15 years one-stop China custom CNC machining parts factory

184 |

Published by VMT at Jun 03 2025 | Reading Time:About 3 minutes

184 |

Published by VMT at Jun 03 2025 | Reading Time:About 3 minutes

What is bakelite CNC machining?

Manufacturers often encounter difficulties in sourcing materials that effectively combine heat resistance, electrical insulation, and durability. These challenges can result in production inefficiencies and reduced product quality. If you're facing such issues, Bakelite CNC machining provides an ideal solution. By leveraging advanced CNC machining services and the exceptional properties of Bakelite, this process delivers dependable, high-quality components. Whether you're collaborating with a CNC machining factory or managing in-house production, Bakelite CNC machining ensures consistent and superior results.

Bakelite is a groundbreaking material that revolutionized manufacturing and continues to play a vital role in modern industries. Known for its exceptional properties, it is a thermosetting phenol formaldehyde resin that offers unmatched heat resistance, electrical insulation, and durability. These characteristics make it a preferred choice for creating precision components through processes like bakelite CNC machining.

Overview of Bakelite

Bakelite, often referred to as the "material of a thousand uses," was the first synthetic plastic ever created. Its invention in 1907 by Belgian chemist Leo Baekeland marked the beginning of the modern plastics industry. Unlike thermoplastics, Bakelite retains its shape and strength even under extreme heat, making it ideal for high-performance applications. Over the years, it has been used in everything from electrical insulators to automotive parts, showcasing its versatility and reliability.

Fun Fact: The 'Volksempfänger' radio, a product made from Bakelite, became a cultural icon in the mid-20th century, demonstrating the material's practical and aesthetic appeal.

Key Properties of Bakelite

Heat Resistance

Bakelite excels in environments where high temperatures are a concern. It can withstand temperatures up to 300°C without losing its structural integrity. This property makes it indispensable in industries like automotive and electronics, where components often face thermal stress. For instance, Bakelite is commonly used in heat-resistant parts such as engine components and electrical insulators.

Electrical Insulation

One of Bakelite's standout features is its excellent electrical insulating properties. This makes it a go-to material for manufacturing electrical insulators, circuit board components, and other parts that require high dielectric strength. Its ability to prevent electrical conduction ensures safety and reliability in critical applications.

Durability and Rigidity

Bakelite's mechanical robustness sets it apart from other materials. It offers high compressive strength and rigidity, making it suitable for applications that demand durability under mechanical stress. Its resistance to chemicals further enhances its longevity, ensuring that components remain functional even in harsh environments.

| Property |

Description |

| Type |

Thermosetting resin |

| Electrical Insulation |

Excellent electrical insulating properties |

| Heat Resistance |

High resistance to heat, maintaining integrity under thermal stress |

| Chemical Resistance |

Resistant to various chemicals, enhancing durability |

| Mechanical Robustness |

Strong and durable, suitable for various applications |

| Appearance |

Available in various colors, from dark brown to bright hues |

| Cultural Significance |

Represents the beginning of the modern plastics industry and mass production |

Why Bakelite is Suitable for CNC Machining

Bakelite's unique properties make it an excellent candidate for CNC machining. Its rigidity and compressive strength allow for precise cutting and shaping, ensuring high-quality results. Additionally, its thermal resistance enables it to withstand the heat generated during machining processes. Compared to metals like steel and aluminum, Bakelite offers cost-effectiveness without compromising performance. It also outperforms many high-performance plastics, such as PEEK and PTFE, in terms of affordability and machinability.

When you choose bakelite CNC machining, you gain access to a material that combines mechanical strength, thermal stability, and cost efficiency. This makes it a practical choice for industries ranging from electronics to automotive manufacturing.

Definition and Basics of CNC Machining

CNC machining is a manufacturing process where computers control machine tools to produce parts with exceptional precision. Unlike manual machining, CNC machining automates operations, ensuring consistent quality and efficiency. This process is widely used in industries requiring tight tolerances, such as aerospace and medical device manufacturing.

Key components of CNC machining include:

The programming languages G-code and M-code play a crucial role. G-code controls the movement and positioning of tools, while M-code manages auxiliary functions like coolant flow and tool changes. Together, they enable precise and efficient machining.

Tip: CNC machining is ideal for producing complex parts with high accuracy, making it a cornerstone of modern manufacturing.

How CNC Machines Operate

Computer-Controlled Precision

CNC machines operate by following pre-programmed instructions, ensuring unparalleled precision. Once you input the design specifications, the machine executes the commands with minimal human intervention. Advanced algorithms and real-time monitoring systems enhance performance, allowing for dynamic adjustments during operations. This ensures that every part meets exact specifications, even in large-scale production.

Tools and Techniques Used

CNC machining employs a variety of tools and techniques to achieve desired results. Common tools include end mills, drills, and turning tools, each designed for specific tasks like cutting, shaping, or finishing. Techniques such as multi-axis machining enable the creation of intricate designs by allowing tools to move in multiple directions.

|

Evidence Type |

Description |

| Case Studies |

Real-world examples of intelligent control systems improving CNC operations. |

| Operational Data |

Insights into advanced algorithms enhancing machining performance. |

| Predictive Maintenance |

Use of sensors for real-time monitoring and dynamic adjustments. |

These tools and techniques make CNC machining a versatile and reliable process for manufacturing high-quality components.

Benefits of CNC Machining for Bakelite

CNC machining offers several advantages when working with Bakelite. Its precision ensures that you can create intricate designs without compromising the material's structural integrity. The process minimizes waste, making it cost-effective for large-scale production. Additionally, CNC machining enhances system reliability, reducing operational disruptions and maintenance costs.

| Benefit |

Quantifiable Improvement |

| Uptime |

30% increase |

| Maintenance Costs |

20% reduction, saving $2 million |

| Replacement Frequency |

50% reduction |

| System Reliability |

30% improvement |

| Operational Disruptions |

Reduced significantly |

By combining the unique properties of Bakelite with the precision of CNC machining, you can achieve superior results in industries like electronics and automotive manufacturing. This synergy makes bakelite CNC machining a preferred choice for creating durable and high-performance components.

Preparing Bakelite for Machining

Material Selection and Preparation

Selecting the right Bakelite material is the first step in ensuring a successful machining process. You need to evaluate the specific requirements of your project, such as thermal resistance, electrical insulation, and mechanical strength. Bakelite comes in various grades, each tailored for different applications. For instance, electrical-grade Bakelite is ideal for insulators, while mechanical-grade Bakelite works well for structural components.

Once you’ve chosen the appropriate grade, proper preparation is essential. Start by inspecting the material for any surface defects, such as cracks or voids, which could compromise machining quality. Cleaning the Bakelite surface is equally important to remove dust, grease, or other contaminants. This ensures that the material interacts smoothly with the cutting tools, reducing the risk of errors during machining.

Tip: Always store Bakelite in a dry, temperature-controlled environment to prevent moisture absorption, which can affect its properties.

Safety Considerations

Machining Bakelite requires strict adherence to safety protocols. The material can release fine dust particles and fumes when cut or drilled, which may pose health risks if inhaled. To protect yourself and your team, always use proper ventilation systems and wear personal protective equipment (PPE), such as dust masks, safety goggles, and gloves.

Additionally, Bakelite is brittle, so it can chip or crack under excessive force. Ensure that your CNC machine operates at the recommended speeds and feeds to minimize stress on the material. Regularly inspect your tools for wear and tear, as dull tools can generate excessive heat and compromise safety.

Alert: Never machine Bakelite without a dust extraction system in place. Prolonged exposure to phenolic dust can lead to respiratory issues.

Techniques for Machining Bakelite

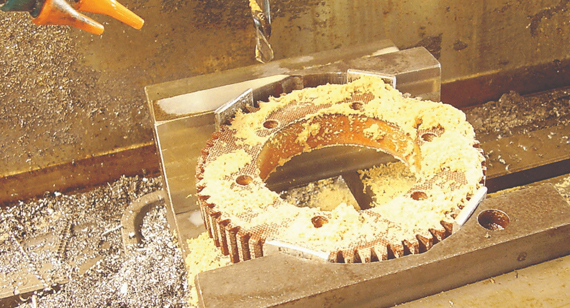

Cutting and Shaping

Cutting and shaping Bakelite require precision and the right tools. Carbide-tipped or diamond-coated tools are highly effective due to their durability and ability to handle the material's hardness. You should use lower cutting speeds to prevent overheating, as excessive heat can cause the material to warp or degrade.

Multi-axis CNC machines are particularly useful for creating complex shapes and contours. These machines allow you to achieve intricate designs with minimal material waste. To enhance accuracy, always secure the Bakelite firmly on the machine bed to prevent movement during cutting.

Pro Tip: Use coolant sparingly when cutting Bakelite. While it helps manage heat, excessive coolant can cause the material to swell or crack.

Drilling and Finishing

Drilling Bakelite requires careful attention to detail. Use sharp, high-speed steel (HSS) or carbide drills to minimize the risk of chipping. Start with a pilot hole to guide the drill and reduce stress on the material. Gradually increase the drill size to achieve the desired diameter, avoiding sudden force that could cause cracks.

Finishing processes, such as sanding and polishing, enhance the final product's appearance and functionality. Use fine-grit sandpaper to smooth rough edges and remove any burrs. For a polished finish, consider applying a lacquer or paint that complements the material's natural aesthetics.

Note: Always test finishing techniques on a small sample of Bakelite to ensure compatibility with the material.

Avoiding Cracks and Chips

Bakelite's brittle nature makes it prone to cracking and chipping during machining. To avoid these issues, you must use sharp tools and maintain consistent cutting speeds. Avoid applying excessive force, as this can stress the material and lead to fractures. Pre-heating the Bakelite slightly can also reduce brittleness, making it easier to machine.

Managing Heat During Machining

Heat management is critical when machining Bakelite. The material's thermal resistance allows it to withstand high temperatures, but prolonged exposure to heat can still cause surface degradation. To manage heat effectively, use tools with high thermal conductivity and apply intermittent cutting techniques. This approach allows the material to cool between cuts, reducing the risk of overheating.

Reminder: Regularly monitor the temperature of your tools and the material during machining. Overheating not only affects the material but can also damage your CNC equipment.

By mastering these techniques and addressing potential challenges, you can achieve exceptional results with bakelite CNC machining. This process allows you to create durable, high-performance components that meet the demands of industries like electronics and automotive manufacturing.

Advantages

High Durability

Bakelite stands out for its exceptional durability, making it a reliable choice for demanding industrial applications. Its resilience reduces the need for frequent maintenance, saving you time and resources. For example, industries using Bakelite have reported up to a 25% reduction in maintenance costs due to its long-lasting performance. This durability ensures that components remain functional even under mechanical stress, enhancing operational efficiency.

| Advantage |

Evidence |

| High Durability |

Bakelite's resilience allows it to excel in demanding industrial environments, reducing maintenance costs by up to 25%. |

Excellent Heat Resistance

Bakelite's ability to withstand extreme temperatures makes it indispensable in industries like automotive and electronics. It maintains its performance even in conditions exceeding 300°C, ensuring safety and reliability. This heat resistance protects components from thermal degradation, allowing them to function efficiently in high-stress environments.

| Advantage |

Evidence |

| Excellent Heat Resistance | Bakelite maintains performance in extreme conditions, ensuring safety and efficiency in industrial applications. |

Cost-Effectiveness

Bakelite offers a cost-effective solution without compromising quality. Its durability reduces the frequency of replacements, aligning with sustainability goals and lowering operational costs. Compared to metals and advanced plastics, Bakelite provides a more affordable option for mass production while delivering comparable performance.

| Advantage |

Evidence |

| Cost-Effectiveness | Its durability leads to fewer replacements, aligning with sustainability goals and reducing operational costs. |

Disadvantages

Brittle Nature

While Bakelite excels in durability, its brittle nature requires careful handling during machining and application. Excessive force or improper machining techniques can lead to cracks or chips. To mitigate this, you should use sharp tools and maintain consistent cutting speeds during the machining process.

Limited Flexibility

Bakelite's rigidity, while beneficial for structural stability, limits its flexibility. This characteristic makes it unsuitable for applications requiring materials that can bend or stretch. However, its rigidity ensures that it retains its shape and strength under mechanical stress, making it ideal for specific use cases.

Environmental Concerns

As a thermosetting resin, Bakelite is not biodegradable, which raises environmental concerns. Its production and disposal require careful consideration to minimize ecological impact. However, its long lifespan and reduced need for replacements contribute to sustainability by lowering overall material consumption.

Note: Despite these limitations, the advantages of Bakelite CNC machining, such as its durability, heat resistance, and cost-effectiveness, make it a preferred choice for many industries.

Bakelite CNC machining has revolutionized the production of components across multiple industries. Its unique properties, such as heat resistance, electrical insulation, and durability, make it indispensable for creating high-performance parts. Below, we explore its applications in the electronics, automotive, and industrial equipment sectors.

Electrical Insulators

Bakelite's exceptional electrical insulating properties make it a top choice for manufacturing insulators. These components are critical in preventing electrical conduction, ensuring the safety and reliability of devices. Bakelite insulators are widely used in switchgear, transformers, and other electrical systems. Certifications like UL 94 HB to V-0 and IEC 60893 validate its flame retardancy and dielectric strength, ensuring compliance with industry standards.

| Certification/Standard |

Description |

| UL 94 HB to V-0 |

Indicates flame retardancy based on filler load. |

| IEC 60893 |

Ensures traceable dielectric and thermal data for Bakelite. |

| RoHS and REACH |

Guarantees safety and environmental compliance for exports. |

Tip: When designing electrical systems, consider Bakelite for its proven performance in insulation and safety.

Circuit Board Components

Bakelite is also a preferred material for circuit board components. Its thermal stability ensures that it can withstand the heat generated during operation without degrading. This makes it ideal for use in connectors, terminal blocks, and other high-stress areas. The material's cost-effectiveness further enhances its appeal for large-scale production in the electronics industry.

Heat-Resistant Parts

In the automotive sector, Bakelite's heat resistance is a game-changer. It is extensively used in components like brake pads, clutch discs, and distributor caps, where high temperatures are a constant challenge. Its ability to maintain structural integrity under thermal stress ensures the safety and efficiency of these parts. As electric vehicles gain popularity, Bakelite's role in battery insulation and thermal management systems continues to grow.

Lightweight Components

Bakelite's lightweight nature, combined with its mechanical strength, makes it an excellent choice for automotive interiors and lightweight components. It reduces the overall weight of vehicles, contributing to improved fuel efficiency and reduced emissions. Applications include ashtray handles, insulation plates, and even decorative trims.

Note: The automotive industry's demand for Bakelite is projected to grow, driven by its role in lightweight and heat-resistant solutions.

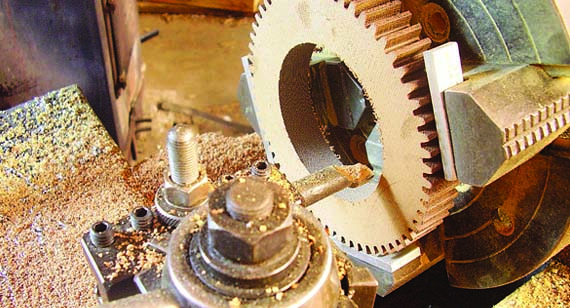

Machine Parts

Bakelite CNC machining enables the production of durable machine parts that can withstand mechanical stress and harsh environments. These parts include jigs, fixtures, and moldings, which are essential for maintaining operational efficiency in manufacturing processes. The material's resistance to wear and corrosion ensures long-lasting performance, reducing downtime and maintenance costs.

| Metric |

Description |

| Production Volume | Meets or exceeds daily quotas for molded parts. |

| Defect Rate | Maintains low defect rates to uphold quality standards. |

| Safety Compliance | Adheres to workplace safety protocols, ensuring secure operations. |

Handles and Knobs

Bakelite's rigidity and aesthetic versatility make it a popular choice for handles and knobs in industrial equipment. These components not only provide functionality but also enhance the visual appeal of machinery. Finishing options like polishing and lacquering allow for customization, ensuring that the final product meets both functional and design requirements.

Pro Tip: Use Bakelite for handles and knobs to combine durability with a professional finish.

Bakelite CNC machining continues to expand its applications across industries, supported by its unmatched properties and cost-effectiveness. Whether you're designing electrical systems, automotive components, or industrial equipment, Bakelite offers a reliable and versatile solution.

Choosing the Right Tools

Selecting the appropriate tools is crucial for achieving precision and efficiency in bakelite CNC machining. Due to Bakelite's hardness and brittleness, carbide-tipped or diamond-coated tools are highly recommended. These tools offer superior durability and can handle the material's unique properties without excessive wear. Sharp tools minimize the risk of chipping and ensure clean cuts, which is essential for maintaining the integrity of the final product.

For drilling, high-speed steel (HSS) or carbide drills work best. These tools reduce stress on the material and prevent cracks during the process. Multi-axis CNC machines equipped with advanced tool holders can further enhance accuracy by allowing complex shapes and contours to be machined with ease.

Tip: Regularly inspect and replace worn tools to maintain consistent machining quality and avoid potential damage to the material.

Optimizing Machining Parameters

Fine-tuning machining parameters is essential for maximizing efficiency and achieving high-quality results. Factors such as cutting speed, feed rate, and depth of cut significantly influence the machining process. For instance, maintaining a cutting speed of 120 m/min, a feed rate of 0.25 mm/rev, and a depth of cut of 0.6 mm has been shown to improve surface quality and dimensional accuracy.

| Parameter |

Effect |

| Cutting Force |

Measured using piezoelectric dynamometer for accuracy. |

| Surface Roughness |

Assessed with Talysurf, indicating the quality of the machining process. |

| Statistical Analysis |

ANOVA used to identify influential parameters on output quality. |

Environmental conditions also play a vital role. A controlled temperature of 20-25°C and humidity levels between 40-60% ensure reliable results. Using coated tools during dry turning can further enhance surface quality while reducing the need for excessive coolant.

Note: Employ statistical methods like the Taguchi design of experiments to optimize parameters and achieve consistent results.

Ensuring Safety and Precision

Safety and precision go hand in hand when machining Bakelite. The material releases fine dust particles and fumes during cutting, which can pose health risks. Always use a dust extraction system and wear personal protective equipment (PPE), including dust masks, safety goggles, and gloves. Proper ventilation in the workspace is equally important to maintain air quality.

Precision depends on the stability of the material and the machine. Secure the Bakelite firmly on the machine bed to prevent movement during operations. Regularly calibrate your CNC machine to ensure it adheres to programmed specifications. Monitoring tool temperatures and using intermittent cutting techniques can also help manage heat, reducing the risk of surface degradation.

Alert: Never compromise on safety measures. Prolonged exposure to phenolic dust can lead to respiratory issues.

By following these tips, you can enhance the efficiency, safety, and quality of your bakelite CNC machining projects. Proper tool selection, parameter optimization, and adherence to safety protocols ensure that you achieve superior results every time.

Bakelite CNC machining offers a reliable way to produce components with exceptional heat resistance, electrical insulation, and durability. Its precision and efficiency make it a preferred choice for industries like electronics, automotive, and industrial manufacturing. By understanding its properties and processes, you can optimize production and achieve superior results. Whether you need electrical insulators or heat-resistant parts, this machining method ensures consistent quality and performance.

What is Bakelite CNC machining used for?

Bakelite CNC machining is used to create precision components for industries like electronics, automotive, and industrial equipment. Applications include electrical insulators, heat-resistant parts, and machine handles. Its durability and thermal stability make it ideal for demanding environments.

How does Bakelite compare to other materials in CNC machining?

Bakelite offers superior heat resistance, electrical insulation, and cost-effectiveness compared to metals and advanced plastics. While it lacks flexibility, its rigidity and machinability make it a preferred choice for high-performance applications.

What tools are best for machining Bakelite?

Carbide-tipped or diamond-coated tools work best for machining Bakelite. These tools handle its hardness and brittleness effectively, ensuring clean cuts and reducing the risk of chipping or cracking.

Can Bakelite withstand high temperatures during machining?

Yes, Bakelite can withstand temperatures up to 300°C without losing its structural integrity. However, managing heat during machining is crucial to prevent surface degradation and ensure precision.

Is Bakelite environmentally friendly?

Bakelite is not biodegradable, but its long lifespan and reduced replacement frequency contribute to sustainability. Proper disposal and recycling practices can minimize its environmental impact.

What industries benefit most from Bakelite CNC machining?

Industries like electronics, automotive, and industrial manufacturing benefit the most. Bakelite's properties make it ideal for electrical insulators, heat-resistant automotive parts, and durable machine components.

How do you ensure safety when machining Bakelite?

Always use a dust extraction system and wear PPE, including masks, goggles, and gloves. Proper ventilation and tool maintenance also enhance safety during machining.

Why is Bakelite considered cost-effective?

Bakelite's durability reduces the need for frequent replacements, lowering operational costs. Its affordability compared to metals and advanced plastics makes it a practical choice for mass production.

Tip: For more insights into Bakelite CNC machining, explore our detailed sections on techniques for machining Bakelite and applications in various industries.