15 years one-stop China custom CNC machining parts factory

285 |

Published by VMT at Jun 11 2025 | Reading Time:About 10 minutes

285 |

Published by VMT at Jun 11 2025 | Reading Time:About 10 minutes

Choosing the right material for a project can feel overwhelming, especially when it comes to high-performance metals like aluminum and titanium. You might be struggling to balance strength, weight, cost, and corrosion resistance—only to be met with conflicting data and vague recommendations. The wrong choice could increase manufacturing costs, cause premature failure, or even put your product’s reputation at risk.

But there's a solution. By comparing aluminum vs. titanium side-by-side across mechanical, thermal, and chemical properties, you can make an informed, strategic decision that meets your application’s unique needs. In this article, we break down everything you need to know—from composition and conductivity to machining, cost, and industry-specific applications—to help you choose with confidence.

Aluminum is best for lightweight, cost-sensitive applications with high conductivity needs, while titanium excels in high-stress, corrosion-prone environments where strength and durability are critical. Choosing between aluminum vs. titanium depends on project-specific priorities like mechanical load, machining ease, and budget.

Still unsure which metal is the better fit for your project? Don’t worry—this in-depth guide will walk you through all the essential comparisons, from elemental composition and strength to cost, corrosion resistance, and machining performance. Plus, you’ll discover real-world use cases and the best CNC machining services to support your decision. Let’s dive in.

When choosing between aluminum and titanium for CNC machining parts, understanding their fundamental material properties is crucial. These two metals differ significantly in strength, weight, conductivity, corrosion resistance, and workability, making them ideal for different use cases. Aluminum is renowned for being lightweight, highly conductive, and cost-efficient, while titanium is prized for its superior strength, biocompatibility, and performance in harsh environments. Whether you're sourcing components for aerospace, medical, or industrial applications, comparing these physical and mechanical characteristics helps determine the best fit for your design, function, and cost priorities.

In this section, we’ll break down the key properties that influence material selection in CNC machining services—especially within industries that demand precision, durability, and efficiency. By the end of this comparison, you’ll better understand how aluminum CNC machining parts and titanium CNC machining parts perform under stress, heat, and corrosive conditions, and why choosing the right metal is essential for quality manufacturing.

Aluminum vs. Titanium: Elemental Composition

The elemental makeup of a metal directly influences its mechanical behavior, corrosion resistance, and thermal performance. Both aluminum and titanium are often alloyed with other elements to enhance their properties for specific industrial applications. Understanding the alloying elements commonly found in these metals helps engineers and product designers select the right material for CNC machining factories and parts production. Below, we explore the key elements that appear in aluminum and titanium alloys, and how each contributes to their behavior in demanding environments.

Aluminum Alloys

Aluminum alloys are lightweight and versatile, often enhanced with small amounts of additional elements to boost strength, corrosion resistance, and machinability. The most common alloying elements include:

Zirconium

Zirconium is added to aluminum to improve recrystallization resistance and mechanical stability at high temperatures. It enhances fatigue strength, especially in aerospace-grade alloys, and helps maintain structural integrity during welding.

Zinc

Zinc significantly increases the strength of aluminum alloys, especially in the 7xxx series (e.g., 7075). However, it may reduce corrosion resistance, requiring surface treatments in marine or humid environments.

Chromium

Chromium contributes to corrosion resistance and strength, especially in combination with other alloying elements. It’s often used in 5xxx series aluminum for marine applications due to its resistance to stress-corrosion cracking.

Silicon

Silicon lowers the melting point of aluminum and improves its castability and wear resistance. Alloys containing silicon, such as 6061, are widely used in CNC machining services for parts requiring precision and formability.

Magnesium

Magnesium enhances strength and corrosion resistance. It’s a principal element in 5xxx and 6xxx series aluminum alloys and offers good weldability, which is ideal for structural components in transportation and architecture.

Titanium

Small amounts of titanium are sometimes added to aluminum alloys to refine grain structure and increase strength without a significant weight penalty.

Manganese

Manganese improves corrosion resistance and tensile strength, commonly found in 3xxx series alloys. It also helps maintain uniform grain structure, which improves forming and drawing performance.

Iron

Iron is usually present as an impurity but can enhance wear resistance in cast alloys. In excessive amounts, it may negatively affect ductility and corrosion resistance.

Copper

Copper increases strength and hardness, especially in 2xxx series aluminum (e.g., 2024), but reduces corrosion resistance. These alloys are often used in aerospace and military CNC machining parts due to their high fatigue resistance.

Certainly! Here's a professional and easy-to-read comparison table summarizing the elemental composition of aluminum and titanium alloys—including each element, its role, and which base metal it is commonly alloyed with.

Table: Common Alloying Elements in Aluminum vs. Titanium Alloys

|

Element |

Used In |

Purpose / Effect |

| Zirconium (Zr) |

Aluminum | Enhances grain refinement, improves fatigue strength, and stabilizes microstructure. |

| Zinc (Zn) |

Aluminum | Boosts strength in heat-treatable alloys (e.g., 7075), reduces corrosion resistance. |

| Chromium (Cr) |

Aluminum | Improves corrosion resistance, prevents stress corrosion cracking. |

| Silicon (Si) |

Aluminum | Improves castability and wear resistance, lowers melting point. |

| Magnesium (Mg) |

Aluminum | Increases strength and corrosion resistance, enhances weldability. |

| Titanium (Ti) |

Aluminum (trace) | Refines grain size, increases strength without adding weight. |

| Manganese (Mn) |

Aluminum | Improves corrosion resistance and tensile strength, stabilizes grain structure. |

| Iron (Fe) |

Aluminum (impurity) | Improves wear resistance; in excess, can reduce ductility and corrosion resistance. |

| Copper (Cu) |

Aluminum | Raises strength and hardness; lowers corrosion resistance. |

| Oxygen (O) |

Titanium | Naturally present; strengthens the alloy, but excessive amounts may reduce ductility. |

| Nickel (Ni) |

Titanium | Improves corrosion and heat resistance in high-performance alloys. |

| Nitrogen (N) |

Titanium | Increases strength and creep resistance at elevated temperatures. |

| Iron (Fe) |

Titanium | Increases strength but can impair ductility and corrosion resistance. |

| Carbon (C) |

Titanium | Slightly raises strength; excessive carbon can make titanium brittle. |

| Hydrogen (H) |

Titanium | Must be minimized; hydrogen embrittlement is a concern in titanium processing. |

This table offers a concise yet informative view of how alloying elements affect the performance of aluminum CNC machining parts and titanium CNC machining parts.

Titanium Alloys: Elemental Composition

Titanium is a high-performance metal widely used in CNC machining services due to its exceptional strength, corrosion resistance, and biocompatibility. Unlike aluminum, which is alloyed with many elements for performance versatility, titanium alloys typically include fewer but highly impactful elements. These additives enhance titanium’s already impressive mechanical properties, making it suitable for aerospace, medical, military, and industrial CNC machining parts.

The two primary categories of titanium alloys are commercially pure titanium (CP-Ti) and titanium alloys (usually with aluminum, vanadium, or other elements). While CP-Ti emphasizes corrosion resistance and ductility, titanium alloys are engineered for strength and stress resistance. Regardless of the grade, the trace elements listed below play a vital role in defining each alloy’s structural, chemical, and thermal behavior.

Table: Alloying Elements in Titanium and Their Functions

| Element |

Purpose in Titanium Alloys |

| Oxygen (O) |

Strengthens titanium significantly; present as a natural interstitial element. Excess can reduce ductility. |

| Nickel (Ni) |

Improves corrosion resistance and heat tolerance; often added in high-temperature titanium alloys. |

| Nitrogen (N) |

Enhances tensile and creep strength, especially in elevated temperatures. |

| Iron (Fe) |

Boosts strength and hardness, but too much can impair ductility and corrosion resistance. |

| Carbon (C) |

Slightly improves strength and wear resistance; high levels make titanium brittle. |

| Hydrogen (H) |

Typically undesirable; absorbed hydrogen can cause embrittlement, leading to reduced performance and cracking. |

Together, these alloying elements make titanium CNC machining parts ideal for extreme applications where weight savings, biocompatibility, and corrosion resistance are essential. Next, we’ll compare electrical and thermal conductivity between aluminum and titanium—critical factors for engineers designing heat-sensitive or power-distribution components.

Electrical conductivity is a vital factor in material selection for components that must carry current, shield against electromagnetic interference, or dissipate static charge. In CNC machining services, electrical conductivity not only influences the material’s end-use applications but also affects its behavior during certain fabrication processes like electrical discharge machining (EDM). When comparing aluminum vs. titanium, the difference in conductivity is stark—and understanding this can help you avoid costly mismatches between material and application.

Aluminum: Exceptional Electrical Conductor

Aluminum is renowned for its excellent electrical conductivity. In fact, it ranks second only to copper among common industrial metals. Pure aluminum offers conductivity around 61% of the International Annealed Copper Standard (IACS). Its high conductivity, coupled with low density, makes it a go-to material for power transmission lines, electronics, and heat sinks. Even when alloyed, aluminum retains a respectable level of conductivity, which is why aluminum CNC machining parts are often found in electrical enclosures, automotive wiring systems, and consumer electronics housings.

The lightweight nature of aluminum also allows for longer spans and reduced structural support in applications like overhead cables and heat dissipation components. For projects where weight and conductivity must be balanced, aluminum is typically the most efficient and cost-effective solution.

Titanium: Poor Electrical Conductor

In contrast, titanium is a poor conductor of electricity. Its electrical conductivity is only about 3% of IACS, making it significantly less conductive than aluminum. This limitation rules it out for most electrical and electronic applications. However, in industries where low conductivity is a benefit, such as in electrochemical and insulation-related components, titanium can offer advantages—especially due to its excellent corrosion resistance and high strength.

Despite its low conductivity, titanium CNC machining parts are sometimes used in electrical systems where structural performance and corrosion resistance are more important than current flow, such as in housings for subsea or aerospace electronics that are externally grounded or isolated.

Conclusion: Conductivity Comparison

If your project requires high electrical performance, aluminum is the clear choice. Its superior conductivity, affordability, and availability make it the ideal material for electrical components. Titanium, while excellent in other respects, should only be used when conductivity is not a critical factor.

Thermal conductivity—the ability of a material to transfer heat—is a critical property when designing components for heat dissipation, insulation, or thermal control. In CNC machining services, thermal behavior directly impacts material selection for electronics, engine parts, aerospace structures, and other high-performance systems. Comparing aluminum vs. titanium, there’s a significant difference in how each metal handles heat. Understanding this can help you optimize your design for thermal efficiency and safety.

Aluminum: Highly Thermally Conductive

Aluminum is well known for its excellent thermal conductivity, making it a top choice for heat-sensitive applications. Pure aluminum boasts thermal conductivity values around 235 W/m·K, which is only second to copper among commonly used metals. Even when alloyed for strength or machinability, aluminum retains impressive thermal performance.

This characteristic makes aluminum CNC machining parts ideal for components such as:

Its ability to rapidly dissipate heat improves performance, enhances safety, and extends the life of electrical and mechanical systems. For this reason, aluminum is a staple in industries ranging from electronics to automotive to aerospace—especially where efficient heat transfer is a priority.

Titanium: Poor Thermal Conductor

Titanium, while excellent in strength and corrosion resistance, is a poor thermal conductor. Its thermal conductivity is approximately 21.9 W/m·K, which is nearly 90% lower than aluminum. This low conductivity limits titanium’s use in applications where rapid heat transfer is necessary.

However, in some cases, titanium’s poor heat conduction can be a benefit—such as in parts where thermal insulation is desired or in high-temperature environments where maintaining structural integrity outweighs the need for heat dissipation. Titanium CNC machining parts are often found in:

Titanium can withstand extreme heat without deforming, but it does not effectively move that heat away from critical surfaces or systems.

Conclusion: Thermal Conductivity Verdict

When your application demands efficient heat dissipation, aluminum is the superior material due to its high thermal conductivity. Titanium’s low thermal conductivity restricts its use in thermal management applications, but its strength and stability at high temperatures still make it valuable in niche roles. Choose aluminum for thermal efficiency; choose titanium when heat resistance and strength are more critical than heat transfer.

Strength is a critical parameter when selecting a material for CNC machining parts—especially those exposed to mechanical stress, impact, or deformation. When comparing aluminum vs. titanium, one of the biggest differences lies in their mechanical strength profiles. This includes yield strength, tensile strength, and shear strength, each of which plays a distinct role in determining the material’s behavior under stress. Engineers, designers, and manufacturers must understand these differences to ensure reliable performance in applications ranging from aerospace to automotive to medical equipment. Let’s examine how aluminum and titanium measure up across all three types of strength.

Yield Strength

Yield strength refers to the stress at which a material begins to deform permanently. It’s a critical factor for any component that must maintain its shape under load.

Aluminum: The yield strength of aluminum varies widely depending on the alloy. For example:

Aluminum alloys offer sufficient yield strength for many applications, especially when lightweight performance is prioritized. However, their yield limits can be too low for high-stress or load-bearing structures.

Titanium: Titanium’s yield strength is significantly higher.

This makes titanium CNC machining parts ideal for aerospace brackets, medical implants, and high-performance automotive components where deformation must be avoided under extreme loads.

Tensile Strength

Tensile strength represents the maximum stress a material can withstand while being stretched or pulled before breaking. This measure is crucial for components under tension, such as fasteners, wires, and structural supports.

Aluminum:

Aluminum alloys can deliver decent tensile strength while keeping weight low, which is ideal for applications where some flexibility is acceptable and the primary focus is weight savings.

Titanium:

Titanium outperforms aluminum by a wide margin in tensile strength, making it better suited for high-performance environments where structural failure is not an option.

Shear Strength

Shear strength is the ability of a material to resist forces that cause its internal structure to slide against itself—an important property for fasteners, joints, and thin-walled structures.

Aluminum:

While high-strength aluminum alloys perform reasonably well in shear, they may still fall short in applications requiring resistance to extreme lateral forces.

Titanium:

Titanium alloys, particularly Grade 5, offer outstanding shear strength, making them ideal for aerospace joints, critical structural elements, and components exposed to repeated or complex stress patterns.

Conclusion: Which Metal Wins on Strength?

Titanium clearly surpasses aluminum in all three categories—yield, tensile, and shear strength. While aluminum is sufficient for many general-purpose and lightweight applications, titanium is the superior choice when maximum mechanical strength is a priority. However, this strength advantage comes at a cost—both financially and in terms of machinability. Choosing between aluminum and titanium CNC machining parts ultimately depends on your specific strength requirements, weight constraints, and budget.

Certainly! Here's a clear, professional table comparing the strength properties of aluminum and titanium alloys commonly used in CNC machining:

| Strength Property |

Aluminum Alloys |

Titanium Alloys |

| Yield Strength | 6061-T6: ~276 MPa (40,000 psi) | Grade 2 (CP-Ti): ~275 MPa (40,000 psi) |

| 7075-T6: ~503 MPa (73,000 psi) | Grade 5 (Ti-6Al-4V): ~880 MPa (128,000 psi) | |

| Tensile Strength | 6061-T6: ~310 MPa (45,000 psi) | Grade 2 (CP-Ti): ~344 MPa (50,000 psi) |

| 7075-T6: ~572 MPa (83,000 psi) | Grade 5 (Ti-6Al-4V): ~950 MPa (138,000 psi) | |

| Shear Strength | 6061-T6: ~207 MPa (30,000 psi) | Grade 5 (Ti-6Al-4V): ~550 MPa (80,000 psi) |

| 7075-T6: ~331 MPa (48,000 psi) |

This table clearly highlights the strength advantages of titanium alloys, especially Grade 5, over common aluminum alloys used in CNC machining parts.

Density and hardness are fundamental material properties that influence the weight, strength, durability, and overall performance of CNC machined parts. When comparing aluminum vs. titanium, these factors are crucial for determining suitability in applications where weight reduction and surface wear resistance are priorities. Understanding how aluminum and titanium differ in density and hardness helps manufacturers and designers optimize their parts for longevity, strength, and functional efficiency.

Density

Density measures how much mass a material contains per unit volume, typically expressed in grams per cubic centimeter (g/cm³) or pounds per cubic inch (lb/in³). It directly impacts the weight of parts and assemblies, influencing everything from fuel efficiency in aerospace to ergonomics in consumer products.

Titanium’s density plays a pivotal role in high-performance applications such as aerospace and medical implants, where strength and durability must coexist with weight constraints.

Hardness

Hardness describes a material’s resistance to deformation, abrasion, and scratching. This property is especially important for wear resistance and maintaining surface integrity under mechanical stress or friction.

Aluminum: Aluminum is relatively soft compared to many metals. Depending on the alloy and temper, its hardness typically ranges from 25 to 150 HB (Brinell Hardness). For example:

While aluminum’s softness facilitates easier machining and forming, it also means aluminum parts can scratch or dent more readily in demanding environments.

Titanium: Titanium alloys exhibit significantly higher hardness, contributing to their excellent wear resistance. For instance:

Titanium’s higher hardness makes it ideal for parts exposed to abrasive conditions, ensuring longer lifespan and reduced maintenance in industries like aerospace, military, and medical device manufacturing.

Conclusion: Density and Hardness Comparison

In summary, aluminum offers lightweight advantages that are unmatched for many applications requiring easy handling and energy efficiency. However, titanium compensates for its higher density with superior hardness and strength, making it the material of choice for high-stress, wear-resistant components. The decision between aluminum and titanium CNC machining parts hinges on balancing weight limitations against mechanical performance and durability requirements.

Certainly! Here's a clear and concise table comparing the density and hardness of aluminum and titanium alloys used in CNC machining:

| Property |

Aluminum Alloys |

Titanium Alloys |

| Density |

~2.7 g/cm³ (0.0975 lb/in³) | ~4.5 g/cm³ (0.162 lb/in³) |

| Hardness |

6061-T6: ~95 HB (Brinell) | Grade 2: ~150 HB |

| 7075-T6: ~150 HB | Grade 5 (Ti-6Al-4V): ~340 HB (heat treated) |

This table highlights aluminum’s lightweight advantage and titanium’s superior hardness, helping guide material selection based on application needs.

Melting point is a key property that affects how materials behave during manufacturing, especially in processes involving heat such as welding, casting, or heat treatment. It also influences the operating temperature range of the finished parts. When comparing aluminum vs. titanium for CNC machining services, understanding their melting points helps manufacturers choose the right metal for temperature-sensitive applications, ensuring structural integrity and performance under thermal stress.

Aluminum has a relatively low melting point compared to many metals, melting at approximately 660°C (1220°F). This low melting point allows aluminum parts to be easily formed and shaped using various manufacturing techniques. However, it also limits aluminum’s use in high-temperature applications because parts may deform, weaken, or fail if exposed to heat near or above this threshold. For CNC machining factories producing aluminum CNC machining parts, controlling heat buildup during machining is important to prevent warping or structural damage.

Titanium has a significantly higher melting point of approximately 1668°C (3034°F). This high melting point makes titanium an excellent choice for applications involving extreme heat or thermal cycling, such as aerospace engine components, chemical processing equipment, and high-performance automotive parts. It also contributes to titanium’s superior heat resistance and stability compared to aluminum.

For CNC machining parts made from titanium, higher melting point means the material can sustain elevated operating temperatures without losing strength or deforming, although machining titanium requires careful heat management to avoid tool wear.

Conclusion: Melting Points Comparison

In summary, aluminum’s lower melting point offers ease of manufacturing but restricts its use in high-temperature environments. Titanium’s much higher melting point supports applications requiring thermal stability and durability under extreme conditions. This contrast is a major factor when selecting between aluminum CNC machining parts and titanium CNC machining parts for industries such as aerospace, automotive, and chemical processing.

Certainly! Here's a concise table comparing the melting points of aluminum and titanium alloys:

| Material |

Melting Point |

| Aluminum |

~660°C (1220°F) |

| Titanium |

~1668°C (3034°F) |

This table highlights titanium’s much higher melting point compared to aluminum, impacting their suitability for high-temperature applications.

The color of a metal can influence both its aesthetic appeal and its suitability for certain applications, especially in consumer products, jewelry, and visible components. While color does not affect mechanical properties directly, it often correlates with surface finish, oxidation behavior, and corrosion resistance. When comparing aluminum vs. titanium, understanding their natural colors and how they respond to treatments is important for selecting the right metal in CNC machining projects where appearance matters.

Color of Aluminum

Aluminum typically exhibits a silvery-white or light gray appearance with a matte finish. Its natural oxide layer gives aluminum a dull, slightly reflective surface that can be polished to a bright, shiny finish. Aluminum is highly versatile in surface treatments, including anodizing, which can add color and increase corrosion resistance. This flexibility allows aluminum CNC machining parts to meet diverse aesthetic requirements across industries like electronics, automotive, and household goods.

Color of Titanium

Titanium naturally has a darker gray or silvery metallic color with a subtle metallic luster. It is often described as having a “gunmetal” or “steel-gray” appearance. Titanium’s surface oxide layer is highly stable and can produce vivid colors through anodizing processes by varying oxide thickness. This property is widely exploited in jewelry and high-end consumer goods to create unique, durable colored finishes. Titanium CNC machining parts often retain their color and finish longer under harsh environmental conditions compared to aluminum.

Conclusion: Color Comparison

In conclusion, aluminum’s bright and light color offers excellent adaptability through various finishes and coatings, making it suitable for visually demanding applications. Titanium’s darker, metallic gray color combined with its ability to hold colorful anodized finishes offers both durability and unique aesthetics. The choice between aluminum vs. titanium for CNC machining parts often depends on the desired look and long-term appearance in the final product.

Certainly! Here’s a clear table comparing the color characteristics of aluminum and titanium:

| Material |

Natural Color |

Surface Finish & Treatment |

Typical Applications |

| Aluminum |

Silvery-white to light gray | Matte finish naturally; can be polished bright; anodizing adds color and corrosion resistance | Electronics, automotive, household goods |

| Titanium |

Darker gray or steel-gray | Stable oxide layer; anodizing produces vivid colors and durable finishes | Jewelry, aerospace, high-end consumer goods |

This table summarizes how aluminum and titanium differ in appearance and finishing options for CNC machining parts.

Corrosion resistance is a critical factor when selecting materials for CNC machining parts, especially those exposed to harsh environments such as marine, chemical, or outdoor applications. The ability of a metal to withstand oxidation, rust, and chemical attack significantly affects the lifespan and maintenance costs of components. Comparing aluminum vs. titanium reveals important differences in their natural and treated corrosion resistance properties.

Corrosion Resistance of Aluminum

Aluminum forms a thin, protective oxide layer naturally when exposed to air, which helps prevent further oxidation and corrosion. This oxide layer is stable and adheres well to the metal surface, providing a basic level of corrosion protection. However, aluminum is vulnerable in certain environments:

Aluminum CNC machining parts benefit from these treatments but require careful selection and maintenance in corrosive settings.

Corrosion Resistance of Titanium

Titanium’s corrosion resistance is exceptional due to a very stable and dense oxide film that forms on its surface, protecting it from most chemical attacks. Titanium is highly resistant to:

This superior corrosion resistance makes titanium CNC machining parts highly desirable for aerospace, medical implants, chemical, and marine industries.

Conclusion: Corrosion Resistance Comparison

While aluminum offers decent corrosion resistance, especially when anodized, titanium stands out with its superior ability to resist a wide range of corrosive environments. For applications demanding long-lasting performance under harsh conditions, titanium CNC machining parts are often the preferred choice despite their higher cost. Aluminum remains a cost-effective option when corrosion conditions are moderate and proper surface treatments are applied.

Certainly! Here’s a clear table comparing the corrosion resistance of aluminum and titanium:

| Material |

Corrosion Resistance Characteristics |

Typical Environment Suitability |

| Aluminum |

Forms protective oxide layer; susceptible to pitting in saltwater; improved by anodizing or coating | Moderate environments; requires treatment for marine or acidic conditions |

| Titanium |

Forms highly stable, dense oxide film; excellent resistance to saltwater, acids, alkalis, and oxidation | Harsh environments including marine, chemical, aerospace, and medical |

This table highlights titanium’s superior corrosion resistance over aluminum, making it ideal for demanding applications.

Heat resistance is a vital property for metals used in applications that involve elevated temperatures, such as aerospace, automotive engines, and industrial machinery. The ability of a material to retain strength, resist deformation, and avoid oxidation under heat directly affects its performance and lifespan. Comparing aluminum vs. titanium in terms of heat resistance reveals distinct differences important for CNC machining parts designed for thermal stress environments.

Heat Resistance of Aluminum

Aluminum has relatively low heat resistance due to its lower melting point (~660°C or 1220°F) and tendency to soften at elevated temperatures. Above approximately 150°C (302°F), aluminum alloys begin to lose strength significantly, which limits their use in high-temperature environments. While aluminum’s thermal conductivity is high, allowing for rapid heat dissipation, this does not compensate for its poor mechanical stability under heat. Therefore, aluminum CNC machining parts are better suited for applications with moderate or short-term heat exposure.

Heat Resistance of Titanium

Titanium exhibits excellent heat resistance thanks to its high melting point (~1668°C or 3034°F) and ability to maintain strength and structural integrity at elevated temperatures. Titanium alloys can withstand continuous exposure to temperatures above 400°C (752°F) without significant loss of mechanical properties. Additionally, titanium forms a protective oxide layer that resists oxidation even at high temperatures. This combination makes titanium CNC machining parts ideal for high-temperature applications in aerospace, power generation, and chemical processing industries.

Conclusion: Heat Resistance Comparison

In summary, titanium outperforms aluminum in heat resistance, maintaining strength and corrosion protection under much higher temperatures. Aluminum offers excellent thermal conductivity but is limited by its lower melting point and strength loss under heat. For CNC machining parts expected to encounter high thermal stress, titanium is the preferred material, while aluminum remains suitable for less demanding thermal conditions.

Certainly! Here’s a table comparing heat resistance of aluminum and titanium:

| Material |

Heat Resistance Characteristics |

Typical Temperature Limits |

Applications |

| Aluminum |

Lower heat resistance; loses strength above ~150°C (302°F); high thermal conductivity for heat dissipation | Melting point ~660°C (1220°F); strength loss above 150°C | Moderate heat applications; electronics; automotive parts |

| Titanium |

Excellent heat resistance; maintains strength at high temps; forms protective oxide layer | Melting point ~1668°C (3034°F); stable above 400°C (752°F) | Aerospace, power generation, chemical processing |

This table highlights titanium’s superior ability to maintain strength and resist oxidation at high temperatures compared to aluminum.

Heat treatment is an essential process in metal manufacturing that alters the physical and sometimes chemical properties of a material to enhance its performance. It affects hardness, strength, ductility, and machinability. When comparing aluminum vs. titanium for CNC machining parts, understanding their heat treatment characteristics helps manufacturers optimize processing techniques and final product quality.

Heat Treatment of Aluminum

Aluminum alloys are often heat treated to improve strength and hardness. Common heat treatment processes include:

These processes, especially common in alloys like 6061-T6 and 7075-T6, significantly enhance mechanical properties while maintaining aluminum’s lightweight nature. Heat treatment also improves machinability and corrosion resistance. However, aluminum’s relatively low melting point limits the maximum heat treatment temperatures to prevent melting or distortion.

Heat Treatment of Titanium

Titanium alloys respond well to heat treatment, which mainly focuses on improving strength and toughness. Key heat treatment methods include:

Due to titanium’s higher melting point, heat treatments can be conducted at higher temperatures than aluminum without risking melting or deformation. Heat treatment enhances titanium’s already excellent mechanical properties and corrosion resistance, making it ideal for demanding CNC machining services.

Conclusion: Heat Treatment Comparison

In conclusion, both aluminum and titanium benefit significantly from heat treatment, but titanium’s higher temperature tolerance allows for more aggressive treatment options, resulting in superior mechanical enhancements. Manufacturers must select heat treatment processes tailored to each metal’s characteristics to optimize CNC machining parts’ performance and lifespan.

Certainly! Here’s a table summarizing heat treatment of aluminum and titanium:

| Material |

Common Heat Treatment Processes |

Effects on Properties |

Temperature Considerations |

| Aluminum |

Solution heat treatment, quenching, aging (precipitation hardening) | Improves strength, hardness, machinability, corrosion resistance | Limited by lower melting point (~660°C); treatments done at moderate temperatures |

| Titanium |

Annealing, solution treating and aging, stress relieving | Enhances strength, toughness, ductility, corrosion resistance | Higher temperature tolerance due to high melting point (~1668°C) allows more aggressive treatments |

This table highlights the differences in heat treatment capabilities and effects between aluminum and titanium for CNC machining parts.

Welding is a crucial process in manufacturing and assembly, affecting the integrity, strength, and durability of metal components. When comparing aluminum vs. titanium in CNC machining projects, understanding the welding characteristics and challenges of each metal helps in selecting the right material and welding technique to ensure quality results.

Aluminum is widely welded using methods such as TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and resistance welding. However, welding aluminum presents challenges including:

Proper surface preparation, controlled heat input, and post-weld treatments are essential for strong, durable aluminum welds in CNC machining parts.

Welding Titanium

Titanium welding requires strict control of the welding environment due to its high reactivity at elevated temperatures. Key points include:

Titanium welding is more complex and costly but essential for applications needing superior strength and corrosion resistance, such as aerospace and medical devices.

Conclusion: Welding Comparison

In summary, aluminum welding is more common and generally easier but requires attention to oxide removal and heat control. Titanium welding is more demanding, requiring specialized equipment and environment controls, but yields superior welds with outstanding strength and corrosion resistance. The choice depends on project requirements, cost, and performance expectations.

Certainly! Here’s a table summarizing welding characteristics of aluminum and titanium:

| Material |

Welding Methods |

Challenges |

Key Requirements |

Typical Applications |

| Aluminum |

TIG, MIG, Resistance welding | Oxide layer removal needed; high thermal conductivity; porosity; distortion risk | Proper surface cleaning; controlled heat input; post-weld treatment | Automotive, electronics, construction |

| Titanium |

TIG, Plasma welding | Requires inert gas shielding; high reactivity; contamination risk; low thermal conductivity | Strict inert atmosphere (argon/helium); ultra-clean surfaces; precise heat control | Aerospace, medical, chemical processing |

This table highlights the distinct welding requirements and challenges for aluminum and titanium CNC machining parts.

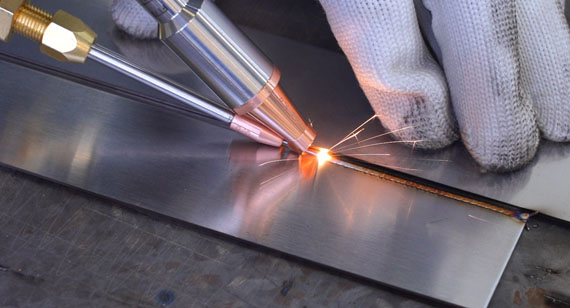

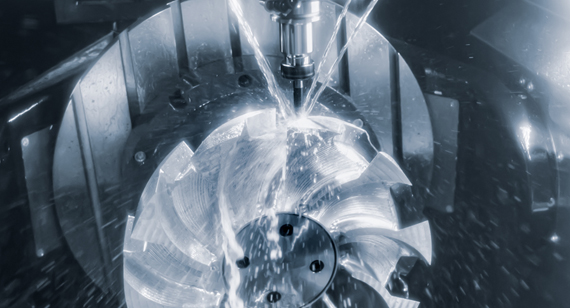

Machinability and formability are essential considerations when selecting materials for CNC machining parts. These properties affect the ease of manufacturing, production costs, and the quality of the final product. Aluminum and titanium differ significantly in these areas, influencing their suitability for various CNC machining services and factory processes.

Machinability of Aluminum

Aluminum is known for its excellent machinability, which makes it a popular choice in CNC machining services. Its relatively soft nature allows for high cutting speeds, reduced tool wear, and efficient chip removal. Aluminum alloys, especially those like 6061-T6 and 7075-T6, offer good machinability while maintaining strength and durability.

Advantages of aluminum’s machinability include:

These factors make aluminum CNC machining parts cost-effective and versatile for industries such as automotive, electronics, and consumer goods.

Machinability of Titanium

Titanium, on the other hand, poses more challenges in machining due to its high strength, low thermal conductivity, and tendency to work-harden. These factors increase cutting forces, tool wear, and heat generation, which require specialized tooling and machining techniques.

Key challenges in machining titanium include:

Despite these challenges, titanium CNC machining parts are invaluable for applications requiring superior strength, corrosion resistance, and biocompatibility, such as aerospace and medical devices.

Formability of Aluminum

Aluminum boasts excellent formability, allowing it to be easily bent, shaped, and extruded without cracking. Its ductility makes it suitable for processes like stamping, deep drawing, and rolling, facilitating the production of complex parts with high precision.

Benefits of aluminum’s formability include:

This makes aluminum highly favored in automotive panels, packaging, and architectural components.

Formability of Titanium

Titanium exhibits lower formability compared to aluminum due to its higher strength and lower ductility. It is more prone to cracking and requires higher forming forces and specialized techniques such as hot forming or superplastic forming to achieve desired shapes without defects.

Key points regarding titanium’s formability:

Despite these limitations, titanium’s exceptional strength and corrosion resistance justify the effort in forming complex parts for aerospace, medical implants, and high-performance applications.

Conclusion: Machinability and Formability Comparison

In summary, aluminum offers superior machinability and formability, making it ideal for high-volume production and cost-sensitive projects. Titanium’s machining and forming require more specialized approaches but result in components with unmatched performance in strength and durability. Choosing between aluminum CNC machining parts and titanium CNC machining parts depends on balancing manufacturing ease with end-use requirements.

Certainly! Here’s a table summarizing machinability and formability of aluminum and titanium:

| Aspect |

Aluminum |

Titanium |

| Machinability |

Excellent machinability; high cutting speeds; less tool wear; low heat generation; easy chip removal | Challenging to machine; high cutting forces; rapid tool wear; heat concentration; work hardening |

| Formability |

Highly formable; easy bending, stamping, and rolling; good ductility; versatile manufacturing methods | Lower formability; prone to cracking; requires hot forming or superplastic forming; needs specialized equipment |

This table highlights aluminum’s ease of machining and forming versus titanium’s tougher but higher-performance characteristics, important for CNC machining services and factories.

Cost is a major factor when selecting materials for CNC machining parts. The price difference between aluminum and titanium affects the overall budget, production planning, and product pricing. Understanding how these costs impact manufacturing helps businesses choose the right metal to balance performance and affordability.

Cost of Aluminum

Aluminum is generally much more affordable than titanium, making it a preferred choice for projects with strict budget constraints. Its abundant availability, lower raw material cost, and ease of processing contribute to cost savings in both material purchase and machining services.

Key cost advantages of aluminum include:

These factors make aluminum CNC machining parts highly cost-effective for industries such as automotive, consumer electronics, and household goods.

Cost of Titanium

Titanium is a premium material with a significantly higher price tag due to its complex extraction, refining, and processing requirements. The cost of titanium alloys and their machining often reflects these challenges.

Factors contributing to titanium’s higher cost include:

Despite the higher cost, titanium’s superior strength-to-weight ratio, corrosion resistance, and biocompatibility justify its use in aerospace, medical, and high-performance applications where performance outweighs cost.

Conclusion: Cost Impact Comparison

In conclusion, aluminum offers substantial cost benefits for CNC machining services and factories focusing on budget-sensitive production. Titanium, while costly, provides unmatched material properties that can justify the investment in critical, high-performance components. Careful cost-benefit analysis is essential to selecting the best metal for your project.

Certainly! Here’s a table summarizing the cost impact of aluminum vs. titanium:

| Cost Factor |

Aluminum |

Titanium |

| Raw Material Cost |

Lower; widely available and abundant | Higher; complex extraction and alloying process |

| Machining Cost |

Lower; faster machining, less tool wear | Higher; slower machining, increased tool wear |

| Tooling and Maintenance |

Less expensive; longer tool life | More expensive; specialized tooling required |

| Production Efficiency |

Higher; quick cycles and easy handling | Lower; slower processes and higher scrap rates |

| Shipping and Handling |

Cheaper due to lighter weight | More expensive due to higher density and care |

| Overall Cost |

Cost-effective for mass production | Premium cost justified by high performance |

This table provides a clear comparison of cost-related factors when choosing between aluminum CNC machining parts and titanium CNC machining parts.

Aluminum is one of the most widely used metals in CNC machining services due to its exceptional versatility, lightweight nature, and cost-effectiveness. This metal is prized for its excellent machinability, corrosion resistance, and thermal properties, making it suitable for a broad range of industrial applications. Aluminum CNC machining parts are commonly found in automotive, aerospace, electronics, and consumer products where a balance of strength, weight, and price is essential.

As a non-ferrous metal, aluminum’s relatively low density allows manufacturers to produce lightweight components without compromising functional performance. Its ability to reflect heat and light, along with good electrical conductivity, further enhances its desirability in many fields. Additionally, aluminum is highly recyclable, supporting environmentally conscious production processes.

Advantages and Disadvantages of Aluminum

Advantages of Aluminum

Aluminum offers numerous benefits that make it a go-to choice for many CNC machining factories and service providers:

These advantages have cemented aluminum’s position as a material of choice in many CNC machining services, especially where performance, cost, and sustainability intersect.

Disadvantages of Aluminum

Despite its many benefits, aluminum also has limitations that must be considered:

Understanding these disadvantages helps manufacturers and engineers decide when aluminum is the best fit for CNC machining projects and when alternative materials might be more appropriate.

Certainly! Here’s a table summarizing the advantages and disadvantages of aluminum:

| Advantages of Aluminum |

Disadvantages of Aluminum |

| Cheaper option compared to many metals | Lower strength than titanium and steel |

| Lightweight, reducing product weight and shipping | Complex welding process due to oxide layer |

| Odorless and impermeable for safe packaging | Corrodes quickly in saltwater without proper treatment |

| Reflective and flexible for diverse applications | Lower melting point limits high-temperature use |

| Highly machinable and recyclable | May affect taste of packaged food without surface treatment |

| Corrosion resistant, especially when anodized | Not biocompatible, unsuitable for many medical implants |

| High thermal and electrical conductivity |

This table clearly outlines the pros and cons of aluminum, helping guide material choice for CNC machining services and factories.

Applications of Aluminum

Aluminum’s versatility and advantageous properties make it an essential material across numerous industries. Its lightweight nature, corrosion resistance, and excellent machinability allow it to be used in various applications, especially where weight reduction, durability, and cost-effectiveness are priorities. Aluminum CNC machining parts are widely used in sectors ranging from machinery to medical devices, demonstrating its broad industrial appeal.

Machinery and Equipment

Aluminum’s strength-to-weight ratio and ease of fabrication make it ideal for manufacturing machinery components and equipment parts. Its corrosion resistance ensures longevity, even in demanding environments, while its machinability allows for precise and complex designs essential in modern machinery.

Electricity

In electrical applications, aluminum is favored for its excellent electrical conductivity and lightweight characteristics. It is commonly used in wiring, transformers, and conductors, contributing to efficient power distribution and energy-saving systems.

Household Goods

From kitchen utensils to appliances, aluminum’s durability and resistance to corrosion make it a popular choice in household goods. Its lightweight and non-toxic nature also contribute to safer, user-friendly products.

Transportation Industry

Aluminum plays a critical role in the transportation sector by helping reduce vehicle weight, thereby improving fuel efficiency and reducing emissions. It is used in manufacturing aircraft, trains, ships, and automotive components.

The electronics industry benefits from aluminum’s thermal conductivity and electromagnetic shielding properties. It is widely used in heat sinks, casings, and structural components for electronic devices.

In automotive manufacturing, aluminum reduces the weight of vehicles without compromising strength and safety. This results in enhanced performance, fuel efficiency, and reduced environmental impact.

Aluminum’s resistance to corrosion and wear makes it a suitable choice for industrial machinery, tools, and components exposed to harsh operating conditions.

Optical

In optical equipment, aluminum’s lightweight and reflective properties are used in lenses, housings, and precision instruments, where material performance directly affects product quality.

Though aluminum is not biocompatible for implants, it is widely used in medical devices, equipment housings, and tools due to its lightweight, sterilizability, and resistance to corrosion.

The robotics industry utilizes aluminum for its structural components and enclosures, capitalizing on its balance of strength, weight, and machinability, which enhances robot agility and performance.

Here’s a table summarizing the applications of aluminum across various industries:

| Industry |

Applications of Aluminum |

| Machinery and Equipment |

Components and parts requiring strength, precision, and corrosion resistance |

| Electricity |

Electrical wiring, transformers, conductors due to excellent conductivity and lightweight |

| Household Goods |

Kitchen utensils, appliances, and durable, corrosion-resistant consumer products |

| Transportation Industry |

Aircraft, trains, ships, and automotive parts for weight reduction and fuel efficiency |

| Electronics |

Heat sinks, device casings, and electromagnetic shielding components |

| Automotive |

Lightweight vehicle parts enhancing performance, fuel efficiency, and safety |

| Industrial |

Machinery parts and tools that endure harsh conditions |

| Optical |

Lenses, housings, and precision instruments benefiting from lightweight and reflective properties |

| Medical |

Medical equipment housings and tools where sterilizability and corrosion resistance are critical |

| Robotics |

Structural components and enclosures improving robot agility and durability |

This table highlights aluminum’s diverse uses, showcasing why it’s a preferred material for CNC machining parts in many sectors.

Titanium is a high-performance metal renowned for its exceptional strength, light weight, and outstanding corrosion resistance. These properties make it an increasingly popular choice in CNC machining services, especially in industries that demand materials capable of withstanding harsh environments and mechanical stress. Titanium CNC machining parts are widely used in aerospace, medical, military, and automotive sectors, where durability and performance are paramount.

Compared to aluminum, titanium offers a superior strength-to-density ratio, which means it provides remarkable strength without adding excessive weight. Additionally, titanium is highly resistant to rust and corrosion, including in marine and chemically aggressive environments. This metal’s biocompatibility further expands its use into medical implants and devices, making it an indispensable material in modern manufacturing.

Advantages and Disadvantages of Titanium

Advantages of Titanium

Titanium offers numerous benefits that distinguish it from other metals in CNC machining:

These advantages make titanium a premium choice for CNC machining factories and services focused on producing high-performance parts.

Disadvantages of Titanium

Despite its many strengths, titanium presents some challenges and limitations:

Understanding these disadvantages is vital for manufacturers and engineers to determine whether titanium is the right choice for specific CNC machining applications.

Here’s a table summarizing the advantages and disadvantages of titanium:

| Advantages of Titanium |

Disadvantages of Titanium |

| Highest strength-to-density ratio | High cutting forces required due to high strength |

| Preferred steel alternative in weight-sensitive uses | Low elastic modulus leading to less flexibility |

| Excellent rust and corrosion resistance | Higher cost compared to aluminum |

| High resistance to stress conditions (fatigue, thermal) | Can be brittle under certain conditions |

| Excellent durability for long-lasting components | |

| Suitable for a wide range of products | |

| Biocompatible for medical applications |

This table clearly outlines the strengths and challenges of titanium for CNC machining parts and services.

Applications of Titanium

Titanium is widely valued across multiple industries for its unique combination of strength, lightweight, corrosion resistance, and biocompatibility. These attributes enable titanium CNC machining parts to perform reliably in extreme environments and critical applications. From aerospace to healthcare, titanium’s versatility makes it a preferred metal for products requiring durability and high performance.

Consumer and Construction

In consumer goods and construction, titanium is used for durable structural components, architectural fittings, and high-end consumer products that benefit from its corrosion resistance and strength.

Aerospace Industry

The aerospace sector relies heavily on titanium for aircraft components, engines, and airframes. Its lightweight and strength help improve fuel efficiency and safety while resisting extreme temperature and stress conditions.

Titanium is used in industrial machinery and equipment, especially where exposure to corrosive chemicals or harsh environments is common, ensuring longevity and reliable operation.

Health Care

Thanks to its biocompatibility, titanium is extensively used in medical implants, prosthetics, surgical instruments, and dental devices, supporting patient safety and recovery.

Chemical Processing

Titanium’s corrosion resistance makes it ideal for chemical processing plants, where it is used in reactors, heat exchangers, and piping systems exposed to aggressive chemicals.

Military

The military uses titanium for armor plating, weapons systems, and vehicles, benefiting from its strength-to-weight ratio and resistance to corrosion and extreme conditions.

Sports Equipment

High-performance sports equipment such as golf clubs, bicycles, and tennis rackets often incorporate titanium to enhance strength, reduce weight, and improve durability.

Titanium is used in high-end automotive parts like exhaust systems, engine components, and structural elements where weight reduction and strength are crucial.

Oil and Gas

In the oil and gas industry, titanium is utilized in drilling equipment, valves, and offshore platforms, offering resistance to corrosion from saltwater and harsh chemicals.

Desalination

Titanium is a key material in desalination plants for components like heat exchangers and piping, where corrosion resistance ensures long-term, reliable performance.

Due to its durability, lightweight, and hypoallergenic properties, titanium is popular in fine jewelry, watches, and body piercings.

Here’s a table summarizing the Applications of Titanium across various industries:

| Industry |

Applications of Titanium |

| Consumer and Construction |

Structural components, architectural fittings, durable consumer products |

| Aerospace Industry |

Aircraft components, engines, airframes for weight reduction and strength |

| Industrial Applications |

Machinery, equipment exposed to corrosive environments |

| Health Care |

Medical implants, prosthetics, surgical instruments, dental devices |

| Chemical Processing |

Reactors, heat exchangers, piping systems in chemical plants |

| Military |

Armor plating, weapons systems, military vehicles |

| Sports Equipment |

Golf clubs, bicycles, tennis rackets for improved performance |

| Automotive |

Exhaust systems, engine parts, structural components in high-performance vehicles |

| Oil and Gas |

Drilling equipment, valves, offshore platform components |

| Desalination |

Heat exchangers, piping in desalination plants |

| Jewelry |

Lightweight, durable, and hypoallergenic jewelry and watches |

This table highlights titanium’s diverse applications, reflecting why it is a critical material in CNC machining services.

Choosing between aluminum and titanium for your CNC machining parts can be a complex decision influenced by multiple factors. Both metals offer unique advantages and disadvantages that make them suitable for specific applications. Understanding how aspects like cost, mechanical properties, environmental impact, and production requirements affect your project will help you select the optimal material that meets your performance, budget, and sustainability goals.

Material Cost

Aluminum is generally more affordable than titanium, making it an attractive option for projects with budget constraints. However, titanium’s superior properties may justify its higher price in high-performance applications where durability and strength are critical.

Applications

Aluminum is widely used in industries requiring lightweight parts with good machinability, such as automotive, electronics, and household goods. Titanium is preferred in aerospace, medical, and chemical processing sectors where high strength, corrosion resistance, and biocompatibility are essential.

Optional Machining Processes

Both metals are compatible with various CNC machining services, but titanium often requires specialized tooling and slower machining speeds due to its hardness, impacting production time and cost. Aluminum’s excellent machinability allows for faster turnaround and lower tooling wear.

Cost

Beyond material price, consider machining costs, tool wear, and finishing processes. Titanium parts usually incur higher overall costs due to these factors, while aluminum parts are generally more cost-effective to produce.

Weight and Strength

Titanium boasts a higher strength-to-weight ratio than aluminum, making it ideal for applications where minimizing weight without sacrificing strength is crucial. Aluminum is lighter but less strong, suitable for less demanding structural needs.

Chemical Resilience

Titanium excels in corrosive environments, resisting rust and chemical damage, while aluminum, although corrosion-resistant, can degrade faster in saltwater or acidic conditions unless properly treated.

Lifespan

Parts made from titanium typically have a longer service life due to their strength and corrosion resistance, reducing maintenance and replacement costs over time compared to aluminum.

Production

Titanium’s machining requires more energy and specialized equipment, influencing production timelines and scalability. Aluminum’s easier workability facilitates faster and larger-scale manufacturing.

Industry Specifications

Certain industries mandate strict material specifications for safety and performance. Aerospace and medical sectors often require titanium CNC machining parts to meet these standards, while aluminum suffices in consumer and industrial products.

Environmental Impact

Aluminum is highly recyclable with lower energy consumption in recycling, making it environmentally friendly. Titanium recycling is less common and more energy-intensive, though its longevity can offset some environmental costs.

Waste Generated

Machining titanium can generate more waste due to slower cutting speeds and tool wear, whereas aluminum machining tends to be more efficient with less material loss.

Surface Requirements

Both metals offer good finishing options, but titanium often requires additional surface treatments to enhance wear resistance and appearance. Aluminum’s surface is easier to anodize for added protection.

Biocompatibility

Titanium is biocompatible and safe for medical implants and devices, while aluminum is generally not suitable for direct contact with the human body due to potential toxicity concerns.

Choosing between aluminum and titanium ultimately depends on your project’s specific requirements, balancing cost, performance, and application environment to achieve the best results in CNC machining parts.

Here’s a detailed comparison table for Aluminum vs. Titanium: Which Metal Should You Choose?

| Factor |

Aluminum |

Titanium |

| Material Cost |

More affordable, lower raw material cost | Higher raw material cost |

| Applications |

Automotive, electronics, household goods, lightweight parts | Aerospace, medical, chemical processing, high-performance parts |

| Optional Machining Processes |

Faster machining, easier tooling, less wear | Requires specialized tooling, slower machining speeds |

| Cost (Total Production) |

Lower machining and tooling costs | Higher machining costs due to material hardness and tooling |

| Weight and Strength |

Lightweight but lower strength | Higher strength-to-weight ratio |

| Chemical Resilience |

Corrosion resistant but vulnerable in saltwater/acidic environments | Excellent corrosion resistance in harsh environments |

| Lifespan |

Moderate, may require replacement sooner | Longer lifespan due to durability and corrosion resistance |

| Production |

Easier, faster production scale | More energy-intensive, slower production |

| Industry Specifications |

Suitable for consumer and industrial sectors | Required in aerospace, medical, and other specialized fields |

| Environmental Impact |

Highly recyclable, lower recycling energy | Less common recycling, energy-intensive but longer life offsets impact |

| Waste Generated |

Less waste due to efficient machining | More waste from slower machining and tool wear |

| Surface Requirements |

Easily anodized and finished | Often requires additional surface treatment |

| Biocompatibility |

Generally not biocompatible | Biocompatible, ideal for medical implants |

This table summarizes the critical considerations when choosing between aluminum CNC machining parts and titanium CNC machining parts for your project, helping you balance cost, performance, and specific needs.

Distinguishing between titanium alloys and aluminum alloys is essential in CNC machining to ensure the right material is used for your project. Despite some visual similarities, these metals have distinct physical and chemical properties that affect their performance, machinability, and suitability for different applications. Understanding key differences such as hardness, color, specific gravity, alkali resistance, and strength can help manufacturers and engineers correctly identify and select the appropriate alloy for CNC machining parts.

Hardness

Titanium alloys generally exhibit higher hardness than aluminum alloys. This increased hardness results in greater wear resistance and strength, but also makes titanium more challenging to machine. Aluminum alloys, being softer, are easier to work with and allow faster machining speeds.

Color

While both metals can appear metallic gray, titanium alloys usually have a slightly darker, more lustrous gray or silver color. Aluminum alloys tend to be lighter in color, with a brighter, silvery-white appearance. This visual difference can help in quick material identification.

Specific Gravity

Specific gravity refers to the density of the metal compared to water. Titanium alloys have a higher specific gravity, around 4.4 to 4.5, meaning they are significantly denser and heavier than aluminum alloys, which typically range from 2.6 to 2.8. This difference is crucial when weight considerations are important in design and manufacturing.

Alkali Resistance

Titanium alloys demonstrate superior alkali resistance compared to aluminum alloys. They maintain structural integrity and resist corrosion in alkaline environments, making them more suitable for harsh chemical processing applications. Aluminum alloys are more prone to corrosion under similar conditions unless specially treated.

Strength

Titanium alloys have a much higher strength-to-weight ratio compared to aluminum alloys. This means titanium can withstand greater stress and strain while being relatively lightweight. Aluminum alloys offer moderate strength but excel in applications where cost and machinability are more important than maximum strength.

Here’s a clear comparison table for Titanium Alloy vs. Aluminum Alloy: How to Distinguish?

| Feature |

Titanium Alloy |

Aluminum Alloy |

| Hardness |

Higher hardness; more wear-resistant and tougher | Softer; easier to machine and faster machining speeds |

| Color |

Darker, lustrous gray or silver | Lighter, bright silvery-white |

| Specific Gravity |

Higher density (4.4–4.5), heavier | Lower density (2.6–2.8), lighter |

| Alkali Resistance |

Excellent resistance to alkalis and corrosive environments | More prone to corrosion in alkaline environments unless treated |

| Strength |

Higher strength-to-weight ratio; stronger and more durable | Moderate strength; better for cost-effective, less demanding uses |

This table helps quickly identify and differentiate titanium alloys from aluminum alloys for CNC machining parts and services.

Choosing the right alloy is critical for CNC machining services to achieve optimal part performance, durability, and cost-efficiency. Both aluminum and titanium alloys come in various grades, each offering specific mechanical properties and suited for different applications. Understanding the most popular alloy specifications helps manufacturers select the best material for their CNC machining parts and projects.

Popular Alloy Specifications and Applications

Aluminum Alloys

This commercially pure aluminum alloy is known for excellent corrosion resistance, high thermal and electrical conductivity, and good machinability. It is often used in electrical components, packaging, and chemical processing.

An aluminum-copper alloy with high strength and good fatigue resistance, commonly applied in aerospace, automotive, and structural components where strength is essential.

Noted for its excellent corrosion resistance, particularly against saltwater, this alloy is popular in marine and transportation industries. It also has good weldability and moderate strength.

A versatile alloy with a good balance of strength, corrosion resistance, and machinability. It is widely used in aerospace, automotive parts, and general engineering.

Known for its very high strength comparable to many steels, this aluminum-zinc alloy is preferred in aerospace, military, and high-performance sports equipment.

Titanium Alloys

Commercially pure titanium with excellent corrosion resistance and good ductility. It’s used in chemical processing, marine environments, and biomedical applications.

The most widely used commercially pure titanium grade, offering a balance of strength, corrosion resistance, and formability, suitable for aerospace and industrial uses.

Strongest commercially pure titanium grade with high corrosion resistance, used in medical devices and aerospace components.

The most popular titanium alloy for CNC machining, combining high strength, low weight, and excellent corrosion resistance. It is widely used in aerospace, automotive, and medical implants.

Similar to Grade 2 but with added palladium for improved corrosion resistance, especially in reducing acid environments, making it ideal for chemical and marine applications.

This overview helps CNC machining factories and engineers select appropriate aluminum or titanium alloys to match their project's mechanical and environmental demands.

Here’s a comparison table of the most common Titanium and Aluminum Alloys Used in CNC Machining:

| Alloy Type |

Grade / Alloy |

Key Features |

Typical Applications |

| Aluminum Alloys | 1100 | Commercially pure, excellent corrosion resistance, highly machinable | Electrical components, packaging, chemical processing |

| 2024-T3 | High strength, good fatigue resistance | Aerospace, automotive, structural components | |

| 5052-H32 | Excellent saltwater corrosion resistance, good weldability | Marine, transportation, general fabrication | |

| 6061-T6 | Good strength, corrosion resistance, versatile machinability | Aerospace, automotive parts, general engineering | |

| 7075-T6 | Very high strength, comparable to steels | Aerospace, military, sports equipment | |

| Titanium Alloys | Grade 1 (CP-Ti) | Commercially pure, excellent corrosion resistance, ductile | Chemical processing, marine, biomedical |

| Grade 2 (CP-Ti) | Balanced strength, corrosion resistance, good formability | Aerospace, industrial applications | |

| Grade 4 (CP-Ti) | Highest strength commercially pure titanium, corrosion resistant | Medical devices, aerospace | |

| Grade 5 (Ti-6Al-4V) | High strength-to-weight ratio, excellent corrosion resistance | Aerospace, automotive, medical implants | |

| Grade 7 (Ti-0.15Pd) | Improved corrosion resistance in acid environments | Chemical, marine industries |

This table provides a quick reference for CNC machining services to choose the best aluminum or titanium alloy for their specific project needs.

At VMT, we specialize in delivering high-quality CNC machining services for both aluminum and titanium parts, catering to a wide range of industries and applications. Our advanced CNC machining factories are equipped with state-of-the-art technology and experienced engineers to ensure precision, efficiency, and consistent quality in every project.

When it comes to aluminum CNC machining parts, VMT excels in working with various aluminum alloys, such as 6061-T6 and 7075-T6, producing components that combine lightweight properties with excellent strength and corrosion resistance. Our capabilities include milling, turning, drilling, and finishing processes tailored to meet tight tolerances and complex design requirements.

For titanium CNC machining parts, VMT handles grades from commercially pure titanium (Grade 1, 2, and 4) to high-strength alloys like Grade 5 (Ti-6Al-4V). Titanium’s unique characteristics, including high strength-to-weight ratio and superior corrosion resistance, make it ideal for aerospace, medical, automotive, and chemical processing industries. Our CNC machining services ensure the highest standards in surface finish, dimensional accuracy, and material integrity.

By choosing VMT, clients benefit from comprehensive CNC machining services that focus on:

As a trusted CNC machining factory, VMT is committed to supporting your project from prototyping to full-scale production, ensuring that your aluminum vs. titanium material choice is fully realized through expert machining and superior service. Whether you need lightweight aluminum parts or high-performance titanium components, VMT is your reliable partner in CNC machining services.

Explore our other pages to learn more about our specialized CNC machining capabilities and how we can help bring your designs to life.

Choosing between aluminum and titanium for your CNC machining projects ultimately depends on your specific application requirements, budget, and desired material properties. Aluminum offers a lightweight, cost-effective solution with excellent machinability and good corrosion resistance, making it ideal for industries like automotive, electronics, and general manufacturing. On the other hand, titanium provides superior strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility, which makes it the preferred choice for aerospace, medical, and high-performance applications despite its higher cost and machining challenges.

At VMT CNC machining services, we understand the unique advantages and limitations of both metals. Our experienced team and advanced CNC machining factories are equipped to deliver precision aluminum CNC machining parts as well as complex titanium CNC machining parts with unmatched quality and efficiency. We guide you through material selection, machining processes, and finishing techniques to ensure your project’s success.

By weighing factors such as mechanical strength, corrosion resistance, thermal properties, and cost impact, you can make an informed decision that aligns with your project goals. Whether you prioritize affordability and ease of machining or high performance and durability, VMT is here to provide expert support and top-tier CNC machining services for both aluminum and titanium components.

Explore our extensive resources or contact us directly to discover how VMT can help turn your design into reality with precision CNC machining solutions tailored to your needs.

1. Titanium vs. Aluminum, which metal should I choose?

Choosing between titanium and aluminum depends on your project’s requirements. Aluminum is lightweight, affordable, and easy to machine, suitable for general applications. Titanium offers superior strength, corrosion resistance, and biocompatibility, ideal for aerospace, medical, and high-performance uses.

2. Which one is more durable?

Titanium is generally more durable due to its higher strength-to-weight ratio and excellent corrosion resistance. Aluminum is durable but can corrode faster, especially in salty or harsh environments.

3. Is titanium always more valuable than aluminum?

Yes, titanium typically costs more because of its complex extraction, processing, and superior mechanical properties, making it more valuable in industrial and commercial applications.

4. How do environmental conditions affect material selection?

Corrosive or high-temperature environments favor titanium for its resistance to rust and heat. Aluminum performs well in less extreme conditions but can corrode in salty or acidic environments.

5. What trends will emerge in the titanium and aluminum manufacturing industry in the future?

Advancements in CNC machining, alloy development, and sustainable manufacturing are driving increased use of titanium and aluminum in aerospace, medical, automotive, and electronics industries, with growing focus on lightweight and eco-friendly materials.

6. Which one is better, aluminum or titanium?

There is no absolute “better” metal—it depends on factors like strength, weight, cost, corrosion resistance, and application needs. Aluminum suits cost-sensitive, lightweight parts; titanium excels where strength and durability are critical.

7. Which one is more expensive?

Titanium is significantly more expensive than aluminum due to higher raw material costs and machining complexity.

8. Does aluminum scratch more easily than titanium?

Yes, aluminum is softer and more prone to scratches compared to titanium, which is harder and more scratch-resistant.

9. What are the disadvantages of titanium?

Titanium is costly, requires high cutting forces during machining, has lower elastic modulus (less flexibility), and can be brittle under certain conditions.

10. For mobile phones, which one is better, aluminum or titanium?

Aluminum is commonly used for its lightweight and cost-effectiveness. Titanium is preferred for premium devices offering higher durability and corrosion resistance but comes at a higher price.

11. What is the strongest metal?

Titanium alloys, especially Grade 5 (Ti-6Al-4V), are among the strongest metals used in machining, balancing strength and lightness. Steel alloys can be stronger but are heavier.

12. Does titanium rust?

No, titanium does not rust. It forms a stable oxide layer that protects it from corrosion, making it highly resistant to rust.

13. Should I buy an aluminum or titanium Apple Watch?

Aluminum Apple Watches are lighter and more affordable, while titanium models offer enhanced durability and scratch resistance with a premium feel.

14. Is titanium a luxury metal?

Titanium is often associated with luxury products due to its high cost, strength, and unique appearance, especially in watches, jewelry, and aerospace.

15. Is aluminum the cheapest metal?

Aluminum is relatively inexpensive compared to titanium and many other metals, making it popular for cost-sensitive manufacturing.

16. Does titanium get hotter than aluminum?

Titanium has lower thermal conductivity than aluminum, so it tends to retain heat longer, meaning aluminum dissipates heat faster.

17. Is aluminum the best metal?

Aluminum is an excellent choice for many applications due to its light weight, machinability, and corrosion resistance, but whether it’s “best” depends on the specific requirements of the project.

18. Why is titanium so expensive?

Titanium’s high cost comes from its complex extraction, energy-intensive processing, machining difficulty, and superior material properties.