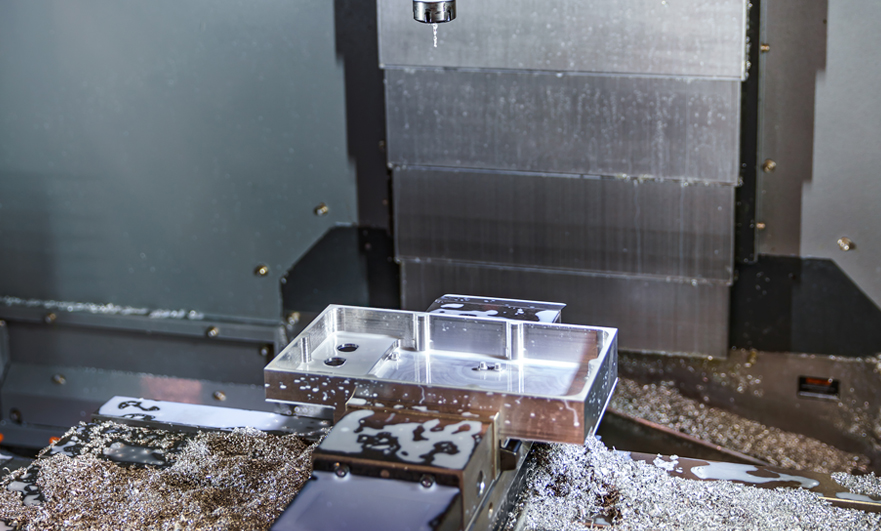

15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

150 |

Published by VMT at Oct 28 2021

150 |

Published by VMT at Oct 28 2021

Aluminum shell parts are common non-ferrous metal products in daily life, and they are also widely used in industrial applications. It is widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding and chemical industries, especially as a shell. The application of extruded aluminum in electronics manufacturing is on the rise, thanks to its perfect combination of durability, cost-effectiveness and aesthetics.

Characteristics of aluminum

The density of aluminum is very small, only 2.7g/cm. Although it is relatively soft, it can be made into various aluminum alloys, such as duralumin, super-duralumin, rust-proof aluminum, cast aluminum, etc. Due to its unique combination of characteristics, Makes it an ideal material choice. Metal shells, the shells of household electrical equipment, such as Bluetooth charger bases, aluminum Bluetooth headset charger shells, etc., have a large part of metal materials made of aluminum. Aluminum alloy is a good heat conductor, and its thermal conductivity can be three times that of iron. Aluminum is commonly used in the industry to manufacture various heat exchangers, heat dissipation materials and cooking utensils to maximize heat dissipation performance.

Some of its most desirable features include:

1. Aluminum is very light, but relatively durable.

2. Beautiful and charming, and accept a variety of common modifications of appearance.

3. Better corrosion resistance than other ordinary metals (such as mild steel).

4. Non-magnetic, with good insulation.

5. Non-flammable and heat-resistant

Provide natural RFI and EMI shielding and anti-interference

The machining and manufacturing of custom aluminum housing parts usually takes the role of durability and protection. So this kind of metal is especially suitable for making all kinds of shells. Let's talk about its specific applications below.

Audio equipment

As long as it is a high-performance audio hardware, the protective shell it uses is basically an aluminum extrusion shell, because it can play a very good protective role and is often used to protect some important equipment. From direct injection boxes to stereo receivers to rack-mounted audio effects, these custom aluminum processing enclosures are favored by many professionals and enthusiasts.

hard disk

Hard drives usually protect our personal important data, so it needs long-lasting protection, not only to prevent daily drops and bumps, but also to pay attention to water and high temperature damage. At the same time, they are often used in professional settings and need an elegant, low-key appearance. . Custom aluminum processing shells meet all these needs.

medical instruments

If you look closely, you will find that most medical devices are made of aluminum shells, whether they are used to monitor patient vital signs or other important data, these devices are encapsulated in extruded aluminum shells. That's because due to its electromagnetic shielding characteristics, which helps protect medical equipment from potentially dangerous RFI and EMI interference. At the same time, because of its high corrosion resistance and cleaning characteristics, aluminum has led to its important position in the application of medical equipment.

Machinery Control Group

In industrial machinery, the control panel of the machine is a shell that requires precision and high performance. It needs to be able to resist dust, water, heat and other hazards, which is the key to ensuring the safe and effective operation of the equipment.

Junction Box

The junction box is used in outdoor scenes, so it needs to be extremely dustproof and waterproof, so the extruded aluminum enclosure can also be used as a junction box to protect our electrical infrastructure. The IP 66 rated design is critical to protect sensitive electrical components and keep power flowing.

new technology

As technological innovation continues to shape the business and scientific environment of the 21st century, we will need enclosures that meet the performance indicators required for the application of new technologies. Extruded aluminum enclosures have versatility, durability and style, making them perfect for breakthrough technologies and ensuring that they will maintain the relevant technological landscape for years to come.

VMT has provided customers with 9582 custom aluminum parts shell machining and manufacturing, from design drawings, production machining and manufacturing, quality inspection, surface treatment, product assembly to packaging and transportation. To provide you with the best solutions and timely feedback, and to provide competitive prices on the basis of the best customized aluminum parts processing services, do you have custom CNC machining parts projects? VMT can help you at any time.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!