15 years one-stop China custom CNC machining parts factory

194 |

Published by VMT at May 30 2025 | Reading Time:About 8 minutes

194 |

Published by VMT at May 30 2025 | Reading Time:About 8 minutes

In the realm of metal fabrication, achieving precision, efficiency, and cost-effectiveness is a constant challenge. Traditional methods often fall short when it comes to producing intricate designs at scale. This is where sheet metal punching emerges as a game-changer. By leveraging advanced sheet metal CNC machining techniques, manufacturers can overcome these hurdles, delivering high-quality metal CNC machining parts with remarkable consistency.

Sheet metal punching is a manufacturing process that utilizes a punch and die to create holes, slots, or specific shapes in metal sheets. This method is integral to CNC machining services, enabling the production of precise and complex components across various industries. Its efficiency and adaptability make it a cornerstone in modern fabrication practices.

Understanding the intricacies of sheet metal punching is crucial for manufacturers aiming to optimize their production processes. From the types of punches and dies to the advantages and potential drawbacks, a comprehensive grasp of this technique can lead to improved product quality and operational efficiency. Let's explore the various facets of sheet metal punching and its role in contemporary manufacturing.

Sheet metal punching is a fabrication process that involves the removal of material from a metal sheet by applying a high-shear force using a punch and die. The punch, a hardened tool, descends onto the sheet, pressing it into the die, which has a corresponding shape. This action shears the material, creating holes or specific shapes as required.

This process is highly efficient and is commonly employed in CNC machining factories to produce components with consistent quality. It's particularly advantageous for creating repetitive patterns or multiple holes in a single operation, thereby reducing production time and costs.

Understanding the Foundation of Precision Metal Fabrication

Metal stamping is a foundational technique in modern manufacturing, particularly within sheet metal CNC machining and metal CNC machining parts production. Whether it's creating simple cut-outs or forming complex geometries, various stamping processes serve different purposes across industries—from automotive and aerospace to consumer electronics. For manufacturers looking to choose the best CNC machining services, understanding the core stamping methods is critical to achieving precision, cost-effectiveness, and production scalability.

Cutting: The First Step in Metal Shaping

Cutting is one of the primary processes in metal stamping. It refers to the removal of material from a metal sheet to achieve a specific shape, usually by applying shear force. Cutting is the foundation upon which other processes like blanking, punching, and notching are built.

This process is typically executed using CNC punch presses or stamping dies in a high-speed press. The result is clean, precise separations that form the basis for more complex parts. Efficient cutting minimizes material waste and ensures repeatability—making it ideal for mass production.

Shearing: Straight-Line Precision

Shearing involves applying a straight-line cut to separate a sheet into multiple sections. The process doesn’t involve melting or burning the material, which preserves the structural integrity of the workpiece. It is widely used in pre-fabrication to prepare raw sheets for secondary processes.

Shearing is ideal for trimming edges, preparing blanks, or segmenting large sheets into manageable sizes. The clean, burr-free cuts it produces are especially important in CNC machining factories where high-quality finishes are a priority.

Blanking: Creating the Workpiece

Blanking is the process of cutting a flat shape from sheet metal, where the removed piece (the "blank") becomes the finished part or workpiece. Unlike punching, where the removed material is waste, blanking is about harvesting the usable component.

This process is frequently used in high-volume production, such as automotive panels, and is highly compatible with metal CNC machining parts that require consistent dimensions and minimal post-processing.

Punching: Crafting Holes and Patterns

Punching uses a punch and die to create holes or patterns in metal sheets. In this case, the punched-out section is discarded, and the surrounding material forms the finished product. It’s particularly useful for adding features like mounting holes, slots, or ventilation patterns.

When integrated with CNC machining services, punching delivers unmatched precision and repeatability, essential for electronics, appliances, and structural applications.

Forming: Beyond Flat Shapes

Forming transforms flat metal sheets into 3D shapes without removing any material. Common forming techniques include bending, flanging, and drawing. These methods are often used to produce enclosures, panels, and other components requiring added depth or contour.

This process is critical in industries where strength and aesthetics go hand-in-hand, such as consumer electronics or medical devices. Sheet metal CNC machining allows for automated forming with excellent accuracy and repeatability.

Notching: Strategic Edge Removal

Notching involves cutting out sections from the edge or corners of a metal sheet. This is often a preparatory step for forming or joining parts together. Notching allows for interlocking designs, precise bends, and easy assembly in complex mechanical systems.

It’s a valuable process for fabrication teams looking to reduce welding time or improve structural integrity during assembly.

Piercing: Clean Hole Creation

Piercing is similar to punching but often leaves the punched-out piece attached or integrated with the material. It's mainly used for ventilation holes or aesthetic features and is ideal for lightweight applications that don't compromise the strength of the metal.

Precision piercing is essential in industries like HVAC, lighting fixtures, and appliance manufacturing.

Embossing: Add Form and Function

Embossing raises or depresses specific areas of a sheet to create textures, logos, or functional indentations. It enhances both aesthetics and usability, for example, by adding grip or allowing fluid flow around embossed features.

Used in both industrial and consumer products, embossing is a zero-material-loss process that adds value without extra cost.

Slotting: Functional Elongated Cuts

Slotting is the process of creating long, narrow openings in metal sheets. These slots are often used in adjustable fixtures, mounting brackets, or for weight reduction.

Slots must be precise and consistent, especially in products where alignment and tension are critical. CNC machining factories often combine slotting with forming or welding to create ready-to-assemble parts.

Slitting: Strip with Precision

Slitting is a high-speed operation that slices large metal coils or sheets into narrower strips using rotary blades. These strips are then used for roll-forming, stamping, or other downstream processes.

This method is cost-efficient and minimizes waste, making it indispensable in large-scale metal CNC machining parts manufacturing.

Nibbling: Flexible, Tool-less Cutting

Nibbling involves removing small bits of material in quick, successive punches, often following a programmed path. This allows for creating complex shapes without the need for custom tooling—ideal for prototyping or low-volume production.

Though slower than other methods, nibbling offers flexibility in design changes and is often integrated into sheet metal CNC machining for one-off or small batch parts.

Final Thoughts

Understanding these metal stamping processes allows manufacturers and clients alike to make informed decisions about design, tooling, cost, and production methods. Each technique offers specific advantages, and when combined with CNC machining services, the result is high-quality, durable, and cost-effective components suitable for a variety of industries.

Here is a professional and easy-to-read table summarizing the Types of Metal Stamping Processes for quick reference:

| Process |

Description |

Typical Use |

Advantages |

| Cutting |

Removes material from sheet using shear force. | Prepares material for further forming or joining. | Clean edges, minimal distortion. |

| Shearing |

Straight-line cuts to divide sheets into sections. | Pre-cutting large sheets into manageable sizes. | Fast, efficient, minimal waste. |

| Blanking |

Cuts out a piece (blank) that becomes the final part. | Used in automotive, electronics, appliance components. | High consistency, fast production. |

| Punching |

Removes material to form holes; waste is discarded. | For bolt holes, slots, ventilation. | Precise, fast, high repeatability. |

| Forming |

Shapes metal into 3D parts without removing material. | Enclosures, brackets, housings. | No material waste, strong structural integrity. |

| Notching |

Cuts edges or corners, usually for preparation. | Assembly prep, interlocking parts. | Speeds up assembly, improves fit. |

| Piercing |

Creates small holes or patterns in material. | Decorative or functional openings. | High-speed, clean results. |

| Embossing |

Raises or depresses material for logos or texture. | Branding, grip surfaces, aesthetic appeal. | No extra material or assembly needed. |

| Slotting |

Creates long, narrow cuts for functionality. | Mounting systems, tension relief. | Adds flexibility to design. |

| Slitting |

Cuts large sheets into strips using rotary blades. | Coil processing, prep for stamping. | High-speed, low waste. |

| Nibbling |

Repeated small punches to form complex shapes. | Prototyping, short-run production. | No custom dies needed, flexible. |

This table can be embedded in your article to help users quickly compare and understand the various stamping processes used in sheet metal fabrication, sheet metal punching, and metal CNC machining parts manufacturing.

Here is a detailed and easy-to-read table comparing the advantages and disadvantages of sheet metal punching, tailored to users seeking clarity in choosing sheet metal CNC machining solutions:

Sheet Metal Punching: Advantages vs. Disadvantages

| Advantages |

Description |

| Speed & Efficiency | High-speed punching allows for mass production with fast cycle times. |

| Versatility | Can produce holes, slots, and shapes of various sizes and geometries. |

| Precision | Offers tight tolerances ideal for high-precision sheet metal CNC machining. |

| Repeatability | Ensures consistent quality across large production batches. |

| Cost | Economical for medium to high-volume runs due to reduced labor and tooling. |

| Minimal Secondary Operations | Often eliminates the need for additional drilling or shaping. |

| Low Waste | Optimized layouts and precise punching minimize material waste. |

| Wide Range of Materials | Suitable for metals like aluminum, stainless steel, copper, and more. |

| Low Labor | CNC automation reduces manual input, lowering labor costs. |

| Disadvantages |

Description |

| Noise | Mechanical punching can generate loud operational noise. |

| Dust & Metal Chips | Produces particulate waste that requires cleanup and proper handling. |

| Safety | Requires proper machine guarding and operator training to prevent accidents. |

| Burr Generation | May require deburring operations for sharp edges post-punching. |

| Upfront Costs | CNC punching equipment and tooling can require significant initial investment. |

| Required Skills | Skilled setup and programming are essential for optimal results. |

| Occasional Jams | Improper setup or material inconsistencies can lead to tool jams. |

Here's a professional and easy-to-understand table summarizing the applications and parts commonly associated with sheet metal punching, especially for industries relying on sheet metal CNC machining and metal CNC machining parts.

Sheet Metal Punching: Applications and Common Parts

| Industry |

Application Description |

Common Parts Produced |

| Automotive |

High-speed punching is ideal for producing vehicle components with precision and repeatability. | Brackets, dashboard mounts, exhaust parts, chassis components |

| Cookware |

Punching enables efficient shaping and venting in kitchen appliances and tools. | Vented lids, stove components, utensil handles, cookware shells |

| Aerospace |

Demands high-precision punched parts for lightweight, high-strength components. | Panels, brackets, ventilation covers, frame mounts |

| Industrial |

Supports fabrication of machine parts and structural elements used in manufacturing. | Machine guards, enclosures, tool holders, base plates |

| Electronics |

Enables mass production of complex metal enclosures and connectors with fine tolerances. | Chassis, circuit housings, shielding plates, heat sinks |

| Medical |

Used in the manufacture of sterile, precision components for medical devices. | Instrument enclosures, surgical trays, brackets, fastening plates |

Sheet metal punching is widely used in CNC machining factories for its speed, material flexibility, and accuracy. Each industry benefits from the ability to create detailed, repeatable metal parts that integrate seamlessly with metal CNC machining manufacturing workflows.

If you're experiencing inconsistencies in punched metal parts or struggling to meet production volume efficiently, chances are your equipment may not be the best fit. With so many types of punch presses available—each designed for specific needs—choosing the wrong one can lead to wasted time, lower precision, and rising costs. Fortunately, understanding the types of punch presses and how they align with your production goals can help you streamline operations and improve part quality.

To choose the right punch press, consider production volume, material type, precision requirements, and automation needs. Mechanical presses are ideal for high-speed, repetitive tasks; hydraulic presses offer versatility and force control; and CNC punching machines provide the highest precision and flexibility for complex geometries.

Each punch press type offers unique benefits tailored to different manufacturing environments. Let’s explore how mechanical, hydraulic, and CNC punch presses compare, and how to determine which is the best match for your sheet metal punching needs.

Mechanical Press

Mechanical punch presses operate using a flywheel mechanism and a clutch system to generate fast, repetitive strokes. These machines are best suited for high-volume production environments where speed and cycle time are critical. Because of their consistent stroke length and high-speed operation, mechanical presses are often used in automotive, appliance, and mass consumer goods industries. However, they may not be as flexible when dealing with varying material thicknesses or complex patterns. Their lower initial cost makes them appealing for high-output CNC machining factories, but the lack of fine control limits their use in applications requiring high precision.

Hydraulic Press

Hydraulic punch presses use pressurized fluid to generate a controlled force, making them ideal for thicker materials, larger part sizes, and applications requiring variable stroke lengths. These presses offer greater control and versatility than mechanical types, especially for deep drawing, embossing, or complex forming processes. While typically slower than mechanical presses, hydraulic machines allow precise force adjustment, improving material utilization and reducing tool wear. They’re commonly used in industrial and aerospace applications where force and flexibility are more important than speed.

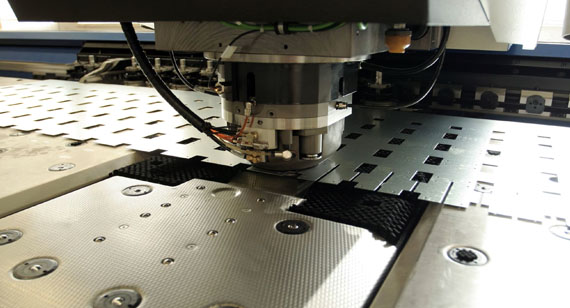

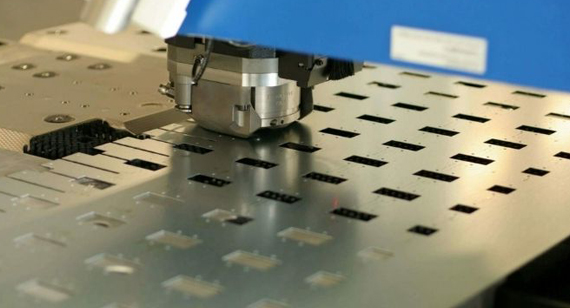

CNC Punching

CNC punch presses combine the advantages of automation, precision, and programmability. Controlled via a computer interface, these machines can produce highly complex patterns with exceptional repeatability and accuracy, making them ideal for metal CNC machining parts in industries like electronics, medical, and custom fabrication. CNC punching is suitable for both low-volume prototyping and mid-volume production thanks to its flexibility and ease of programming. These systems also integrate seamlessly with CAD/CAM software, making them a natural choice for modern CNC machining services and sheet metal CNC machining applications. While they come with a higher upfront investment, the automation, reduced labor, and minimal setup times often translate to long-term cost savings.

Struggling with inconsistent punch quality, downtime, or inefficient use of materials? You’re not alone. Many manufacturers face these challenges when operating a CNC punch press without a standardized process. These problems can lead to delayed orders, increased scrap, and unnecessary tooling wear. The good news? By following a clear, step-by-step approach, you can dramatically improve accuracy, efficiency, and machine life in your sheet metal punching operations.

To operate a CNC punch press effectively, prepare the machine by checking safety and calibration, install the appropriate punch tools, and accurately program the press using CAD/CAM software. A systematic workflow ensures consistent, high-quality results in sheet metal CNC machining.

Whether you're new to CNC punching or looking to improve current processes, mastering these three foundational steps will help ensure precision, repeatability, and high productivity. Let’s break down how to set up and operate a CNC punch press efficiently.

Step 1: Prepare the CNC Punch Press

Before starting production, machine preparation is essential. This includes checking safety guards, hydraulic and pneumatic systems, and ensuring the press is clean and free from obstructions. Inspect the worktable for alignment and verify the machine's zero point settings. Lubrication systems should be checked and refilled as needed. If your CNC punch press is networked, verify system connectivity for loading part programs. Proper setup not only reduces mechanical failures but also ensures optimal sheet alignment, which directly affects hole accuracy and minimizes material waste—a key factor in CNC machining factories and sheet metal CNC machining projects.

Step 2: Select and Install Punch Tools

Tool selection is based on the geometry of the part, material thickness, and desired features such as holes, slots, or embossing. Choose punch and die sets with the correct dimensions and clearance to avoid burring or material distortion. Use tool cartridges or automatic tool changers if available to reduce changeover times. Carefully install each punch tool and ensure it is securely locked into the turret. Regular inspection and sharpening of punch tools also improve tool life and cutting quality, helping you maintain the high standards required for metal CNC machining parts.

Step 3: Program the CNC Punch Press

Programming is where precision meets automation. Use CAD/CAM software to create or load the part design. Assign the correct punch paths, tool numbers, feed rates, and punching sequences. Check for potential collisions or tool interference using simulation tools. Once the program is ready, upload it to the punch press and perform a dry run to ensure accuracy. Make sure to include part nesting strategies to maximize material utilization and reduce scrap. With the right programming, your CNC punch press can produce hundreds—or even thousands—of identical, precise parts with minimal manual intervention.

Sheet metal punching is a versatile and widely adopted technique in the sheet metal CNC machining and metal fabrication industries. One of its key strengths lies in its compatibility with a wide range of metals, allowing manufacturers to produce everything from intricate electronic parts to heavy-duty industrial components. However, not all metals respond equally well to the punching process. Material hardness, thickness, ductility, and tensile strength all influence whether a particular metal is suitable for punching. Choosing the right material for your punching operation is critical to ensuring clean cuts, reducing tool wear, and maximizing cost-efficiency.

Stainless Steel

Stainless steel is a popular material for punching due to its corrosion resistance and strength. It is commonly used in the medical, food processing, and automotive industries. However, its hardness can cause faster punch tool wear, requiring precision tools and careful process control.

Steel

Mild and carbon steels are excellent choices for punching, especially in industrial and construction applications. Their relative softness compared to stainless steel allows for efficient punching, low tool wear, and cost-effective production.

Iron

Iron, particularly ductile or soft iron, can be punched effectively, though it is less common due to its brittleness. Punching cast iron is generally avoided, as it can crack or fracture under the pressure of the punch.

Lightweight and corrosion-resistant, aluminum is easy to punch and well-suited for aerospace, electronics, and automotive components. It has low tool wear characteristics and allows for high-speed production with minimal force.

Copper

Copper’s excellent electrical conductivity makes it ideal for electronics applications. While it's a soft material and easy to punch, its ductility requires tight control over punch speed and force to avoid deformation.

Mild Steel

Mild steel is among the most commonly punched metals due to its balance of strength and ductility. It provides clean holes, is economical, and is used in a wide variety of industries, from consumer products to heavy equipment manufacturing.

Other Alloys

Brass, bronze, titanium, and nickel alloys can also be punched, but they may require specialized punch tools and settings. For example, titanium punching is used in aerospace due to its strength-to-weight ratio, but it demands precise control to prevent damage or tool breakage.

Here is a clear and professional comparison table showing common metals used in sheet metal punching, along with their characteristics and typical applications:

| Metal |

Punching Suitability |

Key Characteristics |

Common Applications |

| Stainless Steel |

Moderate to High | Corrosion-resistant, strong, harder on tools | Medical, food processing, automotive |

| Steel (Carbon/Mild) |

High | Strong, easy to punch, cost-effective | Industrial, construction, general manufacturing |

| Iron |

Low to Moderate | Brittle (especially cast iron), can crack if mishandled | Limited use; select ductile types for basic parts |

| Aluminum |

Very High | Lightweight, corrosion-resistant, low tool wear | Aerospace, electronics, automotive |

| Copper |

High | Soft, conductive, prone to deformation if uncontrolled | Electrical, electronics, decorative components |

| Mild Steel |

Very High | Ductile, low cost, clean punching results | Consumer products, equipment manufacturing |

| Other Alloys |

Varies (depends on alloy type) | May require specialized tools or setups | Aerospace (Titanium), marine (Brass), electronics |

This table helps manufacturers and engineers quickly evaluate material options for sheet metal punching based on their specific production needs. For more guidance on material selection and metal CNC machining parts, check out our CNC machining materials page or contact VMT’s CNC machining experts directly.

When choosing sheet metal punching as a manufacturing method, it’s important to consider factors beyond just the type of metal. Key elements such as production volume, material thickness, and desired surface finish play a critical role in determining the effectiveness and efficiency of the punching process.

Production Volume:

Sheet metal punching excels in medium to high-volume production runs. Because punching uses specialized dies and tooling, the initial setup cost can be significant. However, once set up, it enables rapid, repeatable, and consistent hole or shape creation, making it highly cost-effective for large batches. For low-volume or prototype work, alternative methods like laser cutting or manual punching may be more economical due to lower upfront costs.

Material Thickness:

The thickness of the sheet metal is a major factor in punchability. Most punching machines handle thin to medium gauge metals efficiently, typically ranging from 0.5mm up to around 6mm, depending on the equipment and tooling used. Thicker metals require more robust punch presses and tooling to maintain precision without damaging the material or the machine. It’s essential to match the punch press capacity to the metal thickness for optimal performance and to avoid excessive wear.

Surface Finish:

Surface finish after punching can vary depending on material type, thickness, and the quality of tooling. Well-maintained punches and dies can produce clean edges with minimal burrs, reducing the need for additional finishing operations. For applications requiring high-quality surface finishes, secondary processes like deburring or polishing might be necessary. Maintaining tooling sharpness and using proper lubrication can also enhance the surface finish quality and extend tool life.

Understanding these considerations ensures that sheet metal punching is applied efficiently, minimizing production costs while maintaining quality standards. For more detailed insights on sheet metal CNC machining and related processes, explore our guide on sheet metal fabrication services at VMT.

Effective sheet metal punching requires not only the right equipment and materials but also a strategic approach to ensure quality, efficiency, and longevity of both the parts and tools. By following proven strategies, manufacturers can optimize their punching process and avoid common issues.

Calculate the Maximum Inner Bend Radius:

Before punching, it’s essential to understand the bending limitations of the sheet metal. Calculating the maximum inner bend radius helps avoid cracks or deformities around punched holes or shapes, especially near bends. This ensures that the punched parts maintain their structural integrity and meet design specifications, which is crucial for applications demanding high precision and durability.

Minimize Heat Generation to Prevent Galling:

During punching, friction between the punch and sheet metal generates heat, which can cause galling—a form of material transfer or surface damage where metal sticks to the tooling. Minimizing heat through proper lubrication, selecting suitable punch speeds, and using sharp tooling extends tool life and maintains clean, burr-free edges. Galling not only reduces product quality but also increases downtime for maintenance and tool replacement.

Make Simple Holes with Laser Cutting:

For intricate or very small holes, combining punching with laser cutting can be a smart strategy. While punching is fast and cost-effective for standard hole sizes, laser cutting offers superior precision and the ability to create complex hole patterns without physical contact or tool wear. Using laser cutting for fine features reduces punch wear and improves overall part quality.

Deburr After Punching:

Even with precise tooling, burrs—small rough edges or residual material—are common after punching. Deburring processes, such as grinding or tumbling, improve surface finish, prevent injury during handling, and prepare parts for subsequent finishing operations like painting or coating. Regular deburring enhances product appearance and functionality, especially in industries like aerospace and medical device manufacturing where surface quality is critical.

By implementing these strategic approaches, sheet metal punching becomes more reliable and efficient, contributing to higher quality metal CNC machining parts. For comprehensive insights on punching techniques and CNC machining services, visit our sheet metal CNC machining resources at VMT.

Common Problems and Solutions for Sheet Metal Punching

Sheet metal punching is a widely used process in metal CNC machining parts manufacturing, prized for its speed and precision. However, like any manufacturing technique, it comes with challenges that can affect the quality and efficiency of production. Understanding common problems and their solutions is essential for achieving optimal results in sheet metal punching.

Burr Formation on the Edge of the Punched Hole

Burrs are unwanted raised edges or small pieces of material that remain attached to the punched holes. They can affect the part’s fit, finish, and safety. Burr formation often results from dull punch tools, improper clearance between punch and die, or excessive punching speed. To solve this, regular maintenance and sharpening of punch tools are critical. Adjusting the clearance to the material thickness ensures cleaner cuts. Additionally, deburring processes like grinding or tumbling can remove burrs and improve the surface finish of metal CNC machining parts.

Misaligned or Inaccurate Holes

Accurate hole placement is crucial in sheet metal fabrication, especially for parts that require tight tolerances. Misalignment or inaccurate holes usually stem from improper machine setup, worn tooling, or incorrect programming in CNC punching. Ensuring that the punch press is correctly calibrated and that tools are replaced when worn helps maintain precision. Also, verifying CNC programs through simulation before production reduces errors. Using quality CNC machining services and experienced operators at reputable CNC machining factories, like VMT, further minimizes the risk of misalignment.

Excessive Noise or Vibration

Noise and vibration are common issues in punching operations, often caused by loose tooling, incorrect press speed, or improper maintenance. These problems not only disrupt the working environment but can also damage equipment and reduce part quality. To address this, secure all tooling properly and operate machines at recommended speeds. Regular preventive maintenance helps identify and fix worn parts before they cause excessive vibration. Using advanced CNC punching technology also reduces operational noise and improves stability.

By addressing these common issues with proactive solutions, manufacturers can ensure efficient, precise, and high-quality sheet metal punching. For further guidance, explore our detailed content on sheet metal CNC machining and related metal CNC machining parts services offered by VMT.

Achieving optimal results in sheet metal punching is essential for producing high-quality metal CNC machining parts efficiently. While the process itself is well-established, small improvements in equipment maintenance, machine settings, and material handling can significantly boost productivity and part quality. Here are some key tips to help you enhance your sheet metal punching operations.

Optimize Tool Maintenance

Regular maintenance of punch and die tools is critical to maintaining precision and prolonging tool life. Dull or damaged tools can cause poor-quality holes, burrs, and increased scrap rates. Implementing a routine inspection and sharpening schedule ensures that tools remain sharp and properly aligned. Additionally, using high-quality tool materials and coatings can extend tool durability, reducing downtime and production costs in CNC machining services.

Manage Punch Press Settings

The correct configuration of punch press parameters directly impacts the quality of punched parts. Adjusting press speed, stroke length, and clearance between punch and die based on the material type and thickness optimizes the punching process. Overly fast speeds or improper clearance can lead to defects like burrs or misaligned holes. Fine-tuning these settings helps achieve cleaner cuts and better repeatability, essential for manufacturing metal CNC machining parts with tight tolerances.

Material Handling Practices

Proper handling and preparation of sheet metal before punching are equally important. Ensure materials are clean, flat, and free from contaminants that could affect punching accuracy or cause machine jams. Organizing materials in manageable batches reduces the risk of damage during loading and unloading. Furthermore, using automation where possible to feed materials into the punch press improves consistency and throughput, aligning with modern CNC machining factories' efficiency standards.

By focusing on these tips—tool maintenance, machine settings, and material handling—you can significantly enhance the quality and efficiency of your sheet metal punching operations. For more insights into CNC machining and metal fabrication techniques, visit our CNC machining services and explore how VMT supports precision manufacturing with advanced technology.

In the world of metal CNC machining parts manufacturing, sheet metal punching is a widely used technique due to its speed and precision. However, it is not the only method available for creating holes or shapes in sheet metal. Laser cutting has emerged as a powerful alternative, offering unique advantages that may be better suited for certain applications. Understanding when to choose laser cutting over traditional punching can help you optimize production efficiency, quality, and cost.

Laser cutting uses a focused laser beam to melt, burn, or vaporize material with extreme accuracy. Unlike mechanical punching, which physically forces a punch through the metal, laser cutting is a non-contact process. This means it can handle complex shapes, very small holes, and delicate materials with minimal mechanical stress or deformation. Laser cutting also produces a smooth edge finish that often requires less secondary processing, saving time and labor costs.

For applications where design complexity is high, or materials are thin and prone to distortion, laser cutting is often preferred. It also excels in small batch production or prototyping due to its flexibility and quick setup times. However, laser cutting equipment typically involves higher upfront investment and operational costs compared to punching, which can impact cost considerations for large-volume manufacturing.

At VMT, our CNC machining factories are equipped with both advanced sheet metal punching and laser cutting technologies, allowing us to recommend and provide the best solution tailored to your specific project requirements. For a deeper dive into laser cutting and other metal fabrication processes, feel free to explore our page on metal CNC machining parts.

Choosing the right process depends on your product design, volume, material, and budget. Continue reading to discover more about the detailed operations of sheet metal punching, or learn about CNC punching machine types that might fit your needs better.

When it comes to sheet metal CNC machining and fabrication, choosing the right punching method is crucial for efficiency, precision, and cost-effectiveness. Manual and automatic sheet metal punching are two common approaches, each with distinct features and best-use scenarios. Understanding their differences will help you select the ideal process for your metal CNC machining parts and production needs.

Manual sheet metal punching involves an operator physically controlling a punch press to create holes or shapes in the metal. This method is typically suited for low-volume jobs, prototype development, or simple shapes where flexibility and hands-on control are important. Manual punching offers the advantage of lower equipment costs and easy setup but is labor-intensive, slower, and less precise compared to automated systems. It also requires skilled operators to ensure accuracy and reduce errors.

On the other hand, automatic sheet metal punching employs CNC (computer numerical control) technology to operate punch presses with minimal human intervention. This process excels in high-volume production, delivering consistent precision, repeatability, and faster throughput. CNC punching machines can handle complex patterns and multiple punching operations in a single cycle, significantly reducing production time and labor costs. The initial investment and maintenance costs are higher, but the overall efficiency gains often justify the expense for large-scale manufacturing.

At VMT, our CNC machining services include both manual and automatic sheet metal punching options, tailored to suit various production scales and complexity levels. For projects requiring high precision and volume, our CNC punching capabilities ensure superior quality and consistency. To explore more about punch press types, visit our detailed guide on choosing the right punch press.

If you want to learn about other sheet metal fabrication methods, check out our articles on sheet metal cutting processes and metal CNC machining factories for comprehensive insights.

Sheet metal punching involves pressing a shaped tool through the metal to create holes or cutouts, while sheet metal shearing cuts straight lines across a metal sheet using a blade without removing material. Punching is ideal for complex geometries; shearing is best for straight cuts and high-speed trimming.

Understanding the Basics: What Is Sheet Metal Punching?

Sheet metal punching is a fabrication process where a punch and die set is used to forcefully pierce through metal to create holes, shapes, or contours. The punching tool removes material, leaving behind clean-edged features in various shapes such as circles, squares, and slots.

This method is commonly used in high-volume production runs where repeated, uniform cutouts are needed. Punch presses may be mechanical or CNC-controlled, providing flexibility for automation and design complexity.

Applications:

Key Benefits:

What Is Sheet Metal Shearing?

Sheet metal shearing involves cutting sheet metal along a straight line by applying a high-force blade against the material, much like a pair of scissors. Unlike punching, shearing does not remove material; it separates it along the desired line.

Shearing is widely used for trimming edges, cutting sheets to size, or producing rectangular and square blanks quickly. The process offers high throughput and minimal tooling costs, especially for simple geometries.

Applications:

Key Benefits:

Key Differences Between Sheet Metal Punching and Shearing

| Feature |

Sheet Metal Punching |

Sheet Metal Shearing |

| Cut Type |

Holes and complex shapes | Straight lines only |

| Material Removal |

Yes (material is punched out) | No (material is separated) |

| Tooling Requirements |

Requires punch and die sets | Uses a single blade |

| Design Flexibility |

High (custom cutouts possible) | Limited to straight-line cuts |

| Production Speed |

High, depending on CNC automation | Very high for straight trimming |

| Waste Generation |

More (scrap from holes and cutouts) | Minimal |

| Ideal For |

Perforated parts, vent holes, mounting slots | Cutting sheets to size, trimming excess |

Choosing the Right Method: Factors to Consider

When deciding between punching and shearing, consider these factors:

Common Challenges in Punching and Shearing

| Method |

Challenges |

| Punching |

Tool wear, burr formation, alignment issues, higher noise |

| Shearing |

Blade dulling, edge distortion, limitations in shape variety |

Conclusion: Optimize Based on Project Needs

In the debate between sheet metal punching vs. sheet metal shear, there’s no one-size-fits-all answer. Punching offers design flexibility and is ideal for detailed patterns and repetitive shapes. In contrast, shearing shines in speed and simplicity when straight-line cuts are all that's needed.

To choose the best method, evaluate your project’s design requirements, production volume, budget, and material specifications. Working with experienced CNC processing services ensures you select the most efficient approach to meet your manufacturing goals.

Introduction: Why Is Power Calculation Crucial for Sheet Metal Punching?

If you're operating or selecting a sheet metal punching machine, estimating the required punching power is critical to avoid underpowered equipment, excessive tool wear, or inefficient production. Whether you're working in CNC fabrication or custom metal stamping, an accurate power calculation ensures the machine can handle your material’s thickness and punching diameter with the right force.

Many engineers and production managers overlook this step—leading to delays, poor part quality, or even equipment failure. This guide provides a practical, step-by-step approach to calculating the punching force and power for sheet metal operations.

Featured Snippet Excerpt:

To calculate punching power for sheet metal, use the formula:

This ensures your punching machine has enough capacity to cleanly pierce the material without damage.

The Basic Formula for Punching Force

The required punching force (also called cutting force) can be calculated using this standard formula:

Punching Force (F) = L × t × τ

Where:

Step-by-Step Example: Punching a 10 mm Hole in Mild Steel

Let’s say you want to punch a 10 mm diameter round hole in a 2 mm thick mild steel sheet. The shear strength of mild steel is approximately 400 N/mm².

Step 1: Calculate Perimeter (L)

A circular hole’s perimeter = π × diameter = 3.14 × 10 = 31.4 mm

Step 2: Multiply by thickness (t)

31.4 mm × 2 mm = 62.8 mm²

Step 3: Multiply by shear strength (τ)

62.8 mm² × 400 N/mm² = 25,120 N = 25.12 kN

Result: A punching force of approximately 25.12 kN is needed.

Material Shear Strength Reference Table

| Material |

Approx. Shear Strength (N/mm²) |

| Aluminum | 150–200 |

| Mild Steel | 350–450 |

| Stainless Steel | 500–700 |

| Copper | 200–250 |

| Brass | 250–350 |

| Always check with the material supplier for exact values. | |

Additional Considerations for Machine Power Calculation

Safety Factor: Add 10–20% to the result to account for wear, clearance, or dynamic load variation.

Machine Tonnage: Convert the result from kilonewtons to tons.

Multiple Holes or Shapes: For multi-hole punching, calculate the force for each shape and sum them up.

Tool Shape and Clearance: Complex or irregular shapes may require more force due to uneven load distribution.

Conclusion: Get Accurate Power Specs Before You Punch

Proper power calculation is non-negotiable in sheet metal punching. It ensures that your equipment is capable, your tooling lasts longer, and your production runs efficiently. By applying the simple formula and adjusting for real-world variables, you can confidently select or set up your CNC punching machine for optimal results.

Choosing Sheet Metal Punching Tool Service: Which Tool Is Right for Your Job?

Introduction: Struggling to Pick the Right Punching Tool for Sheet Metal?

Choosing the correct sheet metal punching tool can make or break the success of your project. Use the wrong tool, and you could end up with jagged holes, damaged parts, or wasted material—not to mention lost time and higher costs. Whether you're prototyping, running a small-batch job, or managing high-volume fabrication, the decision between a twist drill, hole saw, manual punch, or punch press with dies can be confusing.

This guide compares the most common punching tools for sheet metal, helping you match the right service and tool to your specific needs—by material thickness, hole size, production volume, and precision requirements.

Twist Drill for Sheet Metal Punching

Twist drills are common in workshops and often used for drilling small holes in thin sheet metal. They cut by rotating and shearing through the material, typically using a drill press or hand drill.

Best For:

Pros:

Cons:

Hole Saw for Sheet Metal Punching

Hole saws cut larger diameter holes by using a serrated, circular blade mounted on a drill. Unlike twist drills, hole saws remove a ring of metal rather than the full core.

Best For:

Pros:

Cons:

Portable Manual Punch

Portable manual punches use hand-lever action to pierce holes in sheet metal without drilling or sawing. They use interchangeable dies and are suited for thin metals.

Best For:

Pros:

Cons:

Punch Press for Sheet Metal

A punch press is a machine-driven system—manual, mechanical, or hydraulic—that uses dies to cut or form holes in sheet metal. These are standard in fabrication and CNC punching operations.

Best For:

Pros:

Cons:

Punching Die: Precision Tooling for Punch Presses

Punching dies are custom or standard toolsets used with a punch press. The die determines the shape and size of the hole, making it critical for custom parts or repeatable features.

Best For:

Pros:

Cons:

Tool Comparison Table

| Tool |

Best For |

Thickness Range |

Speed |

Precision |

Volume Suitability |

| Twist Drill | Small holes, general use | Up to 3 mm | Low | Medium | Low |

| Hole Saw | Large holes, electrical | Up to 3 mm | Low | Low | Low |

| Manual Punch | Fieldwork, control panels | Up to 2 mm | Medium | Medium | Low-Medium |

| Punch Press | Industrial production | Up to 10 mm+ | High | High | High |

| Punching Die | Custom part production | Varies | High | Very High | High |

Choosing the Right Service: What to Consider

Before selecting a sheet metal punching service or tool, consider:

Conclusion: Match the Tool to the Job

The ideal sheet metal punching tool depends on your material specs, production needs, and precision goals. For small jobs or field adjustments, manual punches, twist drills, and hole saws may suffice. For high-volume or high-precision work, a punch press with the correct punching die is the gold standard.

Choosing the right punching tool service ensures clean cuts, reduced waste, and cost-effective production—especially when working with experienced CNC processing services or sheet metal fabrication factories.

Introduction: Struggling to Find Reliable CNC Sheet Metal Punching Services?

In today’s fast-paced manufacturing environment, sourcing precise, high-quality sheet metal punching CNC machining parts can be a challenge. Inconsistent tolerances, poor surface finishes, and missed deadlines can cripple your production line or ruin end-product quality.

That’s where VMT steps in.

VMT provides advanced CNC punching services tailored to your sheet metal component needs, whether you require high-volume production or custom prototypes. Our services combine speed, precision, and cost-efficiency—designed for industries ranging from automotive to consumer electronics.

VMT offers precision sheet metal punching CNC machining parts services, using automated CNC punch presses and custom tooling to deliver high-accuracy components with tight tolerances and fast lead times.

Why Choose VMT for CNC Sheet Metal Punching?

At VMT, we specialize in CNC-controlled sheet metal punching, a process that uses programmable machines and precision dies to create complex holes, slots, and patterns in a wide range of metals. Our capabilities include:

Whether you need aluminum enclosures, stainless steel brackets, or mild steel frames, VMT ensures every part is produced to spec—on time, every time.

Our Sheet Metal Punching Capabilities

| Parameter |

Specification |

| Material Thickness | 0.5 mm – 10 mm |

| Materials Supported | Aluminum, Stainless Steel, Mild Steel, Copper |

| Hole Shapes | Round, square, rectangular, slotted, custom |

| Max Sheet Size | Up to 1250 mm × 2500 mm (varies by press) |

| Tolerance | ±0.05 mm (typical) |

| Production Volume | Low-volume prototyping to mass production |

We use CNC turret punching machines equipped with multi-station rotary tools to minimize setup time and maximize flexibility—perfect for batch variations and quick design changes.

Applications of Sheet Metal Punching CNC Machining Parts

VMT supplies punched metal components for industries such as:

Each component is punched to high standards with optional deburring, powder coating, anodizing, or secondary CNC milling to meet your design and performance requirements.

Why CNC Punching Over Other Methods?

Compared to laser cutting or manual punching, CNC punching offers unique advantages for many production runs:

| Feature |

CNC Punching |

Laser Cutting |

| Speed (High Volume) | Faster for holes and repetitive patterns | Slower for hole-heavy components |

| Cost Efficiency | Lower tooling cost for repeat runs | Higher cost for prototypes |

| Edge Quality | Clean edges with minimal burr | Requires post-processing |

| Forming Capability | Can punch, emboss, and bend | Cutting only |

For projects requiring multiple holes, consistent spacing, and high productivity, CNC punching is often the superior choice—especially when done by experienced providers like VMT.

Every CNC punched part at VMT undergoes strict quality checks including:

We also provide DFM (Design for Manufacturability) feedback, helping customers optimize designs for punching, reduce tooling costs, and accelerate time to market.

Get Started with VMT's Sheet Metal Punching CNC Machining Services

Whether you need custom metal parts, high-volume production, or precision prototyping, VMT is ready to deliver:

Ready to start your project?

Contact VMT today to request a quote for sheet metal punching CNC machining parts—engineered for accuracy, built for performance.

In conclusion, sheet metal punching stands out as a vital and versatile process within the metal fabrication industry, offering unmatched speed, precision, and efficiency for producing complex metal components. Whether for automotive, aerospace, medical, or industrial applications, the right selection of punching techniques and machinery—ranging from manual to advanced CNC punch presses—can significantly impact production quality and cost-effectiveness. While there are challenges such as noise, burr formation, and upfront equipment costs, the benefits of minimal waste, repeatability, and compatibility with a wide range of metals make sheet metal punching an indispensable solution. At VMT, we combine cutting-edge CNC machining services with expert knowledge in sheet metal punching to deliver superior metal CNC machining parts tailored to your specific needs. By choosing the right punch press, optimizing operations, and leveraging advanced technologies, manufacturers can achieve high-quality, reliable parts with consistent performance. For those looking to streamline their metal fabrication process, understanding and utilizing sheet metal punching effectively can be the key to driving innovation and competitiveness in today’s manufacturing landscape.

1. How do I choose the right punch and die for my job?

Choosing the right punch and die depends on the material type, thickness, hole shape, and production volume. For tight tolerances and repetitive operations, CNC-compatible hardened steel dies are ideal. Always match punch/die clearance to material thickness to prevent tool wear or deformation.

2. How thick metal can a standard punch handle?

Standard manual or mechanical punches can typically handle sheet metal up to 3–6 mm thick, depending on the punch size and material hardness. Hydraulic and CNC punch presses can handle up to 10 mm or more with appropriate tooling.

3. How often should I service my punch?

Punch tools should be inspected and sharpened after every 5,000–20,000 hits, depending on material hardness and frequency of use. Regular lubrication, alignment checks, and die wear inspection help extend tool life and ensure precision.

4. What does metal stamping mean?

Metal stamping is a cold-forming process where sheet metal is shaped or cut using dies and presses. It includes operations like punching, blanking, embossing, bending, and coining—commonly used in high-volume automotive and appliance manufacturing.

5. What is the difference between punching and blanking?

Punching removes scrap material from the workpiece to create a hole.

Blanking removes the desired part from the sheet, and the blank is the usable component. Both processes use similar equipment but yield different results.

6. How to punch a hole in sheet metal?

You can punch a hole using manual punches, a CNC punch press, or a portable hand-punch tool. Choose the punch size, align the sheet, apply force (or start the CNC cycle), and remove the punched slug. Proper die clearance is crucial to avoid deformation.

7. What is the process of punching?

Punching involves pressing a punch through sheet metal using a die beneath. The punch shears through the material, creating a clean hole and ejecting the scrap slug. This is often automated in CNC turret punch presses for repeatability and speed.

8. How to perforate sheet metal?

Perforation is done using a punch press with a die set designed to create multiple holes in a specific pattern. CNC machines can be programmed to produce uniform, intricate, or decorative perforations across large sheets.

9. What is the method of punching a hole in a perforated sheet?

Punching into perforated sheet metal requires special care to avoid deforming existing holes. Use precision punches, slow feed rates, and lower force settings. Custom dies may be needed to maintain structural integrity.

10. What is the sheet metal slitting operation?

Slitting is a continuous cutting process where a coil or sheet is passed through circular blades to divide it into narrower strips. It is used for coil preparation, custom widths, or feeding roll-forming and stamping lines.

11. How to punch holes in metal at home?

For DIY or light-duty projects, use a hand punch, drill with metal bit, or hole saw. Always clamp the metal, wear safety gear, and lubricate the tool to reduce heat and burrs.

12. What is a metal stamping tool?

A metal stamping tool refers to the die and punch system used in press machines to cut, form, or shape sheet metal. These tools are often custom-designed for specific parts and include progressive dies, compound dies, and blanking dies.

13. What is the purpose of slotting?

Slotting creates long, narrow openings in sheet metal, typically for ventilation, cable routing, or part assembly. It is performed using rectangular punches and corresponding dies in a CNC punch press.

14. What is the perforation operation in sheet metal?

Perforation involves punching multiple small holes in a sheet, often arranged in rows or grids. It's used for filtration, airflow, aesthetics, or weight reduction. CNC punch presses are ideal for high-precision perforation.

15. What is the process of metal slitting?

Metal slitting cuts wide coils into narrower ones using rotary slitter knives. The process involves uncoiling, slitting, and recoiling into smaller rolls, useful for custom-sized feedstock in roll forming or stamping.

16. What is the purpose of perforated metal?

Perforated metal enhances functionality by allowing airflow, drainage, sound absorption, or weight reduction. It's widely used in architectural panels, filters, speaker grills, and machine guards.

17. How to use perforated sheet metal?

Perforated sheets can be cut, bent, and fabricated like standard sheet metal. They are used in ventilation systems, screens, facades, enclosures, decorative elements, and industrial guards. Proper edge finishing helps maintain structural integrity.