15 years one-stop China custom CNC machining parts factory

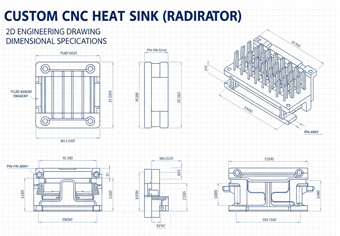

Are you choosing the right supplier for your custom CNC heat sink machining project? In high-performance electronic and mechanical equipment, heat sink performance directly impacts product lifespan and reliability. Conventional heat sink machining suffers from low precision, limited materials, and slow delivery times, making it difficult to meet high standards. Dimensional errors or uneven heat dissipation can lead to overheating, failure, and ultimately equipment scrap, increasing costs. Our CNC heat sink machining services offer high-precision machining, premium material selection, and fast delivery, eliminating the need to worry about heat sink performance issues.

Professional CNC Heat Sink (Radiator) Machining Team

24-hour CNC machining, samples can be provided within 7-10 days

We have a professional CNC heat sink (radiator) machining team equipped with advanced equipment and strict quality control to ensure high-precision and high-efficiency delivery, providing you with stable and reliable customized cooling solutions.

CNC Heat Sink (Radiator) Machining Materials

We offer CNC heat sink machining in a variety of materials, including aluminum alloy, copper, stainless steel, magnesium alloy, and engineering plastics. We balance thermal conductivity, lightweight construction, and corrosion resistance to meet the needs of the electronics, automotive, and industrial sectors. We can also provide recommendations and selection of the most suitable materials based on your project requirements.

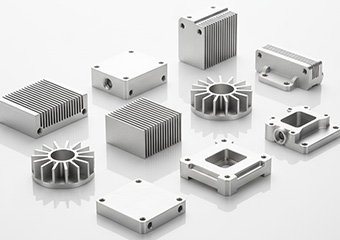

Aluminum Heat Sink (Radiator)

CNC aluminum heat sinks offer an accuracy of ±0.01mm, a thermal conductivity of 200 W/m·K, and a 30% increase in efficiency. Prototypes can be delivered within 3 days, solving problems with insufficient heat dissipation and complex, difficult-to-process structures.

Common grades include: 6061, 6063, 1050, 1070, A380, ADC12, AL7075, etc.

Features: Lightweight, thermal conductivity of approximately 200 W/m·K, easy machining, and low cost.

Applications: LED heat sinks, electronic products, and automotive parts.

Stainless Steel Heat Sink (Radiator)

We offer stainless steel heat sink (radiator)s with strength exceeding 500 MPa and corrosion resistance exceeding 96 hours of salt spray testing, solving the challenge of structural heat dissipation integration in extreme environments.

Common grades: 304, 316, 410, 420, 430 etc.

Features: High strength and excellent corrosion resistance, but low thermal conductivity (approximately 15 W/m·K).

Applications: Industrial equipment, chemical environments, and specialty equipment.

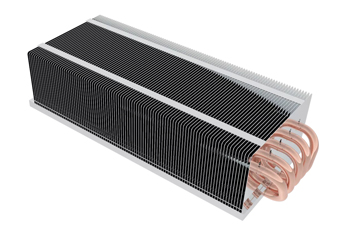

Red Copper Heat Sink (Radiator)

Red copper boasts a thermal conductivity of up to 400 W/m·K, improving heat dissipation efficiency by 40%. CNC precision reaches ±0.01mm, solving the challenges of high heat flux and complex structure machining.

Common grades: C11000 (red copper), C10200 (oxygen-free copper), C12200 (phosphorus-deoxidized copper).

Features: Thermal conductivity up to 400 W/m·K, providing optimal heat dissipation performance.

Applications: High-performance CPU/GPU heat sinks, servers, and power electronics.

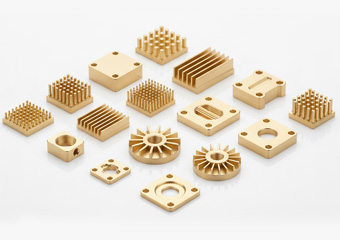

Brass Heat Sink (Radiator)

CNC-machined brass heat sinks offer 60% higher corrosion resistance than aluminum. They're specifically designed for heat dissipation components in medical and marine equipment, with customized solutions delivered within 12 days.

Common grades: H59, H62, H65, C26000 , C28000 (brass tube), C36000 (free-cutting brass).

Features: Brass radiator has good thermal conductivity (120W/m·K), high strength and corrosion resistance, and excellent cost performance.

Applications: Industrial equipment heat sinks, electrical connectors, and electronic device heat dissipation components.

Steel Heat Sink (Radiator)

Steel heat sink (radiator)s offer strengths up to 500 MPa and are suitable for applications where heat dissipation requirements are not extreme but strength or corrosion resistance is a concern.

Common grades: Q235, 45# steel, AISI 1018, AISI 1045 etc.

Features: High strength, low cost, and excellent workability. Heat treatment can be used to increase hardness and wear resistance. Thermal conductivity is approximately 50 W/m·K.

Applications: Industrial equipment heat sink (radiator)s, mechanical components, and low-cost, high-strength applications.

Magnesium Alloy Heat Sink (Radiator)

We offer magnesium alloy heat sinks with a density of only 1.8g/cm³, 35% lighter than aluminum alloys. They address the extreme lightweighting and heat dissipation needs of aerospace and military equipment.

Common grades: AZ91D, AM60, ZK60

Features: 30% lighter than aluminum, with a thermal conductivity of approximately 70 W/m·K, making them suitable for lightweight designs.

Applications: Heat sinks for aerospace, automotive, and portable devices.

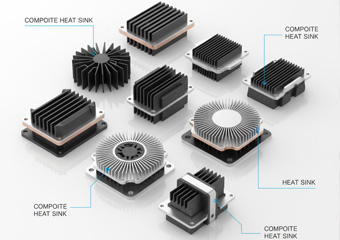

Composite Heat Sink (Radiator)

Composite materials reduce weight by 40%, improve corrosion resistance by 50%, and offer CNC precision of ±0.01mm, helping customers address lightweighting challenges while dissipating heat in harsh environments.

Common Grades: CFRP, GFRP, Kevlar®/Aramid Fiber Composites, MMC etc.

Features: Lightweight, high specific strength/stiffness, excellent corrosion resistance, adjustable thermal conductivity, and high-temperature resistance.

Applications: Electronics and communications, aerospace, new energy vehicles, medical devices, and high-end industrial equipment.

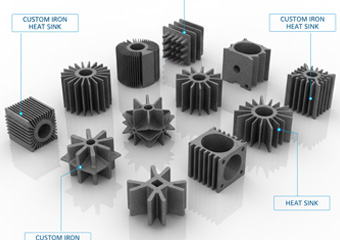

Iron Heat Sink (Radiator)

We offer iron heat sink (radiator)s with a 50% cost reduction and strength exceeding 500 MPa, perfectly meeting the rigid demands of industrial equipment for low-cost, high-strength heat sink components.

Common grades: Q195, 20#, 35#, 45#, DT4, T8, T10 etc.

Features: High strength, moderate thermal conductivity, good wear resistance, low cost, stable machining performance, and surface treatment capabilities.

Applications: Industrial equipment heat sink (radiator)s, automotive parts, home appliances and electronic equipment, magnetic heat sinks, and heavy-duty environments.

Custom CNC Heat Sink Machining: Quality Control

As a professional CNC machining factory, we provide full-process quality inspection for CNC heat sinks. Through ±0.01mm coordinate measurement, Ra0.8μm surface roughness testing, and up to 95% heat dissipation performance simulation verification, we ensure product dimensional accuracy, surface smoothness, and stable performance. Our stringent testing standards provide customers with peace of mind when using our products in the electronics, automotive, and other fields. Choosing us means choosing high quality and reliability. We can help you reduce return rates by 50% and shorten project delivery cycles by 20%.

A professional CNC machining factory will go through multiple quality inspection steps to ensure the qualification and high performance of each heat sink (radiator), including:

1. Raw Material Testing

2. Process Inspection

3. Precision Testing

4. Functional and Performance Testing

5. Full Shipment Inspection and Test Report

Custom CNC Heat Sink Machining Process

We offer a variety of heat sink manufacturing processes, including CNC precision machining, aluminum extrusion, and die-casting. Whether you're looking for high-precision, small-batch customization or large-scale, low-cost production, we can provide efficient heat dissipation and reliable structural solutions based on customer needs.

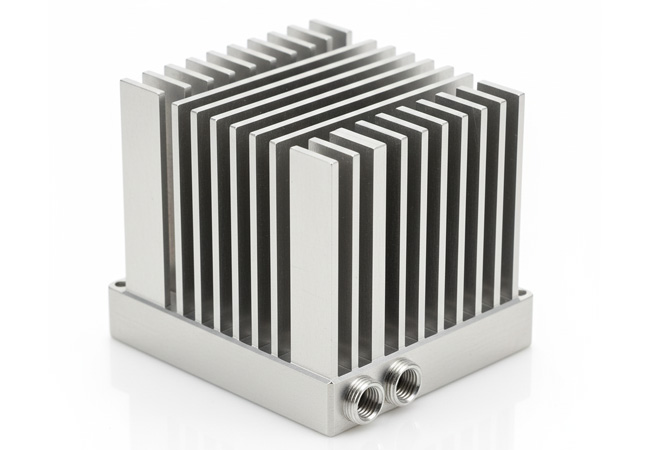

CNC Machining Heat Sink (Radiator)

Our CNC heat sinks achieve machining accuracy of ±0.01mm, supporting microchannel structures as thin as 0.3mm, improving heat dissipation efficiency by up to 30%. We offer flexible, low-volume production and fast delivery, effectively addressing issues such as poor heat dissipation, complex designs, and inconsistent quality, ensuring reliable product performance.

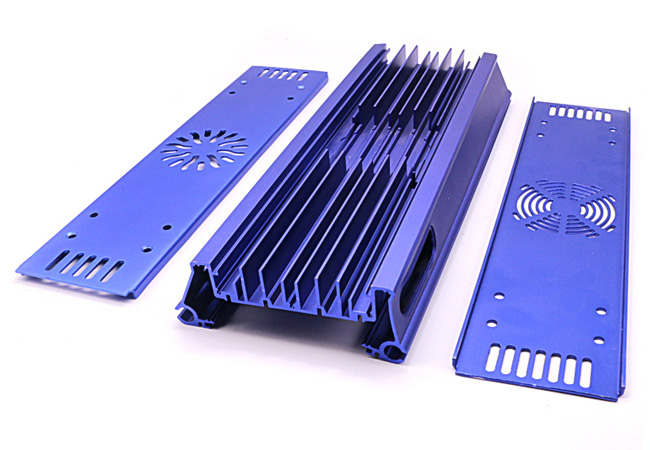

Extruded Heat Sink (Radiator) Machining

Aluminum extruded heat sinks achieve ultra-thin fins of 0.4mm and high precision of ±0.1mm, reducing unit costs by 20%. They provide high-volume, cost-effective heat dissipation solutions specifically for customers in LED lighting, power modules, and other industries, effectively addressing product overheating and high costs while ensuring equipment life and stability.

Die-Casting Heat Sink (Radiator) Machining

Die-cast heat sinks enable complex, innovative designs and support batch production of 10,000+ units, reducing material waste by 20% and lowering machining costs by 25%. They are an ideal choice for high-volume production in the consumer electronics and automotive parts industries, helping you overcome design complexity, high costs, and low production efficiency.

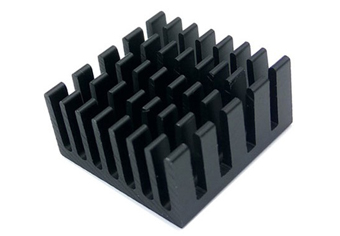

Custom CNC Heat Sink (Radiator) Machining Types

We produce various types of CNC machined heat sinks and provide one-stop CNC heat sink machining solutions to meet your performance needs.

Flat Heat Sink (Radiator)

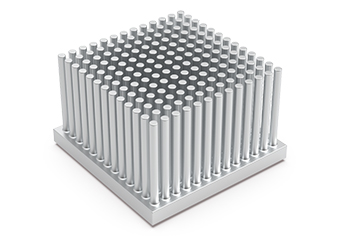

Pin Fin Heat Sink (Radiator)

Flange Heat Sink (Radiator)

Star Heat Sink (Radiator)

Cross-Cut Heat Sink (Radiator)

Zipper Fin Heat Sink (Radiator)

Wave Fin Heat Sinks (Radiator)

Custom CNC Heat Sink (Radiator)

Flexible Turnaround Time

We customize production schedules for various projects to ensure we meet your CNC machining heat sink needs.

Project Type

Urgent high-Precision Samples

CNC Heat Sink Prototype Manufacturing

Molding Requirements

High-Volume Production

Turnaround Time

24-Hour Delivery

Simple Parts: 1–3 days,Complex Parts: 3–7 days

Mold Production: Completed in 5 days, with samples delivered within 7 days.

Lead Times: Depend on part complexity, with typical delivery within 2–4 weeks, always meeting customer deadlines.

For projects with urgent deadlines, please contact us immediately for expedited processing.

Customized Precision CNC Heat Sink (Radiator) Machining Surface Finishing

The surface treatment process after CNC machining of customized heat sink (radiator)s is crucial to meet the requirements of heat dissipation performance, corrosion resistance, aesthetics and wear resistance, improve mechanical properties or achieve specific functions.

Anodized CNC Heat Sink (Radiator) Machining

Material: Aluminum Alloy etc.

Function: Improves corrosion resistance, surface hardness, and can be dyed for aesthetic appeal.

Applications: LED heat sinks, electronic housings etc.

Sandblasting CNC Heat Sink (Radiator) Machining

Applicable Materials: Aluminum, Copper, Steel etc.

Function: Improves surface roughness, increases adhesion, and prepares for subsequent painting or spraying.

Applications: Industrial heat sink (radiator), Automotive heat sink (radiator).

Electroplated CNC Heat Sink (Radiator)

Material: Suitable for a variety of CNC heat sink materials, including aluminum alloy, copper, steel, and brass.

Function: Improves corrosion resistance, wear resistance, and thermal conductivity, extending service life.

Application: Widely used in high-power heat sinks for LEDs, electronic devices, automotive, and industrial applications.

Powder-Coated CNC Heat Sink (Radiator)

Materials: Aluminum, Steel etc

Features: Wear-resistant, corrosion-resistant, aesthetically pleasing.

Applications: Home appliance heat sinks, industrial equipment heat sinks.

Polished CNC Heat Sinks (Radiator)

Applicable Materials: Aluminum, Copper, Steel etc.

Function: Improve surface finish, reduce air resistance, or enhance aesthetics.

Applications: High-end LED heat sinks, precision electronic heat sinks.

Brushed CNC Heat Sinks (Radiator)

Material: Suitable for CNC heat sinks made of aluminum alloy, copper, and stainless steel etc.

Function: Improves surface finish, aesthetics, and anti-slip properties, while facilitating subsequent painting.

Application: Widely used for surface treatment of automotive, electronic equipment, LED, and industrial heat sinks.

Electrophoretic CNC Heat Sinks (Radiator)

Material: Suitable for CNC heat sinks such as aluminum alloy, steel, and stainless steel etc.

Function: Improves corrosion and wear resistance, ensuring long-term stable operation of the heat sink while also achieving a multi-color aesthetically pleasing surface.

Application: Widely used for surface treatment of automotive, electronic equipment, LED, and industrial high-power heat sinks.

Nickel/Tin/Galvanized CNC Heat Sinks (Radiator)

Applicable Materials: Copper, Steel etc.

Function: Anti-oxidation, Anti-corrosion, Improved Thermal Conductivity

Applications: Power Electronics Heat Sinks, Telecommunications Cooling Modules

Customized Heat Sinks (Radiator) CNC Machining Application

We provide customized CNC heat sink machining for the automotive, new energy, communications, medical and other industries, supporting 3D special-shaped curved structures, and complete the process from design to mass production in 14 days to fully meet the cooling needs of high-performance equipment.

Custom CNC Machined Heat Sink Assembly and Packaging Services

We offer professional radiator assembly and packaging services, including precise pre-application of thermal conductive media and fastener installation, ensuring performance meets expectations. Our individually packaged, shock-resistant enclosures effectively protect high fins and delicate surfaces, ensuring flawless product delivery.

Custon CNC Heat Sink Assembly

If you need to install all screws, spring bolts, clips, etc., we can tighten the assembly torque according to your standards to ensure uniform and secure pressure between the heat sink and the chip.

Custon CNC Heat Sink Package

We can package or customize the outer box according to your needs:

ISO 9001:2015 Certified Factory

VMT is ISO 9001:2015 certified and IATF 16949 certified. Every CNC machined part undergoes rigorous internal quality control and industry standard testing during production:

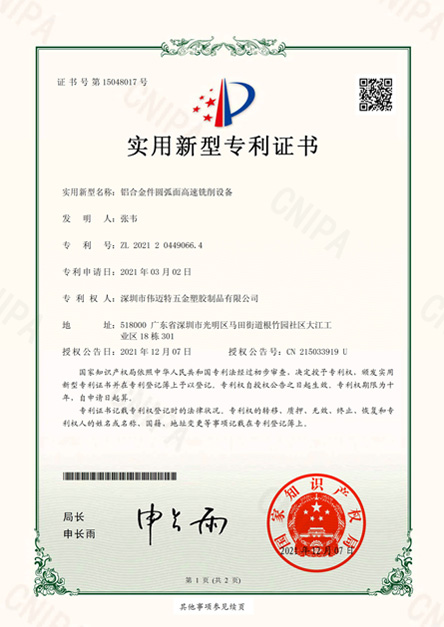

Patent Certified

ISO 9001:2015

IATF 16949

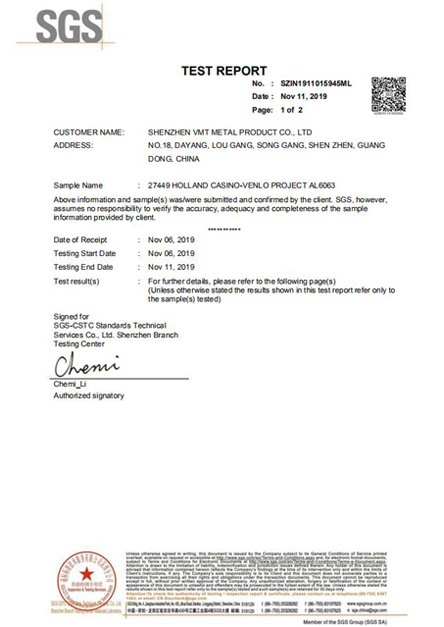

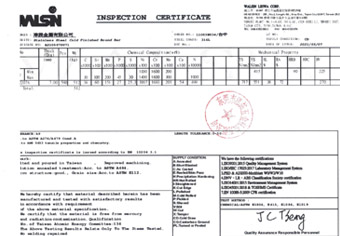

SGS Materials Test Report

Resource

Material Reports

Before CNC machining, we provide a certificate of origin and spectral testing for each batch of CNC materials. The data error is ≤±2%, and we comply with RoHS/ASTM standards, with 100% traceability.

CNC Machining Video

We provide you with a full CNC machining video, covering the machining process, precision testing and assembly links, intuitively demonstrating ±0.01mm accuracy and quality control, allowing you to remotely monitor visually and work with VMT with confidence.

Blog

We provide you with a professional CNC blog covering material selection, machining technology, surface treatment and case analysis. We update 10+ practical articles every month to help customers reduce material selection risks by 20%, shorten project cycles by 30%, build trust and promote cooperation.

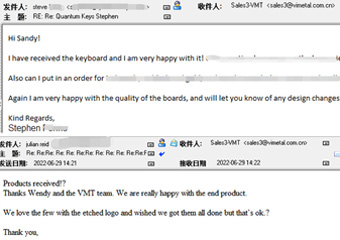

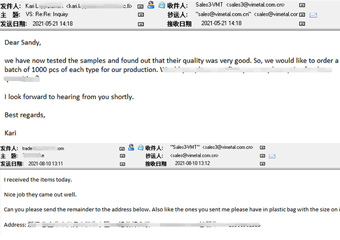

Customer Testimonials

Accuracy Problem

Our previous factory had inconsistent machining accuracy, resulting in a 0.05mm error during heat sink installation. VMT provided a CNC precision machining solution with a ±0.01mm accuracy, along with a comprehensive inspection report. This ultimately ensured the parts perfectly matched the entire system, increasing our assembly yield by 30%.

Delivery Delay

Our project schedule was very tight, and in the past, insufficient equipment at our factory often delayed delivery. VMT completed the machining of 500 aluminum heat sinks within seven days and provided surface oxidation treatment, helping us deliver them to our end customer on schedule and avoiding the risk of contract breach.

Insufficient Heat Dissipation Performance

The heat sink we designed required high thermal conductivity, but our initial supplier's material selection was inappropriate, resulting in suboptimal heat dissipation. The VMT engineering team recommended a red copper CNC heat sink, which achieved standard machining accuracy and surface finish, improving heat dissipation efficiency by 25%, effectively resolving our customer's overheating issue.

Frequently Asked Questions about CNC Heat Sinks (Radiator) Manufacturing

What are the advantages of CNC-machined heat sinks compared to die-casting and extrusion processes?

The advantages include extremely high precision (tolerances up to ±0.025mm), high design freedom (complex 3D surfaces and special-shaped structures can be produced), no tooling fees (suitable for small-batch customization and prototyping), and excellent thermal performance (the monolithic structure has no contact thermal resistance).

Is my heat sink design suitable for CNC machining?

Metal heat sinks of virtually any geometry are suitable. However, please note that fins that are too thin or too high increase machining difficulty and cost; deep cavities or internal right angles may require specialized tooling. We offer free DFM (Manufacturability Analysis) to optimize your design.

What is the minimum fin thickness and maximum aspect ratio you can produce?

Our conventional capabilities allow us to stably process aluminum fins with thicknesses of 0.3mm and above and aspect ratios of up to 8:1. For more extreme requirements (such as ultra-thin fins of 0.1mm), we will need to evaluate the design and tooling options.

How to ensure that thin fins are not deformed or damaged when machining heat sinks (radiator) ?

We employ a variety of specialized processes: using specialized ultra-thin tools, optimizing cutting parameters (high speed, small depth of cut, fast feed), designing specialized fixtures, and performing multi-stage stress relief before finishing.

How to reduce the manufacturing cost of heat sinks (radiator) ?

Recommendations:

1) Select an aluminum alloy that meets performance requirements;

2) Appropriately increase fin thickness and spacing;

3) Avoid unnecessary extreme tolerances;

4) Produce in small batches to spread initial costs.

Why choose CNC heat sink instead of ordinary die-cast heat sink?

Conventional die-cast parts have poor precision, are difficult to assemble, and have low heat dissipation efficiency. CNC heat sinks can achieve an accuracy of ±0.01mm, increase assembly efficiency by 40%, and provide more stable thermal conductivity.

Related Products

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red