15 years one-stop China custom CNC machining parts factory

41 |

Published by VMT at Oct 20 2025 | Reading Time:About 3 minutes

41 |

Published by VMT at Oct 20 2025 | Reading Time:About 3 minutes

Choosing between 431 and 17-4 stainless steel can, in a frankly astounding fashion, make or break your critical application. Are you genuinely confident your current substance choice won't precipitously lead to unexpected failures, ballooning expenditures, or unconscionably compromised operational integrity down the line? This decision, believe it or not, holds truly monumental sway. Let's decisively demystify these two powerhouses of precision engineering.

For engineers and procurement professionals grappling with material specification, understanding the fundamental divergence between 431 and 17-4 PH stainless alloys is indispensable. While both offer impressive attributes, their distinct compositions and subsequent thermal responses dictate markedly dissimilar performance profiles in various demanding environments, directly influencing component longevity and operational reliability.

Honestly, the very essence of any metallic compound lies utterly within its atomic recipe. Ignore this at your peril! The disparate atomic arrangements within 431 and 17-4 PH are what give rise to their remarkably varied capabilities and limitations.

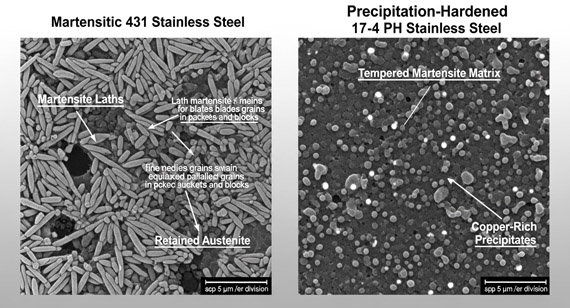

431 Stainless Steel: A Martensitic Overview

431 stainless, a distinguished member of the martensitic family, possesses a composition carefully balanced to facilitate a transformation into a hard, crystalline structure through quenching. It's truly fascinating! This particular alloy typically comprises about 15-17% chromium, alongside nickel in the range of 1.25-2.5%, providing a commendable measure of corrosion resistance, something utterly paramount for many demanding scenarios. Minimal carbon content, around 0.20%, permits effective hardening, a truly pivotal trait for certain mechanical requisites. This matrix, post-quench and temper, grants it superior robustness, often sought in rigorous mechanical engagements.

17-4 PH Stainless Steel: Precipitation Hardening

Contrastingly, 17-4 PH, a designation that rolls off the tongue with a certain gravitas, stands as a prime example of a precipitation-hardening alloy. Its moniker, "17-4," quite directly alludes to its approximate 17% chromium and 4% nickel content, but the real secret, the actual alchemical marvel, lies in its additions of copper (around 3-5%) and niobium (columbium), sometimes supplemented by other elements like manganese and silicon. These minute inclusions, these almost imperceptible constituents, are what enable the alloy to form incredibly fine precipitates within its microstructure during specific thermal cycles, a process that delivers a truly formidable boost to its mechanical properties.

Key Alloying Element Disparities

The nuances of these constituent percentages are what ultimately dictate the functional narrative of each alloy. It's like comparing two subtly different musical scores, each played to a distinct effect.

| Alloying Element | 431 Stainless Steel (Approx. %) | 17-4 PH Stainless Steel (Approx. %) |

| Chromium (Cr) | 15.0 – 17.0 | 15.0 – 17.0 |

| Nickel (Ni) | 1.25 – 2.5 | 3.0 – 5.0 |

| Carbon (C) | Max 0.20 | Max 0.07 |

| Manganese (Mn) | Max 1.0 | Max 1.0 |

| Silicon (Si) | Max 1.0 | Max 1.0 |

| Phosphorus (P) | Max 0.04 | Max 0.04 |

| Sulfur (S) | Max 0.03 | Max 0.03 |

| Copper (Cu) | - | 3.0 – 5.0 |

| Niobium (Nb) | - | 0.15 – 0.45 |

Now, for the crux of the matter: how do these compositional variances truly manifest in brute physical capability? It's not merely academic; these figures translate directly into whether your component endures or, God forbid, catastrophically fails!

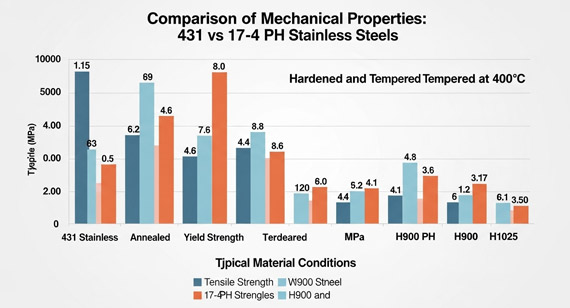

Mechanical Properties: Tensile & Yield Strength

When we talk about resisting deformation, the tensile and yield capabilities are undeniably paramount. One simply cannot overlook these metrics. 17-4 PH, especially in its various heat-treated states (like H900), consistently demonstrates superior tensile and yield values, making it an utterly formidable choice for structures demanding unparalleled load-bearing capacity. 431, while robust, typically presents somewhat more modest figures, particularly when compared to its precipitation-hardened counterpart.

| Property (Condition) | 431 Stainless Steel (Quenched & Tempered) | 17-4 PH Stainless Steel (H900 Condition) |

| Tensile Strength (MPa) | 900 – 1100 | 1310 – 1450 |

| Yield Strength (MPa) | 650 – 850 | 1170 – 1310 |

| Elongation (%) | 15 – 20 | 10 – 14 |

Hardness and Wear Resistance Comparisons

The resilience against surface abrasion, a frequently overlooked yet utterly crucial attribute, is directly linked to an alloy's inherent hardness. 17-4 PH, again, often outshines 431 in this arena, particularly after optimal thermal treatment, allowing it to withstand more punishing conditions without yielding to material degradation. 431 does offer good hardness, but in contexts where extreme wear is a perennial concern, 17-4 PH frequently emerges as the unequivocally preferred option.

Impact Toughness Considerations

Impact toughness, that almost visceral ability to absorb energy before fracturing, is another critical differentiator. Imagine a sudden, sharp blow; how does the material react? While 431 possesses reasonable toughness for its class, 17-4 PH maintains exceptional impact tolerance, even at very respectable strength levels, a truly commendable feat of metallurgical ingenuity! This characteristic is non-negotiable for components subjected to dynamic loading or sudden shock events.

Ah, the silent assassin of metallic longevity: corrosion! It's a truly insidious foe, tirelessly eroding even the most formidable of alloys. Understanding how 431 and 17-4 PH resist this relentless assault is utterly vital for long-term viability.

General Corrosion Behavior in Environments

Both alloys offer respectable resistance to atmospheric corrosion and many mildly aggressive chemical media; however, their performance is not precisely identical. 17-4 PH, with its higher nickel content and cleaner microstructure (due to the precipitation hardening process), generally exhibits somewhat superior broad-spectrum corrosion resilience, especially in scenarios involving mild acids or marine environments, a truly fantastic attribute. 431, while certainly not deficient, can be more susceptible to certain forms of localized attack if its surface condition isn't absolutely immaculate or if exposed to exceptionally harsh, highly concentrated solutions.

Stress Corrosion Cracking Susceptibility

This is a particularly treacherous form of degradation, where tensile stress and a corrosive environment conspire to cause catastrophic, sudden failure, a truly nightmarish scenario for any engineer. 431, like many martensitic grades, can exhibit susceptibility to stress corrosion cracking, especially in highly stressed conditions within chloride-rich or acidic environments. 17-4 PH, by contrast, typically displays excellent resistance to stress corrosion cracking, particularly when properly aged, which is one of its truly standout features and a huge relief to those designing for such volatile conditions.

Oxidization and High-Temperature Performance

In elevated thermal settings, both maintain integrity, but with nuances. 17-4 PH often retains its commendable mechanical properties to a slightly higher operational temperature ceiling than 431, making it a truly indispensable choice for components operating in warmer climes. Its oxidation resistance is also generally very good, enduring thermal challenges with aplomb.

The journey from raw stock to a flawlessly finished component is fraught with technical demands. Each alloy, like a temperamental diva, requires very specific handling. Ignorance here leads to utter disaster!

Essential Heat Treatment Procedures

The thermal conditioning of these alloys is not merely a suggestion; it's a sacred ritual, one that profoundly defines their ultimate mechanical attributes. 431 necessitates austenitizing, followed by quenching to form martensite, and then tempering to alleviate brittleness and achieve the desired balance of strength and ductility. 17-4 PH, however, undergoes a solution annealing step, which is then followed by a lower-temperature aging (or precipitation hardening) treatment, often denoted by conditions like H900, H1025, or H1150, each providing a different strength-toughness equilibrium. A truly complex dance of temperature and time!

Machinability Characteristics for Each Alloy

Machining either of these alloys, I must confess, presents its own distinct set of trials. 431, particularly in its annealed state, can be machined with reasonable facility, but its hardened conditions often demand slower speeds, heavier cuts, and exceedingly robust tooling to manage chip control and prevent work hardening. 17-4 PH, while inherently strong, generally exhibits good machinability in its solution-annealed condition, a real blessing! However, once it's undergone a precipitation hardening cycle, its increased hardness necessitates careful adjustment of cutting parameters and the use of hard, sharp tools to achieve optimal surface finish and maintain tool life, a truly precise operation.

Welding Considerations and Best Practices

Welding these sophisticated alloys requires expert hand, not some haphazard endeavor. 431 is generally considered weldable, though preheating and post-weld heat treatments are often absolutely essential to mitigate cracking and restore desirable mechanical characteristics. It's a delicate balance! 17-4 PH is also weldable, typically via processes like TIG or MIG, but careful attention to filler material selection and post-weld aging is crucial to retain its mechanical properties and corrosion resistance. But let's be real, inadequate thermal management during welding can completely undermine the very benefits these alloys offer. Wait, I need to clarify that point—the susceptibility to cracking or loss of desirable properties without proper post-weld treatment can be a downright catastrophic failure, wasting all previous effort and material expense.

The theoretical distinctions, as we've exhaustively dissected, become truly manifest in their practical utility. Where does each truly shine, and where does it perhaps falter?

Common Applications for 431 Stainless Steel

431, with its commendable balance of strength, hardness, and corrosion resistance, finds itself indispensable in a myriad of demanding roles. It's frequently the material of choice for components requiring excellent torsional strength and good resistance to atmospheric and freshwater corrosion, such as pump shafts, valve stems, fasteners, and various marine fittings. This alloy proves particularly useful in sectors where a moderately high level of strength is paired with the necessity for consistent corrosion resilience, like chemical processing equipment or certain medical apparatus.

Critical Applications for 17-4 PH Stainless Steel

17-4 PH, by virtue of its truly exceptional strength-to-weight ratio and superior corrosion resistance, particularly against stress corrosion cracking, is reserved for the most uncompromising of applications. Think aerospace components, intricate nuclear reactor parts, high-performance marine propeller shafts, oil and gas industry valves, and turbine blades. Its ability to retain high mechanical integrity even after being exposed to demanding environments positions it as an absolutely irreplaceable choice for mission-critical elements where failure is simply not an option, a truly mind-blowing miracle of metallurgy.

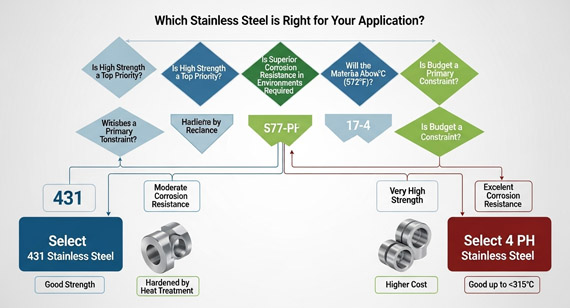

Industry-Specific Selection Guidance

Honestly, selecting the right alloy is less a casual suggestion and more a solemn pledge to a component's entire lifecycle! It absolutely hinges upon a meticulous dissection of operating environment, load profiles, and longevity expectations. One simply cannot afford to guess.

This discussion would be woefully incomplete, indeed an unbelievable foolish assumption of omniscience, without a frank assessment of the pecuniary implications. After all, performance invariably has its price.

Material Availability and Raw Material Costs

Generally speaking, 431 stainless steel tends to be a more readily available, and consequently, a more economically advantageous, raw material than 17-4 PH. This is due in part to the simpler alloying element profile and less complex manufacturing steps required to produce the raw stock. The more specialized chemical composition and the intricate thermal processing involved in producing 17-4 PH billets inevitably translate into a higher initial acquisition cost, a straightforward economic reality.

Machining Complexity and Production Costs

The overall production expense isn't solely dictated by the raw material. Machining complexity plays an utterly pivotal role! While both demand expertise, the superior hardness and toughness of 17-4 PH, especially in its hardened conditions, can sometimes necessitate slower machining speeds, more frequent tool changes, and specialized cutting strategies, all of which undeniably contribute to increased machining costs and longer cycle times. Therefore, while 431 might be a bit more straightforward to work with, the precision required for either mandates an accomplished hand and advanced machinery.

Long-Term Performance vs. Initial Investment

It's a classic conundrum, isn't it? The cheaper upfront option might just be the unbelievably foolish decision that costs you a fortune in future failures, recalls, or reputation damage. Choosing the lower-cost 431 when 17-4 PH is genuinely required for higher strength, superior corrosion resilience, or unparalleled stress corrosion cracking resistance is an absolutely catastrophic error in judgment, leading to performance compromises and premature replacements. Conversely, over-specifying 17-4 PH for an application where 431 would perform admirably represents an unnecessary expenditure. A truly optimal choice involves balancing initial investment against the long-term operational integrity, maintenance expenditures, and the overall longevity of the component. It's about securing maximum value, not simply lowest price.

Here at VMT CNC Machining Parts Services Factory, we understand the truly profound gravity of these material selection decisions. As a source manufacturer, our commitment goes far beyond mere fabrication; we pledge an unwavering partnership. Our deep technical expertise, honed over decades, empowers us to guide you through the intricate labyrinth of material choices, including the nuanced distinctions between 431 and 17-4 PH stainless alloys. We don't just process orders; we engineer solutions, guaranteeing high-quality parts that meet your exact specifications, delivered with transparent pricing and the assurance of uncompromising precision. This dedication to quality and technical discernment is our hallmark!

So, what have we ultimately gleaned from this exhaustive dissection, this truly necessary intellectual odyssey? The choice between 431 and 17-4 PH stainless steel is not merely a matter of casual preference; it's a deeply consequential engineering judgment, one that can make or break the viability of your most crucial projects. While 431 offers a commendable blend of robustness and anti-corrosion attributes for many demanding applications, 17-4 PH undeniably elevates the bar, delivering superior strength and an almost unbelievably formidable resilience in the face of truly punishing conditions, especially when stress corrosion cracking is a concern. The imperative is clear: understand their distinct characteristics, weigh their disparate costs, and, most importantly, align the material's inherent capabilities with your application's absolute, non-negotiable requirements. Don't leave your critical components to chance, a truly egregious error! Consult with our expert metallurgists and CNC engineers today for a personalized material selection analysis and a transparent quote. Partner with VMT, a source manufacturer utterly committed to your part's precision and unparalleled performance.

Q1: What are the primary structural differences between 431 and 17-4 PH stainless steel?

A1: 431 is a martensitic stainless alloy, meaning its properties are derived from a heat treatment that forms a hardened, crystalline martensite structure. 17-4 PH, by contrast, is a precipitation-hardening alloy; its superior mechanical characteristics are achieved by forming incredibly fine precipitates within its matrix during an aging thermal process, which significantly elevates its strength.

Q2: Which alloy offers superior corrosion resistance in general applications?

A2: While both demonstrate good corrosion resistance, 17-4 PH generally exhibits somewhat superior broad-spectrum corrosion resilience, particularly in marine or mild acidic environments. Its higher nickel content and cleaner microstructure contribute to this enhanced performance, making it a very robust option.

Q3: Can 431 stainless steel be hardened, and how does it compare to 17-4 PH?

A3: Absolutely, 431 is a hardenable stainless alloy; its strength and hardness are developed through quenching and tempering procedures. 17-4 PH, however, achieves significantly higher strength and hardness levels through its precipitation-hardening heat treatments (e.g., H900, H1025), surpassing 431 in most high-strength applications.

Q4: What are the typical applications for 431 stainless steel?

A4: 431 is frequently employed in situations requiring a balance of good strength, hardness, and corrosion resistance. Common uses include pump shafts, valve stems, fasteners, marine fittings, and components for chemical processing where moderate strength and corrosion resilience are necessary.

Q5: For which demanding industries is 17-4 PH stainless steel typically chosen?

A5: 17-4 PH is the alloy of choice for industries where extreme performance is non-negotiable. This encompasses aerospace for critical structural elements, nuclear sectors, high-performance marine applications (like propeller shafts), and the oil and gas industry for components exposed to aggressive media and high pressures.

Q6: Is one of these alloys more difficult to machine than the other?

A6: Machinability varies with heat treatment. In its annealed state, 431 is reasonably machinable. However, in its hardened conditions, both 431 and 17-4 PH demand careful cutting parameters, robust tooling, and optimized strategies due to their elevated hardness and strength, with 17-4 PH often presenting greater challenges in its hardest aged conditions.

Q7: What about welding? Are there special considerations for each?

A7: Both alloys are weldable, but specific precautions are vital. 431 often requires preheating and post-weld heat treatments to prevent cracking and restore properties. 17-4 PH necessitates careful filler metal selection and post-weld aging cycles to maintain its desired mechanical properties and resistance to corrosion, a truly pivotal aspect of its usage.

Q8: How do cost factors generally compare between 431 and 17-4 PH?

A8: 431 stainless steel is generally more economical in terms of raw material cost and often presents slightly lower machining costs due to less complex processing requirements. 17-4 PH, with its specialized composition and intricate heat treatments, typically carries a higher raw material price and can incur greater machining expenses due to its superior hardness. The choice ultimately hinges on balancing initial outlay with the long-term performance and reliability imperatives of the specific component.