15 years one-stop China custom CNC machining parts factory

Home / Product / Electronic Industry /

VMT is a CNC machining and manufacturing factory for various electronic equipment casings. With 13 years of experience in CNC machining electronic housings and various types of CNC electronic housing samples, you can send pictures to view and view the factory online, contact us immediately to obtain samples. We can provide you with various types of electronic product casing machining services to meet your customized CNC machining needs.

Product Specification:

Custom CNC Milling Machining Precision Machining Parts Aluminum Flashlight Housing

| Machining process | Contens | Description | Standard |

|---|---|---|---|

| Materia | Aluminum | AL 6061-T6, 6063, 7075-T 2014 2017 2011 etc | SUS,ASTM,DTM |

| Copper | C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | SUS,ASTM,DTM | |

| Iron | 4140, Q235, Q345B,20# ,45# etc. | SUS,ASTM,DTM | |

|

Stainless Steel |

303,304,316L, 17-4(SUS630) etc | SUS,ASTM,DTM | |

| Titanium | TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | SUS,ASTM,DTM | |

| Surface treatment | Plating | Galvanized, Gold Plating, Nickel,Plating, Chrome Plating, Zinc nickel alloy, Titanium Plating | ML-STD-810G |

| PVD | Golden TiN; Black:TiC, Silver:CrN | ASTM B117 ASTM D3359 | |

| Anodized | Hard oxidation ,Clear Anodized,Color Anodized | ASTM B117 ASTM D3360 ASTM G154-2006 | |

| Tolerance | Circularity | +/-0.01mm | ISO 4292:1985 |

| Planarity | +/-0.05mm | ISO 4292:1985 | |

| Surface roughness | Ra0.1 3.2 | ISO 468-1982 ISO 8502-3199305 |

If there is no color you like, please contact us>>> we have many colors to choose.

Company Profile

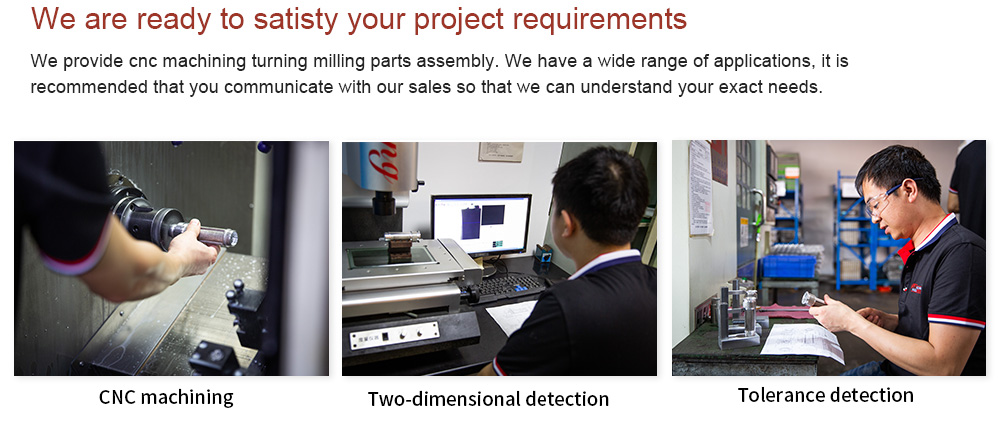

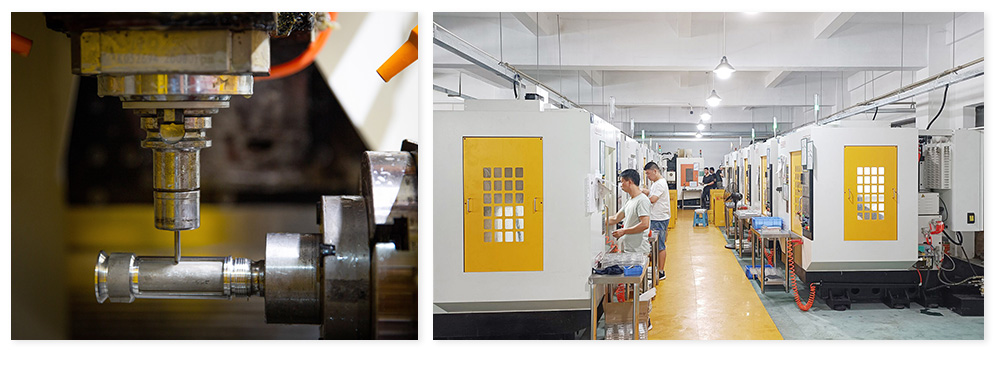

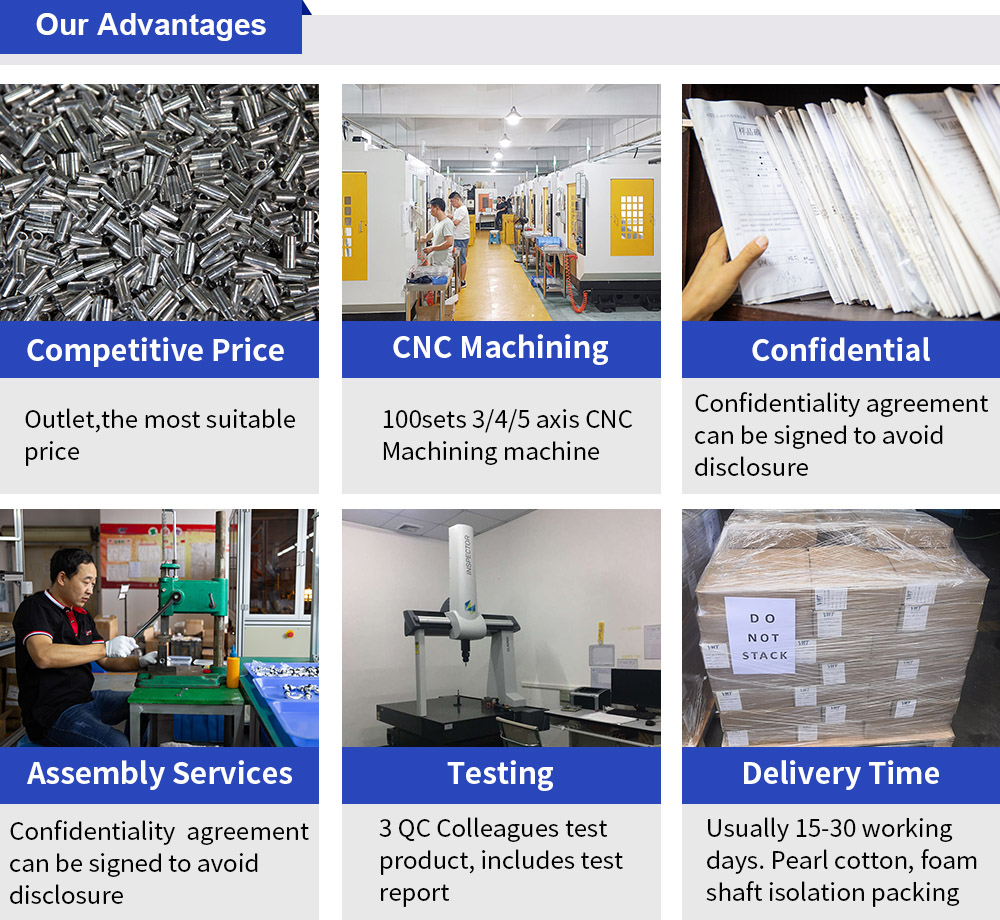

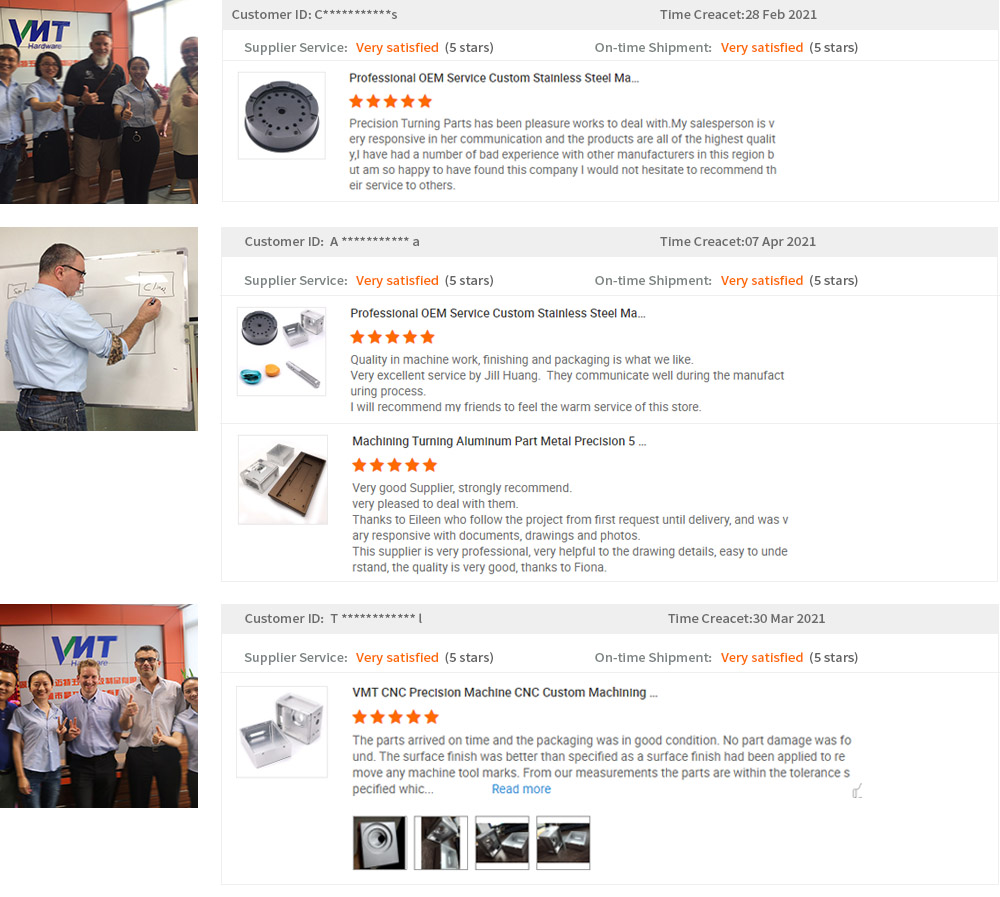

VMT is an ISO 9001:2015 certified manufacturer established in 2010 in Shenzhen, China. We are a manufacturer of OEM and ODM metal parts.

In order to provide high quality and competitive prices, VMT combines different processing techniques for different designs. Our

commitment is to produce quality parts on time with friendly customers to increase our service business.

|

—— cnc aluminum parts ——

|

|

|

|

—— cnc aluminum & stainless steel parts ——

|

|

|

|

—— cnc machining automotive parts ——

|

|

|

What is surface treatment(finish)?

1.Make the surface beautiful

2.Keep the surface no change

3.Antirust,Anticorrosive

4.Change the performance of the material

5.Change the color of the parts

|

|

|

|

|

|

Nickel Plating |

Colors Plated | Chrome Plating | Economic Price |

|

|

|

|

|

|

Color Anodizing |

Hard Anodizing | Sandblasting | Polishing |

|

|

|

|

|

Powder Cating |

Multi-color anodized |

Painting

|

|

|

Different surface treatment

See here Same design,same color but differernt price,Do you know why? See the surface carefully. They are different. The left have textureline, If will make your product not beautiful, right? Why is the surface so different? The material is not completely same, the making peocessing is different. |

Custom CNC Milling Machining Precision Machining Parts Aluminum Flashlight Housing

Related suggestion

Related suggestionGive us a call or send an inquiry to our emailbox, we will answer your doubts according to your customers' requirements, and quote you immediately.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!