15 years one-stop China custom CNC machining parts factory

42 |

Published by VMT at Sep 27 2025 | Reading Time:About 3 minutes

42 |

Published by VMT at Sep 27 2025 | Reading Time:About 3 minutes

Your precision part project demands the right material choice, yet the subtle distinctions between 1020 and 1018 steel often lead to critical confusion. Misselecting can compromise structural integrity, complicate machining, and inflate costs. As a source manufacturer with deep technical expertise, VMT CNC Machining Parts Services Factory is here to clarify these differences, guiding you to the optimal material solution for superior performance and cost-effectiveness.

1020 and 1018 steels are both low-carbon steels, but 1018 contains slightly higher manganese, enhancing its machinability and mechanical properties like tensile and yield strength. 1020, with lower carbon and manganese, offers better ductility and weldability. Understanding these chemical and mechanical variances is crucial for optimal CNC machining and part performance.

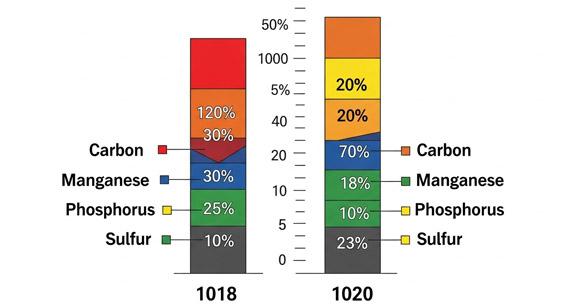

Understanding the elemental makeup of 1018 and 1020 steel is the foundation for comprehending their performance characteristics. While both are categorized as low-carbon steels, subtle variations in their chemical composition significantly impact their mechanical properties and suitability for various applications and manufacturing processes.

Carbon Content: The Core Element Defining Steel Performance

Carbon is the primary hardening element in steel. Its percentage dictates much of the steel's strength, hardness, and weldability. 1018 and 1020 steels fall within the low-carbon range, typically between 0.15% to 0.29%. The slightly higher carbon content often found in 1018 steel contributes to its increased strength compared to 1020.

Other Alloy Elements: Manganese, Sulfur, and Phosphorus

Beyond carbon, other elements play critical roles. Manganese improves strength, hardness, and wear resistance, and acts as a deoxidizer. Sulfur and phosphorus are generally considered impurities, though controlled levels of sulfur can enhance machinability in certain steel grades.

Typical Chemical Composition for 1018 Steel (Weight %)

| Element | Minimum | Maximum |

| Carbon (C) | 0.15 | 0.20 |

| Manganese (Mn) | 0.60 | 0.90 |

| Phosphorus (P) | - | 0.040 |

| Sulfur (S) | - | 0.050 |

Typical Chemical Composition for 1020 Steel (Weight %)

| Element | Minimum | Maximum |

| Carbon (C) | 0.18 | 0.23 |

| Manganese (Mn) | 0.30 | 0.60 |

| Phosphorus (P) | - | 0.040 |

| Sulfur (S) | - | 0.050 |

The most notable distinction here is the manganese content. 1018 steel typically contains significantly more manganese than 1020, which is a key factor in its improved machinability and strength.

Standard Specifications: ASTM and SAE Definitions

Both 1018 and 1020 steels are standardized under systems like ASTM International and SAE International. These standards define the acceptable chemical composition ranges and often the minimum mechanical properties, ensuring consistency and quality for material procurement and engineering specifications. Our factory strictly adheres to these international standards, providing material certifications to verify compliance for every project.

The chemical composition translates directly into the mechanical properties that dictate a steel's performance under stress. Engineers and procurement managers must carefully evaluate these properties to ensure the selected material meets the functional demands and operational environment of their CNC machined parts.

Tensile Strength and Yield Strength: Who is More Resilient?

Tensile strength is the maximum stress a material can withstand before breaking, while yield strength is the stress at which a material begins to deform plastically. Higher values indicate a stronger material. Due to its higher manganese content and sometimes slightly higher carbon, 1018 steel generally exhibits superior tensile and yield strength compared to 1020. This makes 1018 a preferred choice for components requiring greater load-bearing capabilities without permanent deformation.

Typical Mechanical Properties for 1018 Steel (Hot Rolled)

| Property | Imperial Units | Metric Units |

| Tensile Strength | 64 ksi | 440 MPa |

| Yield Strength | 54 ksi | 370 MPa |

| Elongation at Break | 20% | 20% |

| Hardness (Brinell) | 137 | 137 HB |

Typical Mechanical Properties for 1020 Steel (Hot Rolled)

| Property | Imperial Units | Metric Units |

| Tensile Strength | 55 ksi | 380 MPa |

| Yield Strength | 42 ksi | 290 MPa |

| Elongation at Break | 25% | 25% |

| Hardness (Brinell) | 115 | 115 HB |

Hardness and Ductility: Key Considerations for Processing and Forming

Hardness refers to a material's resistance to localized plastic deformation, such as indentation or scratching. Ductility, conversely, is the ability of a material to deform plastically without fracturing, allowing it to be stretched, bent, or drawn. 1018 steel is typically harder due to its composition, while 1020 steel, with lower carbon and manganese, is generally more ductile. This greater ductility makes 1020 more forgiving in applications requiring significant cold forming or bending, though it comes at the expense of strength.

Impact Toughness: Reliability in Various Environments

Impact toughness is a material's ability to absorb energy and plastically deform before fracturing under sudden, dynamic loads. For applications where parts might experience shock or rapid force, impact toughness is a critical parameter. While both are low-carbon steels with good general toughness, specific applications might favor one over the other based on precise design requirements and operating conditions.

Typical Application Scenarios: Where 1018 and 1020 Excel

The distinct mechanical properties of 1018 and 1020 steel guide their optimal application.

1018 steel is commonly found in parts requiring moderate strength and good machinability, such as shafts, pins, rods, machine parts, and couplings, especially where clean surface finish is desired.

1020 steel, with its excellent weldability and ductility, is often chosen for structural components, general machining applications, welded assemblies, and automotive parts that require bending or forming, where ultimate strength is less critical than formability or weld integrity.

The true value of a raw material for CNC machining lies not just in its inherent properties but also in how it behaves under various manufacturing processes. VMT CNC Machining Parts Services Factory possesses deep technical expertise in optimizing these processes for both 1018 and 1020 steels, ensuring efficiency and part quality.

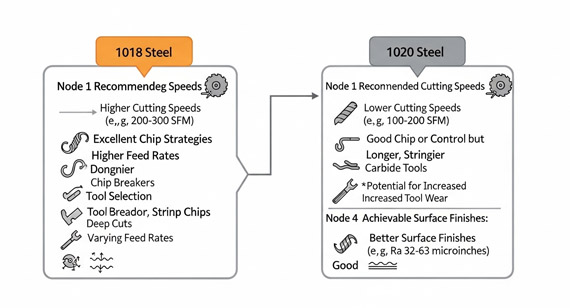

Machinability: Impact on CNC Machining Efficiency and Surface Quality

Machinability refers to the ease with which a material can be cut by a cutting tool. It impacts tool wear, cutting speeds, chip formation, and surface finish. 1018 steel is renowned for its excellent machinability, often referred to as a "free-machining" steel in the low-carbon category. Its higher manganese content contributes to better chip formation and less abrasive tool wear, allowing for higher cutting speeds and superior surface finishes. This makes 1018 a popular choice for intricate CNC parts where tight tolerances and aesthetic appeal are crucial.

1020 steel is also considered highly machinable but generally lags behind 1018 in terms of cutting speed capability and achievable surface finish without specific optimization.

Comparative Machinability Characteristics

| Feature | 1018 Steel (Typical) | 1020 Steel (Typical) |

| Machinability Rating | 78% of B1112 Free-Machining Steel | 65% of B1112 Free-Machining Steel |

| Chip Formation | Short, broken chips | Longer, stringier chips |

| Tool Wear | Lower | Slightly Higher |

| Surface Finish | Excellent | Good |

| Recommended Cutting Speed | Higher | Moderate |

Weldability: Considerations for Joint Strength and Weld Quality

Weldability is a material's ability to be welded without forming defects or degrading its mechanical properties. Both 1018 and 1020 steels are considered highly weldable due to their low carbon content, which minimizes the risk of cracking and embrittlement in the heat-affected zone (HAZ).

1020 steel, with its slightly lower carbon and manganese, often offers marginally better weldability with less preheating or post-weld treatment required for certain applications. However, both can be readily welded using common methods such as shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and gas tungsten arc welding (GTAW). Proper welding procedures, including joint preparation and filler material selection, are essential for robust weldments.

Heat Treatment Response: Hardening and Annealing Effects

Low-carbon steels like 1018 and 1020 do not respond significantly to conventional hardening (quenching and tempering) due to insufficient carbon to form a hard martensitic structure. However, they are excellent candidates for carburizing. Carburizing is a case hardening process where carbon is diffused into the surface of the steel, creating a hard, wear-resistant outer layer while retaining a tough, ductile core.

1020 steel, with its slightly lower carbon content, may achieve a marginally deeper case depth with similar carburizing cycles compared to 1018. Both materials also respond well to annealing for softening, normalizing for grain refinement, and stress relieving to improve dimensional stability.

Cold Formability: Adaptability for Bending, Stamping, and Forming

Cold forming refers to processes like bending, stamping, and drawing performed at room temperature. A material's ductility is a key indicator of its cold formability.

1020 steel generally exhibits superior cold formability compared to 1018 due to its lower carbon and manganese content, which contributes to greater ductility and less work hardening during deformation. This makes 1020 preferable for parts requiring significant bending or shaping without fracturing. 1018 can also be cold formed but may require more care and potentially intermediate annealing for severe bends.

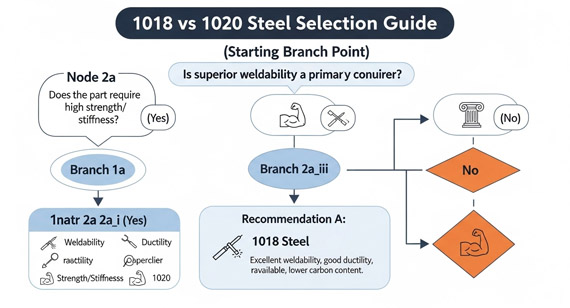

Choosing between 1018 and 1020 steel is a critical decision that impacts part performance, manufacturing costs, and project timelines. Our DFM (Design for Manufacturability) experts at VMT CNC Machining Parts Services Factory provide invaluable guidance, evaluating your specific requirements to recommend the optimal material.

Design Requirement Guidance: Part Function and Stress Conditions

The primary driver for material selection should always be the intended function of the part and the stresses it will endure.

For higher strength and stiffness: If your part requires greater resistance to tensile, yield, or impact loads, 1018 steel is generally the superior choice. This is critical for components that bear significant weight or experience dynamic forces.

For superior formability and weldability: If the part design involves extensive cold forming (bending, stamping) or requires robust welded assemblies where strength is secondary to integrity and ease of joining, 1020 steel might be more suitable.

For surface hardness: If a hard, wear-resistant surface is needed while maintaining a tough core, both materials are excellent candidates for carburizing. The choice then might revert to the core strength requirements.

Processing Considerations: Balancing Efficiency, Cost, and Quality

The chosen material directly influences manufacturing efficiency and cost.

Machining-intensive parts: If your part has complex geometries or requires a very fine surface finish achieved through extensive CNC machining, 1018 steel's superior machinability can lead to faster cycle times, longer tool life, and reduced post-processing, thereby lowering overall manufacturing costs.

Welding-intensive assemblies: For parts primarily fabricated through welding, 1020 steel might simplify the welding process, potentially reducing labor and ensuring higher-quality welds with fewer defects.

Cold-formed components: If your design necessitates significant deformation without fracture, the higher ductility of 1020 steel will facilitate the forming process, minimizing rework and scrap.

Cost-Benefit Analysis: Balancing Material and Processing Costs

While the raw material cost difference between 1018 and 1020 steel is often marginal, the overall cost-benefit must consider processing. A slightly more expensive material that significantly reduces machining time or improves quality can lead to a lower total cost of ownership. Our transparent, factory-direct pricing ensures you receive the most competitive rates for either material, with a clear breakdown of manufacturing expenses.

Common Misconceptions: Avoiding Costly Errors

A frequent misconception is that 1018 and 1020 steel are interchangeable due to their similar classification as low-carbon steels. This overlooks the critical differences in manganese content, which profoundly affects machinability and strength. Using 1020 where 1018's strength is required can lead to premature part failure, while using 1018 for a highly ductile, deep-drawn application might result in cracking during forming. Relying on expert advice from VMT CNC Machining Parts Services Factory can mitigate these risks and ensure material selection aligns perfectly with design intent and functional requirements.

Beyond technical specifications, practical aspects like market pricing, supply chain reliability, and the advantages of working with a source manufacturer significantly influence material selection and project success.

Market Price Fluctuations: Impact on Procurement Decisions

The market price of raw steel can fluctuate based on global demand, raw material costs, and geopolitical factors. While 1018 and 1020 are generally cost-effective low-carbon steels, staying abreast of market trends is crucial for large-volume procurement. Our transparent pricing model at VMT CNC Machining Parts Services Factory ensures you receive current, factory-direct costs without hidden markups, allowing for predictable budgeting.

Supply Channels and Specifications: Ensuring Timely and Stable Access

Securing a stable and consistent supply of specified steel grades is vital for uninterrupted production. As a direct source manufacturer in Shenzhen, China, VMT CNC Machining Parts Services Factory maintains strong relationships with reputable material suppliers, ensuring access to high-quality 1018 and 1020 steel conforming to international standards. This direct access minimizes lead times and mitigates supply chain risks, which is particularly beneficial for projects requiring rapid prototyping or high-volume production.

The Source Factory Advantage: Expert Advice and Processing Guarantee

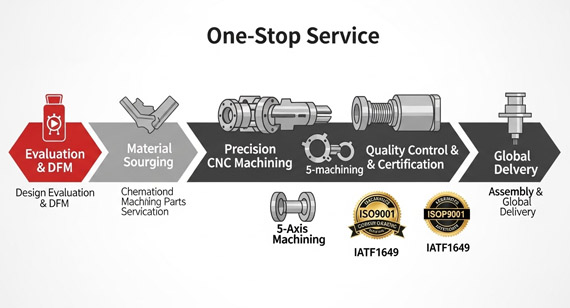

Working with a source manufacturer like VMT CNC Machining Parts Services Factory offers distinct advantages when selecting and processing materials:

Deep Technical Expertise: Our engineers provide DFM reports and expert consultations, helping you navigate the nuances of 1018 vs 1020 steel, optimizing your design for the chosen material and manufacturing process.

Full-Chain Quality Control: We implement rigorous ISO9001 and IATF1649 certified quality control from material incoming inspection to final delivery, guaranteeing the integrity of your parts.

Advanced Equipment: With over 80 high-precision CNC machines, including 5-axis capabilities, we ensure superior quality and efficiency in machining both 1018 and 1020 steels, regardless of part complexity or volume.

One-Stop Service: From material selection and rapid prototyping (available in 24 hours) to precision machining and final assembly, we offer a comprehensive solution with no minimum order quantity (MOQ), making us a flexible and reliable partner.

This article has thoroughly dissected the fundamental differences between 1018 and 1020 steel, emphasizing their distinct chemical compositions, mechanical properties, and processing behaviors. We highlighted that 1018, with higher manganese, excels in machinability and strength, making it ideal for precision parts with good surface finishes. 1020, offering greater ductility and weldability, is better suited for formed or welded components where strength is a secondary concern. Understanding these nuances is critical for optimal material selection, influencing part performance, manufacturing efficiency, and overall project cost-effectiveness. As a direct source manufacturer, VMT CNC Machining Parts Services Factory provides the technical expertise and advanced capabilities to guide your choice and deliver high-quality, precision-machined parts from either material.

Q1: Can 1018 and 1020 steel always be used interchangeably?

A1: No, 1018 and 1020 steel cannot always be used interchangeably. While both are low-carbon steels, their differing manganese and carbon contents result in distinct mechanical properties and processing characteristics. 1018 generally offers higher strength and better machinability, while 1020 provides superior ductility and weldability. Interchangeability depends entirely on the specific application's functional requirements, stress conditions, and manufacturing processes. Misuse can lead to compromised part performance or manufacturing difficulties.

Q2: Which steel is better for welding applications, 1018 or 1020?

A2: 1020 steel is generally considered slightly better for welding due to its lower carbon and manganese content, which reduces the risk of hardening and cracking in the heat-affected zone (HAZ). However, both 1018 and 1020 are highly weldable low-carbon steels and can be effectively welded using standard techniques. Proper welding procedures, including preheating (if necessary) and appropriate filler metals, are crucial for achieving strong, sound weldments with either material.

Q3: What are the primary industries that utilize 1018 steel for CNC machining?

A3: 1018 steel is widely utilized in industries requiring moderate strength, good machinability, and a clean surface finish for precision components. This includes general machinery (shafts, pins, rods, machine parts), automotive (bushings, gears, engine components), and certain aerospace applications (non-critical structural elements, fasteners). Its excellent machinability makes it a cost-effective choice for intricate CNC parts.

Q4: For what types of components is 1020 steel typically preferred?

A4: 1020 steel is typically preferred for components that benefit from its superior ductility and weldability. This includes structural components, general purpose machining where strength requirements are moderate, welded assemblies, and parts requiring significant cold forming, bending, or stamping. It's often found in automotive components, agricultural equipment, and general fabrication where ease of processing and cost-effectiveness are key.

Q5: How does VMT CNC Machining Parts Services Factory ensure the quality of 1018 and 1020 steel parts?

A5: VMT CNC Machining Parts Services Factory ensures material quality through a rigorous full-chain quality control system, certified to ISO9001 and IATF1649 standards. This includes meticulous incoming material inspection, in-process quality checks using advanced metrology equipment, and final inspection before shipment. We also provide material certifications (MTRs) to verify the chemical composition and mechanical properties of the raw material. Our deep technical expertise and advanced machinery (over 80 machines, including 5-axis) further guarantee precision and consistency.

Q6: Can VMT assist with Design for Manufacturability (DFM) for parts made from 1018 or 1020 steel?

A6: Absolutely. As a source manufacturer, VMT CNC Machining Parts Services Factory specializes in providing comprehensive DFM reports and expert consultation. Our experienced engineers will review your designs, offering insights and recommendations to optimize your parts for cost-effective manufacturing with 1018 or 1020 steel, ensuring optimal material utilization, machinability, and structural integrity. This proactive approach helps to avoid potential issues during production and enhances overall product quality.

Q7: What is the typical lead time for rapid prototyping services for parts using these low-carbon steels?

A7: VMT CNC Machining Parts Services Factory offers rapid prototyping services, with lead times as short as 24 hours for certain 1018 or 1020 steel components, depending on complexity and current production schedules. Our advanced machinery and streamlined processes are designed to accelerate your development cycle, allowing for quick iteration and validation of your designs.

Q8: Does VMT CNC Machining Parts Services Factory have a minimum order quantity (MOQ) for 1018 or 1020 steel machined parts?

A8: No, VMT CNC Machining Parts Services Factory operates with no minimum order quantity (MOQ) for CNC machined parts, including those made from 1018 and 1020 steel. We are committed to supporting projects of all scales, from single prototypes to high-volume production runs, providing flexibility and accessibility for all our clients.