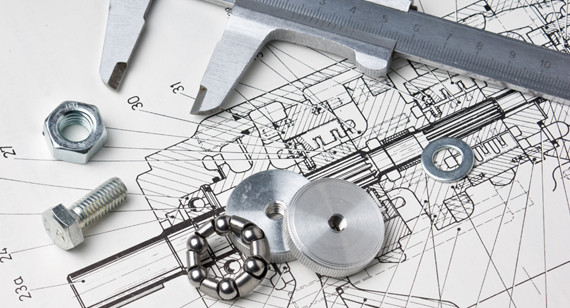

15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2021 09 25

2021 09 25 Nowadays CNC machining does not need to crawl on the workbench as before, and use drawing tools to describe the required machining details. On the eve of manufacturing, a computer is usually required to create CAD drawings and 3D models.

66

66

Read more

Read more

VMT

VMT  2021 09 25

2021 09 25 How can you correctly find or restore the data when the mechanical parts of your machining manufacturing have failed or the data is lost for many years? In this case, the assistance of CNC machining reverse engineering is needed.

66

66

Read more

Read more

VMT

VMT  2021 09 24

2021 09 24 IATF16949 is a quality system that develops a quality system that can be continuously improved in the vehicle supply chain and depots.

66

66

Read more

Read more

VMT

VMT  2021 09 24

2021 09 24 The surface roughness and processing speed of CNC milled parts are determined by the machine. There are many types of milling cutters to choose from, but what do we mean by flying cutters?

66

66

Read more

Read more

VMT

VMT  2021 09 23

2021 09 23 CNC machine tools can be called the mother of industry. It is a great invention in the history of human industry. It helps human beings make ever-changing products and greatly improves people's material living standards.

66

66

Read more

Read more

VMT

VMT  2021 09 23

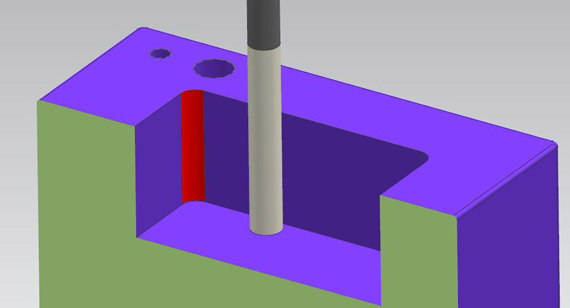

2021 09 23 The ratio of the R angle at the corner to the cavity depth is inappropriate. This ratio is relative to CNC machining. The cavity depth is not more than 10 times the R angle.

66

66

Read more

Read more

VMT

VMT  2021 09 23

2021 09 23 Before becoming a mechanical designer, you must first understand which workshop tools are suitable for you in order to get started quickly. Because every machining shop is different, not all tools are suitable for everyone.

66

66

Read more

Read more

VMT

VMT  2021 09 21

2021 09 21 The Mid-Autumn Festival is coming in 2021. In order to reflect the company's care for employees and make them feel the joy of the festival, the Human Resources Department specially applied for the distribution of Mid-Autumn Festival gifts to all employees of the company.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!