25–50%

Hardness (Brinell): 80–160 HB

Density (g/cm³): 8.49 g/cm³

Melting Point (°C): 890–905°C

Brass HPb63-3 | C38500 | CuZn39Pb3 | CuZn39Pb3 | CZ121 | CuZn39Pb3 | 63Cu–34Zn–3Pb

C38500 Brass (Free-Cutting Architectural Brass) is known for its excellent machinability, good strength, and corrosion resistance. It’s ideal for CNC machining, hot forging, and extrusion. Widely used in architectural fittings, valves, plumbing parts, and decorative hardware. Durable and visually appealing for industrial and decorative use.

Yield strength (MPa): 200–350 MPa

Tensile strength (MPa): 360–480 MPa

Fatigue strength (MPa): ~120 MPa

Elongation at break (%): 20–35%

Hardness (Brinell): 100–150 HB

Density (g/cm³): 8.44 g/cm³

Melting Point (°C): 885–900°C

Brass HSn62-1 | C46400 | CuZn39Sn1 | CuZn39Sn1 | CZ112 | CuZn39Sn1 | 62Cu–37Zn–1Sn

C46400, also known as Naval Brass, is a high-strength copper-zinc alloy with added tin for superior corrosion resistance, especially in marine environments. It offers excellent machinability and wear resistance, making it ideal for CNC machining, forging, and hot working. Widely used for marine fittings, propeller shafts, valves, and fasteners, it ensures long service life in harsh conditions.

Yield strength (MPa): 275–450 MPa

Tensile strength (MPa): 400–550 MPa

Fatigue strength (MPa): ~120 MPa

Elongation at break (%): 25–45%

Hardness (Brinell): 80–150 HB

Density (g/cm³): 8.44 g/cm³

Melting Point (°C): 900–940°C

Brass HAl59-3-2 | C68700 | CuZn20Al2As | CuZn20Al2 | CZ110 | CuZn20Al2 | 59Cu–39Zn–2Al

C68700 (Aluminum Brass) is a corrosion-resistant copper-zinc-aluminum alloy known for its excellent resistance to seawater and biofouling. It offers high strength, good ductility, and excellent weldability. Ideal for heat exchangers, condenser tubes, marine fittings, and desalination equipment.

Yield strength (MPa): 275–450 MPa

Tensile strength (MPa): 400–550 MPa

Fatigue strength (MPa): ~150 MPa

Elongation at break (%): 20–40%

Hardness (Brinell): 100–160 HB

Density (g/cm³): 8.4 g/cm³

Melting Point (°C): 900–950°C

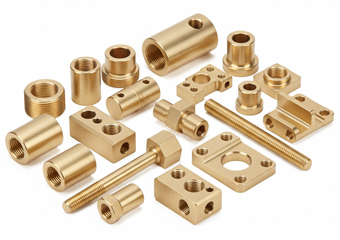

Brass Alloy CNC Machining Parts Gallery

Brass: Various National Standards and Equivalent Grades

We maintain a stock of over 40 certified materials, enabling rapid delivery of precision prototypes and small batch parts within 24 hours. Some of these materials are IMDS certified.

| Chinese (GB) | American (ASTM/UNS) | European (EN) | Japanese (JIS) | German (DIN) | UK (BS) | ISO | Composition (Approx.) | Common Applications |

| H85 | C23000 (Red Brass) | CuZn15 | — | CuZn15 | CZ101 | CuZn15 | 85Cu–15Zn | Decorative parts, musical instruments |

| H70 | C26000 (Cartridge Brass) | CuZn30 | C2600 | CuZn30 | CZ106 | CuZn30 | 70Cu–30Zn | Deep drawing, radiators, cartridges |

| H68 | — | CuZn32 | — | CuZn33 | CZ107 | CuZn33 | 68Cu–32Zn | Tubes, electronic components |

| H65 | — | CuZn35 | — | CuZn36 | CZ108 | CuZn36 | 65Cu–35Zn | Hardware, ornaments, radiator fins |

| H62 | C27200 (Yellow Brass) | CuZn37 | C2700 | CuZn37 | CZ109 | CuZn37 | 62Cu–38Zn | Structural parts, machined fittings |

| H59 | C28000 (Muntz Metal) | CuZn40 | C2801 | CuZn40 | CZ111 | CuZn40 | 59Cu–41Zn | Valve parts, marine hardware |

| HPb59-1 | C36000 (Free-Cutting Brass) | CuZn39Pb1 | C3604 | CuZn39Pb1 (Ms58) | CZ124 | CuZn39Pb1 | 59Cu–39Zn–1Pb | CNC machining parts, connectors |

| HPb63-3 | C38500 (Architectural Brass) | CuZn39Pb3 | — | CuZn39Pb3 (Ms58) | CZ121 | CuZn39Pb3 | 63Cu–34Zn–3Pb | Decorative profiles, precision fittings |

| HSn62-1 | C46400 (Naval Brass) | CuZn39Sn1 | — | CuZn39Sn1 | CZ112 | CuZn39Sn1 | 62Cu–37Zn–1Sn | Marine hardware, corrosion-resistant parts |

| HAl59-3-2 | C68700 (Aluminum Brass) | CuZn20Al2As | — | CuZn20Al2 | CZ110 | CuZn20Al2 | 59Cu–39Zn–2Al | Heat exchangers, condenser tubes |

Why Choose VMT?

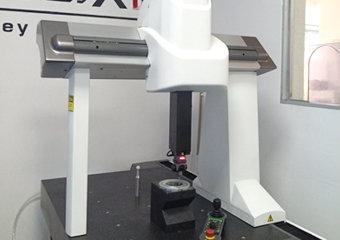

High-Quality Parts with Tight Tolerances

As an ISO 9001-certified manufacturer, VMT delivers high-quality CNC machining parts, expertly handling complex designs. We follow international best practices, achieving dimensional tolerances as tight as ±0.0004″ (0.01mm), ensuring our products meet your exact specifications and fulfill all your requirements.

Fast Quoting and Delivery

VMT provides rapid production and delivery of CNC machining parts, enabling flexible iterations and helping you stay ahead in the market. Upload your design and receive a CNC quote within 2 hours. Our engineering team offers precise cost calculations, transparent pricing, and reduced lead times, significantly boosting your competitiveness.

Engineering Support

Leveraging cutting-edge technology and equipment, we ensure the highest quality, precision, and performance of automotive parts. To expedite our clients' CNC machining product development and validation, we operate over 100 advanced CNC machines and a specialized rapid prototyping team. From design analysis to mass production, we can deliver within 24 hours, providing full support to ensure client success.

Quality Inspection

We maintain a comprehensive quality control system, including IQC, IPQC, and FQC, overseeing every stage from raw materials to final shipment. We retain inspection reports for two years and are equipped with advanced 3D and 2D measuring instruments, as well as a laboratory for precise dimension checks and material compliance. We offer CMM inspection, material testing, and certification of conformity to ensure exceptional quality.

Surface Finishing

We collaborate with surface finishing factories with over 10 years of experience, offering more than 40 surface finishingprocesses. Two senior engineers work on customizing cost-effective solutions based on your needs, strictly controlling every step to ensure a 98% product yield and outstanding surface finishin

gquality.

Certifications and Patents

We are certified by ISO9001:2015, IATF16949, and SGS, and hold 12 patents. With state-of-the-art CNC technology, we ensure precise and efficient CNC machining part machining, meeting your highest expectations for size, performance, and strength, and providing exceptional service.

Brass CNC Machining Capabilities

We focus on brass CNC machining enables high-speed production of durable, corrosion-resistant, and aesthetically pleasing components, making it ideal for custom precision parts manufacturing across multiple industries.Below is an overview of brass CNC machining capabilities:

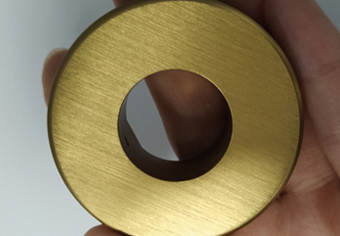

CNC Machining Brass Parts Surface Finishing Options

VMT offers a wide range of high-quality surface finishing processes to enhance the performance of your CNC machined brass parts. According to the part’s functional and aesthetic requirements, we provide mirror polishing, electroplating (nickel, chrome, gold, silver), powder coating, passivation, sandblasting/bead blasting, chemical antiquing/patina, and brushing. Each surface treatment significantly improves the durability, corrosion resistance, and appearance of the parts. These finishes make brass components ideal for high-end decorative, electronic, and industrial applications, ensuring every piece meets the strict quality standards expected by global customers for premium brass CNC machined parts.

As Machined

Mirror Polishing

Plating

Sandblasting/Bead Blasting

Powder Coating

Chemical Antiquing/Bronze Patina

Brushed

Clear or Colored Lacquer Coating

Flexible Turnaround Time

We customize machining lead times for all types of projects to ensure your brass CNC machining needs are met—ranging from rapid prototyping to mass production:

Project Type

Urgent high-Precision Samples

Stainless Steel Prototype Manufacturing

Molding Requirements

High-Volume Production

Turnaround Time

24-Hour Delivery

Simple Parts: 1–3 days,Complex Parts: 3–7 days

Mold Production: Completed in 5 days, with samples delivered within 7 days.

Lead Times: Depend on part complexity, with typical delivery within 2–4 weeks, always meeting customer deadlines.

For projects with urgent deadlines, please contact us immediately for expedited processing.

Advantages and Disadvantages of Brass CNC Machining

Brass machining offers excellent electrical and thermal conductivity, corrosion resistance, and outstanding machinability, providing high-quality, cost-effective, and reliable brass components for various industries. Understanding the advantages and limitations of brass helps you select the optimal material for your brass CNC machining parts project, ensuring both functional performance and aesthetic appeal.

Advantages

Disadvantages

Challenges & Our Solutions:

Application of CNC Machining Brass Parts

Brass CNC machined parts are widely used across multiple industries due to their excellent machinability, corrosion resistance, and aesthetic appeal. Key applications include:

Frequently Asked Questions

Which is Better for CNC Machining: Brass or Copper?

Brass is generally better suited for CNC machining than pure copper. It has lower ductility and better chip formation, resulting in smoother cuts, less tool wear, and faster machining speeds.

Is Brass Easier to Machine Than Aluminum?

Yes, brass is easier to machine than aluminum due to its excellent chip control and lower friction during cutting. It provides better surface finishes and longer tool life in CNC machining.

Which Type of Brass Is Best for Machining?

C36000 (Free-Cutting Brass) is the best brass alloy for machining. It contains a small amount of lead, which improves lubricity and chip breaking, allowing high-speed, precise CNC operations.

What Is the Cutting Speed for Machining Brass?

Typical cutting speeds for brass range from 100–300 m/min (≈ 330–980 ft/min), depending on the alloy, tooling material, and machining conditions.

What Is the Standard Brass Used for Machining?

The standard brass used for machining is C36000 Free-Cutting Brass, widely recognized for its excellent machinability and dimensional accuracy in CNC turning and milling.

Is Brass Easier to Cut Than Steel?

Yes, brass is much easier to cut than steel. It requires less cutting force, generates less heat, and produces consistent chips, which makes it ideal for high-precision CNC machining.

What Is the Difference Between C260 and C360 Brass?

In summary, C260 is for forming, while C360 is for machining.

What Is the Price of 1 kg of Brass?

The price of brass typically ranges from $4 to $6 per kilogram, depending on market conditions, alloy type, and purity.

Why Is Brass Easy to Machine?

Brass is easy to machine because of its low friction coefficient, excellent chip control, and uniform microstructure. These properties reduce tool wear, enable high cutting speeds, and produce smooth surface finishes.

CNC Machining Resources

Top 12 Brass CNC Machining Parts Manufacturers in China (2025)

This guide introduces the top 12 brass CNC machining parts manufacturers in China for 2025, comparing their capabilities, advantages, and services. It also provides insights on how to choose the right supplier for your project. ...

Brass vs. Bronze vs. Copper: Exploring the Differences Between

Do you know the difference between brass, copper and bronze? VMT takes you to understand the characteristics and applications of these copper materials, and choose the most suitable material for your copper CNC machining project. ...

Melting Point of Brass: In-Depth Exploration and Understanding

Starting from the melting point of brass, this article provides a comprehensive analysis of its various forms, melting point range, influencing factors, and performance in high-temperature applications. It also introduces the characteristics, applications, and specific melting points ...

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red