15 years one-stop China custom CNC machining parts factory

The VMT blog is dedicated to sharing our hard-earned knowledge in prototype manufacturing. We hope these articles will help you optimize your product designs and gain deeper insight into the world of rapid prototyping. Enjoy the read!

Get an Instant Quote VMT

VMT  2024 08 18

2024 08 18 In the field of CNC machining and parts manufacturing, roughing and finishing are two critical stages that together determine the final quality and performance of a part. Roughing focuses on quickly removing excess material to set the stage for finishing, which aims to enhance the dimensional accuracy, surface quality, and overall performance of the part. This article will delve into the differences between roughing and finishing and provide a CNC machining guide to help experts and practitioners improve manufacturing efficiency and product quality.

66

66

Read more

Read more

VMT

VMT  2024 08 17

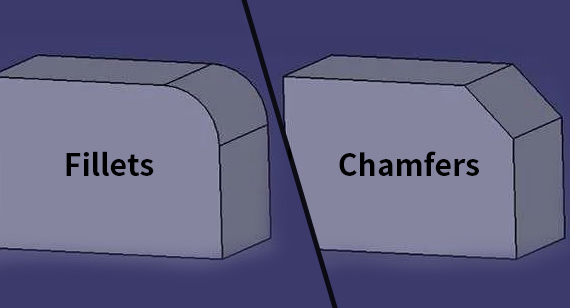

2024 08 17 In CNC machining, fillets and chamfers are common edge treatments that significantly impact product performance, appearance, safety, and machining efficiency. This article aims to provide an in-depth analysis of fillets and chamfers, covering their definitions, design, uses, differences, and implementation methods in AutoCAD. It will help engineers and designers make more informed decisions in CNC machining processes.

66

66

Read more

Read more

VMT

VMT  2024 08 16

2024 08 16 Stainless steel passivation is a crucial surface treatment technique designed to enhance the corrosion resistance of stainless steel parts, extend their service life, and improve surface finish and aesthetics. This article provides a comprehensive overview of stainless steel passivation, covering the fundamental concepts, necessity, functions, process steps, testing methods, precautions, industry standards, equipment characteristics, practical tips, and frequently asked questions. It serves as an extensive guide for professionals in the CNC machining parts manufacturing field.

66

66

Read more

Read more

VMT

VMT  2024 08 15

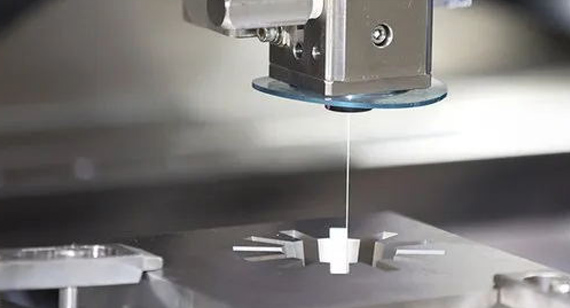

2024 08 15 Wire Electrical Discharge Machining (WEDM) is a high-precision, non-contact metal machining technique that uses electrical sparks to generate high temperatures to erode metal materials, enabling the processing of complex shapes and contours. This article will delve into the working principle of WEDM, machine components, applicable materials, precision characteristics, advantages and disadvantages, differences from traditional EDM, application areas, and frequently asked questions, providing readers with a comprehensive and in-depth understanding.

66

66

Read more

Read more

VMT

VMT  2024 08 14

2024 08 14 When it comes to CNC machining and manufacturing, selecting the right type of steel is crucial to ensuring product performance, durability, and cost-effectiveness. 1045 steel and 4140 steel are two commonly used materials, each with unique chemical compositions, mechanical properties, and ideal use cases. This guide aims to provide a thorough understanding of these two types of steel, helping readers make informed decisions based on their project requirements.

66

66

Read more

Read more

VMT

VMT  2024 08 13

2024 08 13 In the field of CNC machining and parts manufacturing, selecting the right steel material is crucial. Among the commonly used alloy steels, 4140 and 8620 each have distinct chemical compositions, physical properties, and applications. This article provides a detailed comparison of 4140 and 8620 steels, analyzing them from the perspectives of chemical composition, mechanical properties, machinability, heat treatment, and applications. This guide aims to serve engineers, designers, and material procurement professionals with a comprehensive reference.

66

66

Read more

Read more

VMT

VMT  2024 08 12

2024 08 12 The brushed metal surface treatment process involves using mechanical or chemical methods to create fine and uniform textures on the metal surface, imparting a unique tactile and visual effect to the material. This article aims to provide a comprehensive introduction to the brushed surface process, including its definition, operation procedures, influencing factors, applicable materials, common types, comparisons with other surface treatments, areas of application, advantages and disadvantages, and techniques for achieving a uniform brushed finish. Finally, the article discusses VMT CNC machining parts surface treatment services and common FAQs.

66

66

Read more

Read more

VMT

VMT  2024 08 11

2024 08 11 Heat treatment of metals is an indispensable part of metal processing. It involves a series of techniques, including heating, holding, and cooling, to alter the internal structure of metallic materials and adjust their physical, chemical, and mechanical properties. This process not only enhances material strength, hardness, and toughness but also improves special properties like corrosion resistance, wear resistance, and heat resistance, providing a solid foundation for high-quality manufacturing of CNC-machined parts. Heat treatment technology is widely used in aerospace, automotive manufacturing, mechanical engineering, energy, chemical processing, and many other fields, making it a critical pillar of modern industrial development.

66

66

Read more

Read more

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!