15 years one-stop China custom CNC machining parts factory

Professional Stainless Steel CNC Machining Team

24/7 CNC Machining Facility with Samples Ready in 7-10 Days

As lightweight metals gain popularity, stainless steel machined parts have become a preferred choice across various industries. With years of experience, VMT has been a trusted expert in CNC stainless steel machining.

VMT specializes in producing high-precision, complex-structure custom CNC machined stainless steel parts. ISO certified, we offer one-stop services from prototyping to mass production. Equipped with advanced CNC machinery and a professional team, we manufacture high-strength, corrosion-resistant stainless steel components with exceptional accuracy and consistency.

Our comprehensive services include milling, turning, and more, with flexible pricing tailored to different project stages. We meet tight tolerance requirements and ensure fast delivery. By continuously optimizing our processes, we meet diverse production needs and provide strong support to ensure the success of your project.

CNC Machined Stainless Steel Prototypes

Stainless steel CNC prototyping is an ideal solution for verifying designs before mass production. It helps identify structural flaws and process issues early on, significantly reducing production risks and ensuring a smoother transition to full-scale manufacturing.

We offer efficient and cost-effective prototyping services. Our expert team will review your design and customize the optimal solution by integrating processes such as die casting, welding, EDM (Electrical Discharge Machining), or wire-cut EDM. We deliver high-quality prototype parts within your budget and timeline, laying a solid foundation for successful mass production.

Customized Stainless Steel Parts Machining and Manufacturing

If you're looking for custom stainless steel machining services, we are your ideal partner. With advanced technology, extensive experience, and professional expertise, we deliver cost-effective manufacturing solutions. In 2015, we passed ISO 9001:2015, IATF 16949, and SGS on-site factory audits. We strictly follow ISO 9001 quality standards, combining efficient production with flexible customization to ensure fast delivery of complex projects with exceptional quality.

We also offer a full range of custom stainless steel surface treatments, including sandblasting, passivation, polishing, galvanizing, nickel plating, brushing, chrome plating, powder coating, and painting.

Stainless Steel CNC Machining

Stainless steel is a functional alloy primarily composed of iron and chromium, with enhanced properties achieved by adding special elements. Its key characteristics include high strength and excellent corrosion resistance, making it suitable for extreme temperatures ranging from -200°C to 800°C. It also offers outstanding weldability and machining consistency, making it ideal for precision CNC machining. Additionally, its surface is easy to clean and sterilize, making it a preferred material for medical devices. These features make stainless steel one of the top choices in precision manufacturing, especially in fields requiring strict cleanliness and accuracy.

Stainless Steel Materials from VMT: Stainless steel SUS201, Stainless steel SUS303

Stainless steel SUS304, Stainless steel SUS316, Stainless steel SUS316L, Stainless steel SUS420, Stainless steel SUS430, Stainless steel SUS431, Stainless steel SUS440C, Stainless steel SUS630/17-4PH etc.

Advantages

Disadvantages

Price: $$$

Delivery Time: < 10 days

Wall Thickness: 0.75 mm

Tolerance: ±0.005 in. (±0.125 mm)

Maximum Part Size: 200 x 80 x 100 cm

Applications

CNC machining enables the production of high-performance, high-precision, and highly repeatable metal and plastic parts, offering both 3-axis and 5-axis CNC milling services. It is widely used across various industries, including medical devices and surgical implants, aerospace, defense vehicles, automotive, electronics, semiconductors, food processing, energy and chemical equipment, industrial machinery, and automation. CNC machining provides high-quality custom components to meet the diverse needs of different sectors.

Stainless Steel SUS201

SUS201 stainless steel features low cost and good formability, with moderate corrosion resistance. It is commonly used in household items such as cutlery and home appliances, making it a budget-friendly stainless steel option.

Tensile strength at yield (MPa): 275 - 380

Fatigue strength (MPa): 240 - 290

Elongation at break (%): 40 - 60

Hardness (Brinell): 147 - 217

Density (g/cm3): 7.90

Melting point: 1390~1420℃

Stainless Steel SUS303

Sulfur-containing austenitic stainless steel (such as 303) offers excellent machinability, making it ideal for high-volume production of bolts, shafts, and similar components. It provides higher machining efficiency than 304, though with slightly lower corrosion resistance, offering outstanding cost performance.

Tensile strength at yield (MPa): 415 - 450

Fatigue strength (MPa): 240 - 300

Elongation at break (%): 35 - 50

Hardness (Brinell): 190 - 240

Density (g/cm3): 7.90

Melting point: 1390~1440℃

Stainless Steel SUS304

SUS304 stainless steel is corrosion-resistant, easy to machine, and offers excellent cost performance. It is widely used in corrosion-resistant applications such as food and medical equipment.

Tensile strength at yield (MPa): 215 - 505

Fatigue strength (MPa): 240 - 300

Elongation at break (%): 40 - 70

Hardness (Brinell): 170 - 220

Density (g/cm3): 7.90

Melting point: 1400~1450℃

Stainless Steel SUS316

SUS316 stainless steel offers superior corrosion resistance, making it ideal for harsh environments such as marine and chemical industries. It is considered an upgraded version of SUS304.

Tensile strength at yield (MPa): 170 - 310

Fatigue strength (MPa): 240 - 290

Elongation at break (%): 30 - 50

Hardness (Brinell): 140 - 220

Density (g/cm3): 7.90

Melting point: 1375~1400℃

Stainless Steel SUS316L

SUS316L stainless steel provides excellent corrosion resistance and resistance to sensitization, making it the preferred material for high-end applications such as pharmaceuticals and nuclear power.

Tensile strength at yield (MPa): 170 - 290

Fatigue strength (MPa): 240 - 290

Elongation at break (%): 40 - 50

Hardness (Brinell): 140 - 190

Density (g/cm3): 7.90

Melting point: 1375~1400℃

Stainless Steel SUS420

SUS420 stainless steel offers high hardness (HRC 50+), making it ideal for blades and surgical instruments. While its corrosion resistance is relatively lower, it can be enhanced through surface treatments.

Tensile strength at yield (MPa): 345 - 650

Fatigue strength (MPa): 275

Elongation at break (%): 10 - 25

Hardness (Brinell): 180 - 290

Density (g/cm3): 7.80

Melting point: 1480~1530℃

Stainless Steel SUS430

SUS430 stainless steel offers excellent cost performance, with good heat resistance and oxidation resistance. It is well-suited for mid- to low-end applications such as household appliances and automotive components.

Tensile strength at yield (MPa): 275 - 450

Fatigue strength (MPa): 240 -280

Elongation at break (%): 20 - 30

Hardness (Brinell): 150 - 200

Density (g/cm3): 7.75

Melting point: 1480~1530℃

Stainless Steel SUS431

SUS431 stainless steel features high hardness and excellent corrosion resistance, making it ideal for aerospace and marine components. While it requires preheating before welding, it delivers outstanding overall performance.

Tensile strength at yield (MPa): 690 - 900

Fatigue strength (MPa): 350

Elongation at break (%): 15 - 17

Hardness (Brinell): 248 - 293

Density (g/cm3): 7.75

Melting point: 1427~1510℃

Stainless Steel SUS440C

SUS440C stainless steel offers ultra-high hardness (HRC 58–60), making it ideal for high-end cutting tools and bearings. However, due to its relatively lower corrosion resistance, surface protection is recommended to enhance durability.

Tensile strength at yield (MPa): 450 - 1900

Fatigue strength (MPa): 275

Elongation at break (%): 10 - 20

Hardness (Brinell): 285 - 600

Density (g/cm3): 7.75

Melting point: 1480~1520℃

Stainless Steel SUS630/17-4PH

SUS630 stainless steel (also known as 17-4PH) features ultra-high strength, excellent corrosion resistance, and good high-temperature performance. It is ideal for critical components in aerospace and energy industries, offering a perfect balance between durability and lightweight design.

Tensile strength at yield (MPa): 725 - 1170

Fatigue strength (MPa): 480

Elongation at break (%): 6 - 14

Hardness (Brinell): 248 - 388

Density (g/cm3): 7.80

Melting point: 1400~1440℃

Stainless Steel SUS416

SUS416 stainless steel offers excellent machinability, making it ideal for mass production of precision components. However, its corrosion resistance is relatively low, so it is best suited for use in dry environments.

Tensile strength at yield (MPa): ≥345~≥620

Fatigue strength (MPa): 240~300

Elongation at break (%): 18%~25%

Hardness (Brinell): 300~400

Density (g/cm3): 7.75

Melting point: 1420~1460℃

Stainless Steel SUS2205

SUS2205 duplex stainless steel features high strength and excellent corrosion resistance, making it ideal for use in extreme marine and chemical environments.

Tensile strength at yield (MPa): ≥450

Fatigue strength (MPa): 290~350

Elongation at break (%): 25~30

Hardness (Brinell): 290~320

Density (g/cm3): 7.80

Melting point: 1380~1440℃

Stainless Steel SUS630/15-5PH

SUS630 stainless steel offers ultra-high strength and corrosion resistance, making it suitable for critical aerospace and energy components, with a cost-performance advantage over titanium alloys.

Tensile strength at yield (MPa): 1100~1310

Fatigue strength (MPa): 480~550

Elongation at break (%): 10%~15%

Hardness (Brinell): 350~420

Density (g/cm3): 7.80

Melting point: 1400~1440℃

Stainless Steel SUS304/18-8PH

SUS304 stainless steel is corrosion-resistant, hygienic, and non-magnetic, widely used in the food and medical industries, offering the best cost-performance ratio.

Tensile strength at yield (MPa): 205~310

Fatigue strength (MPa): 240~270

Elongation at break (%): 40%~60%

Hardness (Brinell): 170~200

Density (g/cm3): 8.00

Melting point: 1400~1450℃

Stainless Steel CNC Machining Parts Gallery

Stainless Steel: Various National Standards and Equivalent Grades

We maintain a stock of over 40 certified materials, enabling rapid delivery of precision prototypes and small batch parts within 24 hours. Some of these materials are IMDS certified.

| China (GB) |

USA (AISI/UNS) | Europe (EN) | Japan (JIS) | ISO |

Characteristics and Applications |

| 06Cr19Ni10 | 304 / S30400 | X5CrNi18-10 (1.4301) | SUS 304 | X5CrNi18-10 |

General purpose, food/chemical equipment |

| 022Cr17Ni12Mo2 | 316L / S31603 | X2CrNiMo17-12-2 (1.4404) | SUS 316L | X2CrNiMo17-12-2 |

Chloride ion resistant, medical/seawater environment |

| 06Cr18Ni11Ti | 321 / S32100 | X6CrNiTi18-10 (1.4541) | SUS 321 | X6CrNiTi18-10 |

Intergranular corrosion resistant, high temperature parts (≤800℃) |

| 12Cr13 | 410 / S41000 | X12Cr13 (1.4006) | SUS 410 | X12Cr13 |

Tools, turbine blades (HRC35+) |

| 68Cr17 |

440C / S44004 |

X105CrMo17 (1.4125) |

SUS 440C |

X105CrMo17 |

Ultra-high hardness (HRC58+), scalpels/bearings |

| 30Cr13 |

420 / S42000 |

X30Cr13 (1.4028) |

SUS 420J2 |

X30Cr13 |

Wear and corrosion resistant, plastic molds/valves |

| 10Cr17 |

430 / S43000 |

X6Cr17 (1.4016) |

SUS 430 |

X6Cr17 |

Architectural decoration, home appliance panels (low-cost heat resistance) |

| 019Cr19Mo2NbTi |

444 / S44400 |

X2CrMoTi18-2 (1.4521) |

SUS 444 |

X2CrMoTi18-2 |

Chloride ion resistant, water heaters/solar water tanks |

| 022Cr23Ni5Mo3N |

2205 / S32205 |

X2CrNiMoN22-5-3 (1.4462) |

SUS 329J3L |

X2CrNiMoN22-5-3 |

High strength + chloride ion resistance (PREN≥35), chemical pipelines |

| 022Cr25Ni7Mo4N |

2507 / S32750 |

X2CrNiMoN25-7-4 (1.4410) |

- |

X2CrNiMoN25-7-4 |

Super corrosion resistant (PREN≥40), offshore platforms/desulfurization equipment |

| 05Cr15Ni5Cu4Nb |

15-5PH / S15500 |

X5CrNiCuNb15-5 (1.4545) |

SUS 630 |

- |

Aviation fasteners (H900 state σ≥1310MPa) |

| 04Cr13Ni8Mo2Al |

17-4PH / S17400 |

X5CrNiCuNb16-4 (1.4542) |

SUS 630 |

- |

Nuclear power plant valves (corrosion resistant + high strength) |

Why Choose VMT?

High-Quality Parts with Tight Tolerances

As an ISO 9001-certified manufacturer, VMT delivers high-quality CNC machining parts, expertly handling complex designs. We follow international best practices, achieving dimensional tolerances as tight as ±0.0004″ (0.01mm), ensuring our products meet your exact specifications and fulfill all your requirements.

Fast Quoting and Delivery

VMT provides rapid production and delivery of CNC machining parts, enabling flexible iterations and helping you stay ahead in the market. Upload your design and receive a CNC quote within 2 hours. Our engineering team offers precise cost calculations, transparent pricing, and reduced lead times, significantly boosting your competitiveness.

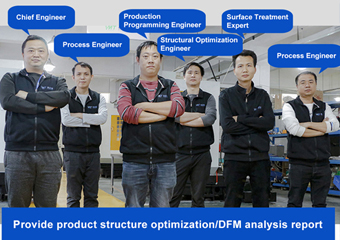

Engineering Support

Leveraging cutting-edge technology and equipment, we ensure the highest quality, precision, and performance of automotive parts. To expedite our clients' CNC machining product development and validation, we operate over 100 advanced CNC machines and a specialized rapid prototyping team. From design analysis to mass production, we can deliver within 24 hours, providing full support to ensure client success.

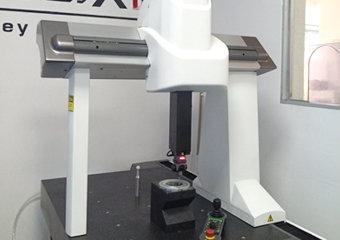

Quality Inspection

We maintain a comprehensive quality control system, including IQC, IPQC, and FQC, overseeing every stage from raw materials to final shipment. We retain inspection reports for two years and are equipped with advanced 3D and 2D measuring instruments, as well as a laboratory for precise dimension checks and material compliance. We offer CMM inspection, material testing, and certification of conformity to ensure exceptional quality.

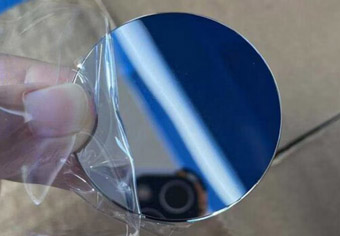

Surface Finishing

We collaborate with surface finishing factories with over 10 years of experience, offering more than 40 surface finishingprocesses. Two senior engineers work on customizing cost-effective solutions based on your needs, strictly controlling every step to ensure a 98% product yield and outstanding surface finishingquality.

Certifications and Patents

We are certified by ISO9001:2015, IATF16949, and SGS, and hold 12 patents. With state-of-the-art CNC technology, we ensure precise and efficient CNC machining part machining, meeting your highest expectations for size, performance, and strength, and providing exceptional service.

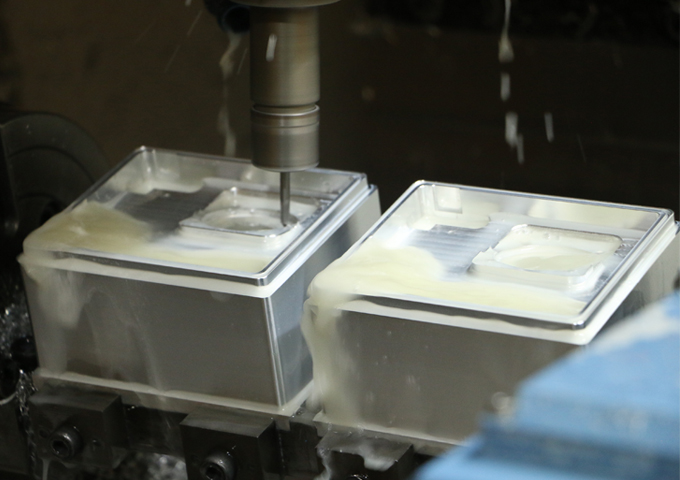

Stainless Steel CNC Machining Capabilities

VMT is dedicated to providing customers with high-precision and complex component manufacturing and processing solutions, covering the full service spectrum from prototype development to mass production. Below are our core machining capabilities:

Multi-Axis Machining: 3/4/5-axis CNC enables complex surface and multi-angle precision machining, meeting strict tolerance requirements for challenging parts.

CNC Milling: Specialized in high-precision, complex structural components with tight tolerance control of ±0.01mm.

CNC Turning: Precision turning of various shafts and bushings, achieving mirror surface finish of Ra 0.8μm and accurate dimensions.

Rapid Prototyping: Functional prototypes delivered in 5–7 days, accelerating the entire design-to-validation process.

Precision Machining: Ultra-precision machining with ±0.005mm tolerance for medical-grade parts, compliant with aerospace certifications.

Material Capabilities: Inventory of 30+ metal and plastic materials with customized cutting parameters to ensure optimal forming results.

Volume Production: Flexible order volumes from 10 to 100,000 pieces, with intelligent scheduling systems ensuring on-time delivery.

Quality Control: ISO-certified with full inspection processes; CMM used to guarantee 100% pass rate on critical dimensions.

Stainless Steel Parts Surface Finishing Options

Proper stainless steel surface treatment not only enhances aesthetics but also improves corrosion resistance and wear protection. VMT offers a wide range of surface finishing options in stainless steel CNC machining to ensure exceptional product quality. Each treatment is customized based on the specific characteristics of stainless steel machined parts, including sandblasting, passivation, polishing, galvanizing, nickel plating, brushing, chrome plating, powder coating, and painting—designed to boost the durability, functionality, and appearance of your stainless steel CNC components.

As Machined

Passivation

Plating

Galvanizing

Polishing

Nickel Plating

Brushed

Powder Coating

Flexible Turnaround Time

We customize machining lead times for all types of projects to ensure your stainless steel CNC machining needs are met—ranging from rapid prototyping to mass production:

Project Type

Urgent high-Precision Samples

Stainless Steel Prototype Manufacturing

Molding Requirements

High-Volume Production

Turnaround Time

24-Hour Delivery

Simple Parts: 1–3 days,Complex Parts: 3–7 days

Mold Production: Completed in 5 days, with samples delivered within 7 days.

Lead Times: Depend on part complexity, with typical delivery within 2–4 weeks, always meeting customer deadlines.

For projects with urgent deadlines, please contact us immediately for expedited processing.

Advantages and Disadvantages of Stainless Steel CNC Machining

Stainless steel is a widely used material across industries such as industrial manufacturing, medical, food processing, and aerospace, prized for its excellent properties. CNC machining enables efficient and precise processing of stainless steel parts, while also presenting certain challenges that must be addressed.

Advantages

Disadvantages

Application of CNC Machining Stainless Steel Parts

The excellent properties of aluminum alloys make them widely used in many fields, including but not limited to:

Food & Beverage Industry: 304 and 316 food-grade stainless steel comply with FDA hygiene standards and are widely used in food processing equipment, beverage filling machinery, kitchen appliances, and food packaging machinery.

Frequently Asked Questions

Stainless steel is not absolutely rust-proof, but with proper material selection, appropriate use, and regular maintenance, it can maintain excellent corrosion resistance over time.

Stainless steels with lower chromium content have reduced corrosion resistance and are more prone to rusting in humid or acidic environments. Inferior stainless steel may lack sufficient chromium and nickel, resulting in decreased rust resistance.

If rust stains appear, they can be removed using a stainless steel cleaner or a mixture of citric acid and baking soda. After cleaning, it's recommended to perform passivation to restore the protective oxide layer.

What are the Challenges of Machining Stainless Steel?

Stainless steel is known for its strength and heat resistance, but these qualities also make it challenging to machine. Common issues include work hardening, rapid tool wear, and heat buildup during cutting. To overcome these, high-performance CNC equipment, proper tool selection, and optimized cutting parameters are essential—just like those used by VMT's expert machinists.

Which Grade of Stainless Steel is Best for Machining?

Grades like 303 stainless steel are specifically designed for machining and offer excellent chip-breaking performance. 304 and 316 are also machinable, but require more precise tooling and speeds. At VMT, we expertly handle all grades based on your part’s design, tolerance, and functional needs.

Why is Stainless Steel Low Maintenance?

Stainless steel's natural chromium-rich oxide layer makes it highly resistant to rust, corrosion, and staining—even without coatings. This passive layer continually self-heals when scratched, making it ideal for long-term applications with minimal upkeep.

How Much does it Cost to CNC Machining Stainless Steel?

The cost varies depending on part complexity, required tolerances, material grade, and production volume. On average, stainless steel CNC machining can range from $60–$150 per hour. For custom quotes, VMT provides competitive pricing tailored to your project.

What is Stainless Steel CNC Machining?

Stainless steel CNC machining is a subtractive manufacturing process that uses computer-controlled tools to precisely cut, drill, mill, and shape stainless steel into complex parts. It offers exceptional accuracy, repeatability, and surface finish—perfect for industries like aerospace, medical, automotive, and food processing.

What Types of Stainless Steel can I Machining?

Common machinable stainless steels include:

At VMT, we machine a wide range of stainless steel grades based on application requirements.

Is 304 or 316 Stainless Steel Easier to Machining?

304 stainless steel is generally easier to machine than 316, due to 316’s higher toughness and molybdenum content. However, 316 offers superior corrosion resistance, making it worth the additional machining effort for demanding environments.

The main difference lies in corrosion resistance.

Both are excellent for CNC machining, but material choice depends on environmental exposure and required durability.

CNC Machining Resources

Stainless Steel Passivation: A Comprehensive Guide

This article provides an in-depth explanation of stainless steel passivation, covering fundamental concepts, functions, process steps, testing methods, precautions, industry standards, equipment features, practical tips ...

CNC Machining Stainless Steel: Challenges, Tips, Types, Advantages, and Disadvantages

Read this article to learn about the challenges, tips, types, advantages, and disadvantages of CNC machining stainless steel. It will help you make informed decisions for your stainless steel parts projects, improving machining ...

Stainless Steel Fasteners: Everything You Need to Know

In this guide, we will explore all the essential information about stainless steel fasteners, including their types, applications, and benefits. Learn how to apply this knowledge to your CNC machining parts projects ...

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red