15 years one-stop China custom CNC machining parts factory

339 |

Published by VMT at Jul 14 2025 | Reading Time:About 8 minutes

339 |

Published by VMT at Jul 14 2025 | Reading Time:About 8 minutes

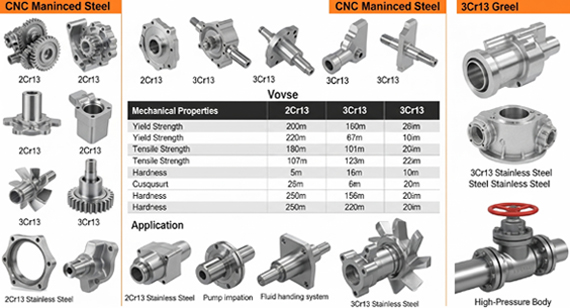

When selecting the right stainless steel for knives, mechanical parts, or CNC machining components, the confusion between 2Cr13 steel and 3Cr13 steel is common. Manufacturers often face challenges balancing cost, corrosion resistance, machinability, and durability. Without a clear comparison, you risk selecting a material that may not perform optimally for your application.

But there’s good news—understanding the real differences between 2Cr13 and 3Cr13 steel can simplify your material selection process. Whether you are sourcing CNC machining parts or developing a high-performance product, knowing how each steel grade behaves under machining, heat treatment, and end-use conditions is crucial.

This article will break down everything you need to know—from chemical composition and mechanical properties to pricing and applications—so you can confidently choose the most suitable material for your needs.

2Cr13 and 3Cr13 are both martensitic stainless steels. The main difference lies in carbon content: 3Cr13 has higher carbon (≈0.3%) than 2Cr13 (≈0.2%), making it harder and more wear-resistant but slightly less corrosion-resistant. 2Cr13 is better for general machining; 3Cr13 suits tools requiring edge retention.

Now that you know the core distinction—carbon content and performance trade-offs—between these two grades, it’s time to explore each steel in detail. Understanding their mechanical, chemical, and physical properties, along with application suitability, will help you choose wisely for stainless steel CNC machining projects.

If you're also considering other options like 440C or D2 tool steel, check out our related guides on those materials as well for broader insights.

Key Points Summary

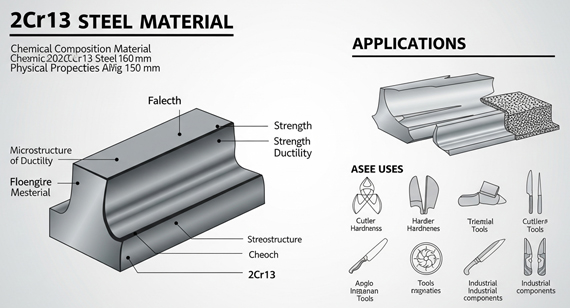

2Cr13 steel is a Chinese standard martensitic stainless steel primarily known for its balanced strength, moderate corrosion resistance, and good machinability. It belongs to the GB (Guobiao) standard system in China and is roughly equivalent to AISI 420 or DIN X20Cr13 in Western standards. As a magnetic stainless steel, it contains 12–14% chromium and a relatively low carbon content of 0.16–0.25%, which gives it good mechanical strength while still being workable in industrial applications.

This steel is commonly used in moderate-load mechanical components, valve parts, surgical instruments, cutlery, and CNC-machined parts that require durability without extreme wear or chemical exposure. Due to its lower carbon content compared to higher grades like 3Cr13 or 440C, 2Cr13 has greater corrosion resistance, especially in humid environments, but offers less hardness and edge retention.

In the context of stainless steel CNC machining, 2Cr13 is a practical material due to its ease of processing, consistent thermal stability, and cost-effectiveness. It responds well to quenching and tempering, allowing its hardness to be adjusted based on specific usage requirements. However, it is not ideal for applications that require high cutting performance or prolonged edge sharpness.

Ultimately, 2Cr13 steel is a versatile and economical solution for many general-purpose applications. It’s a preferred choice in CNC machining factories looking to produce components that balance durability, corrosion resistance, and manufacturability, especially for mid-range or cost-sensitive markets.

3Cr13 steel is a widely used martensitic stainless steel that offers a strong combination of hardness, toughness, and wear resistance, making it ideal for tools and parts that require a durable cutting edge. It is a Chinese steel grade based on the GB standard and is approximately equivalent to AISI 420HC in the American standard system. The name "3Cr13" indicates it contains roughly 13% chromium and 0.26–0.35% carbon, giving it higher hardness and strength than its lower-carbon counterpart, 2Cr13.

The elevated carbon content in 3Cr13 enables it to achieve a higher Rockwell hardness rating (typically up to 56 HRC after proper heat treatment), making it better suited for knife blades, surgical instruments, shears, and wear-resistant tools. At the same time, this increase in hardness comes at the cost of reduced corrosion resistance and slightly more challenging machinability compared to 2Cr13.

In CNC machining services, 3Cr13 steel is valued for its ability to hold tight tolerances in applications requiring both hardness and dimensional stability. However, due to its higher hardness, tool wear may increase, and careful selection of cutting tools and parameters is required during machining. Despite this, it remains a reliable option in CNC machining factories for creating durable, long-lasting stainless steel CNC machining parts.

Overall, 3Cr13 is ideal when the priority is on mechanical performance, especially edge retention and wear resistance, rather than extreme corrosion resistance. Its cost-performance ratio also makes it attractive for mid- to high-grade products in various industries, including consumer knives, industrial tools, and automotive parts.

While 2Cr13 and 3Cr13 are often compared for their performance differences, it's important to first understand their many shared characteristics. Both are martensitic stainless steels developed under the Chinese GB standard, and they fall within the same family of chromium-containing magnetic stainless steels. Their similar metallurgical makeup makes them suitable for a wide range of similar applications, especially in environments where mechanical strength and moderate corrosion resistance are required.

Both steels contain approximately 12–14% chromium, which gives them oxidation resistance and anti-rust capabilities, though not to the same extent as austenitic stainless steels like 304 or 316. They can both be hardened through heat treatment—a defining trait of martensitic steels—enabling users to enhance their strength and wear resistance to fit specific functional requirements.

Additionally, 2Cr13 and 3Cr13 share excellent machinability characteristics when properly heat-treated and are widely used in CNC machining services. These steels are known to maintain dimensional stability under mechanical stress, making them suitable for precision CNC machining parts such as valves, fasteners, turbine blades, surgical instruments, and mid-tier cutlery.

From a cost perspective, both are relatively affordable stainless steels compared to high-end tool steels or corrosion-resistant superalloys. They also demonstrate similar behaviors in annealing, quenching, and tempering processes, allowing flexibility for manufacturers looking to modify material performance as needed.

In short, while 2Cr13 and 3Cr13 differ in carbon content and resultant mechanical traits, their core structural and metallurgical foundation is largely alike. This makes them versatile, cost-effective choices for CNC machining factories and end-users looking for dependable, general-purpose stainless steel components.

Although 2Cr13 and 3Cr13 steels are similar in classification and intended applications, they diverge significantly in key performance parameters due to their different chemical compositions, especially carbon content. These differences directly influence their mechanical properties, machinability, corrosion resistance, and suitability for various CNC machining parts. For engineers, manufacturers, and CNC machining factories, understanding these differences is essential to choosing the right steel for specific part performance and durability requirements.

The main difference between 2Cr13 and 3Cr13 lies in the carbon percentage. 3Cr13 has a higher carbon content, which results in better hardness and edge retention. However, this also makes it slightly more brittle and more challenging to machine than 2Cr13. On the other hand, 2Cr13, with its lower carbon content, offers better corrosion resistance and easier machinability, but at the cost of lower hardness and wear resistance.

These variations make each steel grade better suited to specific applications. For example, 2Cr13 may be preferred for components requiring corrosion resistance and ease of processing, while 3Cr13 is ideal for tools that require sharpness, edge retention, and resistance to mechanical wear.

Next, we’ll compare their chemical compositions to understand how these differences are formed at the elemental level.

2Cr13 Steel and 3Cr13 Steel: Chemical Composition

The performance differences between 2Cr13 and 3Cr13 stem largely from their chemical composition, which dictates the steel's structure, hardness, corrosion resistance, and machinability. Both belong to the martensitic stainless steel family, sharing similar foundational elements like chromium and iron. However, slight adjustments in alloying elements—especially carbon—make a noticeable difference in end use.

Below is a comparison table detailing the typical chemical composition range of 2Cr13 and 3Cr13 steel:

| Element |

2Cr13 Steel (%) |

3Cr13 Steel (%) |

| Carbon (C) |

0.16 – 0.25 | 0.26 – 0.35 |

| Chromium (Cr) |

12.0 – 14.0 | 12.0 – 14.0 |

| Iron (Fe) |

Balance | Balance |

| Manganese (Mn) |

≤ 1.00 | ≤ 1.00 |

| Molybdenum (Mo) |

— | — |

| Nickel (Ni) |

≤ 0.60 (optional) | ≤ 0.60 (optional) |

| Nitrogen (N) |

≤ 0.11 | ≤ 0.11 |

| Phosphorus (P) |

≤ 0.040 | ≤ 0.040 |

| Silicon (Si) |

≤ 1.00 | ≤ 1.00 |

| Sulfur (S) |

≤ 0.030 | ≤ 0.030 |

Key Takeaways:

Understanding these chemical differences is crucial when selecting materials for CNC machining services, as they directly influence cutting efficiency, surface finish, and tool wear during part production.

Understanding the general properties of 2Cr13 and 3Cr13 steels is essential for manufacturers, CNC machining factories, and engineers who need to select materials that balance performance, durability, and cost. While both are martensitic stainless steels under the Chinese GB standard, they offer different mechanical and physical behaviors due to their carbon content and slight differences in alloying elements.

Corrosion Resistance

Both 2Cr13 and 3Cr13 offer good corrosion resistance due to their chromium content (12–14%). However, 2Cr13 performs slightly better in moist or mildly corrosive environments because of its lower carbon content, which reduces carbide formation at grain boundaries. Carbides, while improving hardness, can reduce chromium’s ability to form a protective oxide layer. Therefore, 2Cr13 is better for corrosion-sensitive applications, such as valves, kitchen utensils, and certain medical tools.

Wear Resistance

3Cr13 provides higher wear resistance thanks to its higher carbon content, which allows for a harder microstructure after heat treatment. This makes it ideal for blades, cutting tools, and parts subjected to friction. 2Cr13, while easier to process, has lower wear resistance and is more suitable for non-cutting or low-friction components.

Hardness & Retention

After heat treatment, 3Cr13 achieves greater hardness—typically around HRC 54–56—compared to 2Cr13, which generally reaches HRC 48–52. The added hardness also means better edge retention, making 3Cr13 more suitable for knives, scissors, and tools that require a lasting edge. However, increased hardness comes at the cost of reduced toughness.

Machinability

2Cr13 is easier to machine, especially in its annealed state. Lower hardness allows smoother cutting, less tool wear, and shorter cycle times—making it ideal for CNC machining services focused on volume production. 3Cr13, being harder, can cause more tool wear and may require slower cutting speeds or coated tools during machining.

Impact Toughness (J)

Because it has lower hardness, 2Cr13 generally provides better impact resistance and toughness, reducing the likelihood of cracking under sudden force. 3Cr13, while strong, is more brittle, especially in low-temperature or impact-prone environments.

Sharpening

From a sharpening standpoint, 2Cr13 is easier to sharpen, which is useful in field tools or items requiring frequent maintenance. 3Cr13, while holding an edge longer, takes more effort and skill to sharpen due to its increased hardness.

Brittleness and Toughness

2Cr13 is tougher and less brittle than 3Cr13, making it suitable for structural components that may face occasional shocks or loads. Conversely, 3Cr13 is more brittle, particularly if improperly tempered or over-hardened, and is better for cutting rather than striking applications.

Rust Resistance

Both steels perform well in dry or low-humidity environments, but 2Cr13 resists rust slightly better, making it a better choice for parts exposed to water or mildly corrosive substances over time.

Summary Table: General Properties Comparison

| Property |

2Cr13 Steel |

3Cr13 Steel |

| Corrosion Resistance | Moderate to good (better than 3Cr13) | Moderate |

| Wear Resistance | Moderate | Higher |

| Hardness | HRC 48–52 | HRC 54–56 |

| Edge Retention | Moderate | Better edge retention |

| Machinability | Excellent | Moderate (tool wear higher) |

| Impact Toughness | Better (less brittle) | Lower (more brittle) |

| Sharpening Ease | Easier | More difficult |

| Brittleness | Less brittle | More brittle |

| Toughness | High | Medium |

| Rust Resistance | Slightly higher | Moderate |

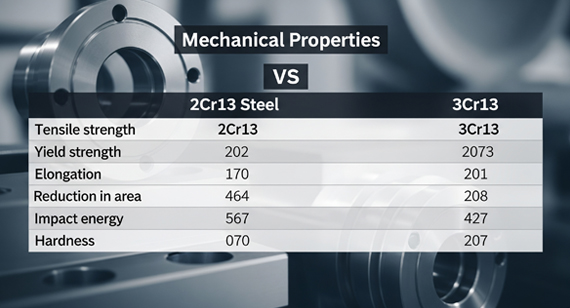

When selecting a stainless steel for CNC machining services, understanding mechanical properties is essential. These properties dictate how a material behaves under physical stress, machining processes, and thermal treatments. Both 2Cr13 and 3Cr13 steels are martensitic stainless steels, but their performance diverges due to variations in carbon content and heat treatment responses. This section compares their behavior under mechanical loads and processing conditions to help CNC machining factories and product designers make better material choices.

Hardness (HRC)

2Cr13 steel typically reaches a hardness range of HRC 48–52 after proper quenching and tempering. In contrast, 3Cr13 steel, with higher carbon content, achieves HRC 54–56, offering a harder surface ideal for wear resistance applications like knives and blades. However, greater hardness in 3Cr13 often comes at the expense of reduced impact toughness.

Hardness (HV) and (HRB)

On the Vickers scale, 2Cr13 registers around 190–220 HV, while 3Cr13 reaches 240–270 HV post-treatment. For Rockwell B scale measurements (used for annealed conditions), 2Cr13 typically falls around HRB 95–100, while 3Cr13 scores slightly higher, at HRB 100–105.

Tensile Strength & Yield Strength

2Cr13 stainless steel demonstrates tensile strength of 520–700 MPa and yield strength of 300–420 MPa, making it a reliable choice for structural parts requiring durability but not extreme hardness. 3Cr13 steel offers a higher tensile strength range of 750–950 MPa and yield strength of ≥450 MPa, which benefits cutting and impact tools requiring rigid resistance.

Elongation & Area Reduction

In mechanical testing, 2Cr13 steel generally provides 18–25% elongation, indicating greater ductility. 3Cr13, being harder, shows a slightly lower elongation range of 12–18%. Similarly, area reduction for 2Cr13 can reach up to 60%, while 3Cr13 is typically around 50%.

Impact Energy Akv(J)

2Cr13 offers better impact energy, with values around ≥40 J, making it more resilient under sudden shocks. 3Cr13, though harder, absorbs less energy before fracturing, typically ≥25 J, which reflects reduced toughness at higher hardness levels.

Hardness by Treatment State

Quenching and Tempering:

Annealing:

Ductility, Reduction of Area, Heating Temperature

Ductility in 2Cr13 makes it more flexible under forming loads, preferred for parts requiring minor deformation. Heating temperatures for hardening vary slightly:

Proper tempering is key to controlling brittleness and hardness in both.

Comparison Table: Mechanical Properties of 2Cr13 vs. 3Cr13 Steel

| Property |

2Cr13 Steel |

3Cr13 Steel |

| Hardness (HRC) | 48–52 | 54–56 |

| Hardness (HV) | 190–220 | 240–270 |

| Hardness (HRB, Annealed) | 95–100 | 100–105 |

| Tensile Strength (MPa) | 520–700 | 750–950 |

| Yield Strength (MPa) | 300–420 | ≥450 |

| Elongation (%) | 18–25 | 12–18 |

| Area Reduction (%) | ≤60 | ≤50 |

| Impact Energy Akv (J) | ≥40 | ≥25 |

| Hardness (Quenching & Tempering) | HRC 48–52 | HRC 48–52 |

| Hardness (Annealing) | ≤207 HB | ≤229 HB |

| Ductility | High | Moderate |

| Heating Temperature (°C) | 980–1050 | 1050–1100 |

This comparison helps manufacturers decide which steel better aligns with their performance goals and CNC machining services needs. Up next, we’ll explore how these materials behave in terms of physical properties, such as thermal expansion, density, and electrical resistivity.

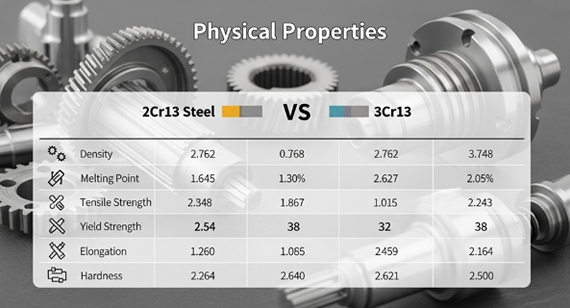

Understanding the physical properties of 2Cr13 and 3Cr13 steel is essential for engineers and CNC machining factories choosing materials for parts that must perform well under thermal, magnetic, and mechanical conditions. While these two steels belong to the same martensitic stainless steel family, subtle differences in their compositions affect how they respond to heat, electricity, and environmental stress. This section provides a side-by-side look at the critical physical parameters that influence their behavior in machining and end-use applications.

Density (g/cm³)

Both 2Cr13 and 3Cr13 stainless steels have a typical density of approximately 7.70 g/cm³. This value is consistent with most martensitic stainless steels and ensures reliable structural integrity without excessive weight. The density affects the final weight of machined parts and is critical in applications like aerospace, automotive, and medical devices where weight-to-strength ratio matters.

Melting Point

The melting points of 2Cr13 and 3Cr13 steels are relatively close:

The slightly lower melting point in 3Cr13 is due to its higher carbon content, which lowers the solidus temperature. This influences the steel’s behavior during high-temperature machining or welding.

Specific Heat Capacity (J/kg·K)

Both steels possess similar specific heat capacities around 460–500 J/kg·K. This property is vital for thermal management during CNC machining operations, where it affects how quickly a material heats up and how much cooling is needed during cutting or grinding.

Thermal Conductivity (W/m·K)

Thermal conductivity is a measure of a material’s ability to transfer heat:

These values indicate moderate heat transfer efficiency. During high-speed CNC machining, moderate conductivity helps prevent heat buildup in the tool interface, improving tool life.

Linear Thermal Expansion Coefficient (10⁻⁶/K)

This coefficient reflects how much the material expands with temperature. While both have relatively low expansion rates, 3Cr13’s slightly higher value could impact dimensional stability in high-precision parts exposed to thermal cycling.

Resistivity (μΩ·m)

Both steels exhibit similar resistivity values, meaning they’re poor electrical conductors—typical of stainless steels. This trait is advantageous in applications requiring electrical insulation or where conductivity is not desired.

Modulus of Elasticity (kN/mm²)

The modulus of elasticity, or Young’s modulus, measures stiffness:

This slight difference means 2Cr13 is marginally stiffer, which may impact deflection and load resistance in structural or load-bearing components.

Magnetic Properties

Both 2Cr13 and 3Cr13 steels are magnetic due to their martensitic structure. This makes them distinguishable from austenitic stainless steels like 304 or 316, which are non-magnetic. Their magnetism is useful in applications requiring magnetic response, such as motor parts, latches, and magnetic sensors.

Table: Comparison of Physical Properties – 2Cr13 vs. 3Cr13 Steel

| Property |

2Cr13 Steel |

3Cr13 Steel |

| Density (g/cm³) | ~7.70 | ~7.70 |

| Melting Point (°C) | ~1500 | ~1450–1480 |

| Specific Heat Capacity (J/kg·K) | 460–500 | 460–500 |

| Thermal Conductivity (W/m·K) | 25–27 | 24–26 |

| Linear Thermal Expansion (10⁻⁶/K) | ~10.4 | ~10.8 |

| Resistivity (μΩ·m) | 0.60–0.75 | 0.65–0.80 |

| Modulus of Elasticity (kN/mm²) | ~200 | ~195 |

| Magnetic Properties | Magnetic | Magnetic |

By comparing these physical properties, it becomes clear that while 2Cr13 and 3Cr13 steels are close in many aspects, 3Cr13’s higher carbon content results in slightly altered thermal behavior and mechanical responsiveness. This information is valuable for CNC machining services and product engineers working with parts exposed to thermal fluctuations, structural loads, or magnetic applications.

Heat treatment plays a critical role in unlocking the full mechanical potential of martensitic stainless steels such as 2Cr13 and 3Cr13. These materials can be transformed significantly in terms of hardness, toughness, and corrosion resistance depending on the thermal processing they undergo. Understanding the differences in heat treatment behavior is essential for CNC machining factories, toolmakers, and engineers looking to optimize component performance.

Heat Treatment Process Overview

Both 2Cr13 steel and 3Cr13 steel respond well to a standard three-stage heat treatment process: annealing, hardening (quenching), and tempering. However, due to the slightly higher carbon content in 3Cr13, it typically achieves higher hardness values after quenching compared to 2Cr13.

Annealing

Quenching (Hardening)

Tempering

Summary of Heat Treatment Differences

| Process |

2Cr13 Steel |

3Cr13 Steel |

| Annealing Temp | 760–790°C | 750–800°C |

| Quenching Temp | 980–1050°C | 1000–1050°C |

| Quenching Media | Air, oil, or polymer | Air, oil, or polymer |

| Tempering Temp | 200–300°C | 180–300°C |

| Max Hardness | ~48–50 HRC | ~54–56 HRC |

| Heat Response | Stable, moderate hardness | Stronger hardening, slightly more brittle |

Implications for CNC Machining

For CNC machining factories offering custom stainless steel CNC machining services, selecting the appropriate heat treatment sequence ensures that the finished components meet both mechanical performance and dimensional precision requirements.

When choosing between 2Cr13 steel and 3Cr13 steel for CNC machining parts, understanding their respective strengths and limitations is critical. Both materials belong to the martensitic stainless steel family and offer a blend of corrosion resistance, hardness, and affordability, but they serve different application needs due to their chemical composition and mechanical properties. This section provides a clear comparison to guide manufacturers, engineers, and buyers in selecting the right material for their projects.

Advantages and Disadvantages of 2Cr13 Steel

Advantages of 2Cr13 Steel

2Cr13 steel is valued primarily for its balanced characteristics at an accessible cost. Its advantages include:

Disadvantages of 2Cr13 Steel

Despite its benefits, 2Cr13 steel also has some limitations:

Advantages and Disadvantages of 3Cr13 Steel

Advantages of 3Cr13 Steel

3Cr13 steel builds upon the properties of 2Cr13 with a higher carbon content, offering several distinct advantages:

Disadvantages of 3Cr13 Steel

However, 3Cr13 steel has its own set of challenges:

Here's a clear table summarizing the advantages and disadvantages of 2Cr13 and 3Cr13 steel:

| Feature |

2Cr13 Steel Advantages |

2Cr13 Steel Disadvantages |

3Cr13 Steel Advantages |

3Cr13 Steel Disadvantages |

| Corrosion Resistance |

Good corrosion resistance for moderate environments | Moderate corrosion resistance, less suited for harsh environments | Improved corrosion resistance compared to 2Cr13 | Limited resistance in highly corrosive environments |

| Hardness |

Moderate hardness prevents brittleness | Lower hardness limits wear resistance | Higher hardness than 2Cr13 | May lose hardness at high temperatures |

| Wear Resistance |

Balanced wear resistance | Wears faster under heavy wear | Better wear resistance than 2Cr13 | Wears faster than high-end steels in severe abrasion |

| Machinability |

Easy to machine and fabricate | - | Easy to machine with balanced toughness |

Requires more frequent sharpening

|

| Cost |

Cost-effective and economical | - | Affordable compared to premium steels | - |

| Toughness |

Good toughness, less brittle | Lower strength compared to high-end steels | Balanced toughness with good strength | Lower strength than premium steels |

| Heat Treatment |

Responds well to heat treatment | - | Responds well to heat treatment | - |

This table helps in quick comparison and informed decision-making when selecting between 2Cr13 and 3Cr13 steel for CNC machining parts.

Summary Table: Advantages and Disadvantages

| Feature |

2Cr13 Steel |

3Cr13 Steel |

| Advantages |

Good corrosion resistance; moderate hardness; easy machining; cost-effective | Higher hardness; balanced toughness; easy machining; affordable; good heat treatment response |

| Disadvantages |

Lower hardness; limited wear resistance; moderate corrosion resistance | Requires frequent sharpening; limited corrosion resistance; lower strength than premium steels; wears under high abrasion; heat sensitivity |

This comparison helps CNC machining factories and service providers offer tailored solutions using 2Cr13 steel CNC machining parts and 3Cr13 steel CNC machining parts, ensuring the right balance of performance and cost-efficiency for various applications.

When selecting stainless steel for your product, especially in precision industries like cutlery, construction, medical devices, or automotive, material performance matters. 2Cr13 and 3Cr13 are two widely used martensitic stainless steels known for their corrosion resistance, hardness, and workability.

Both 2Cr13 and 3Cr13 steels are widely used in various industries due to their excellent balance of corrosion resistance, hardness, and machinability. These stainless steels are favored in applications where moderate wear resistance and durability are required, especially in environments where corrosion could be a concern but not extremely severe. The choice between 2Cr13 and 3Cr13 often depends on the specific mechanical requirements and cost considerations of the application. For example, 2Cr13 is commonly found in products where toughness and ease of fabrication are paramount, while 3Cr13 is preferred when a slightly higher hardness and wear resistance are needed. Below is an overview of typical applications and part examples for both materials across various industries.

So, which one is right for your application?

Let’s break it down by industry and product usage to help you make an informed decision.

Kitchen Knives

2Cr13: Suitable for entry-level kitchen knives. Its moderate hardness and corrosion resistance make it ideal for general-purpose household use where price is a major factor.

3Cr13: Offers slightly better edge retention and toughness. Preferred for mid-range knives needing more durability.

Customer takeaway: For home use, 2Cr13 is cost-effective. For better sharpness and longer lifespan, choose 3Cr13.

Outdoor Knives

2Cr13: Used in economical folding knives and light-use survival gear. Corrosion resistance is good, but edge retention is moderate.

3Cr13: Better suited for heavy-duty outdoor knives, offering superior toughness and strength.

Customer takeaway: Need a budget option? 2Cr13 does the job. For demanding outdoor use, 3Cr13 is more reliable.

Surgical Instruments & Medical Devices

2Cr13: Common in non-cutting tools or instruments with lower mechanical stress.

3Cr13: Preferred for cutting or high-precision tools due to its higher hardness and better wear resistance.

Customer takeaway: 2Cr13 is cost-effective for structural tools; 3Cr13 is ideal for high-performance cutting instruments.

Marine Industry

2Cr13: Good resistance to freshwater corrosion. Used in indoor or less exposed marine parts.

3Cr13: Performs better in saltwater environments. Ideal for components facing higher humidity and salinity.

Customer takeaway: Choose 3Cr13 for coastal or offshore environments; 2Cr13 works for less exposed marine settings.

Chemical Processing

2Cr13: Applicable in low-concentration acidic environments. Cost-effective for short to medium-term use.

3Cr13: More resistant to chemicals and wear. Preferred where longevity and durability are critical.

Customer takeaway: For basic resistance, 2Cr13 is economical. For durability in harsher conditions, use 3Cr13.

Building & Construction

2Cr13: Popular for decorative and non-load-bearing components.

3Cr13: Used in structural and high-wear areas, providing better hardness and resistance to physical stress.

Customer takeaway: Use 2Cr13 for appearance and cost-efficiency; 3Cr13 for durability and structural support.

Food & Beverage Industry

2Cr13: Suitable for basic food contact surfaces and processing tools not exposed to strong acids or salt.

3Cr13: Preferred in more abrasive environments with repeated cleaning and exposure to acidic foods.

Customer takeaway: For general food-grade tools, 2Cr13 is a good start. For rigorous cleaning cycles and higher corrosion risk, 3Cr13 is superior.

2Cr13: Used for non-critical components and trim parts.

3Cr13: Ideal for precision components requiring wear resistance and strength.

Customer takeaway: 2Cr13 keeps costs down for trim and light-duty parts; 3Cr13 delivers performance in moving or stressed areas.

Final Thoughts: Which One Should You Choose?

Here's a clear comparison table between 2Cr13 and 3Cr13 steel, including applications and part examples across different industries:

2Cr13 vs. 3Cr13 Steel – Applications & Part Examples

| Industry |

2Cr13 Steel |

3Cr13 Steel |

| Kitchen Knives |

Budget chef knives, paring knives, utility knives | Multi-purpose knives, carving knives, professional-grade kitchen tools |

| Outdoor Knives |

Folding knives, backup camping knives | Hunting knives, tactical blades, bushcraft knives |

| Surgical Instruments |

Forceps, retractors, orthopedic tool handles | Scalpels, surgical scissors, bone saws |

| Marine |

Interior marine hardware, brackets, clamps | Boat propellers, deck fittings, marine-grade knives |

| Chemical Processing |

Low-concentration acid containers, pump shafts, valves | Reactor vessels, centrifuge parts, high-wear seals |

| Building & Construction |

Door handles, elevator panels, decorative railings | Window locks, security fittings, bolts |

| Food & Beverage |

Mixing blades, trays, food slicers (light-duty) | Industrial slicers, food processor blades, high-cleaning-cycle equipment |

| Medical Devices |

Non-cutting devices, handles, positioning tools | Cutting tools, dental instruments, surgical blades |

| Automotive |

Mirror supports, door locks, trim components | Gear shifters, precision springs, wear-resistant fasteners |

Performance Comparison Table

| Property |

2Cr13 Steel |

3Cr13 Steel |

| Hardness (HRC) |

Moderate (HRC 48–52) |

Higher (HRC 50–56) |

| Corrosion Resistance |

Good | Better |

| Toughness |

Moderate | Higher |

| Edge Retention |

Fair | Better |

| Machinability |

Excellent | Good |

| Heat Treat Response |

Good | Excellent |

| Cost |

Lower | Slightly Higher |

| Applications |

General-purpose | Mid-range, tougher uses |

This format allows buyers, engineers, or procurement professionals to quickly identify the right steel grade based on performance, use case, and industry-specific requirements.

Whether you're manufacturing a surgical tool or designing an outdoor knife, selecting the right steel can make or break your product’s quality and durability. 2Cr13 is your go-to for affordability and decent performance, while 3Cr13 gives you an edge in environments where wear resistance, toughness, and longevity are key.

Need help sourcing the right material or want custom machining advice? Contact our materials expert team today — we’ll help you choose the right steel for your success.

When choosing between 2Cr13 and 3Cr13 stainless steel, the focus often goes beyond just technical properties — cost-effectiveness is a major factor for manufacturers, suppliers, and end-users. While both belong to the martensitic stainless steel family and offer corrosion resistance and mechanical strength, they differ in price point and value over time.

In this guide, we compare the initial purchase cost and the long-term cost benefits of each steel type to help you make the right decision based on your application and budget.

Initial Cost Comparison

| Steel Grade |

Typical Price Range (USD/kg) |

Relative Cost |

Reason |

| 2Cr13 |

$1.30 – $1.70 | Lower | Lower carbon and chromium content; easier to machine and more widely used |

| 3Cr13 |

$1.60 – $2.10 | Moderate | Higher carbon and chromium content; stronger and more durable |

Long-Term Cost Benefits

| Factor |

2Cr13 Steel |

3Cr13 Steel |

| Durability |

Moderate | Higher |

| Maintenance Frequency |

Higher (may require sharpening, polishing) | Lower (better edge retention, corrosion resistance) |

| Replacement Cycle |

Shorter lifespan in harsh environments | Longer lifespan, especially in tough use |

| Total Ownership Cost |

Lower upfront, higher long-term | Slightly higher upfront, lower overall |

Example Scenarios:

Conclusion: Balancing Budget and Performance

| Decision Criteria |

Recommended Steel |

| Lowest purchase price | 2Cr13 |

| Best value over time | 3Cr13 |

| Light-duty use or decorative parts | 2Cr13 |

| High-performance or heavy-duty use | 3Cr13 |

Ultimately, your choice depends on how your product will be used. If you're focused on minimizing initial production costs, 2Cr13 is a strong candidate. But if you prioritize performance, customer satisfaction, and lifecycle savings, 3Cr13 is worth the extra investment.

Choosing the right steel for your product can significantly affect its performance, durability, and overall cost. 2Cr13 and 3Cr13 are two widely used martensitic stainless steels known for their good corrosion resistance, strength, and polishability. But they are not interchangeable — the key is to match the steel grade with your product requirements.

This guide will help you determine when to use 2Cr13 and when 3Cr13 is the better choice, so you can make informed, cost-effective decisions for your business or project.

When Should 2Cr13 Steel Be Used?

2Cr13 is the smarter choice when your application demands moderate performance at a lower cost.

Use 2Cr13 Steel If You Need:

Ideal for mass-market products where price competitiveness matters.

Performs well in mild environments (non-acidic, non-marine).

Excellent for parts that require high-volume machining and simple heat treatment.

Suitable for components not exposed to heavy stress or impact.

Common Applications for 2Cr13:

| Industry |

Part Examples |

| Kitchenware | Budget knives, scissors, cutlery |

| Automotive | Interior trim, brackets, mirror arms |

| Construction | Door handles, hinges, decorative hardware |

| Food Processing | Slicer blades, light-duty tools |

| Medical (Non-cutting) | Forceps, orthopedic tool handles |

When Should 3Cr13 Steel Be Used?

3Cr13 is your go-to option for higher strength, edge retention, and longer life expectancy.

Use 3Cr13 Steel If You Need:

Handles abrasion and friction better — ideal for cutting tools and mechanical components.

After proper heat treatment, 3Cr13 can reach higher hardness ratings, making it more durable.

Longer tool and component life results in lower maintenance or replacement costs.

Withstands saltwater, acidic exposure, and repeated cleaning cycles.

Common Applications for 3Cr13:

| Industry |

Part Examples |

| Cutlery & Outdoor | Mid- to high-end knives, tactical blades |

| Marine | Propellers, deck fittings, marine hardware |

| Medical (Cutting) | Scalpels, bone saws, surgical scissors |

| Automotive | Gear components, springs, wear-resistant fasteners |

| Food Industry | High-speed blades, industrial slicers |

Final Decision Guide

| Selection Criteria |

Choose 2Cr13 |

Choose 3Cr13 |

| Budget-focused project | yes | no |

| High-performance expectations | no | yes |

| Moderate wear and corrosion | yes | no |

| Long-term durability | no | yes |

| Non-cutting or decorative parts | yes | no |

| Cutting, slicing, or moving parts | no | yes |

Conclusion

Choosing between 2Cr13 and 3Cr13 comes down to a simple equation:

Is your focus on price, or performance?

Still unsure? Our engineering team can evaluate your product’s needs and recommend the optimal steel grade for your performance goals and cost targets.

Short Answer:

2Cr13 Steel for Knives

Pros:

Cons:

Best Uses:

| Knife Type |

Target User |

| Budget kitchen knives | Home cooks, gift sets |

| Folding knives | Light everyday carry (EDC) |

| Utility knives | General-purpose cutting tasks |

3Cr13 Steel for Knives

Pros:

Cons:

Best Uses:

| Knife Type |

Target User |

| Mid-range kitchen knives | Culinary enthusiasts |

| Tactical/outdoor knives | Hunters, campers |

| Multi-tools & EDC | Users needing reliability |

Comparison Summary Table

| Feature |

2Cr13 Steel |

3Cr13 Steel |

| Hardness (HRC) |

~48–52 | ~50–56 |

| Edge Retention |

Fair | Better |

| Corrosion Resistance |

Good | Slightly better |

| Ease of Sharpening |

Easy | Moderate |

| Durability |

Moderate | Better for daily use |

| Best For |

Entry-level knives | Mid-range, utility knives |

| Cost |

Lower | Slightly higher |

Final Verdict

Use 2Cr13 for:

Use 3Cr13 for:

Precision. Performance. Partnership.

At VMT, we specialize in high-precision CNC machining services for a wide range of stainless steel components, serving industries where quality and durability matter most — including automotive, medical, aerospace, food processing, electronics, and more.

What We Offer

Stainless Steel CNC Machining Services

We provide end-to-end machining solutions for all major stainless steel grades, including:

Whether it’s small batches, high-volume production, or prototype runs, VMT delivers with consistent quality and precision.

Core Capabilities

| Service |

Details |

| CNC Milling & Turning | 3/4/5-axis precision machining with ±0.01mm tolerance |

| Complex Geometries | Internal threads, undercuts, deep holes, and intricate contours |

| Surface Finishing | Brushed, mirror polish, sandblasting, passivation, and laser marking |

| Custom Part Manufacturing | Designed to meet your CAD, drawing, or sample requirements |

| Assembly & Packaging | Optional assembly, kitting, labeling, and export-standard packaging |

Why Choose VMT?

| Advantage |

What It Means for You |

| Factory-Direct Pricing | Reduce procurement costs with no middleman |

| Expert in Stainless Steel | Over 10 years of experience machining various stainless steel alloys |

| Rapid Lead Times | Fast quoting, short production cycles, and reliable delivery |

| Quality Assurance | ISO 9001-certified with full dimensional reports, CMM, and inspections |

| Global Service | Export-ready parts shipped to Europe, North America, Asia, and beyond |

Industries We Services

Let’s Build Better Stainless Parts, Together

Looking for a reliable stainless steel CNC machining factory?

VMT is ready to bring your design to life with precision, efficiency, and cost control.

Contact us now for a free quote or to discuss your project:

In summary, both 2Cr13 steel and 3Cr13 steel offer valuable properties suited for a range of CNC machining applications, but they differ in key aspects such as hardness, corrosion resistance, and wear durability. 2Cr13 steel stands out for its balanced toughness, good machinability, and cost-effectiveness, making it ideal for applications that require moderate strength and corrosion resistance without excessive wear demands. On the other hand, 3Cr13 steel provides enhanced hardness and wear resistance, making it better suited for parts exposed to higher stress and abrasion, though it may require more frequent maintenance such as sharpening. Understanding these differences allows manufacturers, CNC machining factories, and service providers to select the most appropriate material based on project specifications, performance requirements, and budget constraints. Ultimately, choosing between 2Cr13 and 3Cr13 steel ensures optimized product quality, longevity, and cost-efficiency in stainless steel CNC machining parts. VMT CNC machining services are well-equipped to provide expert guidance and precision manufacturing for both steel grades, helping clients achieve superior results in their industrial applications.

When it comes to 2Cr13 and 3Cr13 stainless steels, each offers unique strengths tailored to different applications and industries:

Choosing between the two depends on your project requirements, end-use environment, and product lifecycle goals.

At VMT, we don’t just machine parts — we help you make smarter material decisions. With deep expertise in stainless steel CNC machining and a commitment to quality, speed, and precision, VMT is your trusted manufacturing partner for everything from knife components and surgical tools to automotive, food-grade, and industrial parts.

Ready to Turn Your Design into High-Performance Stainless Steel Parts?

Let’s collaborate. Let’s manufacture better — with VMT.

Contact Us Today

1. How strong is 3Cr13 steel?

3Cr13 offers good strength and hardness, especially after heat treatment. It typically achieves HRC 50–56, making it suitable for knives, tools, and structural parts that require moderate wear resistance and toughness.

2. What is the difference between 2Cr13 and 3Cr13?

The main difference lies in carbon content:

3. What steel is 3Cr13 equivalent to?

Equivalent to:

It is a low-end martensitic stainless steel with decent corrosion resistance and moderate hardness.

4. Is 2Cr13 stainless steel good?

Yes — it's good for light-duty applications, especially when cost, corrosion resistance, and machinability are top priorities (e.g., kitchen tools, handles, automotive parts).

5. What is the difference between 3Cr13 steel and D2 steel?

D2 is superior for heavy-duty cutting, while 3Cr13 is better for mid-level stainless applications.

6. Is D2 better than 8Cr13MoV?

Yes, in terms of edge retention and wear resistance, D2 outperforms 8Cr13MoV. However, 8Cr13MoV offers better corrosion resistance and is easier to sharpen, making it more balanced for general-use knives.

7. What is the equivalent grade of D2 steel in China?

China GB Standard Equivalent: Cr12Mo1V1

This grade closely matches D2 in terms of composition and performance.

8. Is 3Cr13 steel good?

Yes — it’s a versatile and reliable stainless steel for mid-range products like knives, tools, and mechanical parts. It's especially valued for its balance of corrosion resistance, hardness, and affordability.

9. Is Chinese steel as good as American steel?

It depends on the manufacturer and quality control. Many Chinese factories (like VMT) offer international-standard machining and metallurgy. While raw material quality can vary, certified Chinese mills often produce steel comparable to American standards.

10. Why is D2 steel so popular?

D2 offers exceptional wear resistance, edge retention, and toughness, making it ideal for high-performance cutting tools and knives. It's also semi-stainless, reducing maintenance compared to carbon steels.

11. What are the disadvantages of D2 steel?

12. Does D2 steel rust easily?

Yes, D2 is semi-stainless, meaning it can rust if not properly maintained, especially in humid or salty environments.

13. Is D2 steel better than M390?

M390 outperforms D2 in nearly all aspects:

14. What is 2Cr13 equivalent to?

Equivalent to:

A basic stainless steel with good corrosion resistance and fair mechanical strength.

15. Does 3Cr13 steel rust?

Not easily, but it can if exposed to harsh conditions like saltwater or acids. It's more corrosion-resistant than D2 but less than 304 or 316 stainless steel.

16. Is 3Cr13 steel easy to sharpen?

Yes — it is relatively easy to sharpen using standard whetstones or sharpeners, making it a user-friendly choice for knives and tools.

17. What is the equivalent material of 3Cr13?

As mentioned earlier, it’s equivalent to:

18. Is 3Cr13 better than 440?

440C offers higher hardness and edge retention, but 3Cr13 is more affordable and easier to machine. For high-end blades, 440C is preferred. For budget and mid-range, 3Cr13 is a strong choice.

19. Is 3Cr13 steel good or bad?

It’s good for mid-level performance at a budget-friendly cost. It won’t match premium steels, but it's well-balanced for knives, tools, and mechanical parts where moderate strength and corrosion resistance are enough.

20. Is D2 steel better than 440C?

Choose D2 for heavy-duty tasks and 440C for environments where rust protection is a top priority.

21. Is 3Cr14 suitable for cutting tools?

Yes — 3Cr14 has a slightly higher chromium content than 3Cr13, offering improved corrosion resistance. It’s suitable for light- to mid-duty cutting tools, kitchen knives, and scissors.