15 years one-stop China custom CNC machining parts factory

Our Custom CNC Machining Factory

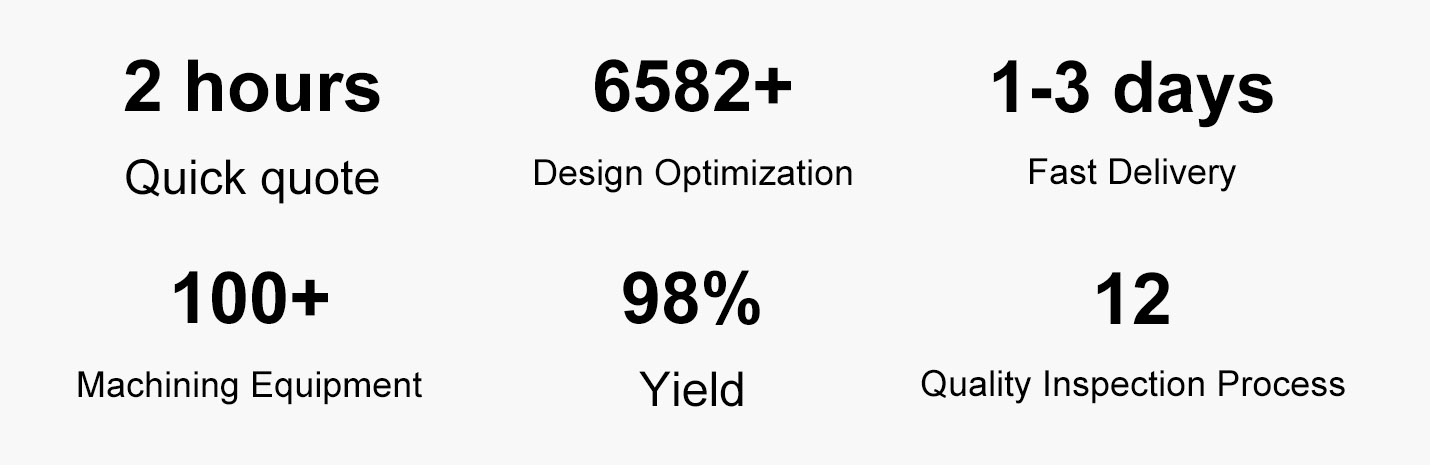

| We can custom manufacture a variety of complex design parts, provide you with drawing design analysis and prototype manufacturing, material selection, surface treatment. |

|

|

|

||

|

|

|

|

|

|

|

Custom Cooperation Process

|

|

|

|

||||

|

Quotes |

Production |

Inspection |

| We have all kinds of CNC machining equipment and testing equipment to provide you with CNC machining parts services. |

|

|

|

|

||||

|

|

|

|

||||

|

|

|

||||

|

|

|

CNC Machining Materials

We can generate instant machining quotes for 50+ metals and plastics.

|

|

|

|

|||||

|

Aluminum |

Brass | Stainless Steel | |||||

|

|

|

|

|||||

| Titanium | Plastic |

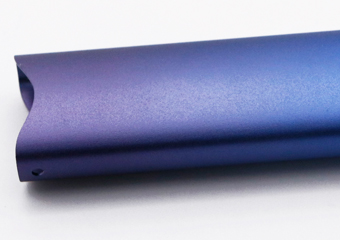

Surface Treatments

We can do the following surface treatment:

|

|

|

|

|

||||||

|

As machined |

Brushed | Powder Coating | |||||||

|

|

|

|

|

||||||

| Polishing |

Hard Anodizing |

Chrome Plating | |||||||

|

|

||||||||

| Sand blasting | Color Anodizing |

CNC Machining Tolerance

|

During the production process, we will implement the stricter standards than ISO Tolerances DIN ISO 2768-1 for the unrequired parts, and the CNC machining components standard tolerances of our machines. |

|

Nominal linear range tolerance (mm) |

Linear dimensions DIN ISO 2768-F |

Our CNC machining parts |

Our plastic parts |

|---|---|---|---|

|

0.5 up to 3 |

±.0.05 | ±.0.02 | ±0.05 |

|

over 3 up to 6 |

±.0.05 | ±.0.03 | ±0.05 |

|

over 6 up to 30 |

±0.1 | ±0.05 | ±0.1 |

|

over 30 up to 120 |

±0.15 | ±0.05 | ±0.15 |

|

over 120 up to 400 |

±0.2 | ±0.1 | ±0.2 |

|

Nominal angle range tolerance (mm) |

Linear dimensions DIN ISO 2768-F | Our metal parts | Our plastic parts |

|

≦10 |

±1° | ±1° | ±1° |

|

10~50 |

±0°30′ | ±0°30′ | ±0°30′ |

|

50~120 |

±0°20 | ±0°20 | ±0°20 |

|

120~400 |

±0°10 | ±0°10 | ±0°10 |

|

|

|||

|

Text and color |

VMT can use CNC engraving or laser carving to create standard text based on customers’requirements. VMT can customize any color according to customers' requirements. |

||

|

|

|||

| Lead Time | Simple CNC machining componeents parts: 1 day prototype machining delivery. Complex CNC machining componeents parts: 3 days prototype machining delivery. |

||

12 Quality Inspection Process

| Learn how VMT's quality control team maintains strict quality standards by conducting dimensional and cosmetic inspections of each order during production. |

|

|

|

|

||||

| DFM Analysis | Tolerance | Material | ||||

|

|

|

|

||||

| Production | FQC | SPC / CKP | ||||

|

|

|

|

||||

| Problem Found | Problem Solving | OQC Detection | ||||

|

|

|

|

||||

| Surface Treatment | Full Inspection | Package |

|

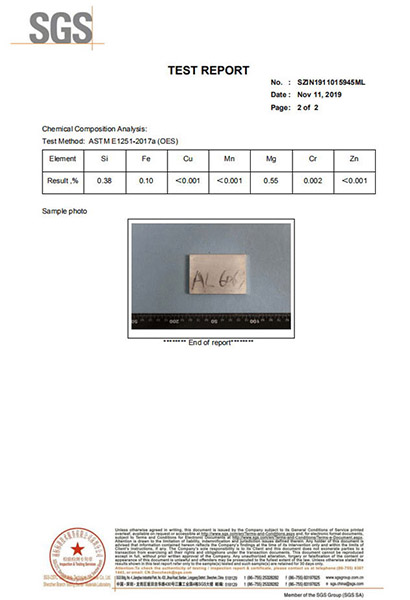

Quality inspection reports are an important tool to ensure the quality and precision of your CNC turning work. We can provide a comprehensive overview of the finished product with a detailed test report on material and product performance, either from an in-house auditor or a third-party laboratory. Ensure finished product meets all customer requirements. |

|

Qualify Evaluation Report

For each order we receive, we can provide a list of quality inspection reports according to your processing requirements.

Inspection report

Certificate

ISO 9001:2015 IATF 16949:2015 ROHS Directive 12 patent certifications

|

Our Certificate

|

|

|

Custom CNC Machining FAQs

|

Here are some frequently asked questions (FAQs) about custom CNC machining parts:

Q: What are the advantages of custom CNC machining? A: Custom CNC machining offers exceptional precision, versatility, and the ability to create complex geometries. It's suitable for various industries and allows for efficient production.

Q: What types of materials can be used in custom CNC machining? A: Custom CNC machining can work with a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics and even wood.

Q: Is custom CNC machining cost-effective for small production runs? A: Yes, custom CNC machining is cost-effective for both small and large production runs. Its precision and automation make it a viable option for various scales of production.

Q: What industries benefit the most from custom CNC machining? A: Industries such as aerospace, automotive, electronics, and medical fields benefit significantly from custom CNC machining due to its precision and ability to produce complex parts.

Q: How can I choose the right CNC machining service provider?

A: Look for a provider with a strong reputation, experience in your industry, advanced machinery, and a commitment to quality control and timely delivery.

Q: What factors influence the cost of custom CNC machining? A: The cost is influenced by factors like material selection, complexity of the design, tolerances, production volume, and additional processes like finishing and assembly.

These frequently asked questions should give you a better understanding of custom CNC machined parts and their applications. If you have any other questions or need more information, our professional engineering team is always ready to serve you, 24 hours online. |

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red