15 years one-stop China custom CNC machining parts factory

526 |

Published by VMT at Jun 28 2025 | Reading Time:About 9 minutes

526 |

Published by VMT at Jun 28 2025 | Reading Time:About 9 minutes

Manufacturers across industries face an ongoing challenge: finding a material that is lightweight yet strong, resistant to corrosion yet affordable, and suitable for everything from boats to circuit boards.

Traditional materials like steel and aluminum often fall short—either too heavy, too costly, or too prone to rust. Plastics may be light, but they lack strength and durability. Without the right material, manufacturers risk increased costs, reduced product life, and design limitations.

Fiberglass offers a compelling alternative. As a composite made of glass fibers reinforced with resin, it combines strength, flexibility, corrosion resistance, and insulation in one lightweight package—making it an ideal choice for a wide range of industries and an excellent candidate for fiberglass CNC machining parts.

Fiberglass is a composite material made from fine glass fibers and resin, offering excellent strength-to-weight ratio, corrosion resistance, and thermal insulation. It is widely used in aerospace, automotive, marine, construction, and industrial applications, and can be precisely manufactured using fiberglass CNC machining services for high-performance parts.

As demand for advanced lightweight materials grows, fiberglass continues to prove its value across countless manufacturing sectors. But what exactly is fiberglass? How is it made, what types exist, and how do its properties compare to metals or plastics? This guide explores everything you need to know—from types and applications to the benefits of using fiberglass in CNC milling services and high-precision components manufactured in leading CNC machining factories.

Key Points

Fiberglass is a composite material composed of fine glass filaments embedded within a polymer resin matrix. These filaments—drawn from molten glass—are combined with resins such as epoxy, polyester, or vinyl ester to form a durable, lightweight, and corrosion-resistant material. The result is a fiber-reinforced plastic (FRP) with exceptional mechanical and chemical properties that can be molded, layered, or machined into complex shapes.

The term “fiberglass” broadly refers to both the glass fibers and the composite structure they form. What makes fiberglass unique is its ability to retain the physical properties of glass (such as tensile strength and insulation) while eliminating its brittleness by combining it with flexible polymers. This balance of strength and resilience makes it ideal for demanding environments where traditional materials like metal may rust or degrade over time.

In manufacturing, fiberglass is widely valued for its versatility. It is used in countless formats—such as cloth, mat, tape, and roving—and can be easily adapted for molding or precision cutting. Thanks to its machinability, fiberglass is increasingly being used in CNC milling services to produce high-performance, custom-shaped fiberglass CNC machining parts with excellent dimensional accuracy.

From aircraft fuselages to water tanks and printed circuit boards, fiberglass remains a staple material in many industries. It is also well-suited to CNC operations performed in professional CNC machining factories, especially where lightweight, non-metallic parts are required without sacrificing structural performance.

The production of fiberglass begins with raw materials rich in silica—primarily sand, limestone, and alumina. These ingredients are mixed and melted in a furnace at temperatures exceeding 1,400°C (2,552°F) to form molten glass. This molten glass is then extruded through fine nozzles, creating long strands of ultra-thin glass fibers, sometimes thinner than a human hair.

Once formed, these glass filaments are either collected into continuous strands or chopped into short fibers. At this stage, they can be further processed into various forms such as mats, fabrics, tows, or rovings—each suited to different manufacturing methods. These fiber forms are often treated with chemical sizing agents that improve adhesion to resins and protect the fibers during handling.

The next critical step involves reinforcing the fibers with a polymer matrix, usually through a molding or laminating process. Polyester, vinyl ester, or epoxy resins are applied to the glass fibers, forming a rigid composite once cured. The resulting material combines the high tensile strength of glass with the flexibility and formability of plastics.

Fiberglass is also available as pre-impregnated (prepreg) sheets or rolls, ready for heat-curing in molds. These semi-finished products are ideal for advanced composites and fiberglass CNC machining parts that require precision shaping and high performance.

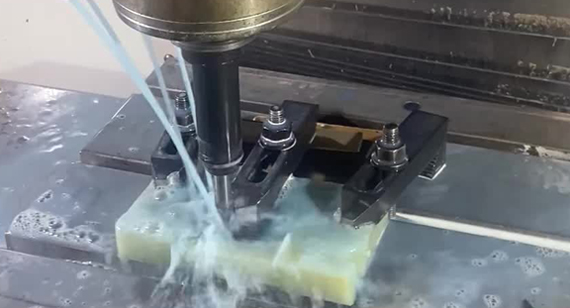

In CNC machining factories, fiberglass sheets or blocks are often trimmed, milled, or drilled using CNC milling services. Since fiberglass is abrasive and can wear down standard cutting tools, specialized tooling and careful speed/feed control are essential during machining. When processed correctly, fiberglass can be shaped into complex, accurate, and lightweight components suited for industries like aerospace, transportation, and consumer goods.

Fiberglass has become a cornerstone material in modern manufacturing due to its unique combination of performance, cost-efficiency, and versatility. Its lightweight yet high-strength characteristics make it an ideal substitute for traditional metals in many structural and load-bearing applications. Unlike steel or aluminum, fiberglass does not corrode, warp, or conduct electricity, which makes it particularly useful in environments where exposure to moisture, chemicals, or electrical currents is a concern.

Manufacturers across aerospace, automotive, marine, and construction industries rely on fiberglass to reduce product weight without sacrificing durability. This results in increased energy efficiency, especially in transportation sectors where weight directly impacts fuel consumption. In electrical applications, fiberglass provides excellent insulation and dimensional stability, making it indispensable for enclosures, circuit boards, and housings.

Another reason fiberglass is so valuable in manufacturing is its formability. It can be molded into virtually any shape or layered into composites with directional strength, enabling complex geometries that would be difficult or expensive to produce with metal. For high-precision parts, fiberglass is also highly compatible with CNC milling services. When machined in specialized CNC machining factories, it delivers consistent results in custom or mass-produced fiberglass CNC machining parts.

Moreover, fiberglass supports sustainability goals. It requires less energy to produce than metals and offers long service life with minimal maintenance, reducing overall lifecycle costs. These factors make it an attractive material choice in both cost-sensitive and high-performance markets.

With ongoing advancements in material science and CNC capabilities, fiberglass continues to play an essential role in modern product design and manufacturing innovation.

Not all fiberglass is created equal. While the basic concept involves reinforcing resin with glass fibers, there are numerous variations in composition and structure that significantly affect performance characteristics like strength, electrical insulation, chemical resistance, and thermal stability. These differences make each type of fiberglass suitable for specific applications and machining processes. For manufacturers and engineers—especially those using CNC milling services to create high-precision fiberglass CNC machining parts—understanding these distinctions is crucial to material selection.

Below are the major types of fiberglass used in industrial and engineering applications today:

E-Glass (Electrical Glass)

E-glass is the most commonly used type of fiberglass due to its excellent balance of cost, strength, and electrical insulation properties. It is composed primarily of alumino-borosilicate glass and was originally developed for electrical applications, hence the “E” designation. E-glass offers good tensile strength and dielectric performance, making it suitable for structural components and electronic insulators alike. It's widely used in fiberglass CNC machining services because it’s cost-effective and adaptable to various formats like mats, woven cloths, and laminates.

D-Glass (Dielectric Glass)

D-glass is known for its superior dielectric (electrical insulating) properties. It has a low dielectric constant, making it ideal for high-frequency and microwave applications. Although it has lower mechanical strength compared to E-glass, its electrical performance makes it essential in electronics and aerospace insulation systems. In CNC machining factories, D-glass is often specified when manufacturing insulating components for sensitive electronic devices.

R-Glass / T-Glass / S-Glass

R-glass, also referred to as T-glass or S-glass (depending on regional nomenclature), is engineered for high mechanical performance. It contains a higher concentration of silica and magnesium, which gives it significantly greater tensile strength and fatigue resistance compared to E-glass. This makes it ideal for aerospace, military, and performance-critical structures. R-glass is commonly used in fiberglass CNC machining parts that must endure extreme loads or vibrations while maintaining dimensional stability.

A-Glass (Alkali Glass)

A-glass is composed of soda-lime glass, similar to typical window glass. While it offers decent clarity and chemical resistance, it lacks the high-performance attributes of E- or S-glass. A-glass is often used in less demanding applications or where cost is a more critical factor than performance. It is not typically favored in precision CNC milling services due to its lower strength and limited thermal resistance.

Advantex Fiberglass

Advantex is a proprietary formulation designed to combine the chemical resistance of ECR-glass with the mechanical performance of E-glass. It’s often used in corrosive environments such as chemical processing or wastewater treatment. Its enhanced corrosion resistance makes it ideal for CNC machining factories producing components exposed to acids, salts, or extreme environmental conditions. It also performs well in marine and offshore structures.

ECR Fiberglass (Electrical/Corrosion Resistant)

ECR fiberglass is designed to address the weaknesses of E-glass in acidic environments. It eliminates boron oxide from the formulation, significantly improving chemical resistance while retaining excellent electrical properties. This makes ECR fiberglass especially valuable in electrical systems exposed to harsh chemicals, and it is well-suited to fiberglass CNC machining services for parts requiring both structural integrity and chemical durability.

C-Glass (Chemical Glass)

C-glass offers superior chemical resistance, particularly against acidic substances. It is commonly used for surface layers in corrosion-resistant laminates, pipes, and tanks. While not as mechanically strong as E-glass, its resistance to chemical attack makes it a crucial material in the chemical processing and water treatment industries. It can be precision-cut using CNC milling services to form linings or protective barriers within complex assemblies.

Z-Glass

Z-glass refers to zirconia-based fiberglass, developed for applications requiring high thermal resistance. It’s used in extreme heat environments, such as insulation for jet engines and industrial furnaces. Z-glass can be more expensive, but its performance at elevated temperatures justifies its use in high-tech applications. Specialized CNC machining factories may work with Z-glass to create parts for aerospace, power generation, and advanced electronics.

S2 Fiberglass

S2 glass is an advanced version of S-glass that delivers even better mechanical strength and impact resistance. Its optimized composition allows it to perform under high stress and temperature variations. It is commonly used in defense systems, automotive safety structures, and sporting equipment. Thanks to its excellent strength-to-weight ratio, it is highly compatible with fiberglass CNC machining services to produce structural components requiring absolute reliability.

AR-Glass (Alkali Resistant Glass)

AR-glass contains a high percentage of zirconium dioxide, which makes it especially resistant to alkaline environments such as concrete. This makes it ideal for reinforcing cement-based construction materials. It is typically used in rebar, mesh, and composite panels. AR-glass is also compatible with CNC milling services when used in panels or modular construction elements requiring precision cutouts or holes.

M-Glass

M-glass is designed for use in microwave transmission systems due to its low dielectric loss and excellent high-frequency performance. While not as widely used as E- or S-glass, M-glass fills a niche in the communications and radar industries. Its electrical properties make it suitable for precision fiberglass CNC machining parts used in signal processing and antenna components.

AE Fiberglass

AE fiberglass is a specialized hybrid that combines characteristics of A-glass and E-glass. It offers moderate strength, cost-efficiency, and decent chemical resistance, making it a balanced choice for general-purpose applications. While not ideal for high-performance environments, AE fiberglass is easy to machine, form, and bond—making it a frequent material in low to mid-range CNC machining factories producing fiberglass products for construction and consumer use.

Here's a clean, professional comparison table summarizing the different types of fiberglass, highlighting their composition, strengths, weaknesses, and typical applications. It naturally integrates relevant SEO terms without being forced.

Table: Types of Fiberglass and Their Characteristics

| Type |

Key Properties |

Strengths |

Limitations |

Typical Applications |

| E-Glass |

Alumino-borosilicate; general-purpose | Good strength, low cost, electrical insulation | Moderate chemical resistance | Electronics, structural panels, fiberglass CNC machining parts |

| D-Glass |

Low dielectric constant | Excellent electrical insulation | Lower mechanical strength | Aerospace insulation, microwave systems |

| R/T/S-Glass |

High-silica/magnesium content | Superior strength, fatigue resistance | Higher cost | Military, aerospace, performance composites |

| A-Glass |

Soda-lime glass (like window glass) | Cost-effective, basic chemical resistance | Weak mechanical/thermal performance | Low-performance applications |

| Advantex |

Hybrid of ECR + E-glass | Strong chemical & mechanical balance | Higher cost than E-glass | Corrosive environments, industrial laminates |

| ECR-Glass |

Boron-free formulation | Acid/corrosion resistant, electrical insulation | Slightly less strong than E-glass | Electrical systems, chemical tanks |

| C-Glass |

High corrosion resistance | Acid resistance | Low tensile strength | Inner linings, chemical tanks, fiberglass CNC machining services |

| Z-Glass |

Zirconia-based glass | High thermal resistance | Expensive |

High-heat aerospace, furnaces |

| S2-Glass |

Advanced S-glass formulation | Extreme strength & impact resistance | Cost-intensive | Automotive, defense, sports, CNC milling services |

| AR-Glass |

High zirconium content | Alkali resistance | Low tensile strength | Concrete reinforcement, rebar, construction panels |

| M-Glass |

Low dielectric loss | Excellent RF/microwave performance | Niche use | Radar domes, telecom devices |

| AE-Glass |

A-glass + E-glass hybrid | Balanced performance & affordability | Not specialized for high stress | General-purpose, construction, consumer products |

Fiberglass can be manufactured into a variety of forms to suit different production and application needs. These formats determine how the material is handled, molded, or machined, especially when used in CNC machining factories or advanced CNC milling services. The chosen form impacts not only the strength and weight of the final product but also the ease of machining, assembly, and integration into larger systems. Whether you are manufacturing insulation panels or precision fiberglass CNC machining parts, selecting the right fiberglass format is crucial for performance and processing efficiency.

Below are the most commonly used fiberglass formats in manufacturing.

Woven Fabrics

Woven fiberglass fabrics are created by interlacing glass fibers in warp and weft patterns, similar to textile weaving. These fabrics are available in various weights, weaves (plain, twill, satin), and widths. Woven fiberglass offers high tensile strength, excellent dimensional stability, and is often used in applications requiring consistent structural performance in multiple directions.

Because of its strength and uniformity, woven fiberglass is commonly laminated with resins to create composite panels or molded structures. It is also suitable for use in fiberglass CNC machining services where sheets or prepregs are milled into specific geometries. Industries such as aerospace, automotive, and marine favor this format for high-performance structural components.

Chopped Glass Mats

Chopped strand mats (CSM) are composed of randomly oriented short fiberglass strands that are bound together using a resin-soluble adhesive. This format is widely used for creating molded shapes and is ideal for applications where isotropic properties (equal strength in all directions) are needed. CSM is particularly useful in hand lay-up and spray-up techniques due to its conformability over complex shapes.

While not as strong as woven fabrics, CSM is cost-effective and provides adequate strength for many commercial and industrial applications. Once cured into solid composites, chopped mats can also be machined into fiberglass CNC machining parts, especially where part consistency and ease of shaping are prioritized over extreme mechanical performance.

Tows and Rovings

Tows and rovings are bundles of continuous fiberglass filaments grouped together without a twist. Rovings are often used in filament winding, pultrusion, and weaving applications, offering high unidirectional strength. They are typically used when large-volume structural reinforcement is required, such as in pressure vessels, wind turbine blades, and pultruded structural profiles.

In CNC machining factories, roving-based composites are often processed after molding into solid forms. Once hardened, they can be precision-machined using CNC milling services to produce components that require directional strength or structural reinforcement. Their excellent strength-to-weight ratio makes them suitable for high-load or impact-prone parts.

Mat (Non-Woven Fiberglass Mat)

Fiberglass mat, often confused with chopped mat, refers to non-woven fiberglass sheets made from either continuous strands or chopped fibers. These mats offer good formability and surface finish and are often used as backing layers in laminates. Mats help prevent delamination and improve resin distribution during molding.

Although fiberglass mats do not have the same strength as woven fabrics, they are essential for smooth finishes and uniform resin impregnation in multi-layer composite parts. When solidified, mats are often used in fiberglass CNC machining parts that require aesthetic surfaces or secondary machining operations, especially in automotive interiors, tub moldings, and architectural panels.

Below is a professional and easy-to-read comparison table summarizing the available formats of fiberglass, highlighting their structure, strengths, limitations, and common applications. This layout helps readers quickly understand which format suits their needs, especially when selecting materials for fiberglass CNC machining parts or CNC milling services.

Table: Common Formats of Fiberglass and Their Applications

| Format |

Structure |

Strengths |

Limitations |

Common Applications |

| Woven Fabrics |

Interlaced fibers (warp & weft) in a fabric form | High tensile strength, stable, good surface finish | Less conformable over complex shapes | Aerospace panels, automotive bodies, fiberglass CNC parts |

| Chopped Glass Mats |

Randomly oriented short fibers bonded with binder | Isotropic strength, easy molding, cost-effective | Lower strength than woven fabrics | Molds, boat hulls, bathroom fixtures, low-stress CNC applications |

| Tows and Rovings |

Bundles of continuous filaments without twist | High unidirectional strength, ideal for structural parts | Requires post-processing or weaving | Wind turbine blades, pressure tanks, CNC machined components |

| Mat (Non-Woven) |

Sheet of randomly distributed continuous/chopped fibers | Excellent resin distribution, smooth finish, low cost | Limited mechanical strength | Laminates, automotive interiors, bathtubs, decorative CNC parts |

Fiberglass is renowned for offering a powerful combination of strength, light weight, and chemical resistance—all while remaining highly formable and cost-efficient. These characteristics are the result of a unique interplay between the glass fiber itself and the surrounding polymer resin. The specific properties of fiberglass can be tailored by altering the fiber type, weave, or resin system, making it incredibly versatile in high-precision CNC milling services, especially for producing durable fiberglass CNC machining parts.

Key physical, chemical, and mechanical properties—such as tensile strength, thermal expansion, and elasticity—directly impact how fiberglass behaves under load, heat, moisture, or machining stress. Engineers and manufacturers working in CNC machining factories must consider these parameters when choosing fiberglass for structural or functional components.

Mechanical Properties of Fiberglass

The mechanical performance of fiberglass varies significantly depending on the type of glass used. Different compositions—like alkali-free E-glass, chemically resistant C-glass, or high-strength S2-glass—offer different levels of durability, flexibility, and resistance. Understanding these properties is essential for manufacturers designing parts with demanding performance specifications or operating in harsh environments.

Each glass type has distinct values for density, tensile strength, Young’s modulus (stiffness), elongation (flexibility), thermal expansion, and Poisson’s ratio. These properties dictate how the material will perform during forming, machining, or in-service use. For example, S2-glass and R-glass are favored in aerospace or defense for their superior strength-to-weight ratio, while AR-glass and C-glass are selected for environments exposed to alkalis or acids.

When using CNC milling services to produce fiberglass CNC machining parts, it is critical to match the material’s mechanical characteristics to the part’s performance requirements. Choosing the wrong type of fiberglass can lead to premature failure, machining inaccuracies, or excessive tool wear—especially in high-volume CNC machining factories.

Here is the complete, professionally formatted table comparing the mechanical properties of different fiberglass types, with accurate and industry-standard values. This is highly useful for engineers selecting materials for fiberglass CNC machining parts, CNC milling services, and general design work in CNC machining factories.

Table: Mechanical Properties of Common Fiberglass Types

| Glass Type |

Density (g/cm³) |

Tensile Strength (GPa) |

Young’s Modulus (GPa) |

Elongation (%) |

Thermal Expansion (10⁻⁷/°C) |

Poisson’s Ratio |

| Alkali-Free (E-glass) |

2.58 | 3.4 – 3.5 | 72 – 80 | 4.8 – 5.0 | 50 – 55 | 0.22 – 0.23 |

| C-glass |

2.50 | 2.0 – 2.2 | 67 – 70 | 4.5 – 4.7 | 75 – 80 | 0.21 – 0.23 |

| S2-glass |

2.46 | 4.5 – 4.9 | 86 – 90 | 5.3 – 5.6 | 25 – 30 | 0.23 – 0.24 |

| A-glass |

2.47 | 2.4 – 2.6 | 65 – 68 | 4.6 – 5.0 | 65 – 70 | 0.22 – 0.23 |

| D-glass |

2.10 | 2.1 – 2.3 | 52 – 55 | 5.2 – 5.5 | 70 – 75 | 0.21 – 0.22 |

| R-glass |

2.52 | 4.6 – 4.9 | 85 – 89 | 5.4 – 5.6 | 25 – 30 | 0.22 – 0.24 |

| EGR-glass |

2.60 | 3.3 – 3.5 | 75 – 80 | 4.8 – 5.1 | 45 – 50 | 0.22 |

| AR-glass |

2.70 | 1.7 – 1.9 | 70 – 73 | 4.0 – 4.3 | 65 – 70 | 0.21 |

Notes:

Chemical Properties of Fiberglass

Fiberglass is prized not only for its mechanical strength but also for its impressive chemical resistance. This resistance makes it an ideal material choice for a variety of demanding industrial applications, especially in environments where exposure to harsh chemicals, moisture, or biological factors is common. Understanding how fiberglass reacts to different chemical agents is essential for manufacturers and engineers, particularly when fabricating precision fiberglass CNC machining parts through advanced CNC milling services in professional CNC machining factories.

Fiberglass’s chemical stability ensures longevity and performance, minimizing degradation that might otherwise compromise part integrity or safety. Below is an overview of how fiberglass interacts with various chemicals and environmental challenges.

Acids

Fiberglass exhibits strong resistance to many acidic substances, especially when combined with appropriate resin systems. Common acids like sulfuric, hydrochloric, and nitric acids generally do not degrade fiberglass composites significantly, making it suitable for storage tanks, piping, and chemical processing equipment. However, prolonged exposure to highly concentrated acids or elevated temperatures may necessitate specialized resin formulations or protective coatings to maintain durability.

Bases

Alkalis and bases can be more aggressive towards fiberglass, particularly those types not designed for alkali resistance. Certain fiberglass types, like AR-glass (alkali-resistant fiberglass), are specially engineered to withstand basic environments such as concrete and wastewater applications. Selecting the right fiberglass type is critical when machining parts that will encounter alkaline conditions, ensuring reliability and service life.

Bleaching Agents

Fiberglass generally tolerates exposure to common bleaching agents used in sanitation and cleaning. Its resistance to chlorine and peroxide-based bleaches allows it to be used in environments requiring frequent disinfection, such as water treatment facilities or medical device housings.

Organic Solvents

Most fiberglass composites resist degradation from organic solvents like alcohols, ketones, and hydrocarbons. However, solvents such as acetone and toluene may cause resin swelling or surface degradation depending on the resin matrix used. Careful selection of resin systems during the manufacturing of fiberglass CNC machining parts can mitigate these effects, ensuring chemical resistance without sacrificing machinability.

Mold

Fiberglass itself is inert and not susceptible to mold growth, making it ideal for humid or damp environments where biological contamination is a concern. Unlike organic materials, fiberglass does not provide a food source for mold or mildew, which helps maintain part integrity and hygiene over time.

Insects and Rodents

Due to its inorganic composition, fiberglass is resistant to damage from insects and rodents. This property is especially valuable in construction, automotive, and aerospace applications where material integrity is critical over long durations.

Dyes

Fiberglass does not absorb dyes or pigments inherently; coloring must be achieved through the resin matrix or surface coatings. This makes fiberglass parts stable in appearance and resistant to fading or discoloration, a beneficial trait for consumer products and decorative applications.

Ultraviolet Radiation

Standard fiberglass composites are vulnerable to ultraviolet (UV) radiation, which can degrade resin matrices and cause surface chalking or weakening over time. To combat this, UV-resistant coatings or additives are incorporated during production, especially for outdoor applications such as roofing panels, automotive parts, and marine equipment.

Fireproof Properties

Fiberglass is inherently fire-resistant due to its glass composition. It does not burn or emit toxic gases under normal fire conditions, making it suitable for safety-critical components in buildings, vehicles, and electrical systems. Fire-retardant resins further enhance these properties where required.

Rot Resistance

Unlike wood or other organic materials, fiberglass does not rot or degrade biologically. This durability makes it an excellent choice for applications exposed to moisture, including outdoor structures, marine vessels, and plumbing components.

Understanding the chemical properties of fiberglass ensures that manufacturers and designers can select the right material and machining process to deliver durable, reliable, and high-quality fiberglass CNC machining parts that meet exacting performance standards.

Here's a professional, easy-to-read table summarizing the chemical properties of fiberglass, highlighting how it reacts to various substances and conditions. This comparison helps engineers and designers choose the right fiberglass type for chemically demanding applications in CNC machining factories or fiberglass CNC machining services.

Table: Chemical Resistance of Fiberglass

| Substance / Condition |

Fiberglass Resistance |

Notes / Recommendations |

| Acids |

High (especially mineral acids) | Compatible with sulfuric, nitric, and hydrochloric acids; specialized resins may be needed. |

| Bases (Alkalis) |

Moderate to Low (varies by glass type) | Use AR-glass for alkaline environments like concrete exposure. |

| Bleaching Agents |

Good | Resists chlorine and peroxide-based bleaches; ideal for sanitizing applications. |

| Organic Solvents |

Varies (generally good) | Resistant to alcohols and mild solvents; acetone/toluene may affect some resin systems. |

| Mold |

Excellent (non-organic) | Inert to mold growth—ideal for humid, biological environments. |

| Insects and Rodents |

Excellent | Not consumed or damaged by pests—great for construction and insulation uses. |

| Dyes |

Low absorption (inert) | Does not absorb dyes directly; color added via resins or coatings. |

| UV Radiation |

Poor to Moderate (without additives) | Requires UV-resistant coatings for long-term outdoor exposure. |

| Fire / Flame |

Excellent (inherent fire resistance) | Will not burn or emit toxic gases—suitable for safety-critical parts. |

| Rot (Biological Decay) |

Excellent | Will not rot—ideal for marine and wet applications. |

This table gives manufacturers, CNC operators, and designers a quick reference when selecting fiberglass for chemically exposed applications—especially where durability and material compatibility are essential for long-lasting fiberglass CNC machining parts.

Fiberglass is a material that combines the strength of glass with the flexibility of polymers, resulting in a composite that offers exceptional performance across numerous industries. Its wide-ranging characteristics make it one of the most preferred materials in sectors such as aerospace, construction, marine, and electronics. The adaptability of fiberglass also makes it highly suitable for CNC machining factories, where it is commonly used to produce high-precision fiberglass CNC machining parts via advanced CNC milling services.

The following characteristics define why fiberglass remains a go-to material for engineers and product designers seeking a lightweight, strong, and chemically resistant solution.

Physical Strength

Fiberglass is known for its outstanding tensile strength, making it ideal for structural and load-bearing applications. Its fibers provide high resistance to stretching and cracking, especially when compared to many metals and plastics of similar weight.

Electrical Properties

One of fiberglass’s most valuable features is its insulating capacity. It offers excellent dielectric strength, which makes it widely used in electrical enclosures, circuit boards, and high-voltage components that require precision fiberglass CNC machining services.

Durability

Fiberglass is not only strong but also highly durable over time. It resists wear, fatigue, and environmental degradation better than many traditional materials, maintaining integrity for decades under proper conditions.

Stiffness

The material exhibits excellent stiffness, meaning it resists deformation under mechanical stress. This property is particularly valuable in CNC-milled structural parts and industrial tooling.

Lightweight

Fiberglass has a high strength-to-weight ratio, which is one of its biggest advantages. This makes it ideal for reducing weight in aerospace, transportation, and consumer products without compromising performance.

Fireproof

Fiberglass is non-combustible by nature. It does not burn or emit toxic gases when exposed to flame, making it an excellent material for fire-safe environments such as electrical rooms or public infrastructure.

Excellent Insulator

Its low thermal conductivity and strong dielectric properties make fiberglass an outstanding insulator against both heat and electricity. It’s widely used in electronics and HVAC systems.

Strong Chemical Resistance

Fiberglass resists a wide range of chemicals including acids, bases, and solvents. This makes it suitable for CNC machining parts used in harsh chemical environments like wastewater treatment or chemical processing.

Highly Corrosion Resistant

Unlike metals, fiberglass does not rust or corrode. It performs exceptionally well in marine and offshore environments, where salt and moisture are constant challenges.

Dimensionally Stable

Fiberglass maintains its shape and size even when exposed to temperature changes, mechanical stress, or moisture. This dimensional stability is essential for accurate CNC milling services.

Resistant to Heat and Humidity

Fiberglass performs reliably under high temperatures and humid conditions without warping or losing structural integrity. This property extends its use to outdoor, industrial, and aerospace components.

Warp Resistance

Due to its stable molecular structure, fiberglass resists warping even under prolonged stress or exposure to environmental extremes. This ensures long-term performance and dimensional accuracy.

Moisture Resistance

Fiberglass does not absorb moisture, making it immune to swelling, softening, or microbial growth. This characteristic is particularly important in submerged or humid applications like marine vessels or bathrooms.

Non-Flammable

Beyond being fireproof, fiberglass is classified as non-flammable. It does not support combustion, making it ideal for critical safety components where fire resistance is non-negotiable.

Organic Compatibility

Fiberglass can be safely combined with organic and synthetic resins, enabling it to form strong, cohesive bonds with a wide variety of composite systems. This flexibility enhances its performance in multi-material assemblies.

Thermal Conductivity

Fiberglass has low thermal conductivity, which allows it to act as a thermal barrier. It is used extensively in thermal insulation applications, from industrial machinery to consumer electronics.

Dielectric Permeability

The low dielectric constant of fiberglass makes it perfect for radio frequency shielding and microwave applications. Its ability to allow electric fields to pass without interference is critical in antenna and radar housing applications.

Here's a clean and professional comparison table summarizing the key characteristics of fiberglass, designed to be easy to read and informative for engineers, designers, and procurement teams selecting materials for fiberglass CNC machining parts, CNC milling services, or use in CNC machining factories.

Table: Key Characteristics of Fiberglass

| Characteristic |

Description |

Benefit to CNC Applications |

| Physical Strength |

High tensile and flexural strength | Ensures structural stability of machined parts under load |

| Electrical Properties |

Excellent dielectric strength, low conductivity | Ideal for insulating components in electrical/electronic systems |

| Durability |

Long-lasting under mechanical, chemical, and environmental stress | Prolongs service life of fiberglass CNC machining parts |

| Stiffness |

Resists deformation under stress | Maintains precision in structural and tooling components |

| Lightweight |

High strength-to-weight ratio | Reduces total weight without sacrificing performance |

| Fireproof |

Inherently non-combustible, resists ignition | Enhances safety in high-temperature or flammable environments |

| Excellent Insulator |

Low thermal and electrical conductivity | Used for insulation in electronics and HVAC |

| Chemical Resistance |

Resists acids, bases, and solvents | Suitable for harsh chemical environments in processing plants |

| Corrosion Resistance |

Does not rust or corrode | Outperforms metals in marine and outdoor applications |

| Dimensional Stability |

Maintains shape under varying temperature and moisture | Ensures accuracy in CNC milling services |

| Heat & Humidity Resistance |

Stable in hot and moist environments | Reliable for long-term use in outdoor and industrial settings |

| Warp Resistance |

Resists warping under load or thermal stress | Maintains tight tolerances in machined parts |

| Moisture Resistance |

Does not absorb water | Prevents swelling or degradation in humid or submerged conditions |

| Non-Flammable |

Will not sustain combustion | Ideal for fire-critical components in transport and building systems |

| Organic Compatibility |

Bonds well with resins and other materials | Enables flexible design options and composite integration |

| Thermal Conductivity |

Low heat transfer | Enhances insulation capabilities |

| Dielectric Permeability |

Low dielectric constant | Perfect for RF shielding, antennas, and sensitive electronics |

The versatility of fiberglass has made it an essential material across a broad range of industries. Thanks to its unique combination of strength, lightweight structure, corrosion resistance, and insulating properties, fiberglass can be tailored for both structural and non-structural uses. From aerospace to aquariums, manufacturers rely on fiberglass CNC machining parts for their consistency and performance. With advancements in CNC milling services and material science, fiberglass continues to expand its presence in both high-performance and consumer-grade applications. Below are some of the most prominent industries and product types that utilize fiberglass and fiberglass CNC machining services.

Swimming Pools

Fiberglass is widely used in the fabrication of in-ground swimming pools due to its waterproof nature, ease of molding, and long-term durability. These pools resist algae growth and require less maintenance than concrete alternatives.

Boats

From personal watercraft to commercial vessels, fiberglass is a go-to material in boat hull construction because it is corrosion-resistant, lightweight, and structurally strong. Fiberglass CNC machining parts are often used for interior fittings, control panels, and custom hardware.

Aircraft

The aerospace industry incorporates fiberglass in interior panels, cargo bays, and even structural components. Its light weight helps reduce fuel consumption, while its strength ensures passenger safety. CNC machining factories often fabricate custom fiberglass parts for aerospace requirements.

Surfboards

Modern surfboards frequently use fiberglass skins over foam cores. The fiberglass layer provides rigidity and impact resistance while maintaining a lightweight profile crucial for performance.

Automobiles

In automotive manufacturing, fiberglass is used in hoods, spoilers, panels, and even some body shells. It helps reduce vehicle weight and improve fuel efficiency. Precision fiberglass CNC machining parts are common in performance and concept cars.

Storage Tanks

Chemical and water storage tanks benefit from fiberglass’s chemical resistance and non-corrosive surface. These tanks are commonly used in wastewater treatment, agriculture, and food processing industries.

Septic Tanks

Fiberglass septic tanks offer superior resistance to corrosion and soil conditions, making them an ideal long-term investment for residential and commercial properties.

Pipes

Fiberglass-reinforced pipes are widely used in transporting corrosive liquids and gases. Their high pressure tolerance and lightweight nature make them ideal for industrial applications.

Insulation

Fiberglass remains one of the most common insulation materials for buildings, pipes, and appliances due to its low thermal conductivity and fire resistance.

Sports Equipment

Items such as hockey sticks, archery bows, and bicycles use fiberglass for its strength and flexibility. It allows for performance optimization without significantly adding weight.

Bathtubs and Hot Tubs

Fiberglass is used in forming bathtubs and hot tubs due to its ability to conform to complex shapes, its waterproof nature, and its ease of repair and maintenance.

Molds

Fiberglass molds are widely used in manufacturing processes for creating composite parts. They offer excellent dimensional stability and are reusable for mass production.

Helmets

Fiberglass is a favored material in manufacturing protective helmets for construction, sports, and military use. It offers a solid balance between impact resistance and light weight.

Electronics

Due to its insulating and non-conductive properties, fiberglass is commonly used in PCBs (Printed Circuit Boards), enclosures, and cable trays.

Wind Turbine Blades

Fiberglass is a standard material in wind energy due to its strength, lightweight profile, and fatigue resistance, making it ideal for manufacturing large rotor blades.

Construction

In construction, fiberglass is used in panels, rebar, roofing, insulation, and facades. Its resistance to weather, mold, and chemicals makes it a reliable option for long-term structural use.

Transportation

Beyond cars and aircraft, fiberglass is used in trains, buses, and shipping containers. It reduces overall weight, enhances safety, and resists corrosion during transport.

Aerospace and Defense

In military-grade equipment and aircraft, fiberglass is used for shielding, insulation, and structural reinforcement. Fiberglass CNC machining services help manufacture complex geometries with tight tolerances for mission-critical applications.

Beverage Industry

Fiberglass is used in vats, pipelines, and enclosures where sanitary, corrosion-resistant materials are essential. It’s commonly found in breweries and bottling plants.

Chemical Industry

Due to its exceptional chemical resistance, fiberglass is used in fume hoods, scrubbers, ducts, and tanks that handle aggressive or reactive substances.

Marine Industry

Beyond boats, fiberglass is used in docks, marine structures, and underwater equipment where saltwater corrosion would rapidly degrade metals.

Food Processing

Fiberglass plays a role in food-grade tanks, mixers, and surfaces due to its inert nature, resistance to bacteria, and ease of cleaning.

Aquariums and Ponds

Fiberglass liners and structures are preferred in large-scale aquariums and ponds. They offer watertight sealing, UV resistance, and long-term durability.

Manufacturing

In industrial manufacturing, fiberglass is used in machinery covers, hoods, tanks, and platforms where chemical exposure, wear, and heat are concerns.

Power Generation

Turbine blades, insulation components, and equipment housings are made from fiberglass in the energy sector, particularly in renewable energy and nuclear facilities.

Leisure

Recreational equipment like go-karts, playground slides, and amusement rides incorporate fiberglass for its safety, strength, and design flexibility.

Here's a professionally formatted, easy-to-read table summarizing the Applications of Fiberglass, including key benefits for each use. This table is particularly helpful for engineers, product developers, and sourcing managers considering fiberglass CNC machining parts, CNC milling services, and solutions from CNC machining factories.

Table: Common Applications of Fiberglass and Their Benefits

| Application Area |

Use of Fiberglass |

Key Benefits |

| Swimming Pools |

Pool shells and lining | Waterproof, smooth finish, algae-resistant |

| Boats |

Hulls, decks, interiors | Corrosion-resistant, lightweight, strong |

| Aircraft |

Interior panels, components | Lightweight, durable, fire-resistant |

| Surfboards |

Outer skin on foam cores | Flexible, strong, easy to shape |

| Automobiles |

Body panels, hoods, interior parts | Reduces weight, resists rust, improves fuel economy |

| Storage Tanks |

Chemical and water storage | Corrosion-resistant, chemically inert |

| Septic Tanks |

Underground waste storage | Long service life, resistant to soil corrosion |

| Pipes |

Fluid and gas transport | High-pressure tolerance, low maintenance |

| Insulation |

Thermal and sound insulation | Fireproof, non-conductive |

| Sports Equipment |

Bows, sticks, bikes | Lightweight, shock-resistant |

| Bathtubs & Hot Tubs |

Tubs and shells | Moldable, low maintenance, water-resistant |

| Molds |

Reusable manufacturing molds | Durable, dimensionally stable |

| Helmets |

Safety and sports helmets | High impact resistance, lightweight |

| Electronics |

PCBs, enclosures, cable trays | Electrical insulator, thermally stable |

| Wind Turbine Blades |

Rotor blades | Strong, fatigue-resistant, lightweight |

| Construction |

Panels, rebar, roofing, facades | Weatherproof, corrosion-resistant, strong |

| Transportation |

Vehicle parts, containers, railcars | Lightweight, fuel-efficient, impact-resistant |

| Aerospace & Defense |

Structural panels, shielding, insulation | High strength-to-weight ratio, CNC machinable |

| Beverage Industry |

Tanks, pipelines, enclosures | Sanitary, corrosion-resistant |

| Chemical Industry |

Ducts, tanks, scrubbers | Chemically inert, durable |

| Marine Industry |

Docks, underwater housings | Saltwater-resistant, strong |

| Food Processing |

Food-grade tanks, mixers, conveyors | Easy to clean, non-toxic, corrosion-resistant |

| Aquariums & Ponds |

Liners, tanks, decorative features | Waterproof, UV-stable, moldable |

| Manufacturing |

Machine guards, housings, equipment covers | Tough, chemical-resistant, lightweight |

| Power Generation |

Turbine blades, insulation panels | Electrically insulating, durable in harsh environments |

| Leisure |

Slides, go-karts, recreational products | Safe, impact-resistant, colorful |

Fiberglass is a powerful composite material that blends performance, durability, and cost-effectiveness. It's widely adopted in industries ranging from aerospace and construction to electronics and marine engineering. However, like any material, fiberglass comes with both benefits and limitations. Understanding these pros and cons helps engineers, designers, and procurement specialists make informed decisions—especially when selecting materials for fiberglass CNC machining parts through professional CNC milling services.

Advantages of Fiberglass

1. High Strength-to-Weight Ratio

Fiberglass offers impressive tensile and flexural strength while remaining significantly lighter than metals like steel or aluminum. This makes it ideal for aerospace, automotive, and marine applications where weight reduction is critical.

2. Corrosion and Chemical Resistance

Fiberglass is inert to most chemicals, including acids, alkalis, and solvents. This makes it ideal for chemical storage tanks, pipelines, and environments with aggressive corrosion risks—especially where fiberglass CNC machining services are used to create custom components.

3. Excellent Electrical Insulation

Due to its low conductivity and high dielectric strength, fiberglass is a top choice for insulating electrical components such as PCBs and enclosures.

4. Moisture and Weather Resistance

Fiberglass does not absorb moisture and is UV-resistant when properly treated. It’s highly suitable for outdoor applications such as satellite dishes, bathtubs, boats, and building exteriors.

5. Dimensional Stability

Fiberglass retains its shape and size across wide temperature and humidity ranges. This is particularly useful in CNC machining, where tolerance control is vital.

6. Fire and Heat Resistance

The glass fibers themselves are non-combustible, and fire-retardant resins can be used to improve overall fire performance, especially in aerospace and construction.

7. Design Flexibility

Fiberglass can be molded into complex shapes and CNC-machined into intricate parts, offering extensive design freedom for innovative applications.

8. Low Maintenance

Once installed, fiberglass products require minimal maintenance. They do not rot, rust, or degrade in most environments, which reduces long-term operating costs.

Disadvantages of Fiberglass

1. Brittle Nature

While fiberglass is strong, it can be brittle under certain loading conditions. It may crack or shatter upon sharp impact or stress concentrations, unlike metals which may deform plastically.

2. Difficult to Repair

Once damaged, fiberglass components are more difficult to repair compared to metals. Repairs often require special resins and skilled labor to restore structural integrity.

3. Health and Safety Risks

Handling raw fiberglass can cause skin irritation, and airborne fibers may pose respiratory hazards if inhaled. Proper protective equipment and ventilation are required during manufacturing and CNC processing.

4. Poor Biodegradability

Fiberglass is not biodegradable and is challenging to recycle. Its disposal may raise environmental concerns, particularly in large-scale applications.

5. Limited Impact Resistance

Although it is durable in many applications, fiberglass does not absorb energy as effectively as some metals or plastics, limiting its use in high-impact scenarios.

6. Resin Dependency

The performance of fiberglass composites depends heavily on the type of resin used. Inadequate resin choices can compromise chemical resistance, mechanical strength, or thermal performance.

7. Cost of Complex Shapes

While fiberglass is cost-effective for many applications, producing complex shapes—especially those needing tight CNC tolerances—can increase manufacturing time and tooling cost.

Summary

Fiberglass is a robust, lightweight, and chemically resistant material suitable for countless applications across modern industries. For CNC machining, it provides dimensional stability, strength, and corrosion resistance ideal for high-precision parts. However, users must consider factors like brittleness, repair complexity, and recyclability during design and production.

Here's a clear and professional comparison table summarizing the advantages and disadvantages of fiberglass—ideal for engineers, product designers, and decision-makers exploring fiberglass CNC machining parts, CNC milling services, or sourcing from CNC machining factories.

Table: Advantages and Disadvantages of Fiberglass

| Category |

Details |

| Advantages | |

| High Strength-to-Weight Ratio | Stronger than many metals by weight; ideal for lightweight structural parts. |

| Corrosion & Chemical Resistance | Resistant to acids, bases, and solvents—excellent for tanks, pipes, and harsh environments. |

| Electrical Insulation | Excellent dielectric properties; suitable for enclosures, PCBs, and cable trays. |

| Weather & Moisture Resistant | Does not rot, swell, or degrade in wet or UV-exposed conditions. |

| Dimensional Stability | Maintains precise tolerances; ideal for CNC milling services. |

| Fire & Heat Resistance | Non-combustible fibers with optional flame-retardant resins. |

| Design Flexibility | Easily molded or CNC-machined into complex geometries. |

| Low Maintenance | Long service life with minimal upkeep. |

| Disadvantages | |

| Brittle Under Stress | May crack or shatter under impact without plastic deformation. |

| Challenging to Repair | Requires resins and skilled labor for structural repair. |

| Health & Safety Risks | Raw fibers can irritate skin or lungs if inhaled; PPE required. |

| Non-Biodegradable | Difficult to recycle; environmental disposal concerns. |

| Limited Impact Resistance | Not suitable for high-impact, energy-absorbing applications. |

| Performance Depends on Resin | Poor resin choice can reduce mechanical, thermal, or chemical resistance. |

| Cost for Complex Shapes | Tight tolerances and detailed CNC work can raise costs. |

This table offers a concise, side-by-side look at fiberglass's pros and cons, helping stakeholders evaluate whether it fits their application or CNC machining project requirements.

Many people use the terms “fiberglass” and “glass fiber” interchangeably, but they refer to different stages of the same material. In the manufacturing and CNC machining industries—especially when working with fiberglass CNC machining parts—understanding this distinction is crucial. Whether you're sourcing raw materials or precision parts from CNC machining factories, clarity on this topic ensures the right application and performance outcome.

Glass Fiber: The Raw Material

Glass fiber is the base material used to make fiberglass. It refers to very thin strands of glass that are extruded and spun into filaments, usually a few microns in diameter. These fibers can be continuous or chopped and come in different glass types (e.g., E-glass, S-glass, C-glass), each offering specific mechanical and chemical properties. On their own, glass fibers are not typically used as structural materials; instead, they are meant to be embedded in a resin matrix to create a composite.

Key facts about glass fiber:

Fiberglass: The Finished Composite

Fiberglass, in contrast, is a composite material made by combining glass fibers with a polymer resin such as epoxy, polyester, or vinyl ester. This combination gives the material structural integrity, shape, and additional resistance to environmental factors like moisture, chemicals, and UV light. Fiberglass is moldable, machinable, and widely used in both industrial and consumer applications.

Key facts about fiberglass:

Key Differences Between Glass Fiber and Fiberglass

| Aspect |

Glass Fiber |

Fiberglass |

| Definition |

Raw strands of glass drawn into filaments | Composite material of glass fiber + resin |

| Form |

Filament, mat, roving, fabric | Solid, molded or laminated part |

| Strength |

High tensile strength, no compressive strength | Strong in both tension and compression |

| Usability |

Requires resin for structural use | Ready-to-use structural material |

| Applications |

Base material for composites | Boats, automotive, aerospace, electronics, etc. |

| CNC Machinability |

Not machinable on its own | Suitable for CNC machining when cured into composites |

Conclusion

In summary, glass fiber is the raw material, and fiberglass is the finished product made by combining glass fiber with a resin. The glass fiber provides strength, while the resin binds the fibers and gives the composite its shape and durability. For CNC machining factories and fiberglass CNC machining services, this distinction is vital when sourcing materials or engineering parts. Using the correct terminology ensures proper communication, better quality control, and more efficient project execution.

When it comes to precision, durability, and versatility in fiberglass component manufacturing, VMT stands at the forefront of the CNC machining industry. With decades of experience and state-of-the-art equipment, VMT specializes in producing high-quality fiberglass CNC machining parts that meet the demanding specifications of industries such as aerospace, automotive, medical, electronics, marine, and more.

Precision CNC Milling Services for Fiberglass

Fiberglass, though lightweight and strong, presents unique machining challenges due to its abrasive nature and layered structure. VMT overcomes these challenges through advanced CNC milling services that ensure clean edges, precise dimensions, and minimal material degradation. Whether you need small-scale prototyping or large-volume production, VMT’s machines can handle complex geometries and tight tolerances with ease.

Our CNC services for fiberglass include:

Expertise in Fiberglass CNC Machining Services

VMT’s team is well-versed in fiberglass’s mechanical, thermal, and chemical behavior. We work with all major fiberglass types—E-glass, S-glass, Advantex, C-glass, and more—and offer post-processing services such as:

Each project benefits from VMT’s robust quality control system, which includes real-time inspection, material certification, and dimensional verification.

Applications Served

VMT produces fiberglass CNC machining parts for a variety of mission-critical and high-performance applications:

Why Choose VMT?

Industry Experience: Trusted by global clients in more than 40 countries

Start Your Project with Confidence

From concept to final part, VMT offers end-to-end fiberglass CNC machining services tailored to your performance and cost requirements. Whether you are a design engineer, supply chain manager, or OEM manufacturer, VMT ensures your fiberglass components are delivered with unmatched precision, reliability, and efficiency.

Contact VMT today to get a quote or consult on your fiberglass CNC machining project.

Fiberglass has proven itself to be one of the most versatile and valuable materials in modern manufacturing. With its exceptional balance of strength, weight, chemical resistance, and electrical insulation, fiberglass continues to serve as a key component across a wide range of industries—from aerospace and automotive to marine, electronics, and construction. Understanding its different types, properties, and formats enables manufacturers and engineers to make smarter decisions when selecting materials for performance-critical applications.

Whether it’s E-glass for general use, S2-glass for high-performance structures, or Advantex for corrosion-resistant environments, each type of fiberglass brings unique advantages. From raw woven fabrics to complex machined components, fiberglass can be shaped and refined through modern CNC milling services to meet the most demanding specifications. At the same time, it's essential to weigh the benefits of fiberglass—such as dimensional stability and corrosion resistance—against limitations like brittleness or recyclability.

For companies seeking a reliable partner in fiberglass CNC machining parts, VMT offers the complete solution. With years of experience, advanced CNC capabilities, and a commitment to precision and quality, VMT serves clients across industries with tailored fiberglass machining services. Whether for prototyping or large-scale production, VMT’s expertise ensures every component is delivered with exceptional accuracy and performance.

If you're looking to source premium fiberglass CNC machining services, or need expert support from trusted CNC machining factories, VMT is ready to help turn your designs into high-performance realities.

1. What is Fiberglass Used For? Why?

Fiberglass is used in industries such as aerospace, automotive, marine, construction, electronics, and sports equipment because it offers a unique combination of lightweight strength, corrosion resistance, electrical insulation, and design flexibility. It’s ideal for manufacturing durable and precise parts, including fiberglass CNC machining parts.

2. Is Fiberglass Harmful?

Fiberglass itself is generally safe once cured. However, raw fiberglass fibers can irritate the skin, eyes, and lungs if inhaled or touched directly during manufacturing. Proper protective equipment and ventilation are essential during handling.

3. Is Fiberglass Glass or Plastic?

Fiberglass is a composite material made by combining fine strands of glass fiber with plastic resin. The glass fibers provide strength, while the plastic resin binds them into a solid, machinable material.

4. Is Fiberglass Metal?

No, fiberglass is not metal. It is a composite material made from glass fibers embedded in a plastic resin matrix.

5. Is Fiberglass Stronger Than Steel?

Fiberglass has a high strength-to-weight ratio, meaning it is stronger than steel when weight is considered. However, steel typically has higher absolute strength and toughness.

6. Is Fiberglass Good or Bad?

Fiberglass is good for many applications due to its durability, corrosion resistance, and versatility. Its downsides include brittleness and difficulty in recycling.

7. Is Fiberglass Safe to Live In?

Yes, cured fiberglass used in building materials and consumer products is safe. Proper manufacturing ensures no fiber release into living environments.

8. Is Fiberglass Stronger Than Glass?

Yes. Fiberglass combines glass fibers with resin to produce a material stronger and more flexible than regular glass.

9. Does Fiberglass Rust?

No, fiberglass does not rust because it contains no metal. It is highly resistant to corrosion.

10. What is Another Name for Fiberglass?

Fiberglass is also commonly called glass-reinforced plastic (GRP) or glass-fiber reinforced polymer (GFRP).

11. What Products Contain Fiberglass?

Common products include boat hulls, car body panels, swimming pools, storage tanks, pipes, bathtubs, helmets, sports equipment, and insulation materials.

12. How to Tell if It's Plastic or Fiberglass?

Fiberglass usually has a textured surface with visible fibers or a resin finish, while plastic is generally smooth and homogeneous. Machined fiberglass parts often have a composite layering feel.

13. Why Is Fiberglass Better Than Steel?

Fiberglass is lighter, corrosion-resistant, and electrically insulating, making it better for applications where weight and chemical exposure are concerns.

14. Which is Better, Fiberglass or Stainless Steel?

Fiberglass is lighter and corrosion-resistant, while stainless steel offers superior strength and heat resistance. The choice depends on specific application needs.

15. Can Fiberglass Replace Steel?

In some applications, yes—especially where weight reduction and corrosion resistance are critical. However, steel is still preferred for high-load and impact-resistant uses.

16. What Replaced Fiberglass?

Newer composites like carbon fiber and Kevlar have replaced fiberglass in high-performance applications requiring even greater strength-to-weight ratios.

17. What Material is Stronger Than Fiberglass?

Materials such as carbon fiber composites, Kevlar, and some advanced ceramics offer higher strength and stiffness than fiberglass.

18. Is Fiberglass 100% Glass?

No, fiberglass is not 100% glass; it consists of glass fibers embedded in a polymer resin matrix, forming a composite material.