15 years one-stop China custom CNC machining parts factory

125 |

Published by VMT at Jul 01 2025 | Reading Time:About 14 minutes

125 |

Published by VMT at Jul 01 2025 | Reading Time:About 14 minutes

As industries push the boundaries of performance and innovation, traditional materials like metals often fall short—too heavy, too rigid, or too susceptible to corrosion. At the same time, composite materials are surging in popularity, offering strength, flexibility, and lightweight advantages. However, machining these advanced materials is not as straightforward as working with metals.

Many manufacturers struggle with how to efficiently and accurately machine composite parts without damaging their structural integrity. Poor material selection, tool wear, and delamination can quickly increase costs, reduce product performance, and damage reputations. Navigating composite CNC machining requires more than just advanced tools—it requires knowledge, strategy, and expert insight.

This comprehensive guide to composite CNC machining will walk you through everything you need to know—from understanding what composite materials are, to how they’re machined, which tools and techniques are used, and how to select the right composite for your specific application. Whether you're in aerospace, automotive, or medical, this guide will equip you with the expertise needed to make informed decisions and succeed in a high-performance world.

Composite CNC machining is the process of using computer numerical control to shape and fabricate parts made from composite materials, such as carbon fiber, fiberglass, and aramid-reinforced polymers. It requires specialized tools and techniques to prevent delamination, maintain precision, and achieve high-performance results across industries like aerospace, automotive, and medical.

The use of composite materials has grown dramatically over the past two decades due to their strength-to-weight ratio, corrosion resistance, and adaptability across demanding environments. However, achieving accurate and efficient CNC machining results with composites demands a nuanced understanding of both materials and technology. The following guide will take you step by step through the science of composites, their machining requirements, and how CNC machining services and factories adapt to meet these challenges. Keep reading to explore different types of composites, their unique machining characteristics, and how VMT approaches composite CNC machining for precise, efficient, and high-quality outcomes.

Key Points: What You Need to Know About Composite CNC Machining

Composite materials are engineered by combining two or more constituent materials with significantly different physical or chemical properties to create a new material with superior characteristics. Unlike metals or plastics, composites are not homogeneous; they consist of a matrix and a reinforcement, working together to deliver enhanced performance in terms of strength, durability, and resistance to environmental conditions. This makes them highly valuable in industries where performance, weight, and resilience are critical—such as aerospace, automotive, medical, defense, and marine.

At the heart of every composite lies a matrix, which acts as the binder that holds the structure together and transfers loads between fibers. The reinforcement is usually in the form of fibers (e.g., carbon, aramid, or glass), contributing high tensile strength and stiffness. When combined, these components form a composite that offers a blend of the best properties of both: toughness from the matrix and structural strength from the fibers.

Unlike metals, composites can be tailored precisely to meet application-specific needs. For instance, by changing the fiber orientation, type, or resin system, engineers can fine-tune strength, weight, and thermal performance. Additionally, composites offer outstanding corrosion resistance and fatigue performance, making them ideal for harsh or high-stress environments.

Modern manufacturing technologies—especially composite CNC machining—enable precise fabrication of these complex materials into high-performance parts. CNC machining composite parts requires knowledge of fiber orientation, material behavior under cutting loads, and thermal sensitivity, making it a more sophisticated process compared to traditional metalworking.

In short, composite materials are custom-designed, performance-optimized solutions for modern engineering challenges, and CNC machining plays a crucial role in unlocking their potential in real-world applications.

Composite materials are built on a simple but powerful concept: combining two or more distinct materials to produce a new material with superior properties. The three fundamental components of any composite are the matrix, the reinforcement, and the interface. Each plays a distinct role in determining the composite's mechanical strength, durability, weight, resistance to environmental factors, and performance under stress. Understanding these components is essential for both material selection and the precision machining of composite parts using CNC technologies.

Matrices

The matrix is the continuous phase that surrounds and supports the reinforcement material. It binds the reinforcements together, maintains the shape of the composite, and transfers mechanical loads between fibers. The matrix also plays a vital role in protecting the reinforcing fibers from environmental damage such as moisture, UV exposure, and chemicals. Without the matrix, the individual fibers—though strong—would not be able to function as a unified structural component.

Types of Matrices Include:

Reinforcements

Reinforcements are the dispersed phase embedded within the matrix, typically in the form of fibers, particles, or whiskers. Their primary role is to carry mechanical loads and improve tensile strength, stiffness, and fatigue resistance. Depending on the type of fiber used, reinforcements can be tailored to specific application requirements, such as strength-to-weight ratio, impact resistance, or flexibility. These reinforcements are the key to a composite’s enhanced performance characteristics.

There Are Many Types of Reinforcements, Including:

Interface

The interface is the region where the matrix and the reinforcement meet. Although it’s not a separate physical layer, this transitional zone critically influences the mechanical performance of the composite. A strong, stable interface ensures effective load transfer between the matrix and the fibers, while a weak interface can result in delamination, reduced strength, and failure under stress—especially during CNC machining processes.

Interfaces in Composite Materials Include:

Yes, composites can absolutely be CNC machined—but with important differences from traditional metals or plastics. Composite CNC machining is not just a transfer of standard techniques; it’s a specialized process that requires knowledge of how the unique properties of composite materials respond to cutting, heat, and vibration. Unlike metals, composites are anisotropic and heterogeneous—meaning their properties vary by direction and composition. As a result, improper tooling, speeds, or feeds can lead to issues like delamination, fiber pullout, edge fraying, or thermal damage.

CNC machining composite parts demands tools and strategies tailored for layered and fiber-reinforced structures. For instance, while metals can typically be machined with standard HSS tools, composites often require diamond-coated, polycrystalline diamond (PCD), or carbide tools to minimize wear and ensure clean, precise edges. Moreover, composites are often more abrasive than metals, which accelerates tool wear and necessitates shorter tool life cycles.

Additionally, composites behave differently under heat. Traditional metals conduct heat well and tolerate higher temperatures, whereas composites can degrade, melt, or burn if exposed to excessive thermal energy. This means CNC machining services working with composite materials must carefully control cutting speeds, feed rates, and cooling methods to avoid damaging the material's structure or appearance.

Advanced CNC machines—especially 5-axis CNC machining systems—are often used for composite work due to their flexibility in approaching complex geometries and controlling tool orientation. They allow for multi-directional tool paths, which is critical for maintaining edge integrity and minimizing mechanical stress during cutting.

In summary, CNC machining of composite materials is not only possible but essential in industries requiring high-performance parts. However, it must be approached with the right tools, methods, and expertise to maintain the structural advantages of composites while achieving the precision and finish modern applications demand.

The world of composite CNC machining is vast, with a wide variety of engineered materials designed for specific applications across industries such as aerospace, automotive, medical, and defense. Selecting the right composite depends on numerous factors: mechanical performance, thermal resistance, machinability, chemical stability, and environmental exposure. Some composites are lightweight and strong, while others offer extreme resistance to wear, heat, or chemicals.

Commonly CNC machined composite materials include fiber-reinforced polymers like aramid, carbon, and glass, as well as metal matrix composites (MMCs), ceramic matrix composites (CMCs), and newer entrants like natural fiber composites and hybrid configurations. Each material brings a different balance of properties to the table—making it essential to understand their behaviors during CNC machining.

Professionals in CNC machining services must consider how different composites react under cutting stress, their tool-wear profiles, and the surface finish achievable. At the same time, CNC machining factories must equip themselves with specific toolsets—such as diamond-coated bits or PCD tools—and establish optimized parameters for cutting, feed rate, and spindle speed to handle the abrasive or layered nature of these materials.

The following sections provide a detailed look into the most common composite materials used in CNC machining, breaking down their composition, physical and chemical properties, and best-fit machining applications. This structured breakdown will help engineers, designers, and manufacturers select the right CNC machining composite parts for performance and production efficiency.

Aramid Fiber Reinforced Polymer (AFRP)

What Is Aramid Fiber Reinforced Polymer?

Aramid Fiber Reinforced Polymer (AFRP) is a high-performance composite made by embedding aramid fibers—like Kevlar® or Twaron®—into a polymer matrix, typically an epoxy or thermoplastic. Aramid fibers are synthetic aromatic polyamides known for their exceptional toughness, low density, and impact resistance. AFRP composites are widely used in aerospace structures, military armor, sports equipment, and automotive parts that require resistance to ballistic forces or vibration.

In CNC machining composite parts made from AFRP, care must be taken due to the fibers’ abrasive nature and low thermal conductivity, which can result in heat buildup and tool wear if not properly managed. These parts are typically chosen when protection, durability, and weight savings are essential.

Material Properties

AFRP composites offer a unique balance of mechanical resilience and lightweight construction, making them ideal for high-performance and safety-critical applications. Their performance is defined by both the fiber type and the resin matrix used.

Physical Properties

Chemical Properties

CNC Machining Applications

AFRP is extensively used in applications where lightweight and toughness are critical, such as:

In composite CNC machining, compression routers, diamond-coated tools, and high-speed spindles are often required to minimize fuzzing and delamination. AFRP’s toughness can lead to rapid tool wear, so machining strategies must include optimized feeds and dust collection systems to manage fiber debris and airborne particles safely.

Carbon Fiber Reinforced Polymer (CFRP)

What Is Carbon Fiber Reinforced Polymer?

Carbon Fiber Reinforced Polymer (CFRP) is one of the most widely recognized and utilized composite materials in high-performance industries. It consists of extremely strong and stiff carbon fibers embedded in a polymer matrix, typically epoxy. These fibers are made from polyacrylonitrile (PAN) or pitch precursors and are characterized by their high tensile strength, rigidity, and extremely low weight.

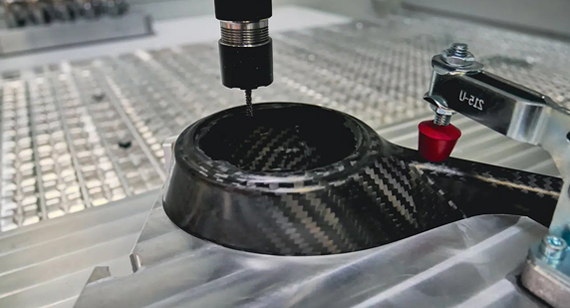

CFRP is favored for its unmatched strength-to-weight ratio, making it ideal for lightweight structural applications. It is used in aerospace fuselages, automotive body panels, sporting equipment, and medical devices where material weight is a critical design constraint. From a composite CNC machining standpoint, CFRP presents unique challenges. Its layered, brittle structure can splinter, delaminate, or develop poor edge quality if not machined with precise tooling and parameters.

This material’s popularity across industries means that CNC machining composite parts from CFRP is a core capability of advanced CNC machining services and CNC machining factories—especially those serving the aerospace and motorsports sectors.

Material Properties

CFRP delivers exceptional structural performance due to the combined properties of high-modulus carbon fibers and strong thermoset resins. Its anisotropic nature (different properties in different directions) is a defining characteristic engineers must consider when designing and machining parts.

Physical Properties

Chemical Properties

CNC Machining Applications

In CNC machining CFRP parts, specific tools such as PCD (polycrystalline diamond) end mills, diamond-coated routers, and compression-style cutters are essential. These tools help reduce delamination, edge chipping, and fiber pullout, which are common problems when machining carbon fiber composites. CFRP’s abrasiveness also leads to rapid tool wear, so frequent tool changes and dust collection systems are important for maintaining safety and part quality.

To machine CFRP effectively, CNC machining factories must use controlled cutting parameters—moderate spindle speeds, low feed rates, and minimal radial engagement—to preserve the integrity of the part. Depending on thickness and layup, 5-axis CNC machining is often preferred to navigate complex geometries while maintaining smooth surfaces and fiber orientation.

Glass Fiber Reinforced Polymer (GFRP)

What Is Glass Fiber Reinforced Polymer?

Glass Fiber Reinforced Polymer (GFRP), also known as fiberglass-reinforced plastic, is a composite material composed of woven or chopped glass fibers embedded within a polymer matrix, commonly polyester, vinyl ester, or epoxy. GFRP is one of the most widely used composite materials globally, valued for its balance of strength, affordability, corrosion resistance, and ease of manufacturing.

While not as strong or stiff as carbon fiber, GFRP offers sufficient mechanical performance for many structural applications and is significantly more cost-effective. It’s also electrically insulating, non-magnetic, and resistant to moisture—making it suitable for electrical housings, watercraft components, and structural panels.

In composite CNC machining, GFRP presents its own set of machining characteristics. It is abrasive due to the hardness of glass fibers, which can cause rapid tool wear. However, it machines more easily than CFRP or aramid-based composites and is well-suited to precision cutting when proper tooling and strategies are applied.

Material Properties

GFRP delivers good overall mechanical performance and excellent resistance to corrosion and weathering. Its properties depend on the fiber orientation, resin type, and fabrication method (e.g., pultrusion, lay-up, RTM).

Physical Properties

Chemical Properties

CNC Machining Applications

GFRP is used extensively across:

When it comes to CNC machining composite parts from GFRP, tool selection is critical. Carbide tools, diamond-coated tools, or PCD cutters are commonly used to resist the wear caused by glass fibers. Compression-style routers help reduce delamination on laminate GFRP, especially when working with multi-ply panels or sandwich structures.

Dust control is essential when machining GFRP, as airborne glass particles can pose health risks and affect machine performance. Coolant is usually avoided, as moisture can react with certain resins or cause swelling. Dry machining with vacuum extraction is the preferred method.

GFRP’s machinability and versatility make it a staple in many CNC machining factories, particularly for mid-tier applications where durability and cost control are important. Its widespread adoption across industries ensures a steady demand in CNC machining services, especially for large, structural, and protective parts.

Basalt Fiber Reinforced Polymer (BFRP)

What Is Basalt Fiber Reinforced Polymer?

Basalt Fiber Reinforced Polymer (BFRP) is an emerging composite material composed of continuous basalt fibers embedded in a polymer matrix, typically epoxy or vinyl ester resin. Basalt fibers are derived from natural volcanic basalt rock, which is melted and spun into filaments. BFRP offers a unique combination of environmental sustainability, strength, and chemical resistance—making it an increasingly attractive alternative to GFRP and even CFRP in certain applications.

BFRP stands out for its eco-friendliness, high thermal stability, and excellent resistance to corrosion and aggressive environments such as saltwater, acids, and alkalis. It’s non-conductive, non-magnetic, and exhibits good mechanical performance—all at a relatively low cost. As a result, BFRP is gaining traction in construction, transportation, infrastructure, and marine industries.

In the context of composite CNC machining, BFRP shares similarities with GFRP in terms of machinability but is generally less abrasive and easier on cutting tools. However, the layered structure and stiffness still require careful cutting strategies to avoid delamination or fiber tearing.

Material Properties

BFRP delivers excellent performance in harsh environments and offers better thermal and chemical stability than GFRP, with strength levels approaching CFRP—making it a competitive, sustainable choice for high-demand applications.

Physical Properties

Chemical Properties

CNC Machining Applications

BFRP is increasingly used in:

In CNC machining BFRP parts, standard carbide, PCD, or diamond-coated tools are recommended. The material’s lower abrasiveness compared to glass fibers results in longer tool life. However, fiber pullout, chipping, or delamination can still occur if feed rates or spindle speeds are not properly optimized.

BFRP’s thermal insulation and corrosion resistance make it a smart choice for CNC machining services serving harsh outdoor or chemical-rich environments. The eco-friendly nature of basalt fibers also aligns well with sustainability goals, positioning CNC machining factories to support greener manufacturing solutions without compromising strength or performance.

Ceramic Matrix Composites (CMC)

What Are Ceramic Matrix Composites?

Ceramic Matrix Composites (CMCs) are a class of advanced composite materials composed of ceramic fibers embedded in a ceramic matrix. Unlike monolithic ceramics, which are hard but brittle, CMCs are engineered to overcome fragility by incorporating reinforcements such as silicon carbide (SiC), alumina (Al₂O₃), or carbon fibers. These reinforcements enhance toughness and fracture resistance while retaining the exceptional high-temperature performance and chemical stability of ceramics.

CMCs are used in extreme environments—such as jet engines, turbine blades, nuclear power plants, and high-speed aerospace applications—where temperatures can exceed 1200°C (2192°F). Their ability to withstand heat, thermal shock, and oxidation without deformation or material fatigue makes them indispensable in modern engineering.

In composite CNC machining, CMCs are challenging due to their inherent hardness, abrasiveness, and brittleness. Special tooling, slow cutting speeds, and non-conventional machining techniques are often required to process these materials without causing microcracks or edge failure.

Material Properties

CMCs deliver a unique combination of high thermal resistance, lightweight construction, and fracture toughness, making them suitable for high-performance and thermally intense applications.

Physical Properties

Chemical Properties

CNC Machining Applications

Typical uses of CMCs include:

Due to their hardness and brittleness, CNC machining composite parts made from CMCs is extremely demanding. Conventional machining methods such as grinding, ultrasonic machining, laser machining, and Electrical Discharge Machining (EDM) are preferred over standard milling or drilling. When cutting is required, diamond-impregnated tools, PCD cutters, and superabrasive grinding wheels are essential to maintain tolerances and surface quality.

CMC machining requires precision control over speed, vibration, and thermal exposure to avoid surface microcracks or catastrophic failure. As such, only the most capable CNC machining services and CNC machining factories—equipped with high-performance, multi-axis systems and specialized cooling/dust control systems—can handle these composites successfully.

Metal Matrix Composites (MMC)

What Are Metal Matrix Composites?

Metal Matrix Composites (MMCs) combine metallic matrices such as aluminum, titanium, or magnesium with reinforcing fibers or particles—often ceramic materials like silicon carbide or alumina. This hybrid structure enhances the metal’s mechanical properties, including strength, stiffness, wear resistance, and thermal stability, while retaining the metal’s inherent ductility and toughness.

MMCs are increasingly popular in aerospace, automotive, and defense sectors where lightweight yet strong materials are critical. Their excellent thermal conductivity and resistance to high temperatures make them ideal for engine components, brake systems, and structural parts.

Machining MMCs involves unique challenges due to their abrasive reinforcements and heterogeneous structure. Specialized tooling and machining parameters are essential to achieve precision while preventing excessive tool wear or surface damage.

Material Properties

MMCs blend the best traits of metals and ceramics, producing materials that can withstand high mechanical loads and extreme thermal environments, making them highly versatile for advanced engineering applications.

Physical Properties

Chemical Properties

CNC Machining Applications

MMCs are utilized in:

Machining MMCs requires robust tooling, such as polycrystalline diamond (PCD) tools and coated carbide cutters, to withstand abrasive reinforcements. The heterogeneous composition demands carefully controlled cutting speeds and feeds to avoid tool chipping and surface damage.

Due to the complex machining requirements, MMC parts are best processed in advanced CNC machining factories equipped with precision multi-axis machines and efficient cooling systems. Expertise in tool wear management and process optimization is vital for cost-effective production.

Hybrid Composites

What Are Hybrid Composites?

Hybrid composites are engineered materials that combine two or more types of reinforcements within a single matrix to capitalize on the benefits of each component. By integrating different fibers—such as carbon with glass, or aramid with basalt—hybrid composites offer a customizable balance of strength, stiffness, impact resistance, and cost-efficiency. This synergy allows designers and manufacturers to tailor materials precisely for demanding applications where a single reinforcement might fall short.

These composites are increasingly popular in industries requiring optimized performance without excessive cost increases, such as automotive, aerospace, sports equipment, and renewable energy. The hybridization approach also enables better control over anisotropy and damage tolerance.

In the realm of composite CNC machining, hybrid composites present unique challenges due to the varied behavior of different fibers and matrices under cutting forces. Machining strategies must accommodate the distinct abrasiveness, thermal sensitivities, and mechanical properties of each reinforcement type to maintain part integrity and surface finish.

Material Properties

Hybrid composites are designed to exploit the complementary properties of different reinforcements. This results in materials with enhanced toughness, stiffness, fatigue resistance, or cost advantages compared to single-fiber composites.

Physical Properties

Chemical Properties

CNC Machining Applications

Hybrid composites find extensive use in:

Due to the mixed reinforcement nature, machining hybrid composites requires a versatile toolset. Tools like diamond-coated end mills, compression routers, and PCD cutters are used to address the varying abrasiveness and mechanical behavior. Optimizing cutting parameters such as spindle speed, feed rate, and depth of cut is crucial to minimize delamination, fiber pullout, and surface defects.

Experienced CNC machining services and CNC machining factories employ advanced CNC machines—often 5-axis—to achieve complex geometries with tight tolerances while preserving hybrid composite integrity.

Polymer Matrix Composites (PMC)

What Are Polymer Matrix Composites?

Polymer Matrix Composites (PMCs) are a class of composite materials where a polymer resin serves as the matrix, reinforced with fibers such as carbon, glass, aramid, or natural fibers. These composites combine the lightweight and corrosion-resistant properties of polymers with the enhanced strength and stiffness provided by the reinforcements. PMCs are among the most widely used composites in modern manufacturing due to their versatility, ease of processing, and excellent mechanical performance.

PMCs are extensively used in aerospace, automotive, marine, and consumer goods industries. The choice of polymer matrix—whether thermosetting (epoxy, polyester) or thermoplastic (PEEK, PPS)—along with fiber type, orientation, and volume fraction, allows engineers to tailor composite properties to specific applications. CNC machining of PMCs requires careful consideration of the matrix’s thermal sensitivity and the fiber’s abrasive nature to maintain dimensional accuracy and surface finish.

Material Properties

PMCs offer a broad spectrum of mechanical and physical properties depending on the fiber-matrix combination, making them adaptable to a wide range of engineering requirements.

Physical Properties

Chemical Properties

CNC Machining Applications

PMCs are widely employed in:

Machining PMCs with CNC equipment requires tools that balance toughness and sharpness, such as carbide or diamond-coated end mills, to minimize delamination and fiber pullout. Managing heat generation is critical since excessive heat can degrade polymer matrices, causing warping or surface defects. Dry machining with effective dust extraction is preferred to maintain part quality and operator safety.

Advanced CNC machines equipped with multi-axis capabilities allow for complex geometries and high-precision finishes necessary for PMC parts. These machines, combined with optimized cutting parameters, ensure that CNC machining composite parts meet stringent industry standards.

Boron Fiber Reinforced Polymer (BFRP)

What Are Boron Fiber Reinforced Polymers?

Boron Fiber Reinforced Polymers (BFRPs) are high-performance composites composed of boron fibers embedded in a polymer matrix, typically an epoxy resin. Boron fibers are made by depositing boron onto a tungsten or carbon core, resulting in fibers that are extremely stiff and strong. These composites are known for their exceptional mechanical properties, particularly their high modulus and tensile strength, which exceed those of many other fiber-reinforced polymers.

BFRPs are used primarily in aerospace, military, and high-technology applications where maximum stiffness and strength are required with minimal weight. Due to the high cost of boron fibers, their use is often limited to specialized components. The challenging nature of machining BFRPs demands advanced CNC machining techniques to maintain part integrity and surface quality.

Material Properties

BFRPs offer some of the highest stiffness-to-weight ratios available in composite materials, making them invaluable in structures requiring extreme rigidity without significant weight penalty.

Physical Properties

Chemical Properties

CNC Machining Applications

BFRPs are applied in:

Machining BFRPs requires extremely sharp, wear-resistant tooling such as polycrystalline diamond (PCD) cutters or diamond-coated tools to handle the material’s abrasive nature. Due to the high stiffness and brittleness, careful control of machining parameters is critical to avoid microcracks, delamination, or fiber pullout.

Advanced CNC machining services and factories utilize multi-axis CNC machines with optimized feed rates and spindle speeds to produce BFRP parts with high dimensional accuracy and excellent surface finishes.

Natural Fiber Reinforced Polymers (NFRP)

What Are Natural Fiber Reinforced Polymers?

Natural Fiber Reinforced Polymers (NFRPs) are composite materials that incorporate fibers derived from natural sources—such as flax, hemp, jute, sisal, or coir—embedded within a polymer matrix. These composites combine the ecological benefits of renewable, biodegradable fibers with the durability and processing versatility of polymer resins, often making them a more sustainable alternative to synthetic fiber composites.

NFRPs have seen growing interest across automotive, construction, and consumer goods sectors due to their lower environmental impact, reduced weight, and favorable mechanical properties. They typically offer moderate strength and stiffness but excel in cost-effectiveness and ease of processing.

From the perspective of composite CNC machining, NFRPs present machining considerations unique to their natural fibers—such as higher variability in fiber quality and behavior, sensitivity to moisture, and potential for fiber fuzz or splintering during cutting.

Material Properties

NFRPs balance mechanical performance with environmental sustainability, with properties varying based on fiber type, treatment, and polymer matrix.

Physical Properties

Chemical Properties

CNC Machining Applications

NFRPs are commonly used in:

Machining NFRPs requires tooling that minimizes fiber damage and surface roughness. Carbide or diamond-coated tools are preferred to maintain sharpness against abrasive natural fibers. Machining parameters often emphasize lower feed rates and spindle speeds to reduce fiber pullout and fuzz formation.

Due to natural fiber variability, close process control and inspection are critical in CNC machining composite parts made from NFRPs. Dry machining with effective dust extraction ensures operator safety and quality surface finishes.

Silicon Carbide Reinforced Polymers (SiCRP)

What Are Silicon Carbide Reinforced Polymers?

Silicon Carbide Reinforced Polymers (SiCRPs) are high-performance composite materials in which silicon carbide (SiC) particles or fibers are embedded within a polymer matrix, typically epoxy or thermoplastics. Silicon carbide is a ceramic known for its extreme hardness, high thermal conductivity, and excellent chemical resistance. When combined with a polymer matrix, SiCRP composites offer a unique blend of toughness, dimensional stability, and wear resistance.

SiCRPs are used in industries that demand strong, lightweight, and thermally stable materials—such as aerospace, defense, energy, and electronics. Their excellent strength and thermal management capabilities make them ideal for high-stress, high-temperature environments, while their relatively lightweight nature gives them an edge over traditional metals.

Due to the abrasive nature of SiC reinforcements, composite CNC machining of SiCRPs is particularly challenging and requires specialized tooling and expertise to maintain dimensional accuracy and surface finish.

Material Properties

SiCRP composites combine the resilience and adaptability of polymers with the advanced thermal and mechanical benefits of ceramic reinforcements, making them highly suitable for extreme environments.

Physical Properties

Chemical Properties

CNC Machining Applications

SiCRP is applied in:

Machining SiCRPs requires ultra-hard tools such as polycrystalline diamond (PCD), diamond-coated end mills, or CVD-coated carbide cutters to withstand the abrasive SiC particles. Improper tooling can result in rapid wear, chipping, and poor surface quality. Feed rates, cutting speeds, and tool engagement must be precisely optimized.

Because SiCRPs generate fine ceramic dust during cutting, dust extraction and dry machining are critical in CNC machining factories. The dust is not only hazardous to equipment but also to operator health, requiring proper filtration and protective systems.

Given these complexities, only advanced CNC machining services with expertise in abrasive composite materials and high-performance tooling are equipped to machine SiCRPs to precision tolerances.

Here is a comprehensive table summarizing the typical composites used in CNC machining, including their abbreviations, reinforcement types, matrix materials, key properties, and common applications:

Typical Composites Used in CNC Machining

| Composite Type |

Abbreviation |

Reinforcement Type |

Matrix Material |

Key Properties |

Common Applications |

| Aramid Fiber Reinforced Polymer |

AFRP | Aramid fibers (e.g., Kevlar) | Epoxy or thermoplastic | High impact resistance, excellent toughness, lightweight | Ballistic armor, aerospace panels, protective gear |

| Carbon Fiber Reinforced Polymer |

CFRP | Carbon fibers | Epoxy or thermoplastic | Extremely high strength-to-weight ratio, stiff, conductive, lightweight | Aerospace, automotive, sports equipment, robotics |

| Glass Fiber Reinforced Polymer |

GFRP | Glass fibers | Polyester, epoxy, vinyl | Moderate strength, good corrosion resistance, non-conductive | Marine, automotive, construction, electrical housings |

| Basalt Fiber Reinforced Polymer |

BFRP | Basalt fibers | Epoxy or vinyl ester | High thermal resistance, corrosion-resistant, eco-friendly | Marine, infrastructure, transportation, energy |

| Ceramic Matrix Composites |

CMC | Ceramic fibers (e.g., SiC) | Ceramic (SiC, Al₂O₃) | High-temperature resistance, thermal shock resistance, brittle but toughened | Aerospace engines, nuclear, industrial furnaces |

| Metal Matrix Composites |

MMC | Ceramic particles or fibers | Metal (Al, Ti, Mg) | High stiffness, wear resistance, good thermal conductivity | Automotive brake systems, aerospace, electronics |

| Hybrid Composites |

– | Multiple fiber types (e.g., glass + carbon) | Epoxy or thermoplastic | Balanced mechanical performance, customizable, cost-effective | Sports gear, aerospace panels, automotive structures |

| Polymer Matrix Composites |

PMC | Various (carbon, glass, natural) | Thermosets or thermoplastics | Versatile, lightweight, customizable mechanical and thermal properties | Aerospace, consumer goods, automotive, marine |

| Boron Fiber Reinforced Polymer |

BFRP | Boron fibers | Epoxy | Extremely high stiffness and tensile strength, lightweight | Aerospace, military, advanced sporting equipment |

| Natural Fiber Reinforced Polymers |

NFRP | Flax, hemp, jute, sisal | Polyester, PLA, epoxy | Eco-friendly, lightweight, low-cost, biodegradable | Automotive interiors, construction, packaging |

| Silicon Carbide Reinforced Polymers |

SiCRP | Silicon carbide particles or fibers | Epoxy or thermoplastics | Extremely wear-resistant, thermally conductive, chemically inert | Electronics, defense, energy, high-precision heat-resistant parts |

This table provides a quick reference for comparing various composite materials used in CNC machining, supporting material selection based on properties and application needs.

Selecting the right composite material for CNC machining is a crucial decision that directly impacts the performance, durability, cost-efficiency, and manufacturability of a part. With the broad variety of composite materials available—each with unique mechanical, thermal, and chemical properties—engineers must assess several factors beyond just material strength. Whether the goal is to minimize weight, enhance thermal stability, or meet regulatory compliance, a structured evaluation process ensures the right match between application needs and material capabilities.

This section provides a step-by-step framework for choosing the most suitable material for composite CNC machining, taking into account mechanical requirements, machining behavior, supply chain reliability, and environmental considerations. This guidance is especially useful for product designers, engineers, and CNC machining factories seeking to deliver optimized, high-precision CNC machining composite parts across industries such as aerospace, automotive, defense, and electronics.

Evaluate Material Properties

Understanding the inherent material properties is the foundation for selecting the right composite. These properties determine how a material behaves under mechanical, thermal, and chemical stress during both operation and machining.

Strength and Durability

Composite materials vary widely in tensile strength, flexural strength, and fatigue resistance. For structural components subjected to heavy loads, materials like carbon fiber reinforced polymers (CFRP) or metal matrix composites (MMC) offer high strength-to-weight ratios and superior mechanical performance. Conversely, natural fiber composites may suffice for low-load, cost-sensitive applications.

Thermal Stability

If the component will experience high temperatures or rapid thermal cycles, thermal resistance is critical. Ceramic matrix composites (CMC) and silicon carbide reinforced polymers (SiCRP) can endure elevated temperatures, whereas polymer matrix composites (PMC) may degrade. Matching material stability with operating conditions ensures dimensional stability and safety.

Understand Specific Application Needs

Each application imposes unique stresses, exposure conditions, and performance requirements. Aligning material capabilities with these needs ensures functionality and longevity.

Mechanical Loads

Determine whether the part must bear tensile, compressive, impact, or fatigue loads. High-performance reinforcements such as boron fibers or aramid fibers offer specialized resistance to specific stresses. Composite stacking orientation and fiber alignment can also be tailored to strengthen the part in critical directions.

Environmental Conditions

Assess environmental exposure such as moisture, UV radiation, saltwater, or corrosive chemicals. Materials like glass fiber reinforced polymers (GFRP) offer excellent corrosion resistance, while basalt fiber reinforced polymers (BFRP) excel in marine environments. For electronics, electrical insulation or conductivity might also be essential.

Consider Machinability

Some composites are easier to machine than others. Evaluating how a material behaves during CNC processing helps avoid production delays, excessive tool wear, and poor surface finishes.

Tool Wear and Cutting Speeds

Abrasive fibers such as glass, basalt, and silicon carbide accelerate tool wear, requiring diamond-coated or PCD tools. Carbon fiber can cause delamination if improper feeds or tools are used. Choosing a machinable composite can reduce costs and maintain quality, especially in high-volume CNC machining services.

Consider Weight Requirements

Weight is a critical factor in aerospace, automotive, and portable electronics. Material choice can significantly influence the performance-to-weight ratio of the finished part.

Weight-Sensitive Applications

Use composites like CFRP, BFRP, or NFRP when lightness is essential. These materials provide high strength with reduced density, contributing to energy efficiency and improved design flexibility without sacrificing durability.

Evaluate Cost and Performance

Balancing performance with cost is essential, especially for scaled manufacturing. Some high-performance composites deliver diminishing returns if the application doesn’t require premium features.

Budget Constraints

Materials like natural fiber composites or GFRP are budget-friendly while still offering acceptable strength and durability. High-end materials like BFRP or CMC are more costly and suited for critical applications.

Performance Trade-Offs

For instance, a hybrid composite may offer the best of both worlds—cost efficiency and high performance—without the extremes of any single material. Define which properties are essential and which are negotiable.

Inspect and Finish Process Compatibility

Certain composites require additional surface preparation or have constraints regarding secondary operations like painting, bonding, or coating.

Surface Preparation

Materials like AFRP or PMC may need sanding or plasma treatment for optimal paint adhesion. Some composites exhibit porosity or fiber exposure that influences finish quality. Choosing a material compatible with post-processing ensures reduced rework and a professional appearance.

Evaluate Supplier Reliability and Material Availability

Even the best material is ineffective if it’s hard to source or inconsistent in quality. Supply chain considerations can make or break production schedules.

Supplier Reliability

Verify that suppliers provide consistent quality, traceability, and certification. Long-term availability of a specific composite is important for ongoing production and maintenance.

Material Availability

Some advanced composites like BFRP or CMC are available only through niche suppliers, which may result in longer lead times and higher procurement risk. More common composites like GFRP and CFRP offer stable supply across multiple vendors.

Consider Environmental and Regulatory Compliance

Sustainability goals and regulatory frameworks increasingly influence material selection in today’s manufacturing environment.

Environmental Impacts

Natural fiber composites are biodegradable and renewable, while others may release VOCs or involve non-recyclable thermosets. Material choices can impact certifications like RoHS, REACH, or LEED.

Regulatory Compliance

Ensure the material complies with industry-specific standards—such as ASTM, ISO, FAA, or FDA—especially for aerospace, medical, or defense applications.

Seek Expert Advice

The material selection process can be complex. Consulting experts helps identify the most suitable composite for each CNC application.

Consult with Material Scientists and Engineers

Professionals can recommend the right fiber-matrix combination and fabrication technique, as well as simulate material behavior under real-world conditions.

Engineering Insights

Engineers can also guide CNC machining factories in tool selection, machining strategies, and fixture design based on the composite’s properties.

Before mass production, prototype testing validates the material's suitability in actual use conditions, ensuring performance and manufacturability.

Real-World Testing

Prototype CNC machining helps identify issues like delamination, warping, or tolerance problems early in the process. It also enables accurate cost forecasting.

Iterative Testing

Testing different composites side-by-side allows engineers to compare performance metrics and machining ease, optimizing for both quality and efficiency.

Here's a clear and professional table summarizing how to choose the right composite material for CNC machining, aligned with your article structure:

Table: How to Choose the Right Composite Material for CNC Machining

| Evaluation Category |

Key Focus |

Considerations |

Examples / Notes |

| Material Properties |

Strength, durability, thermal stability | Match strength to load, resistance to fatigue, and thermal resilience. | CFRP for high strength, CMC for high heat, GFRP for general durability |

| Application Requirements |

Mechanical and environmental needs | Understand stress, vibration, exposure to moisture, UV, chemicals, etc. | AFRP for impact resistance, BFRP for marine use |

| Machinability |

Tool wear, delamination, surface finish | Consider abrasiveness of fibers, matrix softness, and cutting speed tolerance. | SiCRP and GFRP require diamond tools; PMCs are easier to cut |

| Weight Sensitivity |

Minimize component weight | Lighter materials improve efficiency in aerospace, automotive, and portable products. | CFRP, BFRP, and NFRP are ideal for lightweight designs |

|

Cost vs. Performance |

Budget limitations, trade-offs | High-performance materials may be overkill; balance cost with essential properties. | GFRP is cost-effective; BFRP and MMC are expensive |

| Post-Processing Compatibility |

Finishing, bonding, coating | Some composites require surface prep for painting or bonding. | AFRP needs surface sanding; PMCs may need plasma treatment |

| Supply Chain Reliability |

Supplier availability and consistency | Ensure material is available, consistent in quality, and backed by certifications. | CFRP and GFRP widely available; BFRP and MMC may be limited |

| Regulatory & Environmental Compliance |

Sustainability and legal standards | Must comply with industry regulations and sustainability requirements. | NFRP for eco-friendliness; CMC and MMC for compliance in aerospace and defense |

| Expert Consultation |

Engineering input and testing | Work with materials engineers and CNC professionals to evaluate suitability. | Prototyping helps validate material choices |

| Prototyping and Testing |

Real-world validation | Helps confirm dimensional accuracy, machinability, and durability before full production. | Trial runs reduce machining errors and cost surprises |

This table provides a quick-reference decision-making framework for engineers, buyers, or designers selecting composite materials for CNC machining services.

CNC machining of composite materials requires a specialized, detail-oriented approach. Unlike metals, composites such as carbon fiber, glass fiber, and ceramic matrix materials are anisotropic, meaning their properties vary by direction. They are also abrasive and sensitive to thermal and mechanical stress during cutting. To ensure dimensional accuracy, surface finish, and material integrity, a step-by-step process is essential.

This guide outlines each critical phase in the composite CNC machining workflow—from material selection to final inspection—designed to help engineers, manufacturers, and CNC machining factories achieve optimal results with a variety of composite materials.

1. Material Review and Selection

The process begins with a detailed evaluation of the composite material. This includes identifying the matrix type (e.g., polymer, metal, ceramic) and the reinforcement (e.g., carbon, aramid, glass). Engineers must understand how the composite behaves under mechanical loads, heat, vibration, and cutting forces.

Factors to consider include:

Choosing the right composite is crucial for both product performance and machinability. Selecting inappropriate materials can lead to tool failure, delamination, and poor surface quality in the final CNC machining composite parts.

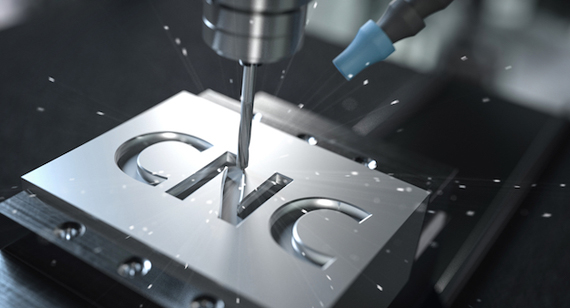

2. CAD File Design and CNC Machine Programming

Once the material is selected, the part is designed in CAD (Computer-Aided Design) software. Special attention is given to:

After the design, a CAM (Computer-Aided Manufacturing) program translates the design into G-code instructions for the CNC machine. For composites, programming may include:

Effective programming reduces cycle time and protects tooling while ensuring part quality.

3. CNC Machine Setup

The next phase is machine preparation. High-speed CNC machines—preferably 3-axis or 5-axis—are calibrated based on the part's geometry and material type. The setup must be optimized to handle the composite’s characteristics.

Key setup considerations:

Correct setup ensures both efficiency and safety in the CNC machining services process.

4. Prepare Fixtures and Tools

Holding the composite securely without damaging it is critical. Fixtures must support the entire part surface to prevent vibration or deflection during machining. Vacuum tables or soft-jawed clamps are often used to avoid surface distortion.

Tool selection is also essential:

Proper fixture design and tooling extend tool life and ensure accurate part geometry.

5. Machining Composites

With everything in place, machining begins. This is the most delicate stage, requiring controlled cutting parameters to prevent issues such as:

Best practices during machining:

Using optimized settings ensures precision and durability in the final CNC machining composite parts.

6. Inspection and Post-Processing

After machining, the part undergoes detailed inspection using tools such as coordinate measuring machines (CMMs), laser scanners, or optical systems to verify dimensional accuracy and surface quality.

Post-processing may include:

In some cases, ultrasonic or X-ray inspection is required for internal defect detection, particularly in aerospace or defense applications.

Inspection guarantees that the part meets engineering specifications, while post-processing enhances durability and readiness for final assembly.

CNC machining of composite materials demands specialized tools engineered to withstand abrasive fibers, layered structures, and anisotropic properties. Unlike metals, composites such as CFRP, GFRP, and SiCRP can cause rapid tool wear, fiber delamination, and surface fraying if incorrect tooling is used. Selecting the proper cutting tools not only improves part quality but also extends tool life, reduces downtime, and ensures process efficiency.

This section introduces the most commonly used tools in composite CNC machining, helping engineers and CNC machining factories choose the right tool for each composite type and machining requirement. Whether you're cutting carbon fiber sheets or milling complex aramid-reinforced parts, tool selection plays a critical role in achieving optimal results.

Carbide Tools

Carbide tools are widely used in CNC machining due to their hardness and resistance to wear. In composite CNC machining, they serve as an economical choice for low to medium production runs. Carbide cutters maintain sharp edges even when working on abrasive materials like glass fibers or carbon reinforcements. However, they tend to wear quickly when used on extremely abrasive composites and are less durable than diamond-coated or PCD alternatives in high-volume environments.

Chip Breaking Tools

Chip breaking tools are designed to fragment chips during cutting, preventing long, stringy debris from wrapping around the tool or part. While composites typically produce dust rather than chips, these tools can still be effective when machining hybrid composites or polymer-heavy materials. Chip control improves airflow around the tool, reducing heat buildup and enabling cleaner cuts, especially in thick or resin-rich materials.

Compression Tools

Compression tools use a dual-helix design—one spiral cuts upward from the bottom, and the other downward from the top. This opposing motion compresses the composite layers toward the center, minimizing delamination, edge fraying, and surface lift. Compression tools are ideal for laminated sheets like CFRP, GFRP, or BFRP where surface quality on both sides is critical. They are commonly used in CNC machining services for producing aerospace panels and sports equipment components.

Compression Routers

A type of compression tool, compression routers are specifically tailored for routing operations in layered composite panels. These tools help maintain edge integrity and eliminate fraying on both entry and exit surfaces, making them valuable for high-speed trimming or contouring in CNC machining composite parts. Compression routers work exceptionally well on woven fiber materials where fiber pullout is a concern.

Diamond-Coated Tools

Diamond-coated tools provide unmatched wear resistance, making them ideal for machining highly abrasive composites like GFRP, SiCRP, and CMCs. The diamond coating improves surface finish, reduces tool wear, and allows for longer continuous operation. These tools are indispensable in high-volume production environments and precision-critical applications like aerospace or electronics, where material integrity and consistency are paramount.

CVD-Coated Tools

Chemical Vapor Deposition (CVD) coated tools offer a strong bond between the substrate and the diamond layer, providing excellent durability during the machining of hard composites. These tools perform well under high-speed conditions and are particularly useful when dry machining is required. Their superior thermal resistance and wear tolerance make them suitable for challenging composites that cause rapid degradation in traditional tools.

High-Speed Steel (HSS) Tools

High-Speed Steel tools are less commonly used in composite machining due to their relatively lower hardness and shorter lifespan. However, they remain useful for prototyping, low-volume runs, or machining soft, non-abrasive composite materials. Their affordability and ease of re-sharpening can be advantageous when working with less demanding composites like natural fiber reinforced polymers (NFRPs).

Polycrystalline Diamond (PCD) Tools

PCD tools are the gold standard for CNC machining composite parts. Manufactured with synthetic diamond particles bonded under high pressure, PCD cutters offer extreme hardness, thermal stability, and longevity. They are especially suitable for continuous machining of carbon fiber, ceramic matrix, or silicon carbide composites, where traditional tools would quickly degrade. Despite their higher cost, the performance benefits make PCD tools essential for critical and large-scale composite machining tasks.

Straight Slot End Mills

Straight slot end mills are commonly used for cutting simple slots, pockets, or contour features in composite panels. They offer predictable performance and are often coated or made of carbide to improve tool life. These tools work best on flat or moderately contoured parts and are often used in conjunction with vacuum tables or fixtures to ensure part stability and reduce vibration during the cut.

Here's a clear, professional table summarizing standard CNC machining tools for composites, including tool type, key features, and typical use cases in composite CNC machining:

Table: Standard CNC Machining Tools for Composites

| Tool Type |

Key Features |

Typical Use Cases |

| Carbide Tools |

Hard, cost-effective, moderate wear resistance | General machining of glass fiber, carbon fiber, and low-abrasion composites |

| Chip Breaking Tools |

Designed to fragment chips, improve airflow, reduce heat | Machining hybrid composites or resin-rich polymer matrix composites |

| Compression Tools |

Dual-helix design compresses layers inward, prevents delamination | Machining laminated composites like CFRP, BFRP, and AFRP sheets where surface finish is critical |

| Compression Routers |

Specialized compression tools for trimming and routing layers cleanly | High-speed edge routing of fiber-reinforced panels, especially in aerospace or sports parts |

| Diamond-Coated Tools |

Exceptional wear resistance, clean surface finish, heat-resistant | High-volume machining of abrasive materials like GFRP, SiCRP, and CMCs |

| CVD-Coated Tools |

Strong adhesion of diamond layer, suitable for dry machining and high-speed ops | Cutting thermally resistant or hard composite materials under dry conditions |

| High-Speed Steel (HSS) |

Economical, easy to re-sharpen, lower hardness | Prototyping or cutting soft composites like NFRP or early-stage design testing |

| Polycrystalline Diamond (PCD) |

Extreme hardness and tool life, optimal for abrasive fibers and mass production | Precision machining of CFRP, SiCRP, MMCs, and other high-performance composite CNC parts |

| Straight Slot End Mills |

Simple, predictable geometry, available in coated variants | Slotting, pocketing, and contouring flat composite panels with stable clamping |

This table provides a quick-reference guide for selecting the appropriate tools in CNC machining services when working with composite materials.

CNC machining offers a powerful and precise way to manufacture components made from composite materials. Unlike traditional fabrication methods, which may involve molds, hand layup, or trimming with handheld tools, composite CNC machining uses computer-controlled cutting to produce complex, high-precision parts efficiently and repeatably. This approach delivers distinct advantages in industries where weight, strength, and accuracy are critical—such as aerospace, automotive, defense, and electronics.

By using advanced tools and programming, CNC machining services can achieve exceptional part quality and surface finish, even with challenging composites like carbon fiber or ceramic matrix materials. Below are the core benefits that make CNC machining a preferred method for producing CNC machining composite parts.

Customization and Flexibility

One of the biggest advantages of CNC machining is its ability to produce highly customized components. Whether for prototyping or full-scale production, CNC allows engineers to easily modify designs and quickly implement changes. Composite parts often have unique fiber orientations, surface contours, or integrated features that are difficult to replicate using manual processes. With multi-axis machining, CNC equipment can create detailed geometries, chamfers, slots, and holes on complex 3D surfaces with consistent quality.

This flexibility is crucial when dealing with hybrid composites, layered structures, or bespoke parts used in aerospace or motorsport applications. Custom fixtures and toolpaths can be programmed for each job, enabling on-demand manufacturing and rapid iteration.

Reduce Material Waste

Composite materials can be expensive, especially high-performance types like carbon fiber reinforced polymers (CFRP) or ceramic matrix composites (CMC). CNC machining minimizes waste by using optimized toolpaths and cutting only what's necessary. Nesting strategies and simulation software further reduce offcuts, which is especially valuable when working with flat composite panels.

In contrast to manual trimming, which often produces inconsistent edges and requires extra finishing, CNC ensures that every cut is exact. This precision not only reduces material loss but also decreases labor and secondary operations, resulting in cost savings across production runs.

Precision and Complexity

CNC machining is renowned for its ability to meet tight tolerances and produce intricate features that would be impractical with hand tools or traditional trimming. This is particularly important when machining composite parts for assemblies that demand perfect alignment, such as turbine components, satellite brackets, or surgical devices.

Even when working with anisotropic or layered materials, advanced CNC setups—including 5-axis machines—can maintain precise control over depth, angle, and feed rate. This results in consistently high-quality edges, clean holes, and symmetrical finishes—essential for applications in aviation and medical devices.

Improve Safety

Manual cutting of composites often releases airborne fibers and fine dust particles that are hazardous to both health and machinery. CNC machines, on the other hand, operate in enclosed environments equipped with powerful dust extraction systems. This dramatically reduces the exposure of operators to harmful particles such as carbon fiber dust or ceramic debris.

In addition, CNC eliminates the need for handheld tools, reducing the risk of repetitive strain injuries, blade accidents, or burns caused by frictional heat. By automating the process, CNC machining factories create safer workspaces and maintain compliance with occupational safety standards.

Efficient and Fast

Time is a critical factor in manufacturing, and CNC machining services offer unmatched efficiency for composite parts. Once the CAD design and toolpath are prepared, machining is fast, repeatable, and scalable. Automated workflows allow manufacturers to run machines continuously with minimal supervision, improving throughput without sacrificing quality.

This efficiency is especially valuable for industries with tight deadlines, such as aerospace or motorsport, where rapid part delivery can be a competitive advantage. Batch consistency also eliminates the delays caused by manual rework or quality checks.

Increase Durability

Proper machining techniques enhance the integrity and durability of CNC machining composite parts. Smooth edges, accurate dimensions, and minimized delamination all contribute to a component that lasts longer in service. This is particularly important for parts exposed to vibration, load, or thermal cycling—common in aircraft, automotive frames, or offshore components.

When precision-machined, composites retain their performance characteristics across their service life. CNC machining ensures that no weak spots, stress risers, or inconsistencies compromise the structural performance of the final part.

Below is a clear and professional table summarizing the benefits of CNC machining composites, including explanations and practical advantages. This is useful for engineers, procurement managers, or clients evaluating CNC machining services for composite materials.

Table: Benefits of CNC Machining Composites

| Benefit |

Explanation |

Practical Advantage |

| Customization and Flexibility |

Allows for precise machining of complex shapes and easy design adjustments | Ideal for prototyping and low-to-mid volume production of unique composite parts |

| Reduce Material Waste |

Optimized toolpaths and nesting minimize offcuts and scrap | Lowers cost when working with expensive materials like CFRP or CMC |

| Precision and Complexity |

Maintains tight tolerances and sharp edge definition even on intricate geometries | Ensures perfect fit in assemblies, essential for aerospace and medical applications |

| Improve Safety |

Dust collection systems reduce fiber particle exposure; no need for handheld cutting tools | Enhances operator safety and complies with health regulations in CNC machining factories |

| Efficient and Fast |

Automated, repeatable process once programmed | Speeds up production and reduces cycle time in CNC machining services |

| Increase Durability |

Minimizes delamination, fiber pull-out, and surface defects | Results in stronger, longer-lasting CNC machining composite parts |

This table offers a quick-reference snapshot of why composite CNC machining is a superior method for fabricating parts with high performance, safety, and cost-efficiency.

CNC machining of composite materials requires a unique blend of technologies designed to handle the challenges of abrasive fibers, directional strength, and thermal sensitivity. Unlike metals, composites do not behave uniformly during cutting, making traditional machining approaches less effective. As a result, a combination of advanced tools and techniques is essential to achieve high-quality results.

From milling and drilling to high-precision laser cutting and 5-axis machining, modern CNC machining services integrate various technologies to machine composite materials safely, accurately, and efficiently. Below is a breakdown of the most common technologies used in composite CNC machining, each offering specific advantages based on the application, material type, and part complexity.

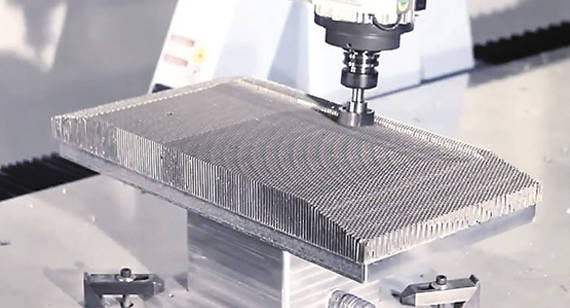

CNC milling is one of the most widely used technologies for machining composite materials. It involves the rotary cutting of materials along multiple axes to remove material from a fixed workpiece. Milling is especially effective for shaping complex 3D parts, surface finishing, and contouring.

In composite CNC machining, high-speed milling with diamond-coated tools is often used to prevent fraying and delamination. Advanced milling machines allow for control over spindle speeds, feed rates, and tool engagement—critical factors when working with CFRP, GFRP, or SiCRP.

CNC drilling is essential for creating precise holes and countersinks in composite parts. However, drilling composites presents unique challenges like fiber pull-out and delamination at the hole exit. To address this, specialized drill bits such as brad point or step drills are used, along with optimized feed rates and backing plates.

Industries like aerospace rely heavily on CNC drilling for fastener holes in composite panels, where consistency and dimensional accuracy are vital for assembly integrity.

While less common than milling or drilling, CNC turning is used for cylindrical composite components, such as bushings, rollers, or tubing. It involves rotating the workpiece while a cutting tool moves linearly. This method is best suited for composites with uniform reinforcement distribution and stable dimensional behavior under rotational forces.

Care must be taken to prevent thermal damage and fiber separation during high-speed turning, especially with hybrid or fiber-rich materials.

Routers

CNC routers are frequently used for trimming and cutting composite panels, especially in low-to-medium strength applications. They offer high-speed processing and are ideal for flat or slightly contoured parts. Compression routers and diamond-coated bits help minimize edge fray, making routers a popular choice for CNC machining composite parts in automotive interiors, marine panels, and wind turbine blades.

Water Jet Cutting

Water jet cutting uses a high-pressure stream of water—often mixed with abrasive particles—to cut through composite materials without generating heat. This cold-cutting technique is ideal for heat-sensitive composites and layered materials like CFRP, BFRP, and PMC.

Its benefits include:

Water jet systems are widely used in CNC machining services for aerospace and defense applications, where edge quality and material integrity are critical.

Laser cutting is suitable for thin composite sheets and detailed profiles. Using a focused laser beam, this method offers high precision and clean edges. However, laser cutting generates heat, which can damage or discolor some composite matrices—especially polymer-based ones.

Laser systems are more commonly applied to non-structural components or decorative elements made from lightweight composites like NFRP or PMC.

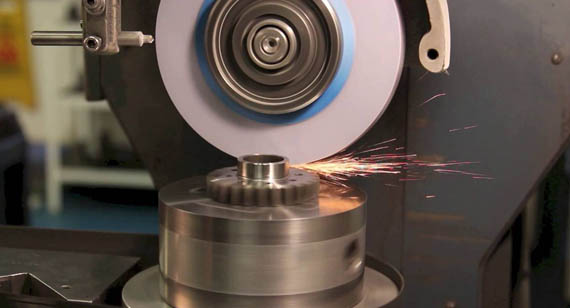

Grinding is typically used for finishing operations on composite surfaces. It smooths edges, removes burrs, and improves tolerances, especially after water jet or rough milling processes. Specialized grinding wheels with high abrasion resistance are necessary for composites to avoid clogging and overheating.

Grinding is also useful for preparing surfaces for bonding or coating, ensuring proper adhesion and cosmetic quality.

Electrical Discharge Machining (EDM)

EDM is not typically used for machining composites, as it requires electrically conductive materials. However, in certain hybrid composites containing metallic matrices or embedded conductors, EDM can be employed to produce intricate shapes or features that are otherwise difficult to machine.

It provides excellent precision but is limited by the material’s electrical properties and thermal sensitivity.

Composite Trimming and Finishing

Trimming and finishing technologies are vital to finalizing CNC-machined composite parts. These include edge sanding, chamfering, polishing, and surface preparation techniques. Proper trimming ensures fitment, safety, and performance in assembly.

Composite finishing often integrates robotic arms or automated sanding stations to handle high production volumes while maintaining consistent quality.

3-Axis CNC Machines

3-axis machines are suitable for simpler parts with flat geometries or limited depth. These machines move the cutting tool in the X, Y, and Z directions and are ideal for trimming, routing, and basic pocketing in panel-based composites. They are widely used in signage, enclosures, and marine applications.

Although cost-effective, they may not be suitable for highly contoured or complex shapes.

5-axis CNC machines offer full flexibility and control, making them the gold standard for composite CNC machining. They allow the tool to approach the material from any direction, enabling machining of undercuts, deep cavities, and complex 3D surfaces.

5-axis machines are essential in aerospace, medical, and automotive industries where multi-angled features and precision are non-negotiable. They also reduce setups and improve accuracy across intricate components.

Here’s a clear, professional table summarizing Common Technologies Used in CNC Machining Composites, including key features and typical applications relevant to composite CNC machining and CNC machining services:

Table: Technologies Commonly Used in CNC Machining Composites

| Technology |

Key Features |

Typical Applications |

| CNC Milling |

Multi-axis rotary cutting; high-speed; diamond-coated tooling for composites | Complex 3D parts, surface finishing, aerospace panels |

| CNC Drilling |

Precision hole-making; specialized bits to reduce delamination | Fastener holes in composite panels for aerospace and automotive |

| CNC Turning |

Rotational machining for cylindrical parts; requires thermal control | Bushings, rollers, composite tubes |

| Routers |

High-speed trimming and cutting; compression and diamond-coated bits | Flat or contoured panels in automotive, marine, wind energy |

| Water Jet Cutting |

Cold cutting with abrasive water stream; no thermal distortion | Heat-sensitive composites, thick layered panels |

| Laser Cutting |

High precision; clean edges; potential heat effects on polymer matrices | Thin sheets, decorative composite parts |

| Grinding |

Surface finishing, burr removal; requires abrasive-resistant wheels | Edge smoothing, surface prep for bonding/coating |

| Electrical Discharge Machining (EDM) |

Precision machining of electrically conductive composites; limited use | Hybrid composites with metal matrices |

| Composite Trimming and Finishing |

Automated sanding, polishing, chamfering for consistent surface quality | Final finishing of aerospace, medical, and automotive parts |

| 3-Axis CNC Machines |

Movements in X, Y, Z axes; suitable for simple geometries and flat parts | Basic panel machining, signage, enclosures |

| 5-Axis CNC Machines |

Full 3D access; complex shape machining; reduces setups | Aerospace components, medical devices, complex automotive parts |

This table provides a quick overview to help select the right CNC machining technology for specific composite materials and part requirements.

Composite materials have become indispensable across a wide range of industries due to their excellent strength-to-weight ratios, corrosion resistance, and design flexibility. The rise of composite CNC machining has enabled manufacturers to produce precise, high-performance parts tailored for these demanding sectors. Whether it’s aerospace components, automotive frames, or sports equipment, CNC machining services deliver accuracy, repeatability, and efficiency in shaping composite materials.

This section explores the key industries and applications where CNC-machined composite parts play a critical role, highlighting the unique benefits composites bring to each field.

In the automotive industry, lightweight composite parts are essential for improving fuel efficiency and performance. CNC machining composites like carbon fiber reinforced polymers (CFRP) enables the creation of complex structural components, interior panels, and custom trims that reduce weight without compromising strength. High precision machining ensures that parts fit perfectly with other assemblies, supporting the production of electric vehicles, sports cars, and luxury models.

Aerospace

Aerospace demands materials that combine lightness with exceptional mechanical strength and thermal stability. CNC machining composite materials such as ceramic matrix composites (CMC) and carbon fiber composites allows manufacturers to produce turbine blades, structural brackets, and fuselage components that withstand harsh environments and reduce overall aircraft weight. CNC precision is vital for meeting the stringent tolerances and safety standards in aerospace manufacturing.

The medical sector uses composite materials for lightweight, durable devices and implants. CNC machining composites facilitates the production of prosthetics, surgical instruments, and diagnostic equipment housings with precise geometries and biocompatible finishes. Composite parts offer enhanced patient comfort, sterilization compatibility, and reduced weight, making them preferable over traditional metals in many medical applications.

Marine

Marine applications benefit from composites’ corrosion resistance and strength-to-weight advantages. CNC-machined glass fiber reinforced polymers (GFRP) and aramid fiber composites are used in boat hulls, propeller blades, and structural reinforcements. CNC machining ensures tight tolerances and smooth finishes that improve hydrodynamics and durability in harsh saltwater environments.

Defense

The defense industry relies on composites for lightweight armor, vehicle parts, and structural components that must withstand impact and extreme conditions. CNC machining of composite materials allows the fabrication of ballistic panels, drone frames, and weapon housings with precise specifications and consistent quality. The durability and weight savings of composites provide strategic advantages on the battlefield.

Wind Energy

Wind turbine blades and components require materials that combine high strength and fatigue resistance. CNC machining composites like basalt fiber reinforced polymers (BFRP) enables the manufacture of large, aerodynamic blades with minimal defects. Precision machining contributes to optimal blade performance and longevity, essential for efficient energy production.

Ocean

Beyond marine vessels, composites are used in underwater applications such as submersibles, sonar housings, and underwater pipelines. CNC machining ensures components are watertight, corrosion-resistant, and capable of withstanding high pressure. Composite parts reduce maintenance and extend service life in oceanic environments.

Sports Equipment

High-performance sports gear—including bicycle frames, tennis rackets, and helmets—often incorporates CNC-machined composite parts. The ability to machine complex shapes with consistent strength and lightness enhances athlete performance and safety. Carbon fiber and aramid composites are favored for their vibration damping and impact resistance.

Construction

In construction, composites are used for architectural panels, reinforcement bars, and structural connectors. CNC machining allows fabrication of customized components with precise dimensions and surface finishes. Composites’ corrosion resistance and longevity reduce maintenance costs in building projects, especially in harsh climates.

Conclusion

From transportation to healthcare, composite CNC machining empowers industries to leverage the unique benefits of composite materials. CNC machining services and factories deliver the precision and efficiency required to produce high-quality composite parts that meet the evolving demands of these critical sectors.

Here’s a professional table summarizing the Typical Applications for CNC Machining Composite Parts, including the industry, key composite benefits, and common parts or components:

Table: Typical Applications for CNC Machining Composite Parts

| Industry |

Key Composite Benefits |

Common CNC Machined Parts |

| Automotive |

Lightweight, strong, fuel efficiency, design flexibility | Structural components, interior panels, custom trims |

| Aerospace |

High strength-to-weight, thermal stability, corrosion resistance | Turbine blades, fuselage components, structural brackets |

| Medical |

Biocompatibility, lightweight, durable, precise geometry | Prosthetics, surgical instruments, diagnostic equipment housings |

| Marine |

Corrosion resistance, strength, hydrodynamic efficiency | Boat hulls, propeller blades, structural reinforcements |

| Defense |

Impact resistance, durability, weight savings | Ballistic panels, drone frames, weapon housings |

| Wind Energy |

Fatigue resistance, strength, aerodynamic performance | Wind turbine blades and components |

| Ocean |

Corrosion resistance, high pressure tolerance | Submersibles, sonar housings, underwater pipelines |

| Sports Equipment |

Lightweight, vibration damping, impact resistance | Bicycle frames, tennis rackets, helmets |

| Construction |