15 years one-stop China custom CNC machining parts factory

A perfect case of stamping, spinning, welding, extrusion, polishing, cold forging and other processes with CNC machining.

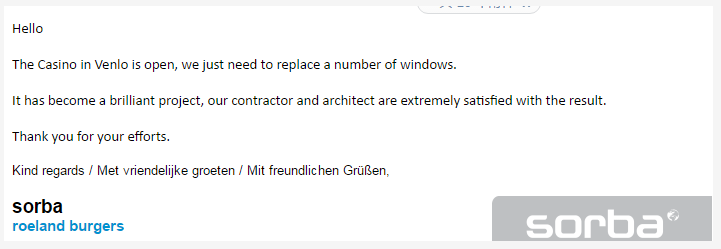

A perfect thank you letter, and another happy weekday! The VMT team's hard work on this project in the past year has finally been affirmed by the customer. Receiving this email is the best reward for us!

After receiving this project, our engineers have been studying how to give the best solution to this project in terms of processing technology. The details of each part of the 19 parts are according to the details of the engineering drawings. We have developed with the customer for 3 months. Communication, from sample production to recognition and optimization, from the coordination of various processes to control the cost of parts within the most reasonable range, we can tell the story of every part! They are as slow as children It is perfectly completed, and we will start the application description of how they realized the process:

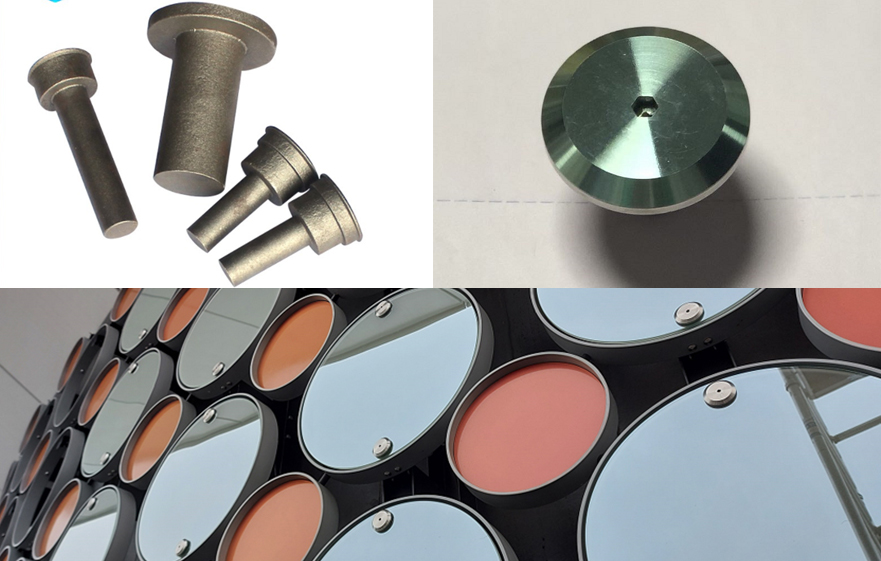

1. A perfect stainless steel part processed by the cold forging process and CNC lathe-advertising nails, in order to save material costs and the cost of too long processing time, we use the forging process under the condition of consistent quality Produce this part.

2. Spinning. Welding and CNC machining cooperate to process an aluminum part, an aluminum alloy ring part with an outer diameter of 500MM, we first use the aluminum row for CNC processing, then use the spinning method to form, after welding, use CNC machining to process Polishing reduces the cost of parts by 30%.

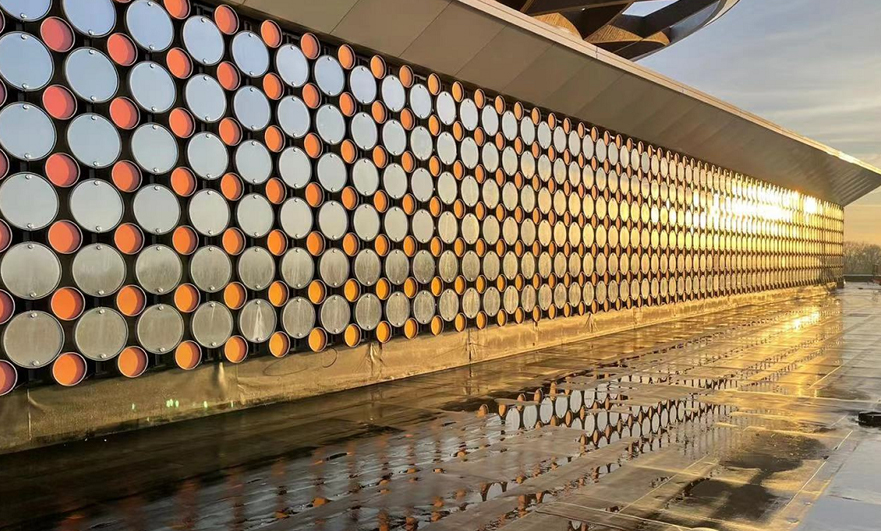

3. Stamping and CNC machining work together to process an aluminum alloy panel part. This panel part is a part with an outer diameter of 280MM and a thickness of 2MM. Because the thickness is only 2MM, it is easy to deform. There are several posts behind the panel to fix it to another The column on the circle must withstand the resistance of the wind, so the torsion must be firmly welded. We use CNC to process the hole of the panel, and then use the riveting and welding process to fix the column, and then polish the surface of the part and spray it. The paint of the chameleon makes this part have different color effects from different directions, from gold, yellow, and purple to express the brilliant effect that the customer said.

4. The extrusion is matched with CNC machining, and all the supporting and fixing columns in this project are machined. For this kind of 8-meter fixed column, there are a lot of buckles and holes to connect and fix each other. We use a CNC that can process 15M long. The equipment comes to complete the processing at one time, which reduces the cost of this part by 10% compared with the original way of processing it several times.

After all the parts are completed, we use AKZONobel powder and perform surface treatment in a qualicoat-certified factory to ensure the quality of each process, making us proud of the brilliant engineering that customers call!

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!