15 years one-stop China custom CNC machining parts factory

81 |

Published by VMT at Sep 27 2025

81 |

Published by VMT at Sep 27 2025

The unique properties of Kovar, a specialized iron-nickel-cobalt alloy, make it indispensable for demanding applications in aerospace, medical, and electronics. However, its high material cost and challenging machinability often present significant hurdles in achieving the required precision and reliability. This guide delves into the intricacies of Kovar CNC machining, offering expert insights and practical solutions to transform your complex designs into perfectly functional components, ensuring material integrity and maximizing project success.

Kovar is a critical iron-nickel-cobalt alloy known for its controlled thermal expansion properties, making it ideal for hermetic sealing with glass and ceramic. Achieving successful Kovar CNC machining requires deep technical expertise to manage its unique hardness, toughness, and thermal characteristics, ensuring dimensional accuracy and surface integrity for high-reliability applications.

Kovar's Unique Composition and Characteristics

Kovar is a specific type of iron-nickel-cobalt alloy, precisely engineered to possess a coefficient of thermal expansion (CTE) that closely matches that of certain types of glass and ceramic materials. This characteristic is paramount for creating robust, vacuum-tight, and hermetically sealed joints, which are critical in high-performance electronic and optical devices. The alloy's composition typically consists of approximately 29% Nickel, 17% Cobalt, 0.3% Manganese, 0.2% Silicon, with the remainder being Iron. This precise balance provides a stable CTE over a wide temperature range, particularly around the transformation temperature of glass. Beyond its thermal expansion attributes, Kovar exhibits good strength and ductility, which are beneficial for manufacturing processes, though these properties also contribute to its machining challenges.

Table: Nominal Kovar Alloy Composition (ASTM F15)

| Element | Weight Percentage (%) |

| Iron (Fe) | Balance |

| Nickel (Ni) | 29 |

| Cobalt (Co) | 17 |

| Manganese (Mn) | 0.3 |

| Silicon (Si) | 0.2 |

Why Kovar is Critical for High-Tech Applications

The unique thermal expansion characteristics of Kovar are not merely a desirable trait; they are a fundamental requirement for the reliable operation and longevity of components in numerous high-tech industries. When dissimilar materials are joined and subjected to temperature fluctuations, differences in their CTE can induce significant stresses at the interface, leading to cracks, leaks, or even complete failure. Kovar's ability to minimize these stresses by expanding and contracting at a rate similar to sealing glasses and ceramics ensures the integrity of hermetic seals. This capability is vital for maintaining vacuum environments, protecting sensitive electronics from environmental contaminants, and preventing signal degradation in critical systems.

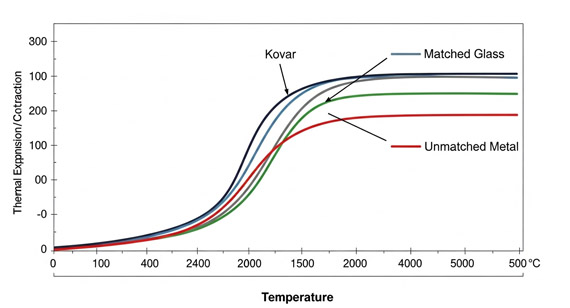

Kovar's Thermal Expansion Match with Glass and Ceramics

The phenomenon of thermal expansion matching is the cornerstone of Kovar's utility. Sealing components with Kovar ensures that as temperatures change, the glass or ceramic and the Kovar metal expand or contract at a nearly identical rate. This prevents the formation of tensile or compressive stresses at the joint, which would otherwise compromise the seal's integrity. For instance, in vacuum tubes or semiconductor packages, even microscopic leaks can lead to catastrophic failure. Kovar's controlled expansion ensures a stable, stress-free interface, guaranteeing the long-term reliability required by aerospace, medical, and defense standards. The selection of the correct sealing glass or ceramic is equally important, as their CTE must be specifically designed to complement Kovar.

Table: Approximate Thermal Expansion Coefficients (CTE)

| Material | CTE (x 10⁻⁶ /°C) at 20-400°C |

| Kovar (ASTM F15) | 5.0 - 5.5 |

| Borosilicate Glass (e.g., Pyrex) | 3.3 - 4.5 |

| Lead Glass (e.g., Corning 0120) | 8.9 - 9.2 |

| Sealing Glass (matched to Kovar) | 4.8 - 5.8 |

| Alumina Ceramic (96%) | 6.5 - 7.5 |

Specific Difficulties: Hardness, Toughness, and Thermal Management

Machining Kovar presents a unique set of challenges rooted in its material properties. While not exceptionally hard compared to some tool steels, Kovar's combination of moderate hardness and significant toughness leads to substantial tool wear. Its high work-hardening rate means that as the material is cut, it becomes harder, further accelerating tool degradation. Poor chip evacuation can also exacerbate this, leading to recutting and localized heat buildup. Furthermore, Kovar's relatively low thermal conductivity compared to more common machining alloys like aluminum means that heat generated during cutting dissipates slowly from the cutting zone. This retained heat can lead to thermal distortion of the workpiece, inconsistent surface finishes, and further stress on the cutting tool. Effective thermal management is therefore not just a matter of prolonging tool life but essential for maintaining dimensional accuracy and material integrity.

Table: Comparative Mechanical Properties

| Property | Kovar (ASTM F15) | 304 Stainless Steel | 6061 Aluminum |

| Tensile Strength (MPa) | 520 - 690 | 515 - 620 | 125 - 310 |

| Yield Strength (MPa) | 275 - 345 | 205 - 240 | 55 - 275 |

| Elongation at Break (%) | 25 - 35 | 40 - 70 | 12 - 25 |

| Hardness (Rockwell B) | 80 - 90 | 70 - 90 | 30 - 60 |

| Thermal Conductivity (W/m·K) | 17 | 16 | 167 |

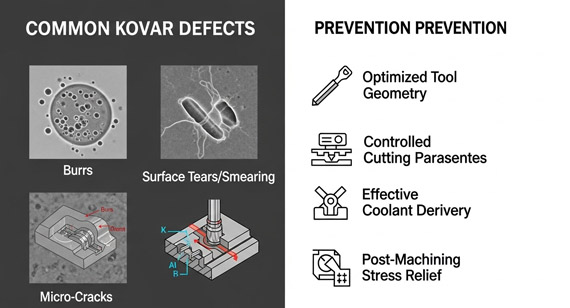

Preventing Common Machining Defects

Common defects in Kovar machining include excessive burrs, surface tears or pull-out, micro-cracking, and part distortion. Burrs are prevalent due to Kovar's toughness and ductility, requiring careful deburring strategies. Surface tears can occur if cutting parameters are not optimized, leading to material smearing rather than clean shearing. Micro-cracking, though often not visible to the naked eye, can compromise the hermetic sealing capabilities and structural integrity, especially near edges or in areas of high stress. Part distortion is a direct consequence of inadequate thermal management and residual stress buildup. Preventing these defects demands a holistic approach, including appropriate tool selection, precise cutting parameters, effective cooling, and controlled stock removal. Careful attention to these factors is crucial to avoid costly rework and ensure the reliability of the final component.

Overcoming Kovar High-Stress Machining

Kovar's propensity for work hardening and low thermal conductivity can lead to significant residual stresses within the machined part. High-stress machining, particularly in deep cuts or complex geometries, can intensify these stresses, leading to post-machining distortion, reduced fatigue life, and compromised hermetic seal performance. To mitigate this, strategies like multi-pass machining with light depths of cut, designed to minimize heat generation and stress accumulation, are often employed. Annealing treatments, either intermediate or post-machining, are vital for stress relief. These thermal treatments restore the material's microstructure, reduce internal stresses, and prepare the component for subsequent processing or critical applications, ensuring long-term stability and reliability.

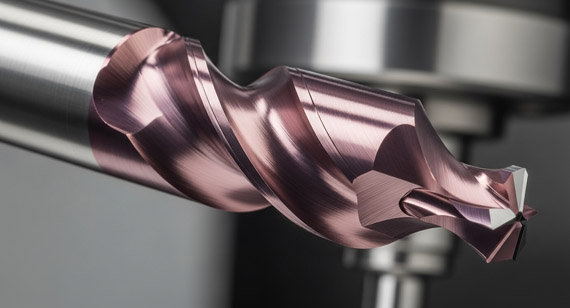

Tool Selection and Geometry Optimization

The selection of cutting tools is paramount for successful Kovar machining. Due to Kovar's abrasiveness and work-hardening tendencies, solid carbide tools with high toughness and wear resistance are typically preferred. Coatings such as TiAlN (Titanium Aluminum Nitride) or AlTiN (Aluminum Titanium Nitride) significantly enhance tool life by reducing friction and increasing hardness. Tool geometry is equally critical; positive rake angles promote shearing action and reduce cutting forces, while a strong edge preparation (chamfer or small radius) helps prevent chipping. Chip breakers are also essential to manage the tough, stringy chips characteristic of Kovar, preventing chip recutting and entanglement. Customized tool designs may be necessary for intricate features or specific applications to optimize performance.

Table: Recommended Tooling Characteristics for Kovar Machining

| Parameter | Recommendation | Benefit |

| Tool Material | Solid Carbide (C2, C3 grades) | High hardness and wear resistance against abrasive Kovar |

| Coating | TiAlN, AlTiN | Reduces friction, increases hardness, prolongs tool life |

| Rake Angle | Positive (5-15°) | Promotes clean shearing, reduces cutting forces |

| Relief Angle | Sufficient (6-10°) | Prevents rubbing, minimizes heat buildup |

| Edge Preparation | Honed or small chamfer (0.02-0.05 mm) | Strengthens cutting edge, reduces chipping |

| Flute Count | Lower (2-4 flutes for end mills) | Provides larger chip pockets, better chip evacuation |

Cutting Parameters: Speed, Feed, and Depth of Cut

Optimizing cutting parameters for Kovar is a delicate balance. Generally, lower cutting speeds are preferred to reduce heat generation and tool wear. High speeds can lead to rapid edge breakdown and thermal distortion. Moderate feed rates are employed to ensure a positive chip load, preventing rubbing and work hardening, while still allowing for efficient material removal. Too low a feed can cause excessive rubbing and premature tool wear, while too high a feed can lead to tool breakage or poor surface finish. The depth of cut should be carefully controlled; while heavy depths can reduce passes, they also increase cutting forces and heat. Often, multiple passes with lighter depths of cut are more effective in minimizing stress and heat, especially for finishing operations where surface integrity is critical. These parameters are often fine-tuned through empirical testing for specific machine-tool-workpiece combinations.

Coolant and Lubrication Strategies

Effective cooling and lubrication are indispensable when machining Kovar. Given Kovar's low thermal conductivity, high heat buildup in the cutting zone is a primary concern. High-pressure flood cooling is often recommended to efficiently remove heat, flush chips, and lubricate the cutting interface. This directly reduces tool wear, improves surface finish, and prevents thermal distortion of the workpiece. Specialized coolants with high lubricity and excellent heat transfer properties are beneficial. In some cases, Minimum Quantity Lubrication (MQL) can be employed, delivering a fine mist of lubricant to the cutting zone, which can be effective for certain operations while reducing coolant consumption and disposal. The method and type of coolant must be carefully selected to match the machining operation and environmental considerations.

Kovar Post-Processing and Surface Finish

Achieving the required surface finish on Kovar components often extends beyond the primary CNC machining operation. For critical hermetic sealing surfaces or areas requiring extremely tight tolerances, additional post-processing steps may be necessary. These can include precision grinding, lapping, or polishing to achieve mirror-like finishes and exact dimensional accuracy. Care must be taken during these processes to avoid inducing new stresses or surface defects. Chemical cleaning and passivation may also be employed to prepare surfaces for subsequent plating, bonding, or sealing operations, ensuring optimal performance and compliance with industry standards. Each post-processing step must be meticulously planned and executed to preserve the integrity and functionality of the Kovar part.

Standards for Dimensional and Geometric Tolerances

Maintaining stringent dimensional and geometric tolerances is critical for Kovar components, particularly those involved in hermetic sealing or precise mechanical assemblies. Our quality control processes involve the use of advanced inspection equipment such as Coordinate Measuring Machines (CMMs), optical comparators, and laser scanners. These tools allow for non-contact, high-precision measurement of complex geometries, ensuring that every feature meets design specifications. Statistical Process Control (SPC) methods are employed throughout the manufacturing chain to monitor and adjust processes proactively, minimizing variation and ensuring consistent quality from the first part to the last. Our adherence to ISO9001 and IATF1649 certifications underscores our commitment to a robust and repeatable quality management system.

Table: Typical Tolerances for Kovar Components (VMT CNC Capabilities)

| Feature Type | VMT CNC Achievable Tolerance | Standard Industry Tolerance (for reference) |

| Linear Dimensions (±) | 0.005 mm | 0.01 - 0.05 mm |

| Flatness | 0.005 mm | 0.01 - 0.02 mm |

| Perpendicularity | 0.005 mm | 0.01 - 0.02 mm |

| Concentricity | 0.005 mm | 0.01 - 0.02 mm |

| Surface Finish (Ra) | Down to 0.4 µm | 0.8 - 1.6 µm |

Surface Integrity and Metallurgical Analysis

Beyond dimensional accuracy, the surface integrity of Kovar parts is paramount for applications requiring hermetic sealing or specific electrical properties. Any surface defects, such as micro-cracks, excessive roughness, or contamination, can compromise performance. Our quality control includes microscopic inspection, and where necessary, scanning electron microscopy (SEM) to analyze surface topography and detect sub-surface imperfections. Metallurgical analysis, including cross-sectioning and grain structure evaluation, confirms that machining processes have not adversely affected the material's microstructure or induced detrimental residual stresses that could impact long-term reliability. We ensure that surfaces are free from detrimental inclusions and exhibit the desired metallurgical characteristics for their intended function.

The Importance of Heat Treatment and Stress Relief

Heat treatment, specifically annealing, plays a critical role in Kovar part manufacturing. After machining, internal stresses can be present due to the material's work-hardening tendencies and the heat generated during cutting. These stresses, if not relieved, can lead to part distortion during subsequent processing (such as brazing or glass sealing) or in service under thermal cycling. Annealing cycles, typically performed in a vacuum or controlled atmosphere furnace, precisely restore the material's ductility, reduce hardness, and, crucially, eliminate residual stresses without altering the carefully matched CTE. This process is meticulously controlled to ensure that the Kovar retains its optimal properties for reliable hermetic sealing and structural stability.

Aerospace and Defense Components

In the aerospace and defense sectors, Kovar's properties are indispensable for components that must withstand extreme conditions and maintain absolute reliability. Applications include hermetically sealed sensor housings for avionics, vacuum tube envelopes for radar and communication systems, and feedthroughs in critical electrical connectors exposed to vacuum or harsh atmospheric environments. The integrity of these Kovar components is vital for the safety and operational effectiveness of aircraft, satellites, and defense systems, where failure is not an option. Our expertise ensures these parts meet the rigorous standards for performance and longevity required by these industries.

Medical Equipment and Implants

The medical industry leverages Kovar for its biocompatibility and hermetic sealing capabilities in a range of advanced devices. This includes components for medical implants, diagnostic equipment, and specialized surgical tools where a stable, sterile, and electrically isolated environment is crucial. Kovar is used in hermetic seals for implantable pacemakers, defibrillators, and neurostimulators, protecting sensitive electronics from bodily fluids. Its precise thermal expansion ensures the long-term integrity of these life-sustaining devices, contributing to patient safety and reliable function.

Electronic Packaging and Semiconductors

Kovar is fundamental to the electronic packaging and semiconductor industries for creating robust, high-performance seals. It is utilized in integrated circuit (IC) packages, power tubes, microwave tubes, and X-ray tubes. The alloy forms a crucial interface for sealing glass or ceramic components to metal lead frames, ensuring vacuum integrity or protection against moisture and contaminants. This allows for the precise operation of sensitive electronic components, extending their lifespan and enhancing performance in applications ranging from industrial controls to high-frequency communication systems.

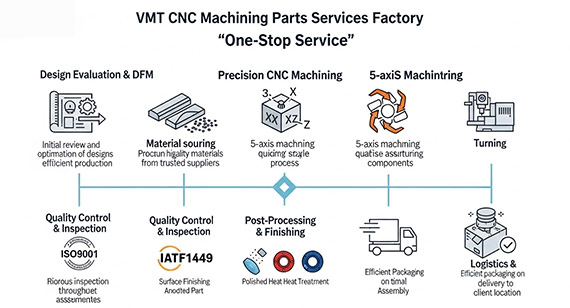

Ensuring Quality and Cost Transparency as a Source Factory

As a source manufacturer, VMT CNC Machining Parts Services Factory operates directly, eliminating intermediaries and ensuring complete transparency in our processes and pricing. This direct relationship offers clients factory-direct pricing without hidden markups, coupled with full visibility into the manufacturing chain. Our status as a source manufacturer means we control every aspect of production, from material sourcing and machine calibration to final inspection and delivery. This integrated control guarantees the highest quality Kovar parts and allows for rapid response to project changes, offering a distinct advantage in terms of cost-effectiveness, reliability, and speed to market.

Leveraging Deep Technical Expertise for Complex Challenges

VMT CNC possesses deep technical knowledge in machining complex and specialized materials like Kovar. Our engineering team provides Design for Manufacturability (DFM) reports, collaborating with clients to optimize designs for efficient production while maintaining critical performance parameters. We specialize in complex structure processing, utilizing advanced 5-axis CNC machining centers to tackle intricate geometries and tight tolerances that are often unachievable with conventional methods. Our expertise extends to specialized material handling, including a comprehensive understanding of Kovar's unique properties, ensuring optimal machining strategies and post-processing for even the most demanding applications.

VMT CNC's Kovar Machining Capabilities and Case Studies

VMT CNC Machining Parts Services Factory is equipped with a large fleet of over 80 advanced machines, including high-precision CNC machining centers, CNC lathes, and multi-axis 5-axis machines. This extensive capacity enables us to handle projects of varying scales with exceptional efficiency and precision. Our capabilities include rapid prototyping, with 24-hour service available for urgent requirements, and a flexible approach with no minimum order quantity (MOQ), supporting both small-batch and large-volume production runs. Our robust full-chain quality control system, certified to ISO9001 and IATF1649 standards, ensures that every Kovar component meets the most stringent quality requirements. We are a trusted partner for critical industries, delivering high-value solutions through superior quality and efficiency.

This ultimate guide to Kovar CNC machining has explored the unique properties of Kovar alloy, emphasizing its critical role in high-tech hermetic sealing applications due to its matched thermal expansion with glass and ceramics. We detailed the significant challenges in machining Kovar, including its hardness, toughness, work-hardening, and thermal management issues, along with strategies to prevent common defects. The guide provided in-depth insights into optimizing Kovar CNC machining processes, covering critical aspects like tool selection, cutting parameters, coolant strategies, and post-processing for superior surface finish. We also highlighted the essential quality control measures, including dimensional and metallurgical analysis and the importance of heat treatment. Finally, we showcased Kovar's diverse applications across aerospace, medical, and electronics, and presented VMT CNC Machining Parts Services Factory's unique advantages as a source manufacturer, emphasizing our technical expertise, advanced equipment, full-chain quality control, and commitment to delivering high-precision Kovar solutions with transparency and efficiency.

1. What makes Kovar so challenging to machine compared to other metals?

Kovar's unique combination of moderate hardness and significant toughness, coupled with a high work-hardening rate, makes it challenging. As it's cut, it becomes harder, rapidly wearing tools. Its low thermal conductivity also means heat generated during machining dissipates slowly, leading to thermal distortion and stress buildup, which requires careful thermal management and specialized tools.

2. Why is thermal expansion matching so critical when using Kovar?

Thermal expansion matching is critical because Kovar is primarily used for hermetic sealing with glass and ceramics in applications exposed to temperature fluctuations. If the metal and the sealing material expand or contract at different rates, significant stresses can develop at the interface, leading to cracks, leaks, and eventual failure of the hermetic seal. Kovar is engineered to have a CTE that closely matches specific sealing glasses to prevent these stresses.

3. What are the most common defects encountered during Kovar machining, and how are they prevented?

Common defects include excessive burrs, surface tears or material pull-out, micro-cracking, and part distortion. These are prevented through a combination of optimized tool selection (e.g., tough carbide tools with specific coatings and geometries), precise cutting parameters (lower speeds, moderate feeds, light depths of cut), effective high-pressure cooling, and strategic post-processing like stress-relief annealing.

4. Can Kovar parts be rapidly prototyped, and is there a minimum order quantity (MOQ)?

Yes, Kovar parts can be rapidly prototyped. At VMT CNC, we offer 24-hour rapid prototyping services for urgent projects. Furthermore, we operate with no minimum order quantity (MOQ), accommodating both small-batch specialized components and larger production runs to meet diverse client needs.

5. What kind of quality control measures are in place for Kovar components at VMT CNC?

Our quality control for Kovar components is rigorous and full-chain, certified to ISO9001 and IATF1649 standards. It includes precise dimensional and geometric tolerance checks using CMMs and optical comparators, microscopic inspection for surface integrity, and metallurgical analysis to ensure optimal microstructure. Heat treatment processes are also meticulously controlled for stress relief and property stability.

6. How does VMT CNC's "source manufacturer" status benefit clients for Kovar projects?

As a source manufacturer, VMT CNC provides direct control over the entire production process, from material procurement to final delivery. This ensures superior quality control, complete process transparency, and direct, factory-level pricing without intermediary markups. Clients benefit from direct communication with our technical experts, faster problem-solving, and a more streamlined supply chain.

7. What post-machining treatments are typically required for Kovar parts?

Beyond primary CNC machining, Kovar parts often require specialized post-treatments. These commonly include precision grinding, lapping, or polishing to achieve specific surface finishes and tight dimensional tolerances. Crucially, annealing heat treatments are almost always necessary to relieve residual stresses induced by machining and to stabilize the material's properties for subsequent sealing or use in demanding thermal environments. Chemical cleaning and passivation may also be applied.

8. Which industries most commonly rely on Kovar CNC machined components?

Kovar components are primarily used in industries requiring high-reliability hermetic seals and precise thermal expansion matching. These include aerospace and defense (sensor housings, vacuum tube envelopes), medical devices (implantable electronics, diagnostic equipment), and electronic packaging and semiconductors (IC packages, power tubes, microwave devices), where critical performance and environmental protection are paramount.