15 years one-stop China custom CNC machining parts factory

Home / Resources / Material / Steel CNC Machining /

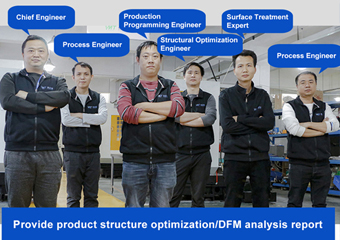

Professional Custom Alloy Steel CNC Machining Team

24/7 CNC Machining Facility with Samples Ready in 7-10 Days

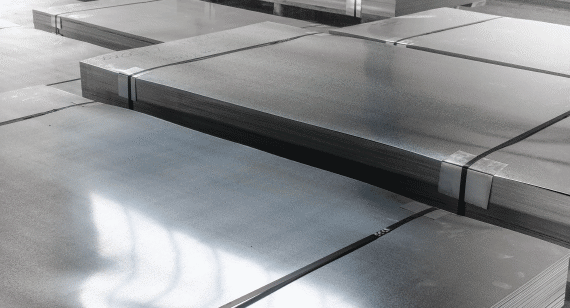

When your project's core requirements are heavy load-bearing and cost control, and it is in a non-corrosive environment, carbon steel is our top recommendation. It has 2-3 times the strength of aluminum alloys, yet its cost can be nearly halved. It is the ideal material for heavy equipment structural components, fixtures, and other applications. Through professional machining and surface treatments (such as galvanizing and blackening), we easily address its susceptibility to rust, providing you with durable and cost-effective parts.

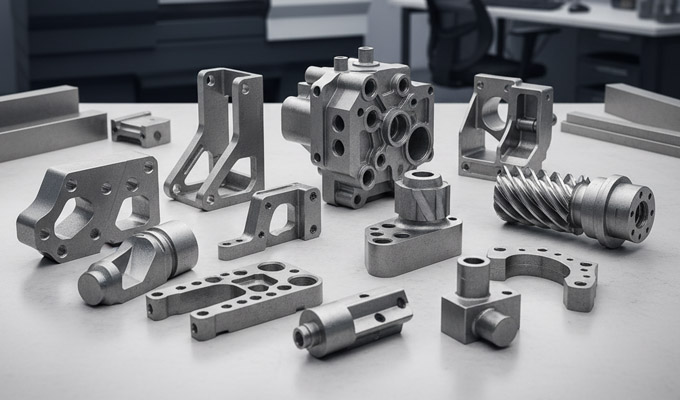

VMT specializes in the production of high-precision, complex custom steel CNC machining parts. With ISO9001 and IATF16949 certifications, we offer one-stop services ranging from prototype development to mass production. Equipped with advanced CNC machines and a professional team, we produce high-strength, corrosion-resistant iron parts while ensuring precision and consistency. Our services include steel milling, turning, and other comprehensive machining processes. We provide flexible pricing based on project stages, meeting strict tolerance requirements and ensuring fast delivery. Continuously optimizing our processes, we cater to your diverse production needs and provide strong support for the success of your projects.

Steel CNC Machined Prototypes

One-Stop Steel Prototype Service: From Drawing to Finished Product, Worry-Free

We provide a complete steel prototype solution, covering design review, quick quotes, precision machining, and post-processing. Our engineering team offers free drawing reviews and feasibility analysis, optimizing the design based on the steel part’s characteristics to ensure prototype success. With our professional quoting system and extensive material library, we can provide transparent quotes and delivery times within 1-4 hours.

Precision Machining and On-Time Delivery

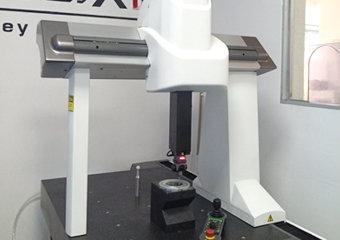

Equipped with multi-axis CNC machines, we can quickly machine various steel part prototypes without the need for molds. Materials range from low carbon steel to tool steel. We support post-processes like heat treatment, electroplating, and sandblasting, and use 3D coordinate measurement to ensure quality control. Each prototype is carefully packaged to prevent rust and shipped safely through efficient logistics, helping you speed up product development.

High-quality steel prototypes are key to the successful launch of your product. We not only provide fast CNC machining but also offer a full solution for ‘zero-risk design validation and low-cost accelerated R&D.’ By choosing us, you gain not just a part, but a professional partner who ensures your project moves forward smoothly.

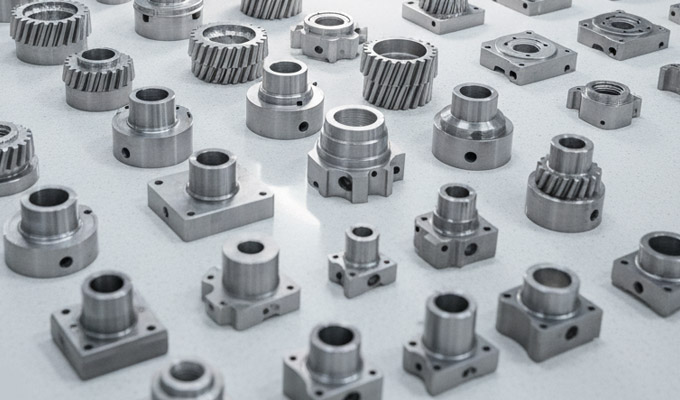

High-Volume Custom CNC Machined Steel Parts Manufacturing

We specialize in high-volume custom CNC machining of steel parts. With automated production lines and professional process control, we can achieve a daily production capacity of 10,000 parts with stable precision of ±0.05mm. By optimizing tool strategies and material usage, we help customers reduce production costs by up to 30%. We provide high-strength, high-consistency parts for automotive components, hydraulic parts, and industrial equipment, ensuring your supply chain remains efficient and reliable.

Steel CNC Milling

Steel is an iron-based alloy mainly divided into carbon steel, alloy steel, tool steel, and stainless steel. We provide precision machining for carbon steel and alloy steel, with material strength ranging from 500 to 1500 MPa. With excellent strength, wear resistance, and cost performance, our steel parts are widely used in heavy machinery, car chassis, and hydraulic fixtures. It offers the best balance between load-bearing needs and budget control.

Steel Materials from VMT: Steel 1018, Steel 4130, Steel 4140, Steel 4140 PH, Steel A36, Steel 1215, Steel 4340, Steel 1020, Steel 1045, Steel 1060, Steel 1095, Steel 8620, A2 Tool Steel, O1 Tool Steel, D2 Tool Steel etc.

Advantages

Disadvantages

Price: $$$

Delivery Time: < 10 days

Wall Thickness: 0.75 mm

Tolerance: ±0.005 in. (±0.125 mm)

Maximum Part Size: 200 x 80 x 100 cm

CNC Machining

CNC machining ensures high strength and durability for parts used in heavy machinery and hydraulic systems.

We offer 3-axis and 5-axis CNC machining with heat treatment. Our process can reach ±0.03mm accuracy and over 800MPa strength in mass production. This helps solve reliability problems in high-load environments and improves your equipment’s performance and service life.

Steel 1018

1018, commonly known as low-carbon steel, offers excellent cold workability and weldability, with improved wear resistance after surface carburizing and quenching. It is widely used in structural parts such as gears, shafts, and bolts in the automotive, machinery, and construction industries.

Tensile strength at yield (MPa): 370 MPa

Fatigue strength (MPa): 230-290 MPa

Elongation at break (%): 15-20%

Hardness (Brinell): 119-159 HB

Density (g/cm3): 7.87 g/cm³

Melting point: 1425-1540°C

Steel 4130

4130 steel, a chromium-molybdenum alloy steel, offers high strength, excellent toughness, and good weldability. It can be hardened to a higher hardness through heat treatment and is widely used in critical structural components such as aerospace frames, racing roll cages, high-performance hydraulic cylinders, and molds.

Tensile strength at yield (MPa): 435-620 MPa

Fatigue strength (MPa): 250-300 MPa

Elongation at break (%): 20-25%

Hardness (Brinell): 190-250 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1425-1540°C

Steel 4140

4140 steel, known as a chromium-molybdenum alloy steel, features high strength, high toughness, and excellent hardenability. Heat treatment can reach a hardness of over 30 HRC and is widely used in critical load-bearing components such as heavy-duty shafts, gears, molds, and oil drilling equipment.

Tensile strength at yield (MPa): 655-850 MPa

Fatigue strength (MPa): 450-600 MPa

Elongation at break (%): 20-25%

Hardness (Brinell): 197-235 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1425-1540°C

Steel 4140 PH

4140 PH steel is known as a pre-hardened alloy steel. Its advantages include excellent strength, toughness, and good fatigue resistance. Pre-hardening reduces subsequent heat treatment processes and makes it suitable for CNC machining and welding. It is widely used in shafts, gears, connectors, and tools in industries such as aviation, automotive, and petroleum.

Tensile strength at yield (MPa): 850-1000 MPa

Fatigue strength (MPa): 550-650 MPa

Elongation at break (%): 20-25%

Hardness (Brinell): 260-285 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1425-1540°C

Steel A36

A36 steel is known as low-carbon steel. Its advantages include good weldability, workability, and moderate strength. It can be used directly without heat treatment and is widely used in parts such as frames, support structures, and pipes in industries such as construction, manufacturing, bridges, and structural components.

Tensile strength at yield (MPa): 250 MPa

Fatigue strength (MPa): 150-250 MPa (depending on processing and loading conditions)

Elongation at break (%): 20-22%

Hardness (Brinell): 119-159 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1425-1538°C

Steel 1215

Steel 1215 is known as a free-cutting steel, known for its excellent turning performance and surface finish. Through sulfur-phosphorus compound optimization, it can achieve high-speed automated machining and is widely used in large-volume and other small precision machining parts such as bolts, nuts, gears, and pins.

Tensile strength at yield (MPa): 310 MPa

Fatigue strength (MPa): 230-300 MPa

Elongation at break (%): 20-30%

Hardness (Brinell): 120-150 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1400-1450°C

Steel 4340

4340 steel is a high-strength nickel-chromium-molybdenum alloy steel with advantages including high strength, toughness, weldability, and wear resistance. Heat-treated to a hardness of 55HRC, it is widely used in critical load-bearing components such as aircraft landing gear, heavy-duty shafts, molds, and high-performance racing car connecting rods.

Tensile strength at yield (MPa): 850-1000 MPa

Fatigue strength (MPa): 450-550 MPa

Elongation at break (%): 15-20%

Hardness (Brinell): 207-235 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1425-1540°C

A2 Tool Steel

A2 tool steel is known as air-cooled, high-carbon tool steel. Its advantages include good wear resistance, toughness, and deformation resistance, making it suitable for heat treatment, CNC machining, and mold manufacturing. It is widely used in the manufacture of molds, cutting tools, stampings, and high-precision mechanical parts.

Tensile strength at yield (MPa): 1300-1600 MPa

Fatigue strength (MPa): 600-800 MPa

Elongation at break (%): 10-12%

Hardness (Brinell): 250-300 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1400-1450°C

01 Tool Steel

O1 tool steel is known as an oil-quenchable alloy tool steel. Its advantages include good wear resistance, hardness, and deformation resistance, making it suitable for heat treatment, CNC machining, and mold manufacturing. It is widely used in the production of cutting tools, stamping dies, cutting tools, stamping parts, and other high-precision industrial parts.

Tensile strength at yield (MPa): 1550-1700 MPa

Fatigue strength (MPa): 800-900 MPa

Elongation at break (%): 10 - 20

Hardness (Brinell): 250-300 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1425-1480°C

Steel 1020

1020 steel is a high-quality low-carbon steel with excellent cold formability and weldability. Surface carburizing produces a wear-resistant surface and a tough core. It is widely used in automotive connecting rods, standard parts, machined components, and various cold-rolled and stamped structural parts.

Tensile strength at yield (MPa): 350-450 MPa

Fatigue strength (MPa): 220-250 MPa

Elongation at break (%): 15-20%

Hardness (Brinell): 120-160 HB

Density (g/cm3): 7.87 g/cm³

Melting point: 1450-1510°C

Steel 1045

1045 steel is a medium-carbon steel with advantages including excellent strength, hardness, and wear resistance. It is suitable for heat treatment (hardness can reach over 55 HRC through quenching and tempering), CNC machining, and welding. It is widely used in the manufacture of key components such as high-strength shafts, gears, connecting rods, and high-strength structural parts.

Tensile strength at yield (MPa): 460-600 MPa

Fatigue strength (MPa): 250-300 MPa

Elongation at break (%): 16-20%

Hardness (Brinell): 170-220 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1425-1530°C

Steel 1060

1060 steel is a high-carbon steel known for its high hardness, strength, and excellent elasticity. Through quenching and tempering at moderate temperatures, it achieves exceptional toughness and wear resistance. It is widely used in key components such as heavy-duty springs, agricultural machinery tools, high-strength shafts, and cutting tools.

Tensile strength at yield (MPa): 550-650 MPa

Fatigue strength (MPa): 250-300 MPa

Elongation at break (%): 10-12%

Hardness (Brinell): 200-250 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1450-1500°C

Steel 1095

Steel 1095 is known as a high-carbon tool steel. Its advantages include extremely high hardness, good wear resistance and toughness, making it suitable for heat treatment, quenching, and CNC machining processes. It is widely used in parts requiring wear resistance and high strength, such as knives, blades, springs, and gears.

Tensile strength at yield (MPa): 650-850 MPa

Fatigue strength (MPa): 300-400 MPa

Elongation at break (%): 6-8%

Hardness (Brinell): 250-300 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1425-1530°C

Steel 8620

8620 steel is a nickel-chromium-molybdenum alloy case-hardening steel known for its excellent core toughness and surface wear resistance. Through carburizing and quenching, it achieves an ideal combination of a hard surface and a strong core. It is widely used in key transmission components in automobiles and machinery, such as gears, shafts, and cams.

Tensile strength at yield (MPa): 480-700 MPa

Fatigue strength (MPa): 300-400 MPa

Elongation at break (%): 20-25%

Hardness (Brinell): 170-250 HB

Density (g/cm3): 7.85 g/cm³

Melting point: 1425-1530°C

D2 Tool Steel

D2 tool steel is known as a high-carbon, high-chromium tool steel. Its advantages include excellent wear resistance, compressive strength, and thermal stability, making it suitable for heat treatment, CNC machining, and cutting processes. It is widely used in the manufacture of molds, shearing tools, stampings, and other precision parts that require high wear and corrosion resistance.

Tensile strength at yield (MPa): 1600-1800 MPa

Fatigue strength (MPa): 600-700 MPa

Elongation at break (%): 5-7%

Hardness (Brinell): 250-300 HB

Density (g/cm3): 7.75 g/cm³

Melting point: 1425-1475°C

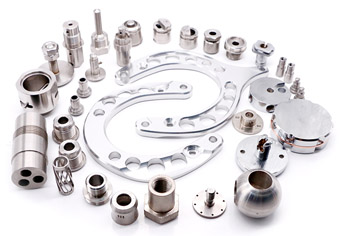

Alloy Steel CNC Machining Parts Gallery

Stainless Steel: Various National Standards and Equivalent Grades

We maintain a stock of over 40 certified materials, enabling rapid delivery of precision prototypes and small batch parts within 24 hours. Some of these materials are IMDS certified.

| Steel Grade | US Standard (ASTM) | European Standard (EN) | Chinese Standard (GB) | Japanese Standard (JIS) | ISO Standard | Characteristics | Applications |

| A36 | ASTM A36 | EN 10025 S275JR | Q235B | SS400 | ISO 630 | Good weldability, machinability, moderate strength | Used in construction, bridges, steel frames, structural parts, etc. |

| 1045 | AISI 1045 | EN C45 | 45 Steel | S45C | ISO 683 | Medium carbon steel, high strength and toughness, good machinability | Used in machinery, automotive parts, gears, shafts, etc. |

| 4140 | AISI 4140 | EN 1.7225 | 40Cr | SCM440 | ISO 683 | Chromium-molybdenum alloy steel, high strength, toughness, wear resistance | Used in aerospace, automotive, oil industries for gears, bearings, couplings. |

| 316 Stainless | ASTM A276 316 | EN 1.4401 | 00Cr17Ni14Mo2 | SUS316 | ISO 683 | High corrosion resistance, good high-temperature strength, oxidation resistance | Used in chemical equipment, marine equipment, food processing equipment, etc. |

| D2 | AISI D2 | EN 1.2379 | 4Cr13 | SKD11 | ISO 4957 | High-carbon high-chromium tool steel, extremely high wear resistance, compressive strength, thermal stability | Used for making molds, cutting tools, stamping tools, etc. |

| S7 | AISI S7 | EN 1.7131 | 1.2714 | SKT4 | ISO 4957 | High strength, impact-resistant, suitable for high toughness applications | Used for tools and molds subjected to impact loads, such as stamping molds. |

| 1050 | AISI 1050 | EN C50 | 50# Steel | S50C | ISO 683 | High-carbon steel, high hardness, wear resistance, suitable for heat treatment | Used for manufacturing gears, springs, tools, etc. |

| 15CrMo | AISI 4130 | EN 1.7218 | 15CrMo | 15CrMo | ISO 683 | Alloy steel, chromium-molybdenum, high strength, wear resistance, high temperature resistance | Used for boilers, pressure vessels, pipelines, etc. |

| St37-2 | AISI 1018 | EN 10025 St37-2 | Q235 | SS400 | ISO 630 | Low carbon steel, good weldability and machinability, moderate strength | Used in machinery, construction, shipbuilding, and structural parts. |

| 35CrMo | AISI 4130 | EN 1.7218 | 35CrMo | SCM435 | ISO 683 | Chromium-molybdenum alloy steel, high strength, toughness, wear resistance | Used for bearings, gears, and other parts in automotive, aerospace, and machinery industries. |

| A2 Tool Steel | AISI A2 | EN 1.2363 | 4Cr13 | SKD2 | ISO 4957 | Air-hardening high-carbon tool steel, good wear resistance, deformation resistance | Used for molds, cutting tools, stamping parts, etc. |

| O1 Tool Steel | AISI O1 | EN 1.2510 | 4Cr13 | SKS3 | ISO 4957 | Oil-hardening tool steel, high wear resistance, hardness, suitable for precision machining | Used for manufacturing cutting tools, molds, blades, etc. |

| A36 Steel | AISI 1018 | EN 10025 St37-2 | Q235 | SS400 | ISO 630 | Low carbon steel, good weldability and machinability, moderate strength | Used in machinery, construction, shipbuilding, and structural parts. |

| 8620 | AISI 8620 | EN 1.6523 | 20CrMo | SNCM220 | ISO 683 | Alloy steel, good strength, toughness, and wear resistance, suitable for heat treatment | Used for gears, shafts, couplings, and other parts in automotive, aerospace, and machinery industries. |

| D2 Tool Steel | AISI D2 | EN 1.2379 | 4Cr13 | SKD11 | ISO 4957 | High-carbon high-chromium tool steel, extremely high wear resistance, compressive strength, thermal stability | Used for making molds, cutting tools, stamping tools, etc. |

| S7 Tool Steel | AISI S7 | EN 1.7131 | 1.2714 | SKT4 | ISO 4957 | High strength, impact-resistant, suitable for high toughness applications | Used for tools and molds subjected to impact loads, such as stamping molds. |

| 1060 | AISI 1060 | EN C60 | 60# Steel | S60C | ISO 683 | High-carbon steel, high hardness, wear resistance, suitable for heat treatment | Used for manufacturing knives, springs, gears, etc. |

| 1095 | AISI 1095 | EN C95 | 95# Steel | SK5 | ISO 683 | High-carbon steel, extremely high hardness and wear resistance, suitable for heat treatment | Used for knives, blades, springs, gears, and other high-wear parts. |

Why Choose VMT?

High-Quality Parts with Tight Tolerances

As an ISO 9001-certified manufacturer, VMT delivers high-quality CNC machining parts, expertly handling complex designs. We follow international best practices, achieving dimensional tolerances as tight as ±0.0004″ (0.01mm), ensuring our products meet your exact specifications and fulfill all your requirements.

Fast Quoting and Delivery

VMT provides rapid production and delivery of CNC machining parts, enabling flexible iterations and helping you stay ahead in the market. Upload your design and receive a CNC quote within 2 hours. Our engineering team offers precise cost calculations, transparent pricing, and reduced lead times, significantly boosting your competitiveness.

Engineering Support

Leveraging cutting-edge technology and equipment, we ensure the highest quality, precision, and performance of automotive parts. To expedite our clients' CNC machining product development and validation, we operate over 100 advanced CNC machines and a specialized rapid prototyping team. From design analysis to mass production, we can deliver within 24 hours, providing full support to ensure client success.

Quality Inspection

We maintain a comprehensive quality control system, including IQC, IPQC, and FQC, overseeing every stage from raw materials to final shipment. We retain inspection reports for two years and are equipped with advanced 3D and 2D measuring instruments, as well as a laboratory for precise dimension checks and material compliance. We offer CMM inspection, material testing, and certification of conformity to ensure exceptional quality.

Surface Finishing

We collaborate with surface finishing factories with over 10 years of experience, offering more than 40 surface finishingprocesses. Two senior engineers work on customizing cost-effective solutions based on your needs, strictly controlling every step to ensure a 98% product yield and outstanding surface finishingquality.

Certifications and Patents

We are certified by ISO9001:2015, IATF16949, and SGS, and hold 12 patents. With state-of-the-art CNC technology, we ensure precise and efficient CNC machining part machining, meeting your highest expectations for size, performance, and strength, and providing exceptional service.

Custom Steel CNC Machining Capabilities

We specialize in precision CNC machining of various types of steel. We have the ability to process the entire process from prototyping to mass production, and are committed to transforming your designs into high-precision, high-quality steel parts.

CNC Machining Steel Parts Surface Finishing Options

The right steel surface treatment not only enhances appearance but also provides enhanced protection against rust, corrosion, and wear. VMT offers a wide variety of surface finishes for steel CNC milling, ensuring consistent quality on every part. Each surface treatment is tailored to the specific characteristics of the steel CNC machined part and includes passivation, zinc plating, nickel/electroless nickel plating, blackening/blueing, chrome plating, powder coating, and oil spraying to enhance the durability, functionality, and appearance of steel CNC machined parts.

As Machined

Passivation

Plating

Galvanizing

Polishing

Nickel Plating

Blackening

Powder Coating

Flexible Turnaround Time

We customize machining lead times for all types of projects to ensure your steel CNC machining needs are met—ranging from rapid prototyping to mass production:

Project Type

Urgent high-Precision Samples

Stainless Steel Prototype Manufacturing

Molding Requirements

High-Volume Production

Turnaround Time

24-Hour Delivery

Simple Parts: 1–3 days,Complex Parts: 3–7 days

Mold Production: Completed in 5 days, with samples delivered within 7 days.

Lead Times: Depend on part complexity, with typical delivery within 2–4 weeks, always meeting customer deadlines.

For projects with urgent deadlines, please contact us immediately for expedited processing.

Advantages and Disadvantages of Steel CNC Machining

Steel is widely used in industries such as construction, machinery manufacturing, automotive, and aviation, offering diverse mechanical properties, corrosion resistance, and wear resistance. We provide customized steel CNC machining milling solutions to ensure quality, reduce costs, and meet diverse and complex requirements.

Advantages

Solution:

Disadvantages

Application of CNC Machining Steel Parts

CNC machined steel parts are widely used in a variety of industries, including:

Frequently Asked Questions

What are the Challenges of Machining Steel?

Machining steel can be challenging due to its high strength, hardness, and heat generation during cutting. These factors can cause tool wear and dimensional inaccuracy. Using optimized cutting parameters and coated carbide tools helps improve tool life and precision.

Which Grade of Steel is Best for Machining?

Free-machining steels such as AISI 1018, 1215, and 12L14 are ideal due to their excellent machinability. For high-strength applications, 4140, 4340, and A36 are widely used in CNC machining industries.

Why is Steel Low Maintenance?

Steel has a low maintenance cost because of its excellent strength, wear resistance, and durability. It resists deformation and impact damage, reducing the need for frequent repairs or replacements. Additionally, many types of steel—especially stainless steel—offer high corrosion resistance, which minimizes surface degradation and maintenance over time, making it a cost-effective material for long-term industrial use.

What is the Cost of CNC Machining Steel?

The cost depends on grade, hardness, part complexity, and quantity. On average, CNC machining steel parts range from $30 to $150 per hour, with bulk production reducing the per-part price by up to 25–40%.

What Precision and Tolerance can be Achieved in Steel CNC Machining?

With advanced CNC machining centers, tolerance levels can reach ±0.01 mm, and surface roughness can be as fine as Ra 0.8 μm, ensuring high dimensional stability for precision components.

What Types of Steel can We Machine?

We can machine a wide range of steels including carbon steel (A36, 1045, 1095), alloy steel (4140, 4340, 8620), tool steel (A2, D2, O1), and stainless steel (303, 304, 316, 420, 440C) — covering both structural and high-performance grades.

How Does the Cost of CNC Machining Steel Compare with Other Materials?

Steel machining is generally 20–30% more expensive than aluminum due to its hardness and slower cutting speeds, but it offers 2–3 times longer lifespan and higher load-bearing capacity — ideal for durable industrial parts.

CNC Machining Resources

Steel vs Stainless Steel: Key Differences

Alloy steel and stainless steel exhibit significant differences in terms of composition, mechanical properties, corrosion resistance, heat treatment and manufacturing, applications, cost, and environmental considerations. Understanding ...

4140 vs. 4130 Steel: A Comprehensive Guide

This article provides a detailed overview of the characteristics of 4140 and 4130 steel, comparing their properties, performance, and application scenarios. It also offers selection strategies to help you choose the right ...

4140 vs. 8620 Steel: A Selection Guide

This article provides a comprehensive comparison of 4140 and 8620 steel, offering an in-depth analysis of their differences in chemical composition, mechanical properties, machining characteristics, heat treatment ...

2024-08-02

2024-08-02

The manufacturer is strongly recommended. In the past few years of cooperation we have ordered several machined products from aluminum and stainless steel. These products are manufactured in compliance with tolerance requirements and require product finish. Now I have ordered another one. The service is excellent and any questions can be answered and resolved in time.

2021-05-13

2021-05-13

The dimensions are all customized according to my drawings no tolerance issues and the parts are delivered on time. I am very satisfied with it.

2021-04-06

2021-04-06

I pay much attention to the surface treatment aspect of this product. I was a little worried about the cooperation at the beginning. I am very satisfied with the product now and hope to cooperate for a long time.

2022-09-22

2022-09-22

AN8 Straight PTFE Hose End Fitting for PTFE Fuel Line Fitting Adapter Black Blue Red