15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

72 |

Published by VMT at Sep 22 2025

72 |

Published by VMT at Sep 22 2025

Monel Alloy, a Ni-Cu alloy, delivers exceptional performance under extreme conditions. CNC machining can provide the exceptional precision required across industries. Manufacturers are increasingly adopting Monel Alloy CNC machining.

The collaboration of Monel Alloy with CNC delivers excellent results by improving Monel Alloy parts’ performance. CNC’s precision also enhances the durability and functionality of Monel Alloy parts. It makes them ideal for demanding applications.

This article contains essential info about Monel Alloy’s composition, physical properties, machining methods, and welding capabilities. You should be able to understand its practical applications and advantages across various industries.

The material in question features the following metals –

Nickel (Ni): 52% - 67%

Copper (Cu): 28% - 34%

Iron (Fe): 1.5% - 2.5%

Manganese (Mn): About 0.8%

Carbon (C): About 0.3%

Silicon (Si): 0.5%

Aluminum (Al) or Titanium (Ti): Trace

Monel Alloy is a solid-solution alloy (Ni and Cu can dissolve in each other).

A higher nickel content improves corrosion resistance and strength, but also accelerates work-hardening.

Cu implies ductility and thermal conductivity. The metal doesn’t compensate for the toughness introduced by nickel.

Iron (Fe) and manganese (Mn) can improve strength and wear resistance. It may also initiate increased tool wear.

Monel Alloy isn’t a single alloy but rather a family of graded nickel-copper alloys. For example –

Monel Alloy 400

Monel Alloy R405

Monel Alloy K-500

Density: 8.80 g/cm³ or 8800 kg/m3

Melting Point: 1300°C – 1350°C (2372°F - 2462°F)

Thermal Conductivity: 21.8 W/m·K

Electrical Resistivity: 0.537 µΩ·m

Specific Heat Capacity: 445 J/kg·K

Curie Temperature: 21°C – 49 °C (70°F – 120°F)

|

Monel Alloy Condition |

Tensile Strength (MPa) |

Yield Strength (MPa) |

Overall Elongation (%) |

|

Annealed (Monel Alloy 400) |

517 – 620 |

172 – 345 |

35 – 60 |

|

Cold-Drawn (Stress-Relieved) |

579 – 827 |

379 – 690 |

22 – 40 |

|

Monel Alloy K-500 (Hardened) |

Up to 1100 |

Around 790 |

About 15 |

Corrosion Resistance

Oxidation Behavior

Galvanic Compatibility

Machining Behavior

Monel Alloy’s almost incomprehensible strength feels like a double-edged sword with CNC machining.

Each machining pass increases hardness. Rapid work-hardening risks tool damage.

Low thermal conductivity may trigger heat buildup. It leads to a poor surface finish.

Built-up edge (BUE) causes chips to adhere to tools, potentially reducing precision.

Modern manufacturers implement distinctive Monel Alloy CNC methods to eliminate the obstacles.

Turning with carbide tools at slow speeds (60 – 100 m/min) enables good feeding rates.

Climb milling with a 30° - 45° helix angle requires robust cooling systems for precision.

Drilling with cobalt/carbide drills provides split-point geometry (peck drilling gets favored).

Wire EDM and Photochemical Machining can accomplish more intricate geometries.

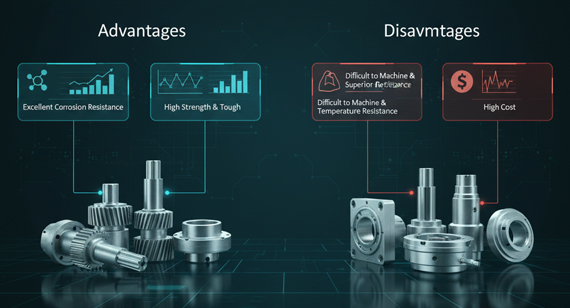

Advantages of Monel Alloy CNC Machining

The material holds impressive resistance against seawater, acids, and alkaline conditions. Reduced pitting and minimal galvanic corrosion result in longer-lasting performance compared to steel. Monel Alloy propeller shafts and hull fittings in naval vessels can last 3x – 5x longer.

Standard Monel Alloy alloys can retain their mechanical integrity over a wide temperature range. CNC Monel Alloy with tight tolerances can withstand high-stress conditions for years.

CNC machining enables high precision, even with tough materials like Monel Alloy. Its advanced features, such as multi-axis capabilities and adaptive feed, help reduce distortion. You can expect consistent dimensional stability for the manufactured Monel Alloy parts.

Highly weldable Monel Alloy alloys can integrate into larger assemblies. CNC-machined Monel Alloy parts, with tight tolerances and compatibility, are ideal for welded structures. Both Monel Alloy 400 and R405 alloys can be welded using TIG, MIG, and resistance welding techniques.

Unsurprisingly, Monel Alloy CNC machining involves higher upfront costs. It primarily comes from the tooling specs and slower feeds. However, you can enjoy reduced maintenance, extended lifespan, and fewer replacement needs.

Disadvantages of Monel Alloy CNC Machining

Monel Alloy’s peculiar characteristics also pose several machining problems. They impact cost, processing efficiency, and material accessibility.

The alloy hardens disturbingly fast under mechanical stress. You’ll need increased cutting forces that may initiate rapid tool wear. Each pass intervenes in tool life while risking potential errors in dimensions.

Concentrated heat leads to a messed-up finish with accelerated degradation. Manufacturers also have to deal with the sticking of chips to cutting tools during low-speed operations.

High nickel (Ni) content and specialized methods make Monel Alloy CNC more expensive. A 7” x 4’ Monel Alloy bar can cost upwards of $12K based on market conditions.

Then there are specialized tools and slower machining to push labor costs. CNC machining Monel Alloy also creates more scraps. It may take additional rework in tight-tolerance parts.

Carbide/cobalt tools are obligatory for custom geometries. A steady cooling system is also necessary to prevent thermal distortion.

Achieving a smooth finish seems burdensome with chips and vibrations. Post-weld heat treatment is called to restore mechanical properties.

Only a few suppliers can produce Monel Alloy. It leads to longer lead times and potential shortages. Variants like Monel Alloy K-500 and R405 are harder to source.

The problem gets worse with custom dimensions or certified batches. Nickel’s price fluctuations can directly impact Monel Alloy pricing and availability.

Toolpath strategy requires adaptive feed control and multi-pass programming. Also, high-rigidity CNC machines with vibration damping are essential.

The operators must possess excellent management and technical skills. Knowledge of alloys, coolant dynamics, and tool wear monitoring is critical.

Marine Industry: Propeller shafts + hull fittings (Monel Alloy 400), fasteners, bolts, seawater valves + pumps.

Aerospace Industry: Rocket fuel system parts, fasteners, connectors, and shielding components.

Oil and Gas Industry: Downhole tools, drill collars, valves + pump components, and heat exchangers.

Chemical Processing Plants: Reactors + pressure vessels, agitators, mixers, and piping systems.

Defense and Nuclear: Submarine components, missile hardware, and nuclear fuel handling equipment.

Medical (Limited): Sterilization equipment, laboratory hardware, dental + orthopedic tooling.

Monel Alloy CNC demands expertise and precision in every stage. It’s possible to accomplish a thriving outcome when executed perfectly. That’s where making suitable Monel Alloy parts for industry-specific uses becomes well worth all those troubles.

Let VMT, a pioneer with 13+ years of experience, handle your demands for CNC-machined parts. Top-notch experts work on innovative solutions to meet project specs thoroughly. Contact us to know why you should partner with VMT from the start.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!