15 years one-stop China custom CNC machining parts factory

Home / Industry / CNC Optical Parts /

Optical projects often face challenges such as ultra-tight tolerances, inconsistent surface quality, long lead times, and suppliers who lack true optical machining experience. As a professional custom optical CNC machining factory, we specialize in solving these problems. With advanced multi-axis CNC equipment, strict quality control, and dedicated optical manufacturing expertise, we deliver high-precision optical components with excellent surface finishes and stable repeatability. From material selection and design optimization to machining, surface treatment, and inspection, we provide a complete one-stop CNC machining service—helping customers reduce risk, shorten delivery cycles, and bring optical products to market faster with confidence.

Custom Prototypes and High-Volume Optical CNC Machining Parts

24-hour CNC machining, samples can be provided within 7-10 days

We are a specialized optical CNC machining manufacturer supporting both rapid prototyping and stable mass production. Backed by advanced multi-axis CNC equipment and strict process control, we help customers overcome common challenges such as long prototype lead times, poor consistency between samples and batches, and scaling risks.

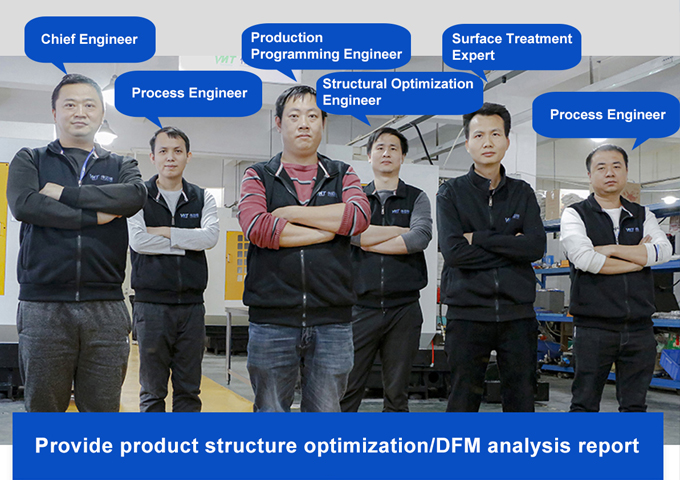

6 Project Engineers With 20 Years Of Experience

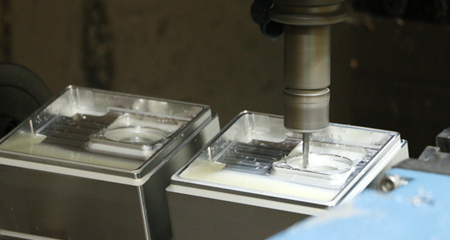

Custom Optical CNC Machining Parts Process Manufacturing

We use multi-axis CNC, ultra-precision machining, grinding, and polishing to achieve tight tolerances and flawless surfaces.Drilling, threading, and surface treatments ensure durability and optical performance.Every part undergoes strict inspection to deliver reliable, high-quality optical CNC machined components.

3/4 Axis CNC Milling

CNC Turn-Mill Combination Machining

Precision Grinding

CNC Drilling

Ultrasonic Cleaning

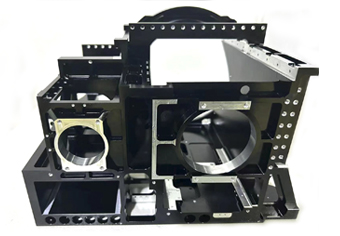

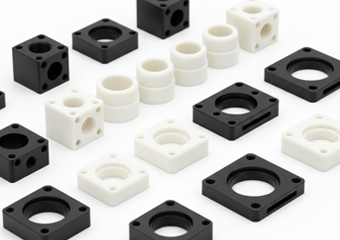

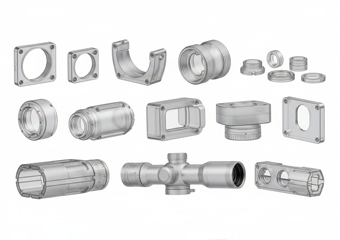

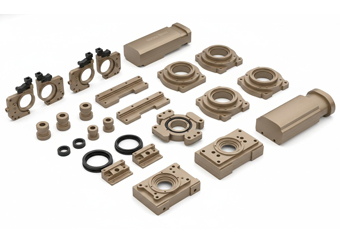

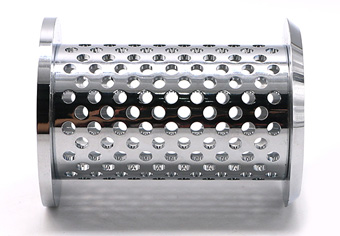

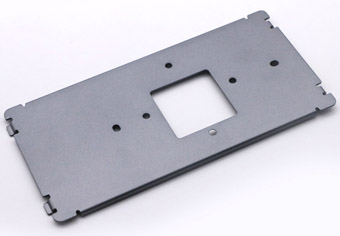

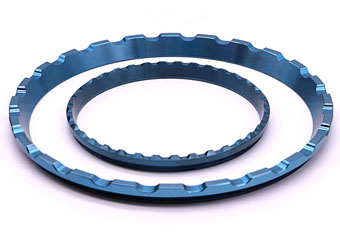

Precision CNC Optical Machining Parts Display

Explore our portfolio of custom precision optical CNC machined parts, engineered for tight tolerances, exceptional surface finish, and reliable performance. Each component is crafted with advanced multi-axis CNC machining, precision grinding, and polishing to meet demanding optical standards. From prototypes to high-volume production, our parts deliver consistent quality, durability, and optical accuracy—helping customers bring complex optical designs to life with confidence.

The parts images have been authorized for use by the customer.

CNC Optical Laser Lens

CNC Optical Mounts Bracket

CNC Optical Mounts Bracket

CNC Optical Radar Scanning Mount

CNC Optical Handheld LiDAR Housing

CNC Optical Laser Internal Cavity Assembly

CNC Optical Scopes Sights Housing

CNC Communication Optics and Chip (Semiconductor) Peripheral Equipment Parts

Selecting the right material is critical for precision, durability, and optical performance. We offer a wide range of materials for CNC optical components, including optical-grade metals, aluminum alloys, stainless steel, and engineering plastics, each chosen for stability, machinability, and surface finish quality. Combined with advanced CNC machining and finishing processes, these materials ensure high-precision, reliable, and long-lasting optical parts that meet the exact requirements of your application.

Aluminum Optical CNC Machining Parts

Common Grades: 6061, 6063, 7075

Properties: Lightweight, high strength, easy to machine, good surface finishability.

Applications: Lens brackets, optical frames, optical housings.

Stainless Steel Optical CNC Machining Parts

Common Grades: 304, 316

Properties: High corrosion resistance, good stability, suitable for high-precision parts.

Applications: Optical instrument components, precision fasteners.

Brass Optical CNC Machining Parts

Properties: Easy to machine, wear-resistant, good thermal conductivity.

Applications: Optical adjustment parts, guide bushings.

Titanium Alloy Optical CNC Parts

Properties: Lightweight, high strength, corrosion resistant.

Applications: High-end optical equipment parts, aerospace optical components.

Polyoxymethylene (POM) CNC Optical Parts

Properties: High rigidity, dimensional stability.

Applications: Used for optical mounts and non-load-bearing optical components.

Polycarbonate (PC) CNC Machined Optical Parts

Properties: Transparent, impact resistant.

Applications: Used for optical lens housings and optical protective covers.

Polyimide (PI) CNC Machined Optical Parts

Properties: High temperature stability, chemical resistance.

Applications: Used for optical parts in special environments.

PEEK CNC Machining Optical Parts

Properties: High temperature stability, chemical resistance.

Applications: Used for optical parts in special environments.

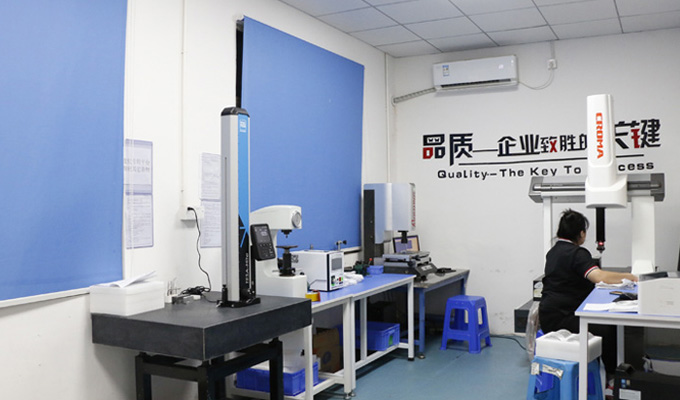

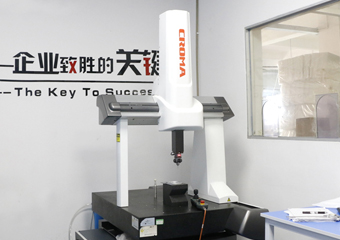

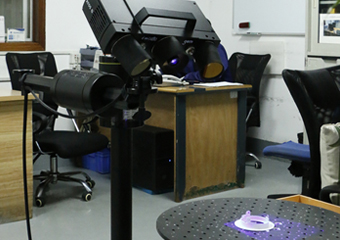

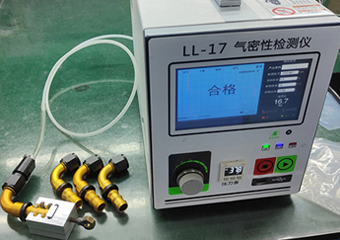

Quality Inspection & Testing Lab

Equipped with CMM, optical comparators, surface roughness testers, and precision measuring tools, our lab ensures every custom optical CNC part meets strict tolerances, flawless surfaces, and reliable performance.

3D Detection

Roundness Meter

Ultrasonic Cleaning

Blu-Ray 3D Scanning

Electronic Height Gauge

2D Detection

Surface Finish Inspection

Microscope Surface Inspection

Air Tightness Test

Hardness Testing

IPQC Inspection

Salt Spray Tester

Optical CNC Machining Parts: 12 Quality Inspection Processes

Learn how VMT's quality control team maintains strict quality standards by conducting dimensional and cosmetic inspections of each order during production. If there is any problem, we will communicate and solve it as soon as possible, or solve it in your way.

DFM Analysis

Before CNC machining, engineers conduct a DFM analysis to identify and resolve potential issues in advance. This ensures optimized designs for efficient manufacturing, minimizes defects, and reduces machining costs.

Dimensional Tolerance Determination

Check whether the parts meet the specified dimensional tolerances, ensure the technical feasibility of the tolerance design, and optimize the production process to meet your quality requirements and cost-effectiveness.

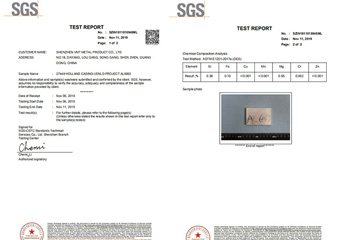

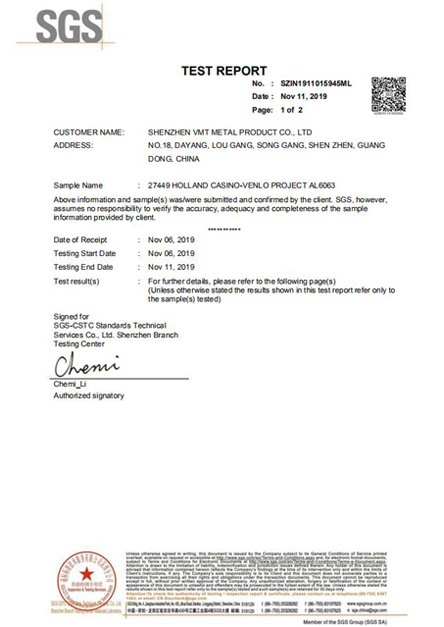

Material Testing

We have long-term stable partnerships with material suppliers for decades and can provide third-party inspection reports from organizations such as SGS, CTI, and TUV.

CNC Machining Production

We have a dedicated team to track order progress, maintaining detailed records for each production run. Photos and videos are transparently shared with customers, keeping you informed about the machining process.

FQC Detection

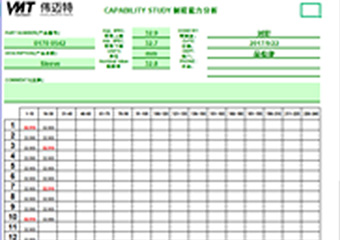

During the machining production process, dimensional tolerance inspections are conducted every two hours, and the first article is inspected to ensure it meets design and quality standards. This guarantees process stability, product consistency, and improved production efficiency.

SPC / CKP

Implement statistical analysis to monitor and control the manufacturing process and provide inspection reports.

Problem Found

If any deviations, defects, or non-compliance issues are discovered during the machining process, an immediate meeting is held to address the problem.

Problem Solving

Respond within 30 minutes, provide solutions within 2 hours, and resolve within 1 day.

OQC Detection

Before CNC parts leave the factory, 100% dimensional inspection is conducted according to customer drawings. Inspection reports are provided before proceeding to the next processing step.

Surface Finishing

In addition to conventional surface treatments, there are a variety of special surface treatments. We have a full-time SQE to follow up and control each process in the surface treatment factory. After returning to our workshop, the product appearance will be 100% inspected.

Full Inspection

QC specilists will check the parts at every step with testing equipments accordingly,like 3D / 2D project, height/thread /roughness gauge. Offering inspection report with full dimensions for each part.

Package

Many different ways to pack the goods,avoid the damage, easy to carry and enviornmentally,Accept customer customization, commonly used pearl cotton, bubble bag.

Custom Optical CNC Machining Parts Surface Finishing

We provide polishing, anodizing, coating, and plating to achieve flawless surfaces, enhanced durability, and superior optical performance, ensuring every part meets the highest quality standards.

Laser Carving

Silk Screen

Etching

Brushed

Anodizing

Sandblasting

Electroplating

Powder Coating

Polishing

Brushed

Electrophoresis

Nickel Plating/Zinc Plating

Silkscreen Printing

PVD

Oil Spraying

Etching

Flexible Turnaround Time

We customize production schedules for various projects to ensure we meet your aluminum CNC machining parts needs.

Project Type

Urgent high-Precision Samples

CNC Prototype Manufacturing

Molding Requirements

High-Volume Production

Turnaround Time

24-Hour Delivery

Simple Parts: 1–3 days,Complex Parts: 3–7 days

Mold Production: Completed in 5 days, with samples delivered within 7 days.

Lead Times: Depend on part complexity, with typical delivery within 2–4 weeks, always meeting customer deadlines.

For projects with urgent deadlines, please contact us immediately for expedited processing.

Customized Optical CNC Machined Parts Ordering Process

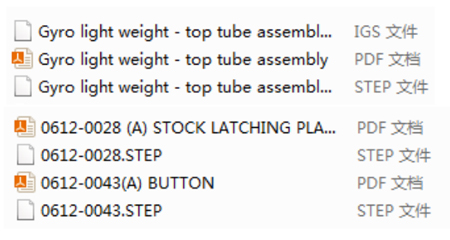

Upload Your CAD Drawing File

Quotation and DFM Analysis

We will send the design back within 12 hours for manufacturability analysis and real-time quotation.

Start Production

Once the order is confirmed, we will begin the production process based on your CAD design.

Received Your Machined Parts

The aluminum prototype parts will be produced within a few days and shipped directly to you via your specified logistics method.

CNC Machining Workshop

Established in 2010 and is located in Guangming District, Shenzhen, Guangdong Province, China,has own factory cover an area of 5000 m2. We are customized machining parts manufacturer with 100 employees,can provide items within 24 hours.

100 sets machines including 4 & 5 axis imported CNC centers,turning & milling machines for fast delivery, 6 engineers who have been working for more than 20 years to provide you with free design service to ensure that parts can reach the appearance of iPhone, the accuracy of Atomic Clock, tolerance per 0.01 mm, the key procedure controlled by CPK1.68 or more. At the same time,2 engineers specialized in surface finishingcontrol the finish procedures. Passed ISO 9001:2005 & IATF 16949 & SGS in 2015.

Devoted to helping 10,000 enterprises to break through the difficulty of processing, and strive for becoming a leader in high-efficiency, high-yield, and precise parts. In the past 15 years, our business has spread to 62 countries around the world,covered military, medical, semiconductor, Telecommunication, automotive and other fields.No matter how complicated part is, or any technical problems faced with,we can find the solution and offer you with professional service.

100+

Sets of Machine

120+

Countries Shipped

100,000+

Parts Manufactured

Custom Optical CNC Machining Parts Applications

Our precision optical CNC machined parts are used in medical devices, cameras, sensors, aerospace, and scientific instruments, delivering high accuracy, reliable performance, and superior optical quality for demanding applications.

CNC Optical Components Assembly and Packaging Services

We provide precise assembly a for custom optical CNC parts, ensuring damage-free delivery, easy integration, and ready-to-use components for seamless production and high-quality performance.

Optical CNC Part Assembly Services

Our CNC machining factory provides comprehensive assembly services for optical parts to ensure precision, functionality, and ready-to-use delivery. The process includes:

This end-to-end service ensures customers receive fully assembled, high-quality optical components ready for integration or use in their products.

Optical CNC Part Packaging Services

Common packaging methods for optical CNC machined parts include:

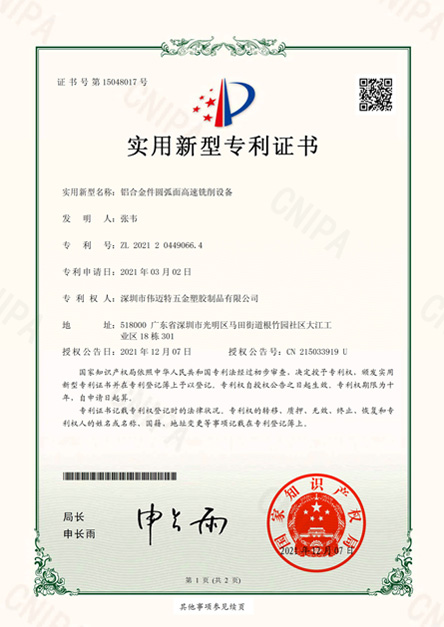

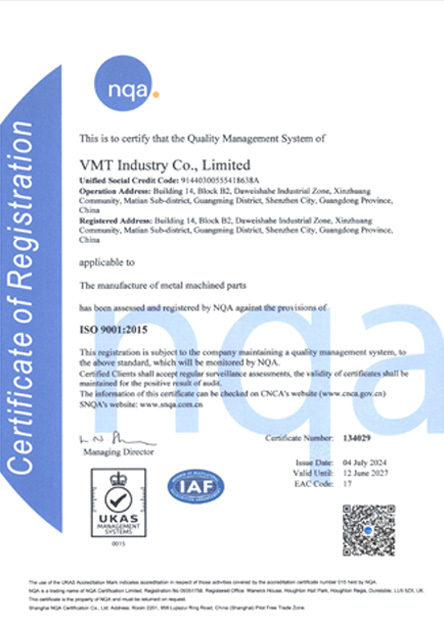

Certifications & Quality Assurance

Our factory holds ISO and industry-standard certifications, ensuring every custom optical CNC part meets strict quality, precision, and reliability standards, giving customers confidence in performance and compliance for demanding applications.

Patent Certified

ISO 9001:2015

IATF 16949

SGS Materials Test Report

FAQs About Optical CNC Machining Manufacturing

What is the machining process for optical CNC machined parts?

The process typically includes design review, material selection, precision CNC milling and turning, grinding, polishing, surface finishing, cleaning, and final inspection. Each step is tightly controlled to achieve high accuracy and optical-grade surface quality.

How can the manufacturing cost of CNC optical parts be reduced?

Costs can be reduced through design optimization, selecting machinable materials, combining features to reduce setups, standardizing tolerances where possible, and choosing a supplier with in-house machining, finishing, and inspection capabilities.

What are the commonly used materials for CNC optical parts? Which materials are unsuitable?

Common materials include aluminum alloys, stainless steel, brass, titanium, engineering plastics, and optical glass. Unsuitable materials are those with poor dimensional stability, excessive softness, or surface characteristics that cannot meet optical finish requirements.

How to choose a suitable factory for optical CNC machining parts?

A reliable factory should have optical machining experience, advanced CNC equipment, strict quality control systems, optical inspection tools, stable production capacity, and proven case studies in optical applications.

What are the advantages and disadvantages of CNC machining for optical parts?

Advantages include high precision, repeatability, flexibility for custom designs, and suitability for prototypes and mass production. Disadvantages may include higher cost for extremely complex optical surfaces compared to molding or casting.

Which CNC machining processes are required for optical parts?

Optical parts typically require multi-axis CNC milling and turning, precision grinding, polishing, micro-machining, drilling, threading, and controlled surface treatments or coatings.

How to perform quality control for CNC optical parts?

Quality control involves CMM measurement, optical comparators, surface roughness testing, visual inspection, cleaning, and functional testing to ensure all dimensional, surface, and optical requirements are met before delivery.

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red