15 years one-stop China custom CNC machining parts factory

142 |

Published by VMT at Jul 15 2025 | Reading Time:About 8 minutes

142 |

Published by VMT at Jul 15 2025 | Reading Time:About 8 minutes

Manufacturers often face a critical decision when choosing the right material for CNC machining parts: should they go with composite materials or traditional metal materials?

Choosing the wrong material can lead to higher costs, reduced part performance, increased machining difficulty, or even product failure. With industries like aerospace, automotive, and medical demanding high precision and functionality, the stakes are high.

This article explores the key differences between composite and metal CNC machining parts, offering a clear guide for engineers, buyers, and designers to choose the right material. From machining challenges to cost, properties, and applications, this in-depth guide will help you make informed decisions — and maximize the value of your CNC machining services.

Composite materials differ from traditional metal materials in CNC machining due to their structure, machinability, and performance characteristics. While metals offer high strength and thermal stability, composites provide lightweight properties, corrosion resistance, and customizability. Each material affects cutting techniques, tool wear, surface finish, and production cost — making material selection crucial for optimized CNC machining parts.

Understanding the fundamental differences between composite and traditional metal materials is key to achieving optimal performance in CNC machining parts. Whether you're a product designer evaluating cost-efficiency or a buyer selecting a CNC machining factory, this guide will provide the practical knowledge you need to make a confident material choice. Let’s start by understanding what each material type is.

Composite materials are engineered from two or more constituent materials with significantly different physical or chemical properties. These components — typically a matrix (like resin) and a reinforcement (like carbon fiber, glass fiber, or aramid) — combine to create a material with characteristics superior to those of the individual elements.

These materials are widely used in industries where weight, strength, and corrosion resistance are critical, such as aerospace, automotive, medical, and sports equipment manufacturing. Composites are not just lightweight — they are tailorable in terms of stiffness, thermal expansion, and even conductivity. In composite CNC machining parts, the choice of fiber and matrix allows precise control over performance characteristics.

Common composite types include:

Because composites are anisotropic (different properties in different directions), CNC machining services must be adapted to handle them carefully. The goal is to avoid delamination, fiber pull-out, and tool wear, all while maintaining dimensional accuracy and finish.

Traditional metal materials used in CNC machining include well-known metals like aluminum, steel, stainless steel, brass, copper, and titanium. These metals are popular for their mechanical strength, heat resistance, ductility, and workability.

Metals are isotropic, meaning they exhibit the same properties in all directions, which makes them more predictable to machine. This uniformity supports the creation of highly complex metal CNC machining parts with tight tolerances and consistent finishes.

Metals are also recyclable, durable, and suitable for load-bearing applications. In industries like construction, automotive, and heavy machinery, traditional metals remain irreplaceable due to their:

Whether you're using CNC turning, milling, or drilling, traditional metals typically offer faster machining cycles, lower tool wear (for softer metals), and easier post-processing compared to composites.

While traditional machining may involve manual controls and simple operations, CNC machining relies on advanced software and automation to produce precise, repeatable parts. The approach drastically changes how composite and metal CNC machining parts are designed and manufactured.

Automation and Control

CNC machining uses pre-programmed digital instructions (G-code) to operate cutting tools with exceptional consistency. Unlike traditional manual machining, which depends on human skill, CNC enables complex geometries, tight tolerances, and consistent quality. This precision is vital when working with composite materials, which are sensitive to tool pressure and direction.

Precision and Repeatability

CNC machining offers repeatability within microns, which is essential for industries like medical and aerospace. Composite materials may require custom tool paths and speeds, while traditional metals allow faster, more aggressive machining due to their predictability.

Operator Skills and Involvement

Traditional machining demands hands-on craftsmanship. CNC, however, relies on CAD/CAM programming, setup calibration, and machine operation. For composites, operators must understand how to prevent fiber breakout and surface delamination, making expertise even more critical.

Other Differences

Here's a clear and easy-to-read comparison table highlighting the key differences between CNC machining and traditional (manual) machining:

| Feature |

CNC Machining |

Traditional Machining |

| Control Method |

Computer-controlled (automated with G-code) | Manually operated by skilled machinists |

| Precision & Repeatability |

Extremely high; consistent part accuracy within microns | Depends on operator skill; lower consistency |

| Complexity of Parts |

Ideal for complex geometries and multi-axis machining | Suitable for simple parts and basic shapes |

| Operator Skill Requirement |

Requires CAD/CAM programming and setup knowledge | Requires manual machining experience and craftsmanship |

| Production Speed |

Faster for high-volume production; minimal downtime | Slower; better for low-volume or one-off parts |

| Tool Changes |

Automatic tool changers available | Manual tool changes required |

| Efficiency |

High throughput, especially in batch production |

Lower efficiency; time-consuming setups |

| Labor Involvement |

Minimal after setup; mostly automated | Continuous human intervention required |

| Surface Finish & Tolerance |

Excellent finish and tight tolerances achievable | Inconsistent finish; harder to maintain tight tolerances |

| Customization & Flexibility |

Easily programmable for multiple part types | Limited by machine capability and operator skill |

| Suitability for Materials |

Handles a wide range including composites and exotic metals | Mostly traditional metals and simpler materials |

| Cost Efficiency |

Higher initial investment; better ROI in large-scale runs | Lower startup cost; more economical for small batches or prototypes |

This table helps CNC machining buyers and engineers clearly see why CNC machining services are ideal for modern manufacturing, while traditional machining still has its niche for basic or low-volume jobs.

Choosing the right material for CNC machining parts is critical in ensuring performance, longevity, and cost-efficiency. Today, manufacturers are no longer limited to traditional metal materials like aluminum or steel; composite materials are increasingly becoming viable alternatives. Each material type brings its own set of benefits and drawbacks. By understanding the advantages and disadvantages of composites and traditional metals, businesses can make informed decisions when selecting materials for CNC machining services, especially in high-performance or cost-sensitive applications.

Composites: Advantages and Disadvantages

Composite materials—typically made by combining two or more distinct substances—have rapidly gained traction in industries requiring lightweight, high-performance components. As CNC machining factories evolve, they are increasingly offering composite CNC machining parts to meet growing market demand.

Composites: Advantages

The rise of composite materials in modern manufacturing isn’t a coincidence. Their unique material properties give them significant advantages over traditional metals in various applications—from aerospace and automotive to medical devices and sports equipment.

Composites are engineered to combine materials like carbon fibers, glass fibers, or aramid with resins. This hybrid structure provides enhanced characteristics, such as tailored strength, weight, and flexibility. Unlike metals, which are uniform in composition, composites can be custom-designed to meet specific performance needs at minimal weight.

One of the most celebrated advantages of composite materials is their exceptional strength-to-weight ratio. Compared to steel or aluminum, composites can offer equivalent or greater mechanical strength at a fraction of the weight. This benefit is invaluable in applications like aerospace or automotive, where reducing weight improves fuel efficiency and overall performance.

Composites naturally resist rust and corrosion, making them highly durable in harsh environments such as marine, chemical processing, or outdoor applications. This can lead to longer-lasting CNC machining parts, reducing maintenance and replacement frequency compared to traditional metal components.

Composites can be molded and machined into complex shapes more easily than many metals. This design flexibility means manufacturers can create intricate components without the limitations of rigid metal geometry, especially beneficial in custom CNC machining services.

Because composites can be engineered with specific reinforcements and resins, manufacturers can tailor properties such as thermal resistance, electrical conductivity, or impact resistance to suit exact application requirements. This customization allows for more innovative and high-performance product designs.

Other Advantages

Composites: Disadvantages

While composites offer many benefits, they also come with challenges:

Traditional Metal Materials: Advantages and Disadvantages

Metals like aluminum, steel, titanium, and brass have long been the backbone of CNC machining. These metal CNC machining parts remain crucial for industries that demand strength, conductivity, and proven material behavior under stress.

Traditional Metal Materials: Advantages

Despite the rise of composite materials, traditional metals still offer unmatched reliability in many applications. Their well-understood properties, coupled with established manufacturing standards, make them essential in CNC machining factories worldwide.

Metals such as titanium and steel provide outstanding mechanical strength and rigidity. This makes them ideal for structural components and load-bearing applications in industries like construction, defense, and transportation.

Unlike many brittle materials, metals can deform under stress without cracking. This makes them more forgiving during machining and in high-impact applications, ensuring durability and long service life.

Certain metals, especially stainless steels and treated aluminum, offer strong resistance to environmental damage. This protects metal CNC machining parts from wear and corrosion, particularly in outdoor or marine applications.

Metals can be cast, welded, forged, and machined into almost any shape. CNC machining services using traditional metals are capable of achieving tight tolerances and highly detailed geometries, ideal for complex industrial components.

Metals can be alloyed with other elements to enhance properties such as strength, conductivity, and thermal resistance. This enables a wide range of material grades to match diverse application needs.

Generally, metals like steel and aluminum are more affordable and readily available than high-performance composites. This makes them suitable for large-volume production and cost-sensitive projects.

Other Advantages

Traditional Metals: Disadvantages

Despite their many benefits, traditional metals also have downsides:

Here's a comprehensive and easy-to-read comparison table that outlines the advantages and disadvantages of composite materials and traditional metal materials in the context of CNC machining parts:

Composite Materials vs. Traditional Metal Materials: Advantages & Disadvantages

| Category |

Composite Materials |

Traditional Metal Materials |

| Material Composition |

Engineered with fibers (e.g., carbon, glass) and resin matrices for tailored properties | Homogeneous or alloyed metals such as aluminum, steel, brass |

| Strength-to-Weight Ratio |

Excellent — very high strength with minimal weight | Generally lower ratio; metals are heavier for the same strength |

| Corrosion Resistance |

Naturally corrosion-resistant without coatings | Stainless steel resists corrosion; others require coatings or treatments |

| Design Flexibility |

Highly moldable into complex geometries | High flexibility through forging, casting, and CNC processes |

| Customized Properties |

Easily engineered for conductivity, impact resistance, heat insulation, etc. | Achievable through alloying but with more limitations |

| Thermal & Electrical Insulation |

Low thermal and electrical conductivity — ideal for electronic and thermal applications | High conductivity — not suitable for insulation unless treated |

| Fatigue Resistance |

Excellent — resists crack propagation under stress cycles | Can fatigue and crack over time depending on the application |

| Machinability |

Requires specialized tools and expertise; risk of delamination | Widely understood; compatible with most CNC machining equipment |

| Durability & Toughness |

Brittle in some cases; less impact resistant than metals | High toughness; metals like steel can absorb high impacts |

| Recyclability |

Difficult to recycle or reuse due to complex makeup | Highly recyclable; metals are commonly reused |

| Environmental Resistance |

Withstands UV, moisture, and chemicals in harsh conditions | Some metals are resistant; others require surface treatment |

| Cost |

Higher material cost and more complex machining increases total cost | Lower material and processing cost (e.g., aluminum, mild steel) |

| Ideal Use Cases |

Aerospace, automotive, electronics, sports equipment, medical parts | Construction, heavy machinery, tools, structural components, industrial equipment |

This table helps product engineers, procurement managers, and design teams quickly evaluate the best material choice for their CNC machining parts, whether composite or traditional metal.

As CNC machining technology continues to evolve, both composite materials and traditional metal materials are widely used to manufacture precision components across industries. However, machining each material type presents its own unique challenges. Understanding the machining difficulties associated with composite CNC machining parts versus metal CNC machining parts is critical for product engineers, manufacturers, and CNC machining factories when selecting the right material and production strategy. This section highlights the major machining concerns related to each type, helping decision-makers improve both efficiency and quality.

Machining Challenges of Composite Materials

Tool Wear and Material Abrasiveness

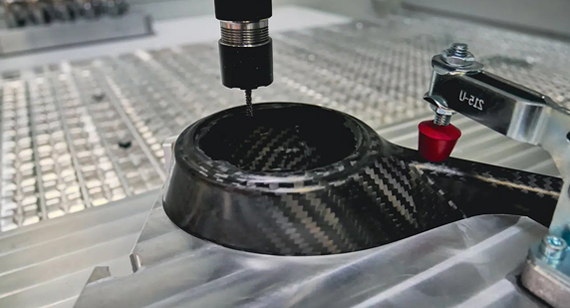

Composite materials, particularly carbon fiber-reinforced plastics (CFRPs) and glass fiber composites, are extremely abrasive. They tend to wear out cutting tools quickly, especially when using conventional tool materials. This means CNC machining services must use coated carbide, diamond-tipped, or polycrystalline diamond (PCD) tools—raising tooling costs and requiring frequent tool changes.

Delamination and Fiber Pull-Out

Unlike homogeneous metals, composites consist of multiple layers and resin-fiber matrices. Improper cutting speeds, feeds, or tool angles can cause delamination, where the layers separate during machining. Another issue is fiber pull-out, where fibers are ripped from the matrix rather than cleanly cut. These defects reduce part strength and may require rework or rejection.

Heat Sensitivity and Melting

Composite materials are often sensitive to heat, especially thermoplastics. Excessive cutting temperatures can lead to resin melting, thermal distortion, or surface burns. CNC machining factories need to implement high-speed, low-heat machining strategies, along with effective coolant systems, to maintain part integrity.

Poor Surface Finish and Burr Formation

Achieving a clean edge and high-quality surface finish with composites is difficult. Edge fraying, burrs, or rough finishes are common, especially if improper tool geometries are used. Post-processing steps such as sanding, trimming, or polishing may be required—adding time and cost to production.

Dust and Health Hazards

Machining composites generates hazardous airborne particulates, including carbon or fiberglass dust, which are harmful when inhaled. CNC machining services must install high-efficiency extraction and air filtration systems to ensure a safe working environment.

Material Variability

Different composite formulations have unique properties and machining behaviors. Manufacturers must carefully test and program their CNC machines to adapt to specific composite types—unlike metals, which generally have predictable characteristics.

Machining Challenges of Traditional Metal Materials

Tool Wear with Hard Metals

While metals are generally more forgiving, certain high-strength metals like titanium, stainless steel, and tool steel can be tough on cutting tools. These materials increase tool wear, require slower machining speeds, and may need coolant systems to manage heat buildup.

Heat Generation and Thermal Expansion

Traditional metals often generate significant heat during cutting, which can lead to thermal expansion, dimensional distortion, or surface hardening. Machinists must compensate for this with slower feeds, better coolant management, and heat-resistant tooling.

Chip Formation and Removal

Metal machining generates solid chips that can clog cutting tools or interfere with the machining path. Efficient chip evacuation systems—such as through-spindle coolant or air blasts—are necessary to prevent defects and maintain cutting quality.

Surface Finish Requirements

For high-precision metal CNC machining parts, surface roughness, tolerances, and finish standards must be tightly controlled. Achieving these can be challenging, especially with hard or ductile metals, requiring fine-tuned speeds, feeds, and finishing processes such as grinding or polishing.

Material Hardness Variability

Metals vary significantly in hardness depending on alloy and heat treatment. CNC machining factories must adjust cutting parameters for each grade, which adds complexity in mixed-material production environments.

Machining Cost and Cycle Time

Machining harder metals often leads to longer cycle times and increased tooling costs. When compared to softer materials or plastics, metals demand more robust machine setups, longer programs, and closer attention to quality control.

Here's a clear and professional comparison table outlining the machining challenges of composite materials versus traditional metal materials, specifically in the context of CNC machining parts production:

Machining Challenges: Composites vs. Traditional Metal Materials

| Machining Challenge |

Composite Materials |

Traditional Metal Materials |

| Tool Wear |

Very high due to abrasive fibers (carbon/glass); requires diamond-coated tools | Moderate to high, especially with hard metals like titanium or tool steel |

| Surface Finish |

Poor edge quality, risk of fraying, delamination, and fiber pull-out | Good to excellent, depending on alloy and tool setup |

| Heat Sensitivity |

High — resin can melt or burn at excessive temperatures | Metals generate heat but are less likely to deform unless improperly cooled |

| Cutting Complexity |

Requires specialized toolpaths, feeds, and speeds to avoid material damage | Standardized procedures available for most alloys |

| Chip or Dust Management |

Produces hazardous dust; needs effective filtration and safety equipment | Produces solid chips; requires chip evacuation systems |

| Material Homogeneity |

Inhomogeneous — layers and fiber orientation complicate machining | Homogeneous or alloyed — easier to predict tool behavior |

| Coolant Use |

Often requires dry or minimal coolant to avoid moisture absorption | Regular coolant use helps manage temperature and tool wear |

| Tool Cost |

High — diamond or PCD tools required | Lower — HSS or carbide tools often sufficient |

| Cycle Time |

Longer — slow machining to prevent defects | Faster — high-speed milling is often feasible |

| Post-processing |

Often needed due to rough edges or surface damage | Sometimes required for polishing or fine finishing |

| Health & Safety Concerns |

Carbon/fiber dust can be hazardous to workers | Metal chips are less hazardous but still require proper handling |

| Consistency in Machining |

Varies with resin/fiber ratio and layup technique | Highly consistent across standard metal grades |

This table is perfect for CNC machining service providers, engineers, or buyers comparing composite CNC machining parts and metal CNC machining parts for feasibility and production cost.

Learn about the key differences and decision-making criteria when choosing between composite and metal CNC machining parts based on application, cost, and performance.

Choosing between composite materials and traditional metal materials is a critical step in the design and manufacturing process. Each material category offers distinct advantages and limitations depending on the part's performance requirements, manufacturing environment, and application. For industries relying on precision, strength, and efficiency—such as aerospace, automotive, electronics, and medical—understanding these key differences is essential. This section compares both types from a machining, application, and cost perspective to help you select the best material for your CNC machining parts.

Key Differences and Considerations

| Aspect |

Composite Materials |

Traditional Metal Materials |

| Material Structure |

Non-homogeneous: made of fibers (carbon, glass) and resin matrix | Homogeneous or alloyed: consistent physical properties throughout |

| Strength-to-Weight Ratio |

Exceptionally high — ideal for weight-sensitive applications | Good, but heavier for the same level of strength |

| Machinability |

Difficult to machine; requires specialized tools and parameters | Easier to machine; compatible with standard CNC machining processes |

| Tool Wear Rate |

High — abrasive nature of fibers causes rapid tool degradation | Moderate — depends on metal hardness |

| Surface Finish |

Challenging to achieve clean edges; may require post-processing | Smooth finishes more easily achieved with proper tooling |

| Thermal Conductivity |

Low — suitable for thermal insulation applications | High — suitable for heat dissipation |

| Electrical Conductivity |

Low (unless specially designed) — used for insulating components | High — used for conductive parts |

| Corrosion Resistance |

Naturally corrosion-resistant (no coating needed) | Some metals require protective coatings or treatments |

| Environmental Resistance |

Excellent against moisture, chemicals, and UV | Varies by alloy — stainless steel performs well, others may degrade |

| Recyclability |

Low — difficult to recycle due to mixed materials | High — widely recyclable and reused |

| Cost |

Higher material cost and complex machining increases total cost | More affordable material and processing cost for many metals |

| Common Applications |

Aerospace, medical devices, automotive interior panels, electronics casings | Construction, machinery, tools, automotive engines, frames |

| Design Flexibility |

High — can be molded into complex shapes and tailored to specific needs | Moderate — shapes formed via machining, forging, or casting |

| Availability & Supply Chain |

Limited suppliers; longer lead times depending on composite type | Widely available; mature global supply chain |

| Sustainability Factors |

Environmentally debatable — low recyclability, but enables fuel savings in end-use | Environmentally friendly if recycled; however, processing is energy-intensive |

Considerations for CNC Machining Services and Buyers

Performance Requirements

If your application demands a lightweight, corrosion-resistant, and high-performance material—such as in drones, prosthetics, or high-end electronics—composite CNC machining parts may be worth the investment.

Cost Efficiency

For cost-sensitive or high-volume projects, metal CNC machining parts made from aluminum or stainless steel often offer the best balance of machinability, durability, and affordability.

Machining Capabilities

Not all CNC machining factories are equipped to handle advanced composite materials. Specialized tooling, dust control systems, and expertise are required, while metals can be machined using standard processes.

Sustainability Goals

Companies with strong environmental goals may prefer metals due to their recyclability. However, composites contribute to fuel and energy efficiency in long-term use.

Summary Snippet for Google Search (Excerpt)

The key differences between composite materials and traditional metals in CNC machining lie in structure, weight, machinability, and cost. Composites offer high performance but are harder to machine and cost more, while metals are easier to process and widely recyclable, making them more practical for many applications.

Learn about the specific materials used in CNC machining — from aluminum and stainless steel to ABS and carbon fiber-reinforced plastics — and how to choose the right one for your project.

Selecting the right material is one of the most crucial decisions in CNC machining. The choice affects not only the performance of the finished component but also its manufacturability, cost, and longevity. CNC machining services utilize a wide range of metals, plastics, and other machinable materials, each with specific advantages tailored to different industries. This section outlines the most common materials used in CNC machining parts, helping manufacturers, engineers, and procurement teams make informed decisions.

Metals Commonly Used in CNC Machining

Metals remain the backbone of modern machining due to their strength, durability, and machinability. They are widely used across industries such as automotive, aerospace, construction, medical, and heavy machinery.

Steel

Brass

Copper

Titanium

Stainless Steel

Other Metallic Materials

Popular Plastics in CNC Machining

Plastics are chosen for their lightweight nature, flexibility, chemical resistance, and low cost. CNC machining plastics is ideal for prototyping, medical devices, and lightweight structural parts.

ABS (Acrylonitrile Butadiene Styrene)

Polycarbonate (PC)

Nylon

Delrin (Acetal/POM)

PEEK (Polyether Ether Ketone)

POM (Polyoxymethylene)

Acrylic (PMMA)

Other Plastic Materials

Other Machinable Materials

In addition to metals and plastics, CNC machining can also work with composites and natural materials, depending on the project's requirements.

Composites

Wood

Conclusion

Understanding the material landscape is key to maximizing the value of your CNC machining services. From lightweight plastics to high-strength metals and advanced composite CNC machining parts, the right material choice impacts not only product performance but also cost and lead time. CNC machining factories must maintain a broad material capability to meet the diverse demands of industries worldwide.

Here's a comprehensive table summarizing the common materials used in CNC machining, categorized by material type, key properties, and typical applications:

Table: Common CNC Machining Materials Overview

| Material Type |

Material |

Key Properties |

Typical Applications |

| Metals |

Aluminum |

Lightweight, corrosion-resistant, highly machinable | Aerospace parts, electronics enclosures, automotive parts |

| Steel |

Strong, durable, good wear resistance | Shafts, gears, machinery components | |

| Brass |

Excellent machinability, corrosion-resistant, aesthetic finish | Valves, fittings, decorative hardware | |

| Copper |

High thermal/electrical conductivity, soft | Heat sinks, electrical contacts, connectors | |

| Titanium |

High strength-to-weight ratio, corrosion-resistant, biocompatible | Aerospace, medical implants, performance components | |

| Stainless Steel |

Corrosion-resistant, strong, available in many grades | Medical devices, food equipment, marine applications | |

| Others (Inconel, Magnesium, Zinc) |

High-temp resistance, lightweight, or cost-effective options | Specialty aerospace, casting, or industrial parts | |

| Plastics |

ABS |

Tough, impact-resistant, easy to machine | Prototypes, housings, consumer electronics |

| Polycarbonate (PC) |

Transparent, impact-resistant, high strength | Shields, light covers, protective casings | |

| Nylon |

Strong, wear-resistant, flexible | Gears, bearings, bushings | |

| Delrin (POM) |

Rigid, low friction, excellent dimensional stability | Gears, pulleys, valve parts | |

| PEEK |

High-performance, heat and chemical resistant | Aerospace, medical implants, electronics insulators | |

| POM |

Strong, stiff, similar to Delrin | Automotive, industrial parts | |

| Acrylic (PMMA) |

Clear, rigid, brittle under stress | Displays, lenses, transparent panels | |

| Other Plastics |

PTFE (Teflon), HDPE, PVC, UHMW, Polypropylene – each with niche properties | Seals, piping, tanks, lightweight parts | |

| Others |

Composites |

Carbon fiber, fiberglass; strong, lightweight, corrosion-resistant | Aerospace, electronics, sporting goods, medical devices |

| Wood |

Natural, easy to machine with proper tools, aesthetic | Furniture prototypes, models, signage |

This table provides a quick comparison that’s useful for CNC machining factories, engineers, and buyers when selecting materials for CNC machining parts.

With the rapid evolution of manufacturing technologies, two major methods have become the cornerstone of modern production: CNC machining and additive manufacturing (also known as 3D printing). Both serve the same goal—creating precise, functional parts—but they approach the process from opposite directions. Understanding the specific differences between these two technologies helps manufacturers and product developers choose the right method based on project needs, cost efficiency, material properties, and design complexity.

Subtractive vs. Additive Processes

CNC Machining: Subtractive Manufacturing

CNC (Computer Numerical Control) machining is a subtractive process. It begins with a solid block of material (metal, plastic, composite) and removes excess material through operations such as milling, drilling, or turning. The machine follows programmed instructions to carve out the final part with high precision.

Additive Manufacturing: Layer-by-Layer Construction

Additive manufacturing builds parts layer by layer using materials like thermoplastics, resin, or metal powders. The process starts from nothing and adds material according to a digital model, typically using FDM, SLA, SLS, or DMLS technologies.

Key Takeaway

Material Utilization and Waste

CNC Machining

Additive Manufacturing

Applicable Applications and Part Complexity

CNC Machining

Additive Manufacturing

Strength and Surface Finish Considerations

CNC Machining

Additive Manufacturing

Conclusion

In summary, CNC machining and additive manufacturing each offer distinct advantages based on the project’s scope, complexity, material requirements, and production volume. CNC machining excels in strength, precision, and mass production of metal CNC machining parts, while additive manufacturing shines in design freedom, customization, and efficient prototyping—especially for composite CNC machining parts.

Choosing the right process comes down to understanding the trade-offs between speed, cost, material waste, and part functionality. Many modern manufacturers even use both methods together in a hybrid approach for optimal results.

Here's a clear, professional comparison table showing the specific differences between traditional CNC machining and additive manufacturing across key criteria:

Table: CNC Machining vs. Additive Manufacturing

| Criteria |

CNC Machining (Subtractive) |

Additive Manufacturing (3D Printing) |

| Process Type |

Subtractive – removes material from a solid block | Additive – builds part layer by layer |

| Material Utilization |

Lower efficiency, high material waste | High efficiency, minimal material waste |

| Design Flexibility |

Limited by tool reach and cutter geometry | Excellent – can produce highly complex geometries |

| Part Complexity |

Ideal for simpler or moderately complex parts | Suitable for complex, organic, or internal features |

| Surface Finish |

Smooth finish, high-quality post-processing available | May require post-processing; varies by technology |

| Mechanical Strength |

High strength, ideal for load-bearing components | Moderate to high (depends on material and process) |

| Precision and Tolerances |

Very high precision and tight tolerances | Moderate precision, tight tolerances with advanced printers |

| Material Options |

Wide range of metals, plastics, composites | More limited (especially in metals); best for plastics and composites |

| Prototyping Speed |

Slower for custom or one-off parts | Fast – ideal for rapid prototyping |

| Production Volume |

Cost-effective for medium to high volume production | More suited to low volume or customized parts |

| Setup and Tooling Costs |

High initial setup and tooling costs | Low setup cost; no tooling required |

| Common Applications |

Aerospace, automotive, medical, industrial machinery | Prototyping, consumer goods, complex custom parts |

| Sustainability |

Less sustainable due to material waste | More sustainable with efficient material use |

This side-by-side comparison helps engineers, designers, and procurement teams at CNC machining factories and product development companies quickly evaluate which process suits their part requirements—whether for metal CNC machining parts, composite CNC machining parts, or hybrid production strategies.

Many manufacturers struggle to decide whether to choose composite materials or traditional metal materials when designing parts for CNC machining. The fear of selecting the wrong material can lead to increased costs, lower performance, or missed opportunities. Fortunately, understanding where each material excels—based on real-world applications—can guide decision-makers toward the right choice.

Composite materials are ideal for lightweight, corrosion-resistant parts in aerospace, automotive, and sports equipment, while traditional metals are best suited for high-strength, heat-resistant parts in construction, tooling, and heavy machinery. Choosing between them depends on application requirements like weight, strength, and environment.

Knowing where and how to apply these materials makes a big difference in performance, cost-efficiency, and manufacturability. Below is a side-by-side look at typical use cases and part examples for both composite and metal CNC machining materials.

Table: Composites vs. Traditional Metal Materials – Applications & Examples

| Industry/Application |

Composite CNC Machining Parts |

Metal CNC Machining Parts |

| Aerospace |

Drone frames, interior panels, radomes | Engine brackets, landing gear components, structural ribs |

| Automotive |

Lightweight body panels, dash structures, battery enclosures | Engine blocks, suspension arms, drive shafts |

| Medical Devices |

Prosthetics, imaging equipment housing, orthotic devices | Surgical instruments, implantable devices, X-ray bed frames |

| Sports & Recreation |

Bicycle frames, golf club shafts, helmet shells | Dumbbell cores, scooter components, skate axles |

| Marine |

Hull panels, rudder blades, instrument enclosures | Propeller shafts, anchor systems, brackets |

| Electronics |

PCB carriers, protective enclosures, EMI shielding parts | Heat sinks, frames, connectors |

| Industrial Machinery |

Lightweight arms, vibration-damping components | Gearboxes, shafts, housings |

| Construction |

Panels, rebar substitutes, structural formworks | Steel beams, mounting brackets, support structures |

| Defense & Military |

Camouflage panels, UAV frames, ballistic shields | Gun barrels, armor plates, vehicle mounts |

| Energy Sector |

Wind turbine blades, cable trays | Turbine housings, generator parts, mounting flanges |

Guiding Discourse

Still not sure which material suits your application best? Check out our detailed comparison on:

Summary

Composite materials shine in industries that demand lightweight, corrosion-resistant, and highly customizable parts—such as aerospace, medical, and sports. On the other hand, traditional metals remain essential for their superior strength, durability, and heat resistance in industrial, automotive, and construction settings.

Choosing the right material depends on the intended use, performance demands, and operating environment. CNC machining factories like VMT help businesses analyze these requirements to deliver optimized CNC machining parts, whether metal or composite.

Choosing the right material for CNC machining often comes down to cost—but the decision isn’t always straightforward. Many clients face uncertainty when weighing the upfront expenses of composites against traditional metals. The challenge lies in understanding not only the initial purchase price but also the long-term cost implications such as machining complexity, durability, and maintenance. Without this insight, companies risk overspending or underperforming in critical applications.

Composite materials generally have a higher initial cost than traditional metals but can offer savings through weight reduction, corrosion resistance, and longer lifespan. Traditional metals tend to be more cost-effective upfront, especially for high-volume production, but may incur higher maintenance and material waste over time.

To help manufacturers and product designers make informed decisions, it’s essential to break down the cost factors for both composite and traditional metallic materials in CNC machining.

Cost Comparison of Composite vs. Traditional Metals

| Cost Factor |

Composite Materials |

Traditional Metallic Materials |

| Raw Material Price |

Generally higher due to complex manufacturing of fibers and resins | Typically lower and widely available; economies of scale reduce cost |

| Machining Complexity |

Often more challenging, requiring specialized tools and slower speeds | Easier to machine with standard tooling and faster cycle times |

| Material Waste |

Minimal waste due to additive layering or precise CNC cutting | Higher waste as material is subtracted from solid blocks |

| Tooling Wear and Maintenance |

Tool wear can be accelerated by abrasive fibers in composites | Standard tool wear rates, generally predictable and manageable |

| Part Weight and Performance |

Lightweight parts can reduce overall system costs (e.g., fuel savings) | Heavier parts may increase operational costs (e.g., transportation) |

| Corrosion and Maintenance |

High corrosion resistance reduces long-term maintenance costs | Metals may require coatings or frequent upkeep to prevent rust |

| Production Volume Impact |

Best suited for low to medium volume; cost per part can be higher | Cost-effective for high-volume runs due to repeatability |

| Lifecycle Cost |

Often lower total cost of ownership in demanding environments | Potentially higher lifecycle costs due to wear and corrosion |

Key Insights

Conclusion

While composites often come with a premium price tag, their cost-effectiveness shines over the product lifecycle, especially in industries like aerospace, automotive, and marine where weight and corrosion resistance are critical. Traditional metals remain the go-to for applications requiring strength, durability, and cost-efficient high-volume production.

At VMT CNC Machining, we guide clients through this complex cost landscape, offering tailored CNC machining services that optimize material selection based on both performance and budget goals.

For a deeper dive into cost-effective CNC machining strategies or to get a custom quote, visit our page on CNC Machining Cost Optimization.

Choosing the right material for CNC machining can be a daunting challenge. Many manufacturers and designers struggle to balance factors such as cost, durability, weight, and machinability. Selecting the wrong material risks increased expenses, suboptimal performance, or even product failure. Fortunately, by understanding the unique strengths and ideal use cases of composite materials and traditional metallic materials, businesses can confidently make the best choice for their specific needs.

Composites are ideal when lightweight, corrosion resistance, and complex shapes are priorities, whereas traditional metals are preferred for applications demanding high strength, toughness, and cost-effective mass production. Material choice should align with the functional requirements and production scale.

To simplify this decision, it helps to explore practical scenarios that highlight when each material excels. Below is a guide on when to choose composites or traditional metals for CNC machining parts.

When Should You Use Composites?

Composite materials, made from a combination of fibers and resins, bring unique advantages that make them the material of choice for specific CNC machining applications:

In summary, composites excel in applications requiring lightweight, corrosion resistance, and design flexibility—perfect for industries demanding high performance and customization.

When Should You Use Traditional Metallic Materials?

Traditional metals such as steel, aluminum, and titanium remain the backbone of CNC machining due to their proven reliability and versatility:

Thus, traditional metallic materials are preferred when strength, cost-efficiency, and machining familiarity are paramount.

Summary

Selecting between composites and traditional metals depends heavily on the specific application requirements. Composites offer unparalleled benefits in weight savings and corrosion resistance, while metals provide unmatched strength and cost benefits for high-volume production. Partnering with experienced CNC machining factories like VMT ensures the material choice aligns perfectly with performance needs and budget constraints.

For more insights, explore our resources on Composite vs. Metal CNC Machining Services and get personalized consultation for your next project.

Here's a clear, client-friendly table summarizing When to Use Composites vs. Traditional Metallic Materials for CNC machining:

| Criteria |

When to Use Composites |

When to Use Traditional Metallic Materials |

| Weight Requirements |

Ideal for lightweight parts needing high strength-to-weight ratio | Heavier parts where weight is less critical |

| Corrosion Resistance |

Excellent corrosion and chemical resistance | May require coatings or maintenance to prevent corrosion |

| Complex Shapes & Design |

Suitable for intricate, complex geometries and integrated features | Best for simpler shapes or where high precision is needed |

| Mechanical Strength |

Good strength, especially in tension and flexibility | Superior strength, toughness, and impact resistance |

| Thermal Performance |

Provides thermal and electrical insulation in many composites | Better suited for high-temperature applications |

| Cost Considerations |

Higher initial cost but potentially lower lifecycle cost | More cost-effective for high-volume production and standard parts |

| Machinability |

Requires specialized tools and slower machining | Easier and faster to machine with standard tooling |

| Application Examples |

Aerospace components, sports equipment, marine panels | Engine parts, structural components, tooling, heavy machinery |

| Volume Suitability |

Best for low to medium production volumes | Ideal for medium to high-volume manufacturing |

| Maintenance Requirements |

Low maintenance due to corrosion resistance | May require regular maintenance or protective coatings |

This table provides a quick overview helping decision-makers select the optimal material for their CNC machining projects based on application needs, cost, and performance.

In today’s competitive manufacturing landscape, finding a reliable CNC machining factory that expertly handles both composite materials and traditional metals can be challenging. Many businesses face delays, quality issues, or high costs due to lack of specialized expertise. VMT understands these pain points and offers comprehensive CNC machining services that meet diverse material needs with precision, efficiency, and consistency.

VMT is a leading CNC machining factory providing high-quality composite and metallic CNC machining parts. With advanced equipment and experienced engineers, VMT delivers tailored solutions that balance cost, precision, and material performance for industries including aerospace, automotive, medical, and more.

Whether your project requires the lightweight strength of composites or the durability of metals, VMT’s integrated CNC machining capabilities ensure your parts meet exact specifications and demanding quality standards.

Why Choose VMT for Your CNC Machining Parts?

Partner with VMT for Comprehensive CNC Machining Services

From composite CNC machining parts that reduce weight and resist corrosion to metal CNC machining parts that ensure strength and durability, VMT is your one-stop factory solution. Leveraging deep industry experience and cutting-edge technology, VMT supports your product development with unparalleled precision and service.

Explore how VMT can bring your next project to life with superior CNC machining services designed to meet today’s demanding manufacturing standards.

Choosing the right material for CNC machining—whether composite materials or traditional metals—plays a pivotal role in the success of any manufacturing project. Composites offer remarkable advantages such as lightweight design, corrosion resistance, and exceptional design flexibility, making them ideal for specialized, high-performance applications. On the other hand, traditional metallic materials provide unmatched strength, durability, cost-effectiveness, and proven machinability, especially suitable for large-scale production and structural components.

Understanding the unique benefits and limitations of each material type, as well as their associated machining challenges and cost implications, empowers manufacturers and designers to make informed decisions tailored to their specific needs. By partnering with experienced CNC machining factories like VMT, clients gain access to expert guidance, advanced technology, and customized solutions that optimize both material choice and machining processes.

Ultimately, the best choice hinges on balancing performance requirements, budget considerations, and production volume. Whether opting for composite CNC machining parts or metal CNC machining parts, leveraging professional CNC machining services ensures superior quality, precision, and efficiency—keys to gaining a competitive edge in today’s manufacturing landscape.

1. What is the difference between composites and metals?

Composites are engineered materials made by combining two or more distinct substances (typically fibers and resin) to achieve superior properties, such as high strength-to-weight ratio and corrosion resistance. Metals are pure or alloyed elements characterized by their ductility, toughness, and conductivity. Both are widely used in CNC machining parts but serve different functional roles based on application needs.

2. What are 5 examples of composites?

Common composites include carbon fiber-reinforced polymer, fiberglass, Kevlar, plywood, and concrete. These materials are increasingly used in composite CNC machining parts for aerospace, automotive, and marine applications.

3. How are composites better than metals?

Composites often outperform metals in weight reduction, corrosion resistance, and design flexibility, enabling manufacturers to produce lighter, more durable parts with customized properties.

4. Why are composites better?

Their customizable fiber orientation and resin types allow composites to meet specific strength, stiffness, and environmental resistance requirements, reducing maintenance and operational costs.

5. What is the difference between traditional and modern materials?

Traditional materials include metals and wood, which have been used for centuries. Modern materials incorporate composites and advanced polymers designed to meet the evolving demands of high-performance applications.

6. How do composites differ from alloys?

Alloys are metallic mixtures designed to enhance metal properties like strength or corrosion resistance. Composites combine non-metallic materials to achieve tailored mechanical and physical characteristics.

7. How do composites differ from pure materials?

Pure materials consist of a single element or compound, whereas composites combine multiple materials at the micro or macro level to improve overall performance.

8. What are the main advantages of using composites in manufacturing?

Advantages include lightweight construction, corrosion resistance, high strength-to-weight ratio, design versatility, and potential lifecycle cost savings.

9. Are composites harmful to the environment?

While some composites pose environmental challenges in disposal, many modern composite materials are designed for recyclability and reduced environmental impact.

10. Are composites environmentally friendly?

With advances in bio-based resins and recycling techniques, composites are becoming increasingly sustainable alternatives to metals in various industries.

11. What are the three main types of composites?

The primary types are polymer matrix composites (PMCs), metal matrix composites (MMCs), and ceramic matrix composites (CMCs), each suited for different CNC machining applications.

12. What is the difference between composites and plastic materials?

Composites include reinforcing fibers within a plastic (polymer) matrix, enhancing mechanical properties, whereas plastics alone lack this reinforcement.

13. What are the two main components of composites?

Composites consist of a reinforcing phase (fibers or particles) and a matrix phase (usually a polymer resin) that binds and supports the reinforcement.

14. Are composite fillings better than metal fillings?

In dentistry, composite fillings offer better aesthetics and bond strength compared to traditional metal fillings, though this is outside the CNC machining scope.

15. Why are composites better than alloys?

Composites can be engineered for specific directional strength and stiffness, often providing better performance-to-weight ratios than metal alloys.

16. Which is better, steel or composites?

The choice depends on the application—steel offers superior strength and toughness for heavy-duty parts, while composites excel in lightweight, corrosion-resistant designs.

17. Why do composites have good strength?

Their strength comes from high-performance fibers (like carbon or glass) embedded in a resilient matrix, combining to distribute loads efficiently.

18. What is the difference between metal and plastic fillings?

In industrial contexts, metal parts typically provide structural strength, while plastic components offer corrosion resistance and electrical insulation.

19. Why are composites better than amalgam?

In medical or dental applications, composites provide improved aesthetics and bonding; in manufacturing, composites offer tailored mechanical properties that amalgams cannot match.