15 years one-stop China custom CNC machining parts factory

41 |

Published by VMT at Oct 21 2025 | Reading Time:About 5 minutes

41 |

Published by VMT at Oct 21 2025 | Reading Time:About 5 minutes

When it comes to CNC machining, the quality of your tools determines everything — accuracy, finish, speed, and even cost. Many shops struggle with tool wear, poor surface finishes, and wasted material because they’re using the wrong cutting or non-cutting tools. Choosing the right CNC machining tools helps you achieve precise cuts, extend tool life, and lower production costs.

CNC machining tools are specialized instruments used to cut, shape, and finish materials in automated CNC machines. They include cutting tools like end mills, drills, and reamers, as well as non-cutting tools such as tool holders and jigs. Selecting the right tool type and material ensures precision, efficiency, and long tool life.

Now that you understand what CNC machining tools are, let’s explore their main types, materials, and applications. Knowing how each tool works — and when to use it — helps you make smarter choices for your CNC machining projects.

CNC machining tools are precision instruments designed to cut, shape, or support workpieces in automated CNC systems. These tools perform various operations — such as milling, drilling, turning, or boring — with high accuracy and repeatability. They come in many types and materials, each optimized for specific machining applications.

CNC machining tools serve as the interface between your CNC machine and the workpiece. They remove or shape material according to programmed tool paths. These tools can be divided into two broad categories:

Each tool must be chosen based on the material being machined — for example, using carbide CNC tools for stainless steel or HSS cutting tools for softer metals. The right selection improves tool life and reduces costs.

CNC machining tools are the backbone of automation and precision manufacturing. They translate digital commands into accurate physical actions, allowing your CNC machine to perform complex cuts and shapes with minimal human intervention. Whether you’re producing simple components or high-tolerance aerospace parts, tool performance determines accuracy, surface finish, and repeatability.

High-quality CNC cutting tools ensure each pass removes material consistently, while non-cutting tools like holders and probes maintain tool alignment and calibration. This synergy between machine control and tool design is what enables modern CNC machining to achieve micron-level precision.

Automation also depends heavily on tool setup and maintenance. Proper tool calibration, balanced toolholders, and consistent wear monitoring reduce downtime and prevent costly part rework. In automated production, even a slightly worn tool can lead to thousands of defective components.

Tool selection directly affects every outcome in CNC machining — from part accuracy and surface finish to tool life and machining cost. Choosing the wrong tool can lead to excessive wear, vibration, poor dimensional control, and even part failure. The right tool, on the other hand, ensures smoother operation, consistent results, and higher productivity.

Each material and machining operation demands a specific tool geometry, coating, and hardness. For example, carbide CNC tools are ideal for cutting hard metals like stainless steel and titanium, while HSS cutting tools work best for softer materials such as aluminum and brass. Selecting the wrong combination can cause chattering, tool breakage, or overheating.

Tool selection also determines cutting speed and feed rate. Tools with the correct geometry and coating — such as TiAlN or DLC — can withstand high temperatures and extend machining life. Additionally, proper tool matching reduces energy consumption and minimizes machine load, improving efficiency over time.

CNC Machines vs. CNC Tools: What’s the Difference?

CNC machines and CNC tools work together but serve different purposes. The CNC machine provides motion and control. The CNC tools perform the actual cutting, shaping, or measuring tasks.

The machine includes components like spindles, drives, and controllers that move the tool according to programmed coordinates. The tool, such as an end mill or drill, removes material to create the desired geometry.

Without precision tools, even the best CNC machine can’t achieve tight tolerances or fine finishes. Likewise, advanced tools are useless without accurate machine motion. Both must work in harmony for high-quality parts.

CNC machining involves several distinct processes, each requiring specialized tools for different operations. The main categories include CNC milling, CNC turning (lathe machining), CNC drilling, grinding, and cutting. Each process demands specific tool geometry, materials, and coatings to achieve the required precision and surface finish.

Cutting Tools

Cutting tools remove material from the workpiece to form the desired shape or surface. These tools must be harder than the material being cut and maintain sharpness under high temperatures and pressure.

Common types include:

Each cutting tool is selected based on the operation, workpiece material, and required finish. Carbide CNC tools are best for hard metals, while HSS cutting tools suit softer alloys or low-volume production.

Note: Monitor tool wear regularly. Dull or chipped tools can cause surface defects and increase machining costs.

Non-Cutting Tools

Non-cutting tools support or control the machining process. They don’t remove material but ensure stability, precision, and repeatability during operation.

Common non-cutting tools include:

These components play a critical role in maintaining machining accuracy and reducing setup time.

Tip: Regularly check non-cutting tools for alignment and wear — small misalignments can lead to costly dimensional errors across large production runs.

CNC machines use a wide range of tools to handle different operations. Each tool is designed for a specific function — from rough material removal to fine surface finishing. Understanding these tools helps you choose the right one for precision, efficiency, and cost control.

End Mills

Note: Use carbide end mills for hard materials like stainless steel to prevent tool deflection and extend lifespan.

Drills

Tip: Match drill point angle and coating (e.g., TiN or TiAlN) to the material for faster drilling and smoother finishes.

Reamers

Note: Use low speeds and steady feed to avoid chatter and maintain dimensional accuracy.

Tap and Thread Mills

Tip: Thread mills are preferred for hard materials and small threads due to better control and less tool breakage.

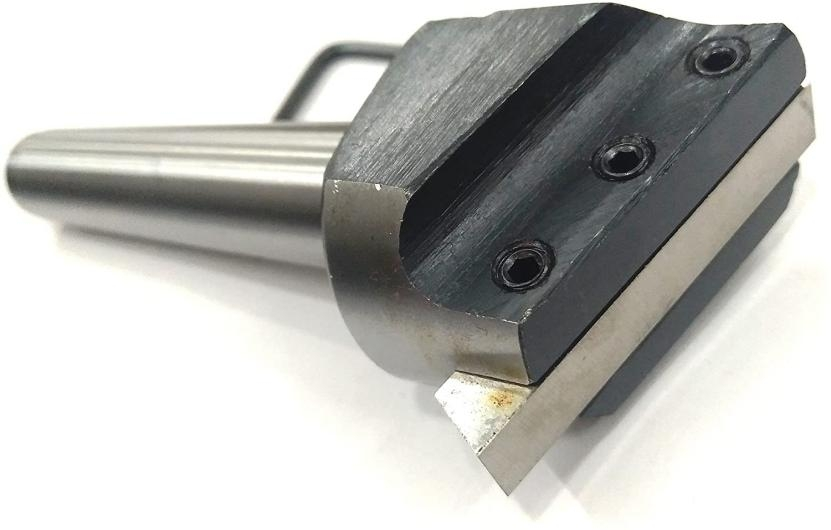

Face Mills

Note: Ensure proper tool diameter and insert grade for your material to avoid surface inconsistencies.

Square End Mills

Tip: Use fewer flutes for softer materials to prevent chip clogging.

Radius End Mills

Note: Use smaller step-overs when finishing to achieve smoother surfaces on curved geometries.

Tip: Choose the correct insert shape (e.g., CNMG or VNMG) for specific cutting angles and finishes.

Boring Bars

Note: Minimize tool overhang to reduce vibration and maintain accuracy.

Cut-Off Tools

Tip: Ensure correct feed rate and coolant flow to prevent tool overheating and edge wear.

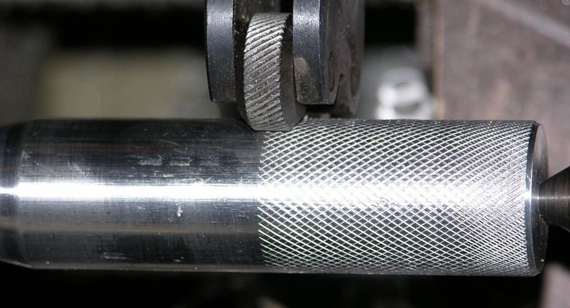

Knurling Tools

Note: Maintain proper pressure and alignment to prevent tool or part damage.

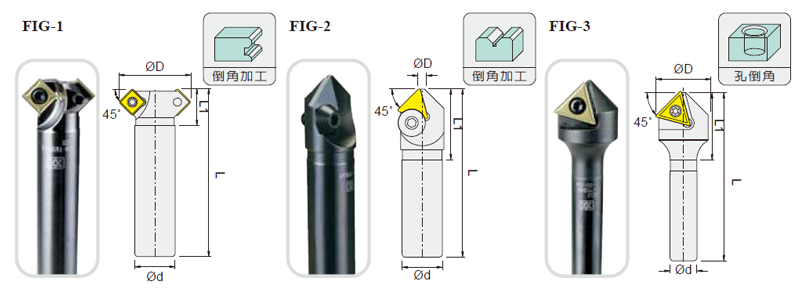

Chamfer Mills

Tip: Adjust the chamfer angle precisely to match design specifications.

Keyway Mills

Note: Use rigid setups to avoid deflection during deep keyway cutting.

Slitting Saws

Tip: Apply consistent coolant to reduce heat buildup and prevent blade warping.

Fly Cutters

Note: Use slower spindle speeds for wide cuts to avoid chatter.

External Radius Mills

Tip: Use coated carbide versions for hard materials to improve surface quality.

Engraving Tools

Note: Adjust depth precisely to avoid over-engraving or damaging delicate parts.

Countersinking Tools

Tip: Match countersink angle (usually 82° or 90°) to the fastener head.

Dovetail Tools

Note: Use rigid setups and consistent feed to prevent chatter during deep cuts.

Table: Common Types of CNC Machine Tools

| Tool Type |

Definition |

Main Use Cases |

Variety / Features |

| End Mills |

Cut laterally or vertically to remove material. | Contouring, slotting, profiling, and face milling. | Flat, ball-nose, corner-radius; HSS, carbide, or coated. |

| Drills |

Rotary tools that create round holes. | Hole-making for bolts, pins, and fittings. | Twist, center, and step drills; HSS or carbide. |

| Reamers |

Finish or enlarge pre-drilled holes. | Achieving tight tolerances and smooth surfaces. | Straight or helical flutes; solid or adjustable. |

| Taps & Thread Mills |

Cut internal or external threads. | Threading in metals and plastics. | Hand taps, spiral taps, solid carbide thread mills. |

| Face Mills |

Remove material from large flat surfaces. | Surface finishing and roughing operations. | Replaceable carbide inserts; multiple diameters. |

| Square End Mills |

Flat-cutting ends create sharp edges. | Slotting, side milling, and contouring. | 2-, 3-, or 4-flute options for chip control. |

| Radius End Mills |

Rounded cutting ends. | 3D contouring, molds, and dies. | Full-radius or corner-radius styles. |

| Turning (Lathe) Tools |

Cut material from rotating workpieces. | Facing, grooving, profiling, threading. | Carbide insert tools; multiple insert geometries. |

| Boring Bars |

Enlarge or finish internal diameters. | Precision hole enlargement in turning. | Solid or modular; replaceable inserts. |

| Cut-Off Tools |

Separate parts from raw stock. | Parting operations on lathes. | Blade-type or insert-type designs. |

| Knurling Tools |

Create textured surfaces. | Grip patterns on handles or shafts. | Straight, diagonal, or diamond patterns. |

| Chamfer Mills |

Produce beveled edges. | Deburring, countersinking, edge prep. | Single- or multi-flute carbide designs. |

| Keyway Mills |

Cut key slots for mechanical assemblies. | Shafts and hub keyway cutting. | Side- or end-cutting styles. |

| Slitting Saws |

Thin circular blades for fine cuts. | Cutting grooves or separating workpieces. | HSS or carbide; fine or coarse teeth. |

| Fly Cutters |

Single-point tools for flat surfaces. | Finishing wide surfaces on aluminum or steel. | Adjustable or fixed with replaceable inserts. |

| External Radius Mills |

Shape rounded external edges. | Decorative or stress-relief rounding. | Multiple radii sizes; coated options. |

| Engraving Tools |

Etch or mark surfaces. | Lettering, branding, serial marking. | V-tip, ball-end, or diamond-point types. |

| Countersinking Tools |

Form conical holes for fasteners. | Preparing holes for flush screws. | Single- or multi-flute HSS or carbide. |

| Dovetail Tools |

Cut angled joints for sliding parts. | Mold bases, mechanical slides. | Various included angles and coatings. |

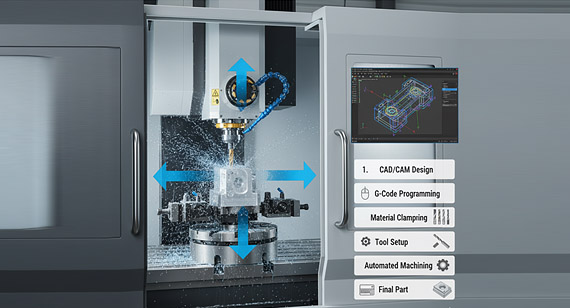

CNC machining tools work by removing material from a workpiece through controlled, automated movements guided by a computer program (G-code). The machine interprets the G-code and moves the cutting tool along multiple axes (X, Y, Z, and sometimes more) to achieve the desired shape and dimensions.

The process involves three key elements:

Cutting parameters such as spindle speed, feed rate, depth of cut, and coolant application are optimized based on material type and tool geometry.

This precise coordination of motion, speed, and cutting pressure allows CNC tools to produce parts with tight tolerances, repeatability, and consistent surface finish, making them ideal for both prototyping and mass production.

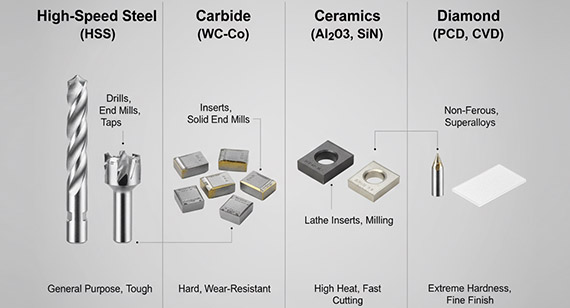

The performance and durability of CNC machining tools largely depend on the materials and coatings used in their construction. Each material offers distinct advantages in hardness, heat resistance, and wear life, influencing cutting efficiency and surface finish quality.

1. Carbon Steel

Carbon steel tools are the most basic type, used for light-duty machining. They are inexpensive and easy to sharpen but lose hardness above 200°C. They are suitable only for soft materials such as wood, plastic, and aluminum.

2. High-Speed Steel (HSS)

HSS tools combine toughness and moderate heat resistance, maintaining hardness up to about 600°C. They are versatile, affordable, and ideal for general-purpose cutting, drilling, and tapping. However, they wear faster than carbide tools at high speeds.

3. Carbide

Carbide tools are made from tungsten carbide and cobalt binders. They offer superior hardness, heat resistance, and wear performance, allowing higher cutting speeds and longer life. They are used for machining hard metals, stainless steels, and high-volume production.

4. Ceramics

Ceramic tools, typically made from aluminum oxide or silicon nitride, resist heat extremely well and maintain hardness at high temperatures. They are best for high-speed finishing of cast iron and hardened steels but are brittle and unsuitable for interrupted cuts.

5. Cermets (Ceramic + Metal)

Cermet tools combine ceramic hardness with metal toughness. They provide excellent wear and oxidation resistance and deliver fine surface finishes. They are often used for finishing operations on steels and cast irons where stability and precision are important.

6. Diamond-Tipped Tools

Diamond tools, either natural or synthetic, are the hardest available. They provide unmatched wear resistance and produce mirror-like finishes. However, they are unsuitable for ferrous metals, as diamond reacts with iron at high temperatures. Commonly used for aluminum, copper, and composites.

7. Cubic Boron Nitride (CBN)

CBN tools are nearly as hard as diamond but can cut ferrous metals effectively. They excel in machining hardened steels, tool steels, and cast irons, offering excellent thermal stability and long tool life in finishing operations.

8. Polycrystalline Diamond (PCD)

PCD tools consist of multiple diamond particles sintered together. They offer outstanding durability, low friction, and minimal wear. PCD is ideal for high-speed cutting of non-ferrous metals, plastics, and composite materials where surface finish is critical.

Table: Common Tool Materials in CNC Machining

| Category |

Type |

Key Features |

Best For / Applications |

| Tool Material | Carbon Steel |

Low-cost, easy to sharpen, limited hardness and heat resistance. | Light-duty operations, soft materials like wood or plastics. |

| High-Speed Steel (HSS) |

Better hardness, wear resistance, and toughness than carbon steel. | General-purpose cutting, drilling, and milling. | |

| Carbide |

Extremely hard, heat-resistant, and wear-resistant. | High-speed machining of steel, stainless steel, and cast iron. | |

| Ceramics |

Excellent heat and oxidation resistance, brittle. | High-speed cutting of hard alloys and cast iron. | |

| Cermets (Ceramic + Metal) |

Combines ceramic hardness with metal toughness. | Finishing and semi-finishing of steels and alloys. | |

| Diamond-Tipped Tools |

Ultra-hard, low friction, excellent wear resistance. | Non-ferrous materials, composites, and plastics. | |

| Cubic Boron Nitride (CBN) |

Second hardest material after diamond, great for hardened steel. | Precision finishing of hardened steels and cast iron. | |

| Polycrystalline Diamond (PCD) |

Exceptional wear resistance and surface finish. | High-speed cutting of aluminum, copper, and composites. |

Tool coatings improve hardness, reduce friction, resist wear, and extend CNC tool life. They also allow higher cutting speeds, better surface finishes, and greater heat resistance, making them critical for precision machining.

1. Titanium Nitride (TiN) Coating

TiN is a gold-colored coating that increases hardness and reduces friction. It improves wear resistance and allows higher cutting speeds on steels and aluminum. Ideal for general-purpose milling, drilling, and turning.

2. Titanium Carbonitride (TiCN) Coating

TiCN is harder than TiN and offers lower friction. It performs well on stainless steel, cast iron, and hardened alloys, reducing tool wear in demanding cutting operations.

3. Titanium Aluminum Nitride (TiAlN) Coating

TiAlN provides excellent heat resistance and oxidation protection. It is ideal for high-speed cutting of steels, stainless steels, and titanium alloys, maintaining hardness at elevated temperatures.

4. Extreme-Life Titanium Nitride (Al-TiN) Coating

Al-TiN offers superior hardness and thermal stability compared with standard TiN. It extends tool life in abrasive and high-speed machining applications.

5. Diamond-Like Carbon (DLC) Coating

DLC reduces friction and prevents material adhesion, improving tool life when cutting aluminum, plastics, and composites. It is not suitable for ferrous metals due to chemical reactions at high temperatures.

6. Titanium Aluminum Nitride (AlTiN) Coating

AlTiN is similar to TiAlN but optimized for extreme heat conditions. It is widely used in dry machining and high-speed steel or carbide cutting of hard metals.

7. Zirconium Nitride (ZrN) Coating

ZrN offers good hardness, wear resistance, and low friction. It is suitable for non-ferrous metals, plastics, and abrasive materials, providing a smooth surface finish.

8. Chromium Nitride (CrN) Coating

CrN increases corrosion resistance and hardness while reducing friction. It is commonly applied in mold-making and machining of abrasive or coated materials.

Table: Common Tool Coatings in CNC Machining

| Category |

Type |

Key Features |

Best For / Applications |

| Tool Coating |

Titanium Nitride (TiN) |

Increases hardness, reduces friction, gold color. | General-purpose cutting, steel and aluminum machining. |

| Titanium Carbonitride (TiCN) |

Harder than TiN, better wear and abrasion resistance. | Stainless steel, cast iron, and hardened materials. | |

| Titanium Aluminum Nitride (TiAlN) |

Excellent heat and oxidation resistance. | High-speed machining of steels and titanium. | |

| Al-TiN (Extreme Life) |

Enhanced hardness and thermal stability. | Abrasive or high-speed machining applications. | |

| Diamond-Like Carbon (DLC) |

Very low friction, anti-adhesion coating. | Aluminum, plastics, and composite machining. | |

| AlTiN |

Withstands extreme heat, ideal for dry machining. | Hard steel and carbide cutting at high speed. | |

| Zirconium Nitride (ZrN) |

Smooth finish, corrosion and wear resistance. | Non-ferrous metals, plastics, and abrasives. | |

| Chromium Nitride (CrN) |

Corrosion-resistant, strong adhesion, reduces friction. | Molds, dies, and abrasive material cutting. |

Choosing the right CNC tool directly affects part quality, cycle time, and cost. You want a tool that matches your material, operation, and tolerance — not the cheapest one. Pick tools that reduce machining time, resist wear, and simplify setup so you hit targets consistently.

Consider the Material You're Cutting

Different materials wear tools differently. Hard steels and titanium need carbide or CBN; aluminum runs best with PCD or polished carbide to avoid built-up edge; plastics and composites favor DLC-coated or diamond tools. Factor hardness, abrasiveness, and thermal conductivity when choosing tool material and geometry.

Match the Tool to the Operation

Pick tools built for the operation: end mills for profiling and slotting, face mills for large-area surfacing, boring bars for internal diameters, and taps/thread mills for threads. For roughing, use tools with larger radii and more aggressive chip evacuation; for finishing, use small-step, high-precision tools. Consider toolholder rigidity and spindle power — they limit what a tool can do.

Check the Tool Coating

Coatings control heat, friction, and adhesion. Use TiAlN/AlTiN for high-temperature steel cuts, TiCN for abrasive stainless, TiN for general-purpose, and DLC/PCD for sticky, non-ferrous materials. Coatings can double or triple tool life but pick coatings that match cutting speed and coolant strategy (wet vs dry).

Consider Form and Tolerances

Tool geometry (flute count, helix angle, corner radius) affects surface finish, chip flow, and accuracy. Use fewer flutes and larger gullets for better chip clearance in soft alloys; use higher flute counts for hard materials and finer finishes. For tight tolerances, minimize tool overhang, use shrink-fit or hydraulic toolholders, and prefer rigid tool geometries to cut vibration and runout.

CNC machining tools are the backbone of precision manufacturing. Choosing the right tool involves understanding the workpiece material, operation type, tool material, coating, and geometry. Proper selection ensures high accuracy, extended tool life, and efficient production. Both cutting and non-cutting tools play critical roles in achieving repeatable results. By carefully matching tools to materials and operations, you can reduce costs, improve surface finish, and maintain consistent quality in CNC machining parts.

1. What is a CNC Machine Tool?

A CNC machine tool is a powered device controlled by a computer that moves cutting or forming tools along programmed paths to shape materials into precise parts. It combines a machine, controller, and tool to achieve repeatable and accurate machining.

2. What Materials Cannot Be CNC Machined?

Extremely brittle materials like some glass types, certain ceramics without support, and very soft sticky materials that cannot be held or cut reliably may be unsuitable. Some composite materials may also require specialized tools.

3. What Tools Are Used in CNC Milling?

End mills, face mills, square and radius end mills, chamfer mills, keyway mills, slitting saws, fly cutters, and specialized engraving tools are commonly used in milling.

4. What Tools Are Used in CNC Turning (Lathes)?

Turning tools include carbide inserts, boring bars, parting/cut-off tools, threading tools, knurling tools, and chamfering tools for shaping rotating workpieces.

5. What Tools Are Used in CNC Cutting?

Cutting operations may use end mills, drills, reamers, taps, thread mills, slitting saws, and fly cutters depending on material removal type.

6. What Tools Are Used in CNC Drilling?

Twist drills, center drills, step drills, and carbide or HSS drill bits are used to create precise holes.

7. What Tools Are Used in CNC Routing?

Routers typically use straight, spiral, or V-bit router bits for plastics, wood, composites, and soft metals.

8. What Tools Are Used in CNC Grinding?

Grinding wheels, cup wheels, mounted points, and specialized abrasive tools are used to finish surfaces or achieve tight tolerances.

9. What Tools Are Used in CNC Electrical Discharge Machining (EDM)?

EDM uses electrodes made of graphite, copper, or copper-tungsten alloys to erode material via electrical sparks.

10. What Tools Are Used in CNC Laser Cutting?

High-powered lasers themselves act as the cutting tool; assist gases and optics guide the beam to cut or engrave metals, plastics, or composites.

11. What Tools Are Used in CNC Plasma Cutting?

Plasma torches are used to cut electrically conductive metals by generating a high-temperature plasma arc.

12. What Tools Are Used in CNC Water Jet Cutting?

Water jet nozzles with abrasive slurry are used to cut metals, composites, glass, and stone without heat-affected zones.

13. What Tools Are Used in CNC Broaching?

Broaching tools or broach bars with sequential cutting teeth are used to machine internal or external profiles like keyways and splines.

14. What Tools Are Used in CNC Gear Hobbing?

Hobs are rotating cutting tools shaped like a gear that cut gear teeth incrementally into workpieces.

15. What Tools Are Used in CNC Swiss Machining?

Swiss-style lathes use turning tools, drills, taps, and specialized micro-milling tools for small, precise parts.

16. What Tools Are Used in CNC Electrochemical Machining (ECM)?

Electrodes made of copper or brass are used; the process removes metal via electrochemical dissolution rather than mechanical cutting.