15 years one-stop China custom CNC machining parts factory

586 |

Published by VMT at Jul 24 2025 | Reading Time:About 7 minutes

586 |

Published by VMT at Jul 24 2025 | Reading Time:About 7 minutes

In CNC machining, material selection can make or break product quality, cost-efficiency, and performance. Many engineers and product developers struggle to find stainless steel that balances corrosion resistance, machinability, and hardness—especially for precision tools and knife components. If you’ve been caught between popular steel options, one material often flies under the radar: 4116 stainless steel. Used widely in European cutlery, 4116 offers an attractive blend of characteristics—but is it the right choice for your CNC machining project?

4116 stainless steel is a martensitic stainless steel known for its high corrosion resistance, moderate hardness, and excellent machinability after heat treatment. Ideal for knives, surgical tools, and CNC machined parts, it balances edge retention and ease of processing, making it a cost-effective choice in CNC machining services.

Understanding the role of 4116 stainless steel in CNC machining involves more than just its basic properties. From chemical composition and mechanical behavior to how it compares with alternatives like 440C or D2, this guide provides a complete technical breakdown. Keep reading to determine if 4116 is the best fit for your CNC machining parts or production line—and explore how expert CNC machining factories like VMT can deliver precision using this versatile material.

Key Points Summary

4116 stainless steel is a high-carbon, martensitic stainless steel developed by ThyssenKrupp in Germany. It is also known by its material number 1.4116 under the DIN EN standard. This steel is best recognized for its balance of corrosion resistance, edge retention, and mechanical strength, making it ideal for products requiring both durability and hygiene—such as kitchen knives, surgical instruments, and CNC machined parts.

What sets 4116 stainless steel apart is its optimized alloy composition. It contains approximately 0.45-0.55% carbon, around 14.5-15.0% chromium, and small additions of vanadium, molybdenum, and silicon. These elements contribute to its resistance to rust and staining, as well as its ability to be hardened to 55–57 HRC with proper heat treatment.

From a machinist’s perspective, 4116 stainless steel is particularly attractive because of its stable structure and predictable response to CNC processes. It responds well to heat treatment, allowing precise control over hardness and toughness, which is crucial when machining custom parts or medical-grade components.

In CNC machining factories, 4116 stainless steel is often chosen when clients require precision stainless steel CNC machining parts with excellent wear and corrosion resistance. It is particularly common in food-safe and medical device applications, where resistance to cleaning chemicals and moisture exposure is essential.

In summary, 4116 stainless steel is a versatile, cost-effective stainless alloy that performs exceptionally well in both blade manufacturing and precision CNC machining services, making it a trusted material in various industries that demand reliability and hygiene.

4116 stainless steel, also known as X50CrMoV15 or 1.4116, is primarily developed and standardized in Germany. It is a martensitic stainless steel known for its well-balanced properties in hardness, corrosion resistance, and machinability. While it does not have a direct one-to-one equivalent in American standards, it is functionally comparable to several popular stainless steels used worldwide.

Here are the most commonly referenced equivalents or near-equivalents:

| Standard/System |

Equivalent or Comparable Steel |

Notes |

| DIN / EN (Germany) |

X50CrMoV15 (1.4116) | Original designation |

| AISI / SAE (USA) |

420HC | Similar in carbon and chromium, but 4116 contains added vanadium and molybdenum for better edge retention and corrosion resistance |

| Japanese JIS |

SUS420J2 | Similar base composition, though typically lower in performance due to fewer alloying elements |

| Chinese GB |

5Cr15MoV | Often used as a Chinese equivalent, though slight variation in alloy balance |

| Swedish |

Sandvik 12C27 or 13C26 | Close in performance, especially in cutlery applications |

In practical terms, 4116 stainless steel is often compared to 420HC in the U.S., but with improved alloy tuning due to the presence of molybdenum (for corrosion resistance) and vanadium (for grain refinement and wear resistance). This makes it particularly desirable in applications where edge sharpness, cleanability, and resistance to wear and oxidation are important—such as kitchen knives, surgical instruments, and CNC machined stainless steel parts.

From the perspective of CNC machining services, knowing the equivalent steels helps manufacturers and engineers choose alternate materials when 1.4116 is not readily available in local markets, ensuring comparable performance in stainless steel CNC machining parts.

4116 stainless steel is a popular martensitic stainless steel alloy that has gained widespread use in various industries, particularly in cutlery, surgical instruments, and precision CNC machining. Manufactured by ThyssenKrupp in Germany, it is known for offering a balanced combination of hardness, corrosion resistance, and ease of processing. As with any material, it presents both advantages and disadvantages that engineers, machinists, and designers must consider when selecting it for stainless steel CNC machining parts or consumer products.

Advantages of 4116 Stainless Steel

Excellent Corrosion Resistance

Thanks to its high chromium content (approximately 15%), 4116 stainless steel provides solid protection against rust and corrosion, especially in humid or acidic environments. This makes it well-suited for kitchen knives, medical tools, and food-processing machinery.

Good Hardness and Edge Retention

With carbon content around 0.5% and optimized heat treatment capability, 4116 can reach Rockwell hardness levels between 55–58 HRC. It maintains sharp edges longer than softer stainless steels, making it ideal for cutting applications.

Improved Toughness

The inclusion of molybdenum and vanadium in its composition contributes to fine grain structure, enhancing toughness and preventing brittle fractures—especially valuable for knives and impact-prone components.

Ease of Sharpening

Unlike high-carbon tool steels, 4116 stainless is relatively easy to resharpen, even with basic sharpening tools, making it ideal for consumer-grade and professional blades.

Good Machinability

In annealed condition, 4116 stainless steel has reasonable machinability, suitable for precision CNC machining services. It allows high dimensional accuracy and clean surface finishes in complex part geometries.

Sanitary and Food-Safe

Due to its corrosion resistance and low carbon migration, 4116 is widely used in hygienic applications such as food-processing blades and surgical instruments.

Disadvantages of 4116 Stainless Steel

Lower Wear Resistance Compared to High-End Tool Steels

While 4116 performs well in general applications, it lacks the superior wear resistance of steels like D2, S30V, or M390, limiting its effectiveness in highly abrasive environments.

Not Suitable for Heavy Structural Loads

As a martensitic stainless steel, 4116 is not designed for structural or load-bearing applications due to its moderate tensile and yield strength compared to austenitic grades like 304 or duplex steels.

Moderate Heat Resistance

It cannot withstand extremely high temperatures for prolonged periods. This limits its use in high-temperature industrial settings where creep and oxidation resistance are critical.

Requires Proper Heat Treatment

To reach optimal performance (hardness and toughness), it must be heat-treated precisely. Inconsistent treatment can lead to brittleness or underperformance, particularly in blade manufacturing.

Limited Availability in Some Regions

As a European-grade steel, 4116 is not as commonly stocked in North America or Asia, which may affect procurement timelines for CNC machining factories that don’t maintain a global supply chain.

Here's a clear, concise, and professional table summarizing the advantages and disadvantages of 4116 stainless steel, suitable for inclusion in your article:

Advantages and Disadvantages of 4116 Stainless Steel

| Advantages |

Disadvantages |

| Excellent corrosion resistance due to high chromium content | Lower wear resistance compared to high-end tool steels (e.g., D2, M390) |

| Good hardness and edge retention (up to 55–58 HRC with proper heat treatment) | Not ideal for high-stress structural or load-bearing applications |

| Enhanced toughness thanks to molybdenum and vanadium | Moderate heat resistance; not suitable for high-temperature environments |

| Easy to sharpen, even with basic tools | Requires precise heat treatment to avoid brittleness or performance degradation |

| Suitable for CNC machining due to good machinability in annealed state | Limited global availability outside Europe, affecting sourcing for some regions |

| Food-safe and hygienic, ideal for kitchenware and medical tools |

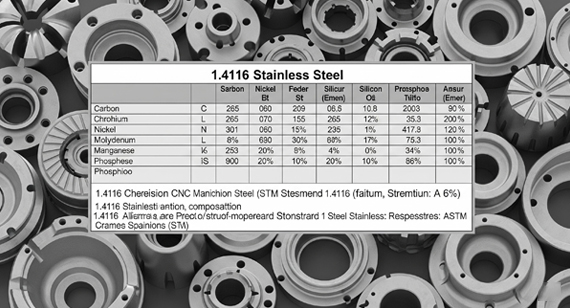

The chemical composition of 1.4116 stainless steel is specifically engineered to offer a balanced combination of corrosion resistance, hardness, and machinability. This makes it particularly suitable for precision CNC machining parts in industries like kitchenware, medical devices, and tools. The alloying elements in 1.4116 steel play vital roles in determining its overall mechanical performance, microstructure stability, and thermal processing response.

Below is a breakdown of the typical composition of 1.4116 stainless steel:

| Element |

Content (% by weight) |

Function |

| Carbon (C) |

0.45–0.55% | Enhances hardness and strength through heat treatment |

| Chromium (Cr) |

14.0–15.0% | Provides corrosion resistance and improves wear resistance |

| Vanadium (V) |

≤ 0.10% | Increases toughness, grain refinement, and wear resistance |

| Molybdenum (Mo) |

0.50–0.80% | Improves pitting resistance and enhances corrosion resistance |

| Phosphorus (P) |

≤ 0.04% | Improves machinability (must be kept low to avoid brittleness) |

| Manganese (Mn) |

≤ 1.00% | Acts as a deoxidizer and improves hot working properties |

| Sulfur (S) |

≤ 0.03% | Enhances machinability (but can reduce corrosion resistance if excessive) |

| Iron (Fe) |

Balance | Main base element of the alloy |

| Nickel (Ni) |

≤ 0.20% | Provides toughness and enhances corrosion resistance |

| Silicon (Si) |

≤ 1.00% | Increases strength and oxidation resistance |

| Nitrogen (N) |

≤ 0.11% | Improves strength and pitting resistance |

This specific combination of elements makes 1.4116 stainless steel a versatile choice in CNC machining services, particularly where corrosion resistance and cutting-edge durability are required.

4116 stainless steel, also known as X50CrMoV15 or 1.4116, is a martensitic stainless steel recognized for its high corrosion resistance, excellent hardness, and good edge retention. It is especially popular in knife manufacturing, surgical instruments, and precision CNC machining parts due to its fine-grained microstructure and responsive heat treatment behavior. The balanced chemical composition, including carbon, chromium, molybdenum, and vanadium, enables this steel to deliver reliable performance across demanding applications.

4116 Stainless Steel: Mechanical Properties

The mechanical properties of 4116 stainless steel reflect its optimized balance between strength, toughness, and machinability. With suitable heat treatment, this steel achieves a high hardness level and wear resistance while maintaining reasonable ductility and toughness — ideal traits for CNC machining and high-precision components.

Here’s a detailed table summarizing its typical mechanical properties:

| Property |

Typical Value |

Description |

| Hardness (HRC) |

55–58 HRC | High hardness ensures edge retention and wear resistance |

| Hardness (HV) |

~540 HV | Vickers hardness – indicates surface strength |

| Hardness (HRC/HRB) |

~58 HRC / ~95 HRB | Indicates comparative Rockwell hardness scales |

| Tensile strength (MPa) |

750–950 MPa | High strength under tension after heat treatment |

| Elongation strength (Rp0.2/MPa) |

~450 MPa | Proof strength or yield strength at 0.2% offset |

| Ductility (%) |

~10–15% | Moderate ductility – sufficient for forming and shaping |

| Yield strength |

~450–500 MPa | Stress at which permanent deformation begins |

| Reduction of area (Z/%) |

~45% | Indicates plastic deformation before fracture |

| Heating temperature |

1040–1060°C (annealing), 1050–1100°C (quenching) | Optimal for hardening and softening processes |

| Elastic modulus (Young's modulus, GPa) |

~200 GPa | Reflects stiffness and resistance to elastic deformation |

| Elongation at break (%) |

~15% | Extent of stretch before breaking |

| Fatigue strength (MPa) |

~350 MPa | Resistance to cyclic stress failure |

| Poisson’s ratio |

~0.27–0.30 | Ratio of lateral strain to axial strain |

| Shear modulus (GPa) |

~80 GPa | Indicates ability to resist shear deformation |

| Shear strength (MPa) |

~550 MPa | Strength under shear loading conditions |

| Modulus of elasticity |

~200 GPa | Same as Young's modulus – reflects tensile stiffness |

These mechanical properties make 4116 stainless steel a highly suitable material for precision CNC machining, particularly where both corrosion resistance and edge durability are required.

4116 Stainless Steel: Physical Properties

4116 stainless steel offers a well-balanced profile of physical properties, making it suitable for a wide range of applications in kitchenware, medical tools, and precision CNC machining. Its physical characteristics—including good corrosion resistance, moderate density, and favorable thermal and magnetic properties—support both performance and manufacturability. These features, combined with good formability and machinability in the annealed state, enhance its appeal for CNC machining services and processing in stainless steel CNC machining factories.

Physical Properties of 4116 Stainless Steel

| Property |

Typical Value |

Description |

| Density |

~7.7 g/cm³ | Typical for martensitic stainless steels, affects weight and inertia |

| Melting point |

~1450 °C | Suitable for heat treatment, forging, and high-temperature applications |

| Thermal conductivity (W/m·K) |

~24 W/m·K | Moderate heat transfer capability |

| Resistivity (Ω·m) |

~0.60 × 10⁻⁶ Ω·m | Electrical resistivity typical for stainless steels |

| Thermal expansion |

Moderate | Expands with heat, suitable for precise dimensional tolerance machining |

| Linear thermal expansion coefficient (10⁻⁶/K) |

~10.5–11.5 × 10⁻⁶/K | Standard for stainless steels, important in thermal cycling applications |

| Corrosion resistance |

Good (especially in humid/wet environments) | Resists rust and oxidation due to high chromium and molybdenum content |

| Magnetic properties |

Magnetic (in hardened condition) | Martensitic structure is ferromagnetic |

| Formability |

Moderate | Can be cold-formed; best formed in annealed state |

| Machinability (annealing) |

Good | Machines well in the soft annealed state, ideal for CNC precision parts |

These physical properties make 4116 stainless steel a practical choice for applications that demand strength, hygiene, corrosion resistance, and precision—especially in environments where both appearance and performance matter.

4116 stainless steel is widely used in CNC machining due to its excellent balance of machinability, hardness, corrosion resistance, and surface finish quality. It is especially favored in industries such as kitchenware, medical devices, and precision instruments. The steel’s chemical composition and metallurgical behavior make it compatible with common CNC processes, including milling, turning, drilling, and grinding.

Key Impacts of 4116 Stainless Steel in CNC Machining

Good Machinability in Annealed State

Heat Treatable for Enhanced Performance

Superior Surface Finish

Corrosion Resistance Enhances Durability

Precision in Tight Tolerances

Tool Compatibility

Limitations to Consider

Conclusion

4116 stainless steel offers a great mix of machinability, hardness, corrosion resistance, and finishing capability—making it highly effective for CNC machining applications that demand hygiene, sharpness, and durability. For CNC machining factories aiming for efficient production and consistent quality, this material represents a cost-effective and high-performing solution.

Here's a clear and professional table summarizing the impact of 4116 stainless steel in CNC machining:

Impact of 4116 Stainless Steel in CNC Machining

| Aspect |

Impact/Performance |

| Machinability (annealed state) |

Good machinability with clean chip formation and minimal tool wear |

| Heat treatment |

Heat-treatable up to 55–58 HRC for improved hardness and wear resistance |

| Surface finish |

Excellent surface finish quality, suitable for aesthetic and hygienic applications |

| Corrosion resistance |

High resistance to rust and mild chemicals due to chromium and molybdenum content |

| Dimensional stability |

Maintains tight tolerances under CNC conditions |

| Tool compatibility |

Works well with carbide and coated HSS tools |

| Thermal conductivity |

Moderate—requires coolant for high-speed operations |

| Post-machining treatment |

Easily polished or passivated for improved finish and durability |

| Limitations |

Harder to machine in heat-treated state; not ideal for high-impact structural parts |

The CNC machining process for 4116 stainless steel is designed to leverage its moderate hardness, excellent corrosion resistance, and fine microstructure. It follows a series of precise, controlled steps to deliver accurate, high-quality stainless steel CNC machining parts.

The manufacturing process of CNC machined parts using 4116 stainless steel involves multiple precision-driven stages, ensuring durability, corrosion resistance, and tight dimensional control.

1. Material Selection & Preparation

2. CAD Modeling & CNC Programming

3. CNC Machining Operations

4. Heat Treatment (Optional)

5. Finishing & Surface Treatment

6. Quality Control & Inspection

7. Packaging & Delivery

Summary

The 4116 stainless steel CNC machining parts manufacturing process offers:

This process is ideal for cutlery, food-processing machinery, surgical tools, and other high-performance stainless steel applications. VMT’s CNC machining services ensure consistent, reliable part production from prototype to mass manufacturing.

Heat treatment is essential to enhancing the mechanical performance of 4116 stainless steel, particularly its hardness, toughness, and corrosion resistance. This process tailors the steel’s microstructure to meet demanding CNC machining and end-use requirements.

1. Annealing

2. Hardening

Purpose: Increases hardness and wear resistance.

Process:

Result: Hardness up to 55–58 HRC, ideal for knives, surgical instruments, and wear-resistant parts.

3. Tempering

Purpose: Reduces brittleness from hardening while maintaining high hardness.

Process:

Result: Balanced toughness and strength, better resistance to cracking or failure under stress.

4. Stress Relieving (Optional)

Heat Treatment Summary Table

| Heat Treatment Process |

Temperature (°C) |

Cooling Method |

Purpose |

Result |

| Annealing |

750–800 | Air or furnace slow cool | Improve machinability | Softer, ductile structure |

| Hardening |

1050–1080 | Oil or air quench | Maximize hardness | 55–58 HRC possible |

| Tempering |

180–200 | Still air | Reduce brittleness, improve toughness | Tough, wear-resistant |

| Stress Relieving |

600–650 | Air cool | Minimize internal stress | Better stability for CNC parts |

Key Notes for CNC Machining

Using optimized heat treatment processes ensures that 4116 stainless steel CNC machining parts deliver high performance in cutting, hygienic, and corrosive environments.

1.4116 stainless steel (X50CrMoV15) is a martensitic stainless steel known for its balance of hardness, corrosion resistance, and edge retention. Its manufacturing process involves several metallurgical stages to enhance purity and mechanical performance—crucial for CNC machining and industrial applications.

Main Manufacturing Steps

| Stage |

Description |

Purpose |

| 1. Melting |

Raw materials (iron, chromium, carbon, molybdenum, vanadium, etc.) are melted in an electric arc furnace (EAF). | Produces molten steel with targeted alloy composition. |

| 2. Secondary Refining |

The molten metal undergoes Argon Oxygen Decarburization (AOD) or Vacuum Oxygen Decarburization (VOD). | Reduces carbon and unwanted elements (S, P), improves cleanliness and corrosion resistance. |

| 3. Casting |

Steel is cast into billets or ingots via continuous or ingot casting methods. | Forms solid shapes for downstream processing. |

| 4. Hot Rolling |

Billets are hot rolled into plates, sheets, rods, or bars at high temperatures (~1100 °C). | Reduces thickness, refines grain structure. |

| 5. Heat Treatment |

Material undergoes annealing, hardening, and tempering based on final use. | Enhances hardness, strength, and toughness. |

| 6. Pickling & Descaling |

Surface oxides are removed using acid treatment. | Improves surface finish and corrosion resistance. |

| 7. Cold Working (Optional) |

Further shaping through cold drawing or rolling. | Increases strength and dimensional precision. |

| 8. Final Inspection & Testing |

Mechanical, chemical, and ultrasonic tests ensure compliance with standards (DIN, EN, ASTM). | Guarantees quality, machinability, and performance for end-use. |

Key Features of the Manufacturing Process

4116 stainless steel (also known as X50CrMoV15) is a high-carbon, martensitic stainless steel with good corrosion resistance, excellent hardness, and high wear resistance. Its balanced properties make it ideal for applications requiring sharpness, durability, and hygiene.

Common Uses of 4116 Stainless Steel

| Application Area |

Specific Uses |

| Cutlery Industry |

- Kitchen knives (chefs, paring, utility) - Butcher knives - Pocket knives |

| Medical and Surgical |

- Surgical blades - Scalpels - Dental instruments |

| Food Processing |

- Meat cleavers - Food-grade processing blades - Ice cream scoops |

| Personal Care Products |

- Razor blades - Scissors - Manicure/pedicure tools |

| Outdoor and Tactical |

- Survival knives - Hunting blades - Folding knives |

| Machined Components |

- Wear-resistant parts - Precision CNC machined parts - Corrosion-resistant shafts and pins |

Why It's Used in These Applications

| Aspect |

4116 Stainless Steel |

440C Stainless Steel |

| Raw Material Price |

Moderate | Higher |

| Machining Cost |

Lower – Easier to machine in annealed state | Higher – Harder, more tool wear |

| Heat Treatment Cost |

Standard (up to ~56 HRC) | Higher (up to ~60 HRC or more) |

| Tool Wear & Replacement |

Less frequent – better machinability | More frequent – aggressive on tools |

| Overall Processing Cost |

More economical for general parts | Costlier due to higher hardness and tool demands |

| Market Price (per kg) |

~$2.50–$3.50 (varies by region and form) | ~$4.00–$6.50 (depends on supplier and condition) |

Summary

| Country/Standard |

Equivalent Grade / Code |

Remarks |

| Germany (DIN) |

X50CrMoV15 (1.4116) | Common kitchen knife steel in Europe; high corrosion resistance |

| USA (AISI/ASTM) |

AISI 420 modified / Not standardized | Closest match is AISI 420 with added Mo and V for better hardness and wear |

| China (GB) |

GB/T 20878-2007 – Similar to 4Cr13MoV | Often classified as 4Cr13 with Mo and V alloying additions |

| Japan (JIS) |

SUS420J2 (modified) | Not a perfect match, but SUS420J2 is similar in hardness and usage |

| ISO (International) |

ISO 4957 X50CrMoV15 | Standardized tool and cutlery steel grade |

| France (AFNOR) |

Z50CDV15 | Used in cutlery and surgical instruments |

| UK (BS) |

BS 970 – Similar to 420 mod. | Not formally defined, but comparable to modified 420 types |

Summary

1.4116 Stainless Steel: Specifications and Equivalent Grades

| Item |

Details |

| Steel Name |

1.4116 stainless steel |

| Standard |

DIN EN 10088 (Germany) |

| Material Number (W-Nr.) |

1.4116 |

| EN Designation |

X50CrMoV15 |

| AISI Equivalent |

Modified AISI 420 (not officially standardized by AISI) |

| ISO Equivalent |

X50CrMoV15 (ISO 4957) |

| JIS Equivalent |

Similar to SUS420J2 (modified) |

| GB (China) |

Comparable to 4Cr13MoV |

| AFNOR (France) |

Z50CDV15 |

| BS (UK) |

Comparable to BS 420 series (modified), not formally standardized |

| Main Applications |

Kitchen knives, surgical instruments, scissors, tools, CNC precision parts |

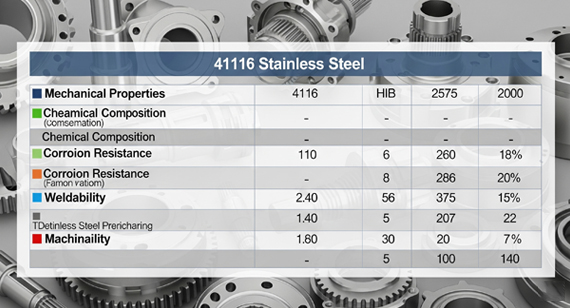

| Property | 1.4116 | D2 | 440C | 7Cr17MoV | AUS-8 |

| Type | Martensitic SS | Tool Steel (Semi-stainless) | High Carbon Martensitic SS | Martensitic SS (Chinese grade) | Austenitic Stainless Steel |

| Hardness (HRC) | Up to 56–58 | Up to 60–62 | Up to 58–60 | Up to 56–58 | Up to 57–59 |

| Corrosion Resistance | High (good for kitchen/surgical) | Moderate (prone to corrosion) | Moderate–High | High | High |

| Edge Retention | Moderate | Excellent | Excellent | Moderate | Moderate |

| Toughness | Good | Low–Moderate | Moderate | Good | Good |

| Ease of Sharpening | Easy | Difficult | Moderate | Easy | Easy |

| Machinability | Good (annealed state) | Poor (hard to machine) | Moderate (tough on tools) | Good (cost-effective) | Good |

| Main Use | Knives, surgical tools, CNC parts | Industrial cutting tools | High-end knives, bearings | Mid-range knives, budget tools | Kitchen knives, budget EDC knives |

| Cost | Moderate | Higher | Higher | Lower | Moderate |

Notes:

While 4116 stainless steel is a popular choice for knives and medical tools due to its balance of corrosion resistance, edge retention, and affordability, it’s not the only option. Depending on your application—whether it’s high-end culinary tools, outdoor blades, or industrial components—there are other stainless and tool steels that may better meet your performance or budget needs. Let’s explore several excellent alternatives to 4116 stainless steel.

1. 440C Stainless Steel

Why consider it:

If you're looking for an upgrade from 4116 in terms of hardness and edge retention, 440C is a standout choice.

Best used for: High-end knives, surgical tools, and industrial cutting components.

2. AUS-8 Stainless Steel

Why consider it:

AUS-8 offers a great balance of toughness, corrosion resistance, and affordability—similar to 4116 but with slightly improved edge retention.

Best used for: General-purpose knives, folding knives, and mass-produced culinary tools.

3. 5Cr15MoV Stainless Steel

Why consider it:

This Chinese stainless steel is very similar to 4116 in composition and performance, making it a cost-effective substitute.

Best used for: Entry-level kitchen knives, low-cost utility blades, and cosmetic parts.

4. D2 Tool Steel

Why consider it:

D2 is a semi-stainless tool steel that offers exceptional hardness and wear resistance, though it sacrifices some corrosion resistance.

Best used for: Outdoor knives, survival tools, and cutting applications where edge longevity is key.

Conclusion: Choose the Right Steel for Your Needs

4116 stainless steel is a reliable mid-range material, but your ideal alternative depends on the specific balance of hardness, corrosion resistance, edge retention, and price. Whether you're designing a commercial-grade knife line or sourcing materials for CNC-machined parts, evaluating these alternatives—440C, AUS-8, 5Cr15MoV, and D2—can help you tailor your product for performance and customer satisfaction.

If you need help selecting the right stainless steel for your CNC project or knife application, VMT offers expert material consultation and precision machining for both stainless and tool steels.

When choosing a knife—whether for culinary use, outdoor adventures, or everyday tasks—the blade material is a major factor in performance and longevity. One popular option is 4116 stainless steel, a high-quality German-made steel known for its balance of edge retention, corrosion resistance, and affordability. But is it good for knives? Let’s explore.

What Makes 4116 Stainless Steel Suitable for Knives?

1. Excellent Corrosion Resistance

4116 stainless steel contains around 15-16% chromium, which provides strong resistance to rust and staining. This makes it a great choice for kitchen knives, medical tools, and marine environments where moisture is a constant factor.

2. Easy to Sharpen

Unlike harder, more brittle steels, 4116 is relatively easy to hone and maintain. Even casual users can sharpen it with basic tools—ideal for chefs or outdoor users who value low-maintenance blades.

3. Balanced Hardness

With a Rockwell hardness typically around 56 HRC, 4116 strikes a balance between toughness and edge retention. It holds a decent edge without becoming brittle, making it less likely to chip or snap under pressure.

4. Affordability

Compared to premium steels like VG-10 or S30V, 4116 is cost-effective while still offering solid all-around performance. It’s often used in mid-range knives that need reliable quality at a reasonable price.

When is 4116 the Right Choice for a Knife?

4116 stainless steel is ideal if you’re looking for:

Conclusion: A Smart Choice for Everyday Use

Yes, 4116 stainless steel is a good choice for knives, especially when you need durability, rust resistance, and easy maintenance without a premium price tag. While it may not compete with high-end steels in edge retention or exotic toughness, it offers excellent value and reliability—which is why it's widely used in German kitchen knives, scalpels, and field tools.

If you’re sourcing materials or looking to manufacture knife blades, VMT offers precision CNC machining services for 4116 stainless steel and many other grades tailored to your application needs.

When it comes to selecting materials for precision components, cutting tools, or medical instruments, choosing the right stainless steel grade can directly impact your product’s performance, cost, and durability. One popular option is 1.4116 stainless steel, a German-engineered, martensitic stainless steel known for its versatility, corrosion resistance, and ease of fabrication. But is it right for your project?

Let’s break it down from the perspective of functionality, application, and value.

Key Benefits of 1.4116 Stainless Steel

With a chromium content of ~15%, 1.4116 performs well in humid, acidic, or saline environments—ideal for kitchenware, medical tools, and marine applications.

This steel maintains a sharp edge while still being easy to re-sharpen—making it a top choice for knives, scalpels, and precision cutting tools.

With a balanced hardness range (typically 55–57 HRC), 1.4116 offers a good blend of strength and resistance to wear, without becoming too brittle.

Its fine grain structure and smooth finish make it perfect for sterile environments, such as food processing or surgical settings.

1.4116 responds well to CNC machining, grinding, and polishing—ideal for manufacturers requiring tight tolerances and consistent quality.

When to Use 1.4116 Stainless Steel

You should consider 1.4116 if your project requires:

When to Consider Alternatives

If your project demands higher hardness, extreme temperature resistance, or superior wear resistance, you may want to explore:

Conclusion: A Practical, Balanced Stainless Steel

1.4116 stainless steel is a smart choice for a wide range of applications—especially where sharpness, hygiene, and corrosion resistance matter most. Whether you're producing kitchen tools, surgical instruments, or custom CNC machined parts, it offers great value with dependable performance.

At VMT, we specialize in CNC machining services for stainless steel materials, including 1.4116, offering tight tolerance control, mirror-polish finishing, and fast turnaround times.

Need help deciding? Contact our engineering team for material selection and custom machining advice tailored to your industry.

Looking for a reliable partner to bring your stainless steel parts from concept to completion?

VMT Metal Products Co., Ltd. offers ISO-certified, high-precision stainless steel CNC machining services, designed to meet the toughest industrial demands with speed, quality, and cost-efficiency.

Why Choose VMT for Stainless Steel CNC Machining?

Serving Key Industries

Popular Stainless Steel Grades We Machine

| Stainless Steel Grade |

Common Applications |

Features |

| 304/304L |

General parts, enclosures | Excellent corrosion resistance |

| 316/316L |

Marine, food-grade, medical | Chloride-resistant, hygienic |

| 17-4PH |

Aerospace, defense | High strength & hardness |

| 410 / 420 / 440C |

Knife blades, valves | Wear resistance, high hardness |

| 1.4116 / 5Cr15MoV |

Cutlery, surgical tools | Sharpness, polishability |

Partner with VMT — Your Trusted Stainless Steel Machining Supplier

At VMT, we don’t just make parts—we deliver precision-engineered solutions to help your business grow. Whether you're working on a custom component or a large-scale production run, our expert team is here to support your goals from start to finish.

Conclusion: Your Reliable Partner for Stainless Steel CNC Machining

Choosing the right stainless steel CNC machining service provider can significantly impact your product's performance, durability, and overall success. At VMT, we combine cutting-edge technology, engineering expertise, and strict quality control to deliver high-precision stainless steel parts that meet the demands of various high-performance industries.

Whether you're developing complex medical components, marine-grade fittings, or high-strength aerospace parts, VMT ensures each part is manufactured with precision, consistency, and care. From prototype to mass production, we offer fast lead times, flexible volumes, and competitive pricing.

Let VMT be the trusted manufacturing partner that helps you turn your designs into reality—with unmatched quality and reliability.

4116 stainless steel stands out as a versatile, cost-effective material offering a balanced combination of corrosion resistance, hardness, and excellent machinability. Its suitability for producing precision CNC machining parts makes it a popular choice across industries such as cutlery, medical instruments, and food processing. When compared to other steels like D2, 440C, 7Cr17MoV, and AUS-8, 4116 offers better corrosion resistance and ease of machining, though it may have slightly lower wear resistance and edge retention than some tool steels.

Understanding these differences allows manufacturers and engineers to select the most appropriate steel grade for their specific applications, balancing performance, cost, and machinability. For projects demanding reliable stainless steel CNC machining parts with solid mechanical properties and cost efficiency, 4116 stainless steel remains a strong candidate. VMT’s CNC machining services ensure that customers receive high-quality, precision parts tailored to these material advantages.

Choosing the right steel grade ultimately depends on the specific functional requirements and budget considerations of the project. Whether for knives, surgical instruments, or industrial components, the insights provided help guide informed decisions and optimize manufacturing outcomes.

Is 1.4116 stainless steel good for knives?

Yes. 1.4116 stainless steel is widely used in German kitchen knives due to its high corrosion resistance, decent edge retention, and easy sharpenability. It's an excellent balance between performance and cost for everyday culinary applications.

What is 1.4116 steel equivalent to?

1.4116 is similar to AISI 420MoV or X50CrMoV15, commonly found in European and German knives. It’s a mid-range stainless steel known for being tough, rust-resistant, and budget-friendly.

What is the difference between 440C and 1.4116 steel?

Choose 440C for outdoor and tactical knives, and 1.4116 for kitchen and food-grade applications.

What is the difference between D2 and 1.4116 steel?

What is the hardest knife steel?

Premium steels like CPM-S110V, M390, and ZDP-189 are among the hardest, with Rockwell hardness (HRC) ratings above 60. However, harder isn’t always better, as it can make knives more brittle and harder to sharpen.

Is D2 steel good for pocket knives?

Yes. D2 steel offers excellent edge retention and toughness, making it popular for EDC (Everyday Carry) knives. However, it’s semi-stainless, so regular maintenance is recommended to prevent rust.

What is the best grade of stainless steel for making knives?

For stainless blades, VG-10, M390, S35VN, and 440C are highly regarded. For kitchen use, 1.4116 and X50CrMoV15 are top choices due to their balance of corrosion resistance and sharpenability.

What are the disadvantages of stainless steel knives?

Is Japanese steel or German steel better for making knives?

It depends on your needs:

Is 440 steel better than D2 steel?

Choose 440C for kitchen or marine use, D2 for tactical or heavy-use knives.

What is the best grade of steel for hunting knives?

Top choices include:

What is the difference between 4140 steel and D2 steel?

Which steel is better, D2 or 14C28N?

For EDC or kitchen use, 14C28N is often preferred. For heavy-duty cutting, D2 stands out.

Is D2 steel better than S30V?

S30V is generally considered superior—it offers better corrosion resistance, sharpenability, and toughness, making it a premium option for high-performance knives.

Which is better, 420 steel or 440 steel?

Is M390 steel better than D2?

Yes. M390 offers superior edge retention, corrosion resistance, and hardness, making it a premium steel choice for high-end knives.

Is D2 better than VG10?

Your choice depends on use-case and maintenance preference.

What type of stainless steel is best for making knives?

Top stainless steels include: