15 years one-stop China custom CNC machining parts factory

872 |

Published by VMT at Jun 10 2025 | Reading Time:About 7 minutes

872 |

Published by VMT at Jun 10 2025 | Reading Time:About 7 minutes

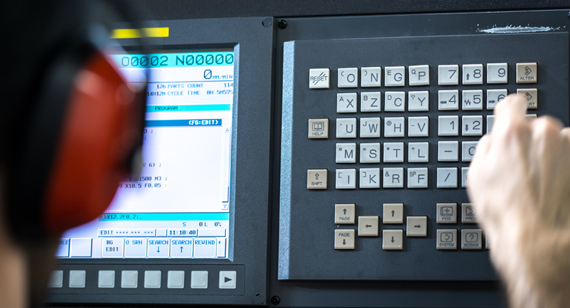

Do you ever wonder what makes your CNC machines respond beyond just cutting motions—how they start and stop coolant, change tools, or signal the end of a program? Many find M‑codes mysterious, yet misunderstanding them can lead to program errors, machine downtime, or even damage.

Imagine a machining job where the coolant never turns on at M08 or the spindle doesn’t reverse with M05—this could ruin parts, tools, or waste hours troubleshooting.

By mastering M code in CNC machining, you gain the ability to control auxiliary functions with confidence. These essential commands—ranging from spindle control (M03/M05) to tool change (M06) and program sequencing—give your CNC programs reliability and precision. Let’s unlock how M‑codes power your CNC machining services and drive results in your CNC machining factories.

M‑code commands in CNC machining activate essential machine functions like spindle start/stop, coolant control, and program end. Understanding and correctly programming M code CNC ensures efficient operations, reduces errors, and enhances part quality—vital in CNC machining parts production and industrial automation.

Now that we’ve highlighted the importance of M‑codes, let’s dive deeper into their definition, structure, and real-world use in CNC machining services workflows.

M codes, often called “miscellaneous codes,” are instructions within CNC programs that control machine peripherals and auxiliary functions—from turning on coolant to signaling the end of a job. Unlike G‑codes, which handle movement and machining paths, M codes manage discrete actions that support the physical process. Without M‑codes, a CNC machine would only move; it wouldn’t know when to stop cutting or change tools.

M codes are essential for CNC machining factories, ensuring that CNC machining parts are produced reliably and to spec. They bring together motion and support systems, creating a seamless process flow from setup to final inspection.

M-codes evolved alongside early CNC systems in the 1960s, as machine control languages developed from manual NC to automated operation. While no single inventor is credited, M-codes became standardized as part of Fanuc’s and other early CNC systems. Today, while differences may exist across controllers, the core functions—like M03 for spindle rotation—remain consistent.

CNC machines are sophisticated tools, but without the proper commands, even the most advanced equipment is nothing more than a silent hunk of metal. Many operators focus solely on G-codes for movement and geometry, neglecting the critical role of M-codes—leading to incomplete programs, poor automation, and increased downtime.

Imagine a situation where your program executes a perfect tool path—but your spindle doesn't start, the coolant never flows, and the tool change never happens. The result? Incomplete parts, tool damage, or even machine failure. That's the consequence of overlooking M-code in CNC machining.

M-codes are the “action triggers” of CNC machining. They control everything beyond movement—such as starting/stopping the spindle, activating coolant, changing tools, and signaling the end of a program. These commands are essential for full-cycle automation, safety, and precision. Without them, G-codes can’t do their job effectively.

M-code commands are essential in CNC machining because they control machine functions such as spindle rotation, coolant flow, tool changes, and program stops. These instructions enhance automation, improve process efficiency, and ensure safety—making M-codes a fundamental component in any reliable CNC program.

To truly understand the power of CNC programming, you need more than motion commands—you need M-codes. Let’s explore exactly why M-code CNC commands are used, and how they impact every step of the machining process.

Why Are M-Code Commands Used in CNC Machining?

M-code commands play a critical role in CNC machining services by enabling auxiliary machine functions that go beyond movement. Unlike G-codes, which guide the tool's path, M-code in CNC machining is responsible for orchestrating the behaviors and responses of the machine that make automated manufacturing possible.

1. Automating Machine Behavior

M-codes tell the machine what to do, not just where to go. For instance:

These commands are essential for fully automated production cycles. Without them, an operator would need to manually perform these steps—slowing down the process and increasing the risk of human error.

2. Enhancing Safety and Control

Safety is a top priority in CNC machining factories. M-codes provide precise, repeatable control over machine components, which ensures predictable performance. For example:

M-codes reduce the likelihood of errors that could result in tool breakage, poor part quality, or operator injury.

3. Integrating With G-Codes

M-codes work hand-in-hand with G-codes. While G-codes define the how of machining (e.g., G01 for linear cutting), M-codes define the when and what. This seamless integration allows the CNC machine to carry out complete, synchronized operations—from toolpath execution to environmental control.

4. Improving Efficiency and Productivity

In high-volume or precision manufacturing, every second matters. M-codes ensure actions like tool changes, spindle starts, or coolant activation happen at the exact moment needed—maximizing uptime and reducing cycle times. This is especially critical in the production of high-spec CNC machining parts where tolerances and timelines are tight.

5. Standardizing Communication Across Machines

Though different machines might have unique M-codes, many core commands are universally understood across CNC platforms. This standardization helps operators and programmers work more efficiently, even when switching between machines or manufacturers.

M-code commands aren’t just programming tools—they’re the key to unlocking full machine automation, safety, and production efficiency. To learn more about how M-codes complement G-code programming or how they’re used in real-world CNC programs, explore our related content or get in touch with VMT for expert insights and custom CNC machining services.

In the field of CNC machining, M-codes play an indispensable role that often goes unnoticed by beginners but is deeply appreciated by experienced machinists and programmers. While G-codes define geometric movements, M-codes control the auxiliary functions that make those movements possible—like turning the spindle on or off, activating the coolant, or changing tools. These commands form the operational backbone of any CNC process, ensuring that machines not only move but do so with intelligence and coordination. Without M-codes, CNC machines would lack the functionality to execute complete tasks efficiently. Understanding their importance isn’t just technical knowledge—it’s essential for productivity, precision, and safety.

CNC Operation Optimization

M-codes significantly contribute to optimizing the operation of CNC machines. Each M-code triggers a specific machine action, such as starting or stopping the spindle, engaging or disengaging coolant, or halting the program entirely. This precise control over machine behavior enhances production efficiency and reduces downtime. For example, using M06 for automatic tool changes eliminates manual intervention, saving both time and labor. Similarly, using M08 to automatically activate the coolant during high-speed milling minimizes tool wear and improves part quality. These smart automation features powered by M-codes streamline complex tasks, reduce errors, and help CNC machining factories maintain consistent, high-quality output. By embedding the right M-codes in your program, you’re not just coding—you’re orchestrating a seamless production performance.

Increased Flexibility

Another major advantage of using M-codes is the operational flexibility they provide. CNC machines become more versatile when programmed with the appropriate M-codes, allowing them to switch between different operations effortlessly. Whether it's engaging a rotary axis, stopping midway for inspection with M00, or activating machine-specific functions like clamps and orientation locks, M-codes allow operators and programmers to tailor machine behavior precisely to job requirements. This is particularly useful in CNC machining services where different projects demand varying setup configurations. With M-codes, machines can adapt quickly without reprogramming the entire G-code structure, saving time and enhancing workflow continuity. This adaptability also makes it easier to scale from prototype runs to full-scale production within CNC machining factories.

Integration with G-Codes

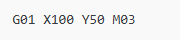

M-codes do not function in isolation—they work in harmony with G-codes to create a complete CNC program. While G-codes instruct the machine on how to move (e.g., linear or circular paths), M-codes instruct it on what to do during or after the movement. For instance, a command like G01 X100 Y50 M03 simultaneously initiates linear motion while turning the spindle clockwise. This integrated operation is essential for executing complex machining sequences with precision. Moreover, this seamless blend of G and M-codes supports automation across multiple machining processes—milling, turning, drilling, and even EDM. For professionals developing CNC machining parts, this coordination ensures that machine behavior is both predictable and programmable, leading to higher-quality outputs and more reliable CNC machining services.

M-codes are essential operational commands that bring a CNC machine to life beyond mere movement. While G-codes dictate how and where the machine moves, M-codes control what happens during and between those movements. Think of them as the switchboard behind the scenes, enabling or disabling machine functions like spindle direction, coolant flow, and tool changes. Whether you're manufacturing complex aerospace components or simple automotive parts, understanding how M-codes work ensures your CNC machining process is smooth, efficient, and safe. For CNC machining factories, M-codes are not just instructions—they are the foundation of operational precision and automation.

M-Code Programming

At the programming level, M-codes are written as part of the CNC program, typically using a simple syntax like M03 (spindle clockwise) or M08 (coolant on). Each M-code corresponds to a specific machine function and is placed in the same line or block as G-codes when necessary. For example:

This tells the machine to move in a straight line to X100 Y50 while simultaneously turning on the spindle clockwise. M-codes are processed by the CNC control unit in real time and executed in the sequence they appear unless otherwise modified by optional stop commands like M01. Depending on the control system, some M-codes are modal (stay in effect until canceled), while others are non-modal (executed once and done). This structured, logic-based programming is a major advantage of modern CNC machining services and allows for highly customizable workflows when producing CNC machining parts.

Execution and Control

When an M-code is executed, the CNC machine sends an electrical or digital signal to activate a specific auxiliary system—like turning on a motor, engaging a hydraulic clamp, or initiating a tool change. This signal can trigger hardware relays, actuators, or internal subsystems depending on the machine configuration. For example, executing M06 initiates an automatic tool change routine, which may involve lifting the spindle, rotating a tool carousel, aligning a new tool, and locking it in place. M-codes can also pause the program (M00), giving an operator time to inspect parts or switch workpieces manually. These real-time controls ensure that CNC machining processes remain adaptable, consistent, and high-quality across various materials and part geometries. For CNC machining factories handling high-volume production, mastering M-code execution is key to minimizing downtime and maximizing precision.

Understanding the structure of an M-code is fundamental for anyone working with CNC machining services. M-codes are standardized, numerical instructions used to control machine functions unrelated to axis movement. They are simple yet powerful commands that activate actions such as turning on the spindle, stopping the program, or changing tools. For CNC machining factories, knowing how to structure and use M-codes correctly ensures the efficiency, safety, and accuracy of every machining cycle. Whether you’re producing precision CNC machining parts or managing automated workflows, grasping M-code structure helps avoid costly errors and maximize productivity.

The Structure of an M-Code: Straightforward but Essential

An M-code typically consists of:

Here’s how it works in practice:

M00: Program Stop

This command tells the CNC machine to pause the execution of the program until the operator resumes it manually. It's commonly used when a visual inspection or manual adjustment is needed before proceeding.

There are no coordinates or additional parameters required. It simply halts the process at that point.

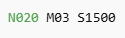

M03: Spindle Rotation Clockwise

This command activates the spindle rotation in the clockwise direction. It often works together with an S-code that defines spindle speed (e.g., S1500 for 1500 RPM).

plaintext

This line of code turns the spindle on at 1500 RPM, rotating clockwise.

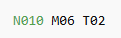

M06: Tool Change

The tool change command tells the CNC machine to swap out the current tool for another based on the tool number specified with a T-code.

This line instructs the machine to change to Tool 2 using the automatic tool changer.

Why Structure Matters

Incorrectly structuring M-codes can lead to tool collisions, program failures, or damage to expensive CNC equipment. By understanding the structure of an M-code, CNC programmers and operators can write safer, more efficient programs that improve consistency and reduce machine downtime. This is especially important when producing high-precision CNC machining parts across multiple projects.

Up next, we’ll dive into “What are the different types of M-codes?”, where you’ll learn the most commonly used commands and how they benefit your machining processes.

M-codes in CNC machining are not just miscellaneous commands—they are the backbone of controlling non-movement machine operations. While G-codes define how a tool moves, M-codes define what happens during that movement or in between. From turning on the spindle to stopping the coolant, each M-code has a specific function that contributes to a smooth, safe, and automated workflow. Understanding the different types of M-codes helps CNC machining factories reduce operator intervention, streamline production, and ensure every CNC machining part is made with precision and efficiency.

Let’s explore the essential M-codes every CNC programmer and machinist should know.

Core Types of M-Codes and Their Functions

| M-Code |

Function |

Purpose in CNC Machining |

| M00 |

Program Stop | Stops the machine immediately. Requires manual restart. Useful for inspection or mid-run checks. |

| M01 |

Optional Program Stop | Similar to M00, but only stops if optional stop is enabled on the control panel. |

| M02 |

Program End | Marks the end of the program. Stops the machine and resets the program counter. |

| M03 |

Spindle Rotate Clockwise | Starts spindle rotation in a clockwise direction. Often paired with a spindle speed command. |

| M04 |

Spindle Rotate Counterclockwise | Rotates the spindle counterclockwise. Used based on tool or material requirements. |

| M05 |

Spindle Off | Stops the spindle rotation. Always used before tool changes or end of a machining cycle. |

| M06 |

Tool Change | Automatically changes the current tool to the specified one. Vital for multi-step operations. |

| M08 |

Coolant On | Activates the flood coolant. Helps with heat dissipation, chip removal, and tool life. |

| M09 |

Coolant Off | Turns off the coolant. Often follows the end of a cutting operation. |

| M30 |

Program End and Rewind | Ends the program and resets it to the beginning. Useful for repetitive batch production. |

Why M-Codes Matter in CNC Machining Operations

Each M-code enhances the automation and safety of the machining process. For example, M03 and M08 work together to start machining under proper spindle and coolant conditions, while M06 ensures the right tool is used for each stage. Meanwhile, M30 prepares the system for the next run—crucial for mass production environments.

By mastering these essential M-codes, CNC programmers can produce consistent, high-quality CNC machining parts with minimal human intervention. These codes are foundational in modern CNC machining services, enabling CNC machining factories to scale efficiently and deliver tight tolerances and fast turnaround times.

Next, we’ll explore Other M-Codes beyond the basics—those that offer even more control and specialization for advanced operations.

Beyond the standard M-codes that most CNC operators are familiar with, many CNC machining factories rely on additional, machine-specific M-codes to control auxiliary functions. These M-codes offer increased flexibility and automation in advanced operations. From activating a mist coolant system to calling subroutines, these “other” M-codes play a crucial role in customizing your CNC processes to suit complex production requirements.

Understanding these M-codes is vital for anyone working in CNC machining services, especially when programming M code CNC sequences for high-precision or repetitive tasks.

Key Auxiliary M-Codes and Their Functions

| M-Code | Function | Description |

| M07 | Coolant On (Mist) | Activates the mist coolant instead of the flood system. Ideal for lighter cooling needs. |

| M10 | Clamp On | Engages clamps or fixtures to hold the workpiece in place. |

| M11 | Clamp Off | Releases clamps or fixtures. Often paired with M10. |

| M19 | Spindle Orient | Orients the spindle to a fixed position. Critical for tool changes or probing. |

| M40 | Spindle Gear in Center | Sets spindle gearing to a neutral or mid-range position. Used in gear-changing machines. |

| M98 | Subroutine Call | Calls a predefined block of code or subprogram. Enhances program efficiency. |

| M99 | Subroutine End/Loop Return | Ends a subroutine and returns to the main program or loops back. |

Note: M-code functions can vary slightly depending on the CNC machine model or manufacturer. Always refer to the specific machine manual when writing your M code CNC programs.

Why These M-Codes Matter

While these M-codes may seem optional, they’re essential for advanced CNC machining parts production, especially in industries requiring high automation, such as aerospace, medical, and automotive. For example, M19 is crucial for orienting the spindle during probing or tool change sequences, ensuring accurate and repeatable machining. Likewise, M98 and M99 make long, complex programs more modular and readable—ideal for mass production using die casting CNC machining parts or custom components.

At VMT, our CNC machining services utilize both standard and advanced M-codes to deliver precise, repeatable, and high-quality results. Whether you need custom clamps activated or a perfectly timed coolant mist system, we tailor M-code programming to meet your unique manufacturing goals.

Next, we’ll dive into how to read and program M-code commands, so you can understand how these critical codes are used in real-world CNC operations.

Unlocking the Meaning Behind M-Code Commands

If you’re new to CNC programming or managing CNC machining services, the variety of codes involved can feel overwhelming. Among the most important are M-code CNC commands—these dictate machine-specific actions like spindle control, tool changes, or coolant activation. To read them correctly is to unlock full control over the behavior of your CNC equipment. Misreading even a single letter or number can lead to machine errors, costly downtime, or part defects. That’s why mastering the structure and meaning of M-codes is a crucial skill for every CNC operator, programmer, or CNC machining factory technician.

How to Read an M-Code: A Simple Breakdown

An M-code typically appears in the program as a single letter followed by a two-digit number, and it usually stands alone or accompanied by minimal information. Here’s how to interpret it:

1. Understand the Format

2. Recognize Standard Examples

| M-Code |

Meaning |

Effect |

| M00 |

Program stop | Stops the program until manually restarted. |

| M03 |

Spindle ON (clockwise) | Rotates the spindle clockwise. |

| M05 |

Spindle stop |

Stops spindle rotation. |

| M06 |

Tool change | Triggers automatic tool change. |

| M08 |

Coolant ON | Turns on the coolant system. |

| M30 |

Program end and rewind | Stops program and returns to the beginning. |

3. Identify Associated Functions

Sometimes M-codes appear in a block (a single line of CNC code) with other letters like:

Example:

This line means: Line 10, tool change to Tool #2.

Another:

This line means: Start spindle clockwise at 1500 RPM.

4. Read the Context

M-codes are non-universal in some machines. A code like M19 (spindle orientation) might exist on one machine but not another. Check your machine’s manual or control software to ensure accuracy.

Why It Matters

Reading M-code commands correctly ensures precise control over CNC machining parts. When used alongside G-codes, M-codes help optimize processes, prevent collisions, and streamline operations. Whether you're running die casting CNC machining parts or handling delicate finishing work, M-codes let you automate, control, and monitor every detail of the operation.

As CNC machining services evolve with multi-axis setups and high-mix production lines, the ability to read and write clean M-code CNC instructions becomes even more critical. At VMT, our programmers and operators are skilled in crafting CNC code that maximizes performance and minimizes risk—because precision starts with the code.

Next, learn how to program a CNC machine using M-code commands and take full control of your machining operations from start to finish.

From Code to Components — Using M-Codes to Run a CNC Machine

If you're aiming for accuracy, consistency, and speed in modern manufacturing, M-code in CNC machining is non-negotiable. Whether you’re producing small-batch CNC machining parts or managing full-scale production through CNC machining services, programming M-codes correctly defines the efficiency and reliability of the entire process. Mistakes in M-code logic can stop your machine, damage tools, or ruin parts—while correct usage delivers flawless, automated performance. Let’s walk through how to effectively write, input, and run a CNC program using M-codes to take full control of your production.

Standard Process: How to Program a CNC Machine Using M-Code

To program a CNC machine using M-code CNC commands, follow these key steps:

1. Understanding M-Codes

Before writing any program, you must know what M-codes do. M-codes are machine control instructions that manage actions such as starting/stopping the spindle, tool changes, coolant control, and program pauses.

Some common examples:

Remember: M-codes are machine-specific. Always check your CNC machine’s manual or control software for model-specific definitions.

2. Writing a CNC Program Using M-Codes

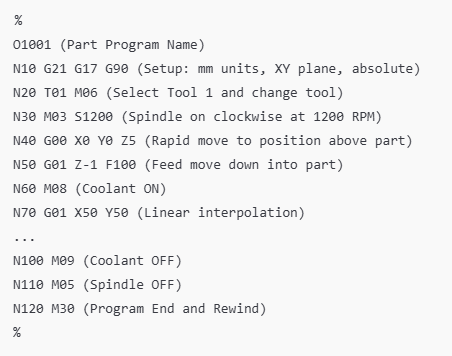

CNC programs are written line-by-line in blocks, and each block may contain multiple commands including M-codes. Here’s a basic format:

Each M-code serves a machine-specific function to automate manual tasks, reduce downtime, and protect tooling.

3. CNC Machine Setup

After programming:

The setup must align with your program’s M-code calls (e.g., M06 assumes the tool is available and positioned correctly).

4. Loading and Running the Program

Once setup is complete:

During execution, M-codes will manage machine functions like spindle rotation (M03), coolant flow (M08), and tool changes (M06) in real time.

5. Monitoring the Process

While the CNC is running:

CNC machines may also display active M-codes on the operator interface during execution for real-time verification.

6. Inspecting the Final Product

After the cycle ends with M30:

From Code to Quality Parts

Programming M-codes is at the heart of CNC machining factories. From controlling the spindle to managing coolant and tool changes, M-codes transform lines of code into smooth, automated actions. At VMT, our expert programmers use optimized M-code sequences to produce die casting CNC machining parts with high efficiency and precision.

Looking to deepen your programming skills? Next, explore real-world M-code examples and simulations to practice interpreting and applying commands in your own CNC projects.

M-codes play a vital role in automating and controlling various auxiliary functions during CNC machining operations. These commands manage machine behaviors such as spindle control, coolant flow, tool changes, and program stops, ensuring precision and efficiency. But which types of CNC machines actually use M-codes? Understanding this helps operators, programmers, and engineers optimize programming and workflow across diverse manufacturing environments. Let’s explore the main CNC machines that rely on M-codes to function smoothly.

Milling Machines

CNC milling machines are widely used to cut and shape metal parts by removing material from a workpiece using rotary cutters. M-codes in milling control critical operations like spindle rotation (M03 for clockwise), coolant management (M08/M09), and tool changes (M06). Since milling often involves complex multi-axis movements and various tooling, M-codes are indispensable for coordinating machine actions beyond simple motion commands. Efficient use of M-codes in milling enhances precision and reduces cycle time.

Lathes

CNC lathes specialize in producing cylindrical parts by rotating the workpiece while cutting tools shape its outer and inner surfaces. M-codes are essential in lathes for controlling spindle direction and speed, tool turret indexing, coolant application, and program pauses. Given that lathes often perform rapid tool changes and require spindle reversals, M-codes facilitate automation and safety during these operations. Multiple mentions of lathes underscore their strong reliance on M-codes for smooth production.

Plasma Cutters

Plasma cutting uses a high-velocity jet of ionized gas to cut through electrically conductive metals. While primarily controlled by G-codes for motion and cutting paths, plasma cutters also utilize M-codes to manage auxiliary functions like gas flow, torch ignition, and safety stops. M-codes help ensure consistent cutting quality and protect the equipment from damage by enabling precise control of operational states.

Electrical Discharge Machines (EDM)

EDM machines remove material by electrical sparks rather than mechanical cutting. Despite the different process, EDMs employ M-codes to control functions such as electrode positioning, spark initiation, flushing coolant, and program control. Integration of M-codes in EDM programming helps synchronize these specialized functions with the machining path, enabling high-precision and automated production.

Conclusion

M-codes are integral to a wide range of CNC machines including milling machines, lathes, plasma cutters, and EDMs. They bridge the gap between motion commands and machine auxiliary functions, providing the flexibility and control necessary for modern CNC machining factories. Proper understanding and implementation of M-code commands ensure enhanced machine performance, safety, and part quality across these diverse platforms.

For a deeper dive, explore related topics such as M code in CNC machining, M code CNC examples, and how these codes optimize CNC machining parts production at VMT’s expert CNC machining services.

M-codes are essential commands in CNC machining that control various machine functions beyond the basic movement commands. They manage everything from starting and stopping the spindle to activating coolant systems and ending programs. Knowing real-world examples of M-codes helps CNC operators and programmers understand how to effectively automate machining processes and improve efficiency. Let’s review some of the most commonly used M-codes and their practical applications.

M03: Spindle Turns Clockwise

The M03 command starts the spindle rotating in a clockwise direction, which is the standard rotation for most machining operations. This command is crucial when beginning any cutting or milling process where the spindle needs to be engaged. For example, in milling a steel part, M03 initiates spindle rotation to enable the cutting tool to engage the workpiece smoothly and efficiently.

M08: Coolant On

M08 activates the coolant system to spray coolant onto the cutting area, reducing heat buildup and extending tool life. In real-world CNC machining, applying coolant is essential during heavy cutting operations, such as deep drilling or rough milling of metals like stainless steel. The M08 command ensures proper cooling and lubrication, improving surface finish and preventing tool damage.

M06: Tool Change

M06 commands the CNC machine to perform a tool change, automatically swapping the current cutting tool with another from the tool magazine. This is especially important in multi-step machining processes where different tools are required, such as switching from a drill bit to an end mill. Automating tool changes with M06 enhances productivity and reduces downtime.

M09: Coolant Off

The M09 command turns off the coolant system once the cutting operation requiring cooling is complete. For example, after finishing a high-heat cutting pass, M09 deactivates the coolant to conserve resources and prepare the machine for the next stage, such as tool changes or inspection.

M05: Spindle Off

M05 stops the spindle from rotating. This command is used to safely pause or end machining operations, such as when a tool change is necessary or before the program finishes. For instance, M05 is often paired with M06 during a tool change cycle to halt spindle movement safely before switching tools.

M30: End of Program, Return to Start

M30 signals the end of the CNC program and resets the machine’s control to the program’s starting point. This allows operators to easily rerun the same machining cycle or prepare the machine for the next batch. It’s a standard command to conclude a machining job and ensure the machine is ready for the next task.

Conclusion

These real-world M-code commands — M03 (spindle on clockwise), M08 (coolant on), M06 (tool change), M09 (coolant off), M05 (spindle off), and M30 (program end) — form the backbone of CNC machine control. Proper use of these codes in programming ensures smooth, efficient, and safe operation across a variety of CNC machining parts and services. For those looking to optimize their CNC machining processes, understanding these M-codes is a fundamental step toward leveraging full machine capabilities.

Discover more about M code in CNC machining and enhance your workflow with VMT’s reliable CNC machining services and expert guidance.

Certainly! Here's a clear table summarizing the real-world examples of M-codes used in CNC machining:

| M-Code |

Function |

Real-World Application |

| M03 |

Spindle turns clockwise | Starts spindle rotation for milling, drilling, or cutting operations |

| M08 |

Coolant ON | Activates coolant spray to reduce heat and extend tool life |

| M06 |

Tool change | Automatically changes the cutting tool during multi-step machining |

| M09 |

Coolant OFF | Turns off coolant after cutting operations |

| M05 |

Spindle OFF | Stops spindle rotation for safe tool changes or operation pauses |

| M30 |

End of program, return to start | Ends the CNC program and resets machine for the next operation |

This table provides a quick overview of essential M-codes, helping CNC operators and programmers quickly understand their purpose and application in CNC machining factories and services.

Understanding M-codes is essential for a variety of professionals involved in CNC machining. First and foremost, CNC programmers rely heavily on M-codes to write accurate and efficient machine instructions that control machine functions beyond mere movement. Machinists and CNC machine operators also need to understand M-codes to properly run and troubleshoot CNC machines on the shop floor, ensuring smooth operation and high-quality parts. Additionally, manufacturing engineers use M-codes knowledge to optimize production processes and improve machine programming. Manufacturing technicians must be familiar with M-codes to maintain equipment and assist in production adjustments. Beyond the operational team, CNC machine designers and sales professionals benefit from a solid understanding of M-codes to design better machines and offer knowledgeable advice to customers, respectively. Whether involved in programming, operation, maintenance, design, or sales, mastering M-code commands is crucial for maximizing efficiency and precision in CNC machining services and CNC machining factories.

Choosing the right M-code simulator can significantly enhance CNC programming accuracy and machine operation efficiency. With so many options available, selecting a tool that fits your skill level, project complexity, and CNC machining services can be challenging. The right simulator helps you visualize and test M-code commands, reducing errors and improving production outcomes before actual machining begins.

For CNC machining professionals and CNC machining factories, several simulators stand out. CNC Simulator Pro is a popular choice known for its comprehensive interface and realistic machine simulation, making it ideal for both beginners and experienced users. Mach3 offers robust control features and is widely used in CNC machining parts production for its integration with various hardware. Mastercam Simulator provides detailed visualization within a widely adopted CAM software, enhancing the programming workflow. For open-source enthusiasts, CAMotics delivers a free and versatile option supporting G-code and M-code simulation. NCSim and NC Viewer offer browser-based simulation solutions, providing easy access without installation. Lastly, G-Wizard Editor combines code editing with simulation and optimization tools, improving CNC program quality and efficiency. Selecting the best M-code simulator depends on your specific CNC machining needs, budget, and preferred features, but these tools are trusted across the industry to optimize CNC machining services.

When programming M-codes in CNC machining, safety must be a top priority to protect both operators and equipment. M-codes control critical machine functions such as spindle rotation, coolant flow, and tool changes. Incorrect or careless use of these commands can lead to equipment damage, product defects, or even serious injury. Therefore, understanding and applying safety precautions is essential for anyone involved in CNC machining services or working in CNC machining factories.

Firstly, always double-check M-code commands before running a program. Confirm that commands like M03 (spindle on clockwise) and M05 (spindle off) are properly sequenced to prevent unintended machine movement. Secondly, avoid programming overlapping or conflicting commands that could cause mechanical collisions or abrupt stops, which pose hazards to both the operator and the machine. Thirdly, ensure that emergency stop protocols are understood and accessible; operators should know how to quickly halt the machine if something goes wrong during M-code execution.

Additionally, comprehensive training on machine-specific M-codes is vital because definitions and responses may vary between different CNC machines and manufacturers. Using a simulator to test M-code sequences before actual machining helps identify risky commands and prevents accidents. Proper maintenance of CNC machining parts and periodic inspection of machines also contribute to safe operations. Lastly, always wear appropriate personal protective equipment (PPE) such as safety goggles and gloves when working near CNC machines.

By following these precautions, manufacturers and machinists can leverage the power of M-code CNC machining commands safely and effectively, ensuring smooth operation and safeguarding valuable assets and personnel.

In CNC machining, understanding the distinction between M-codes and G-codes is essential for effective programming and machine operation. Both types of codes play crucial roles but serve fundamentally different purposes in controlling CNC machining parts and processes.

G-codes, or “geometric codes,” primarily direct the movement of the machine tool. They control the path, speed, and positioning of the cutting tool. For example, G01 commands a linear move at a controlled feed rate, while G02 and G03 command circular interpolation movements. Essentially, G-codes dictate how the tool moves through the material, enabling the shaping and cutting operations required to produce precise parts.

In contrast, M-codes, also known as “miscellaneous codes,” handle the machine’s auxiliary functions. These include turning the spindle on or off (M03, M05), activating coolant flow (M08, M09), tool changes (M06), and program stops (M00, M30). M-codes do not affect the tool path directly but manage the machine’s environment and operational state, ensuring the machine runs smoothly and safely during the machining process.

In summary, while G-codes govern the motion and geometry of machining, M-codes control machine functions that support the operation. Both are indispensable for CNC machining services and CNC machining factories, working together to produce high-quality CNC machining parts with precision and efficiency.

Understanding and correctly applying M code in CNC machining is no longer optional—it's essential. Whether you’re a CNC programmer, machine operator, or manufacturing engineer, mastering M-codes allows you to fully harness the potential of your CNC machine. These codes control crucial auxiliary functions like spindle direction, coolant flow, and tool changes, all of which directly impact part quality, production efficiency, and equipment longevity.

By integrating M codes with G codes, manufacturers can achieve precise coordination between tool movement and machine operations. This leads to better cycle times, fewer manual interventions, and a higher standard of repeatability. Moreover, with the growing demand for complex and high-tolerance CNC machining parts, understanding these command sets empowers you to optimize every stage of your workflow—from simulation and setup to real-time adjustments and inspection.

Choosing the right M-code simulator, following safety best practices, and continuously refining your programming knowledge is key to staying competitive in a fast-evolving manufacturing landscape. Whether you’re working with milling machines, lathes, EDMs, or plasma cutters, M-codes are the silent drivers of process efficiency and machine intelligence.

At VMT, we don’t just offer CNC machining services—we provide engineering support, simulation insight, and the experience of one of the most advanced CNC machining factories in the industry. From prototyping to full-scale production, we integrate the best practices in M-code programming to deliver reliable, scalable, and high-precision die casting CNC machining parts that meet today’s most demanding specifications.

If you’re ready to elevate your production with smarter CNC processes, contact us today and let’s talk about your next project.

1. How many M codes are there in a CNC control?

There are typically 50 to 100 standard M codes, but the exact number can vary depending on the machine model and the CNC controller (e.g., FANUC, Siemens, Haas). Some manufacturers also allow for custom M codes tailored to specific functions.

2. What does an M code activate in a CNC machine?

An M code activates auxiliary functions such as turning the spindle on/off, activating coolant, changing tools, or stopping the program. These codes are essential to control non-movement operations and ensure the correct sequencing of CNC machining tasks.

3. Are M codes universal across all CNC machines?

No. While many M codes in CNC machining are standardized (like M03 for spindle on clockwise), not all are universal. Manufacturers may define custom M codes, so it's important to consult the specific machine's documentation.

4. Can I use multiple M codes in a single line of code?

Most CNC controls allow one M code per block (line). Some advanced systems can accept multiple, but it’s best practice to write each M code CNC command on its own line for clarity and to avoid execution errors.

5. What is the difference between M02 and M30?

Both are program end commands, but M30 resets the program to the beginning for the next cycle (looping), while M02 simply ends the program without resetting.

6. How many M codes are there?

The general list includes around 30–100 M codes, depending on machine complexity. Additionally, CNC machining factories may implement custom M codes for special operations.

7. Can I create custom M codes?

Yes, many controllers support user-defined M codes. These are useful in CNC machining services to perform specialized functions like activating clamps, probes, or external devices.

8. Do all CNC machines use M codes?

Most modern CNC machines (milling, turning, EDM, etc.) use M codes alongside G codes to control machine behavior. However, their implementation may vary slightly.

9. Do M codes affect the quality of machined parts?

Indirectly, yes. Proper use of M codes ensures smooth tool changes, coolant activation, and spindle control—all of which influence the precision and surface quality of the final CNC machined parts.

10. Are there dangerous M codes?

While M codes themselves are not inherently dangerous, incorrect usage (e.g., disabling coolant or misusing spindle commands) can result in tool breakage or damage to parts and machinery.

11. How do I learn to use M codes effectively?

Start with the machine’s manual, then practice on M code simulators like Mach3, CAMotics, or Mastercam Simulator. Partnering with experienced CNC machining factories like VMT also helps accelerate learning.

12. Can M codes be used in Manual Data Input (MDI) mode?

Yes. Most CNC machines allow M codes to be entered manually in MDI mode for testing or one-off operations without running a full program.

13. Are M codes case sensitive?

No. CNC controllers are not case-sensitive, so M03 and m03 are interpreted the same way.

14. How do M codes interact with other parts of a CNC program?

M codes complement G codes by controlling non-movement functions. For example, a G01 linear feed might be followed by an M08 to activate coolant, ensuring the right machining environment is in place.

15. What is G41 in CNC?

G41 activates cutter radius compensation left, which offsets the tool path based on the tool's diameter to ensure accurate cutting along the part profile.

16. What are G40 and G41?

G40 cancels cutter compensation, while G41 and G42 apply it (left and right, respectively). These are critical for accurate contour machining in CNC machining services.

17. What is G99 CNC?

G99 tells the machine to return to the initial point after a canned cycle (drilling or tapping), ensuring consistent cycle paths.

18. What is the G43 code for CNC?

G43 is used to activate tool length offset in the positive direction. It's typically paired with H codes to apply the correct length compensation for each tool.