15 years one-stop China custom CNC machining parts factory

75 |

Published by VMT at Oct 14 2025 | Reading Time:About 5 minutes

75 |

Published by VMT at Oct 14 2025 | Reading Time:About 5 minutes

When working with high-performance metals, you may find that nickel alloys are both a blessing and a challenge. Their superior strength, heat resistance, and corrosion resistance make them ideal for demanding industries — but these same properties also make machining them far more difficult than standard materials.

If not handled correctly, machining nickel alloys can lead to excessive tool wear, poor surface finish, and even dimensional inaccuracies. This means higher production costs, more downtime, and wasted materials — all of which can damage your project’s profitability and delivery schedule.

This guide will help you master nickel alloy CNC machining by explaining their properties, machinability, and the best methods and tools to achieve precision and efficiency. Whether you’re machining Inconel, Monel, or Hastelloy, you’ll learn how to reduce tool wear, control heat, and improve your CNC machining tolerances for nickel alloys with confidence.

Nickel alloy CNC machining requires specialized tools, cutting fluids, and precise parameters to handle tough, heat-resistant materials. These alloys—such as Inconel, Monel, and Hastelloy—offer exceptional strength and corrosion resistance but are difficult to machine. Using carbide tools, proper coolant, and optimized cutting speeds ensures accuracy, extended tool life, and cost-effective precision machining results.

Now that you understand why nickel alloys can be challenging to machine, it’s time to look deeper into what makes them unique. By learning about their composition, types, and properties, you’ll be better prepared to choose the right approach for CNC machining of nickel alloys—from tool selection to machining parameters and cooling methods.

Nickel is a tough, silvery-white metal known for its strength, ductility, and excellent resistance to corrosion and heat. It’s a key element used in many high-performance alloys because it enhances durability and stability in extreme environments such as aerospace, chemical processing, and marine engineering.

In CNC machining, nickel provides a strong foundation for creating corrosion-resistant alloys that maintain tight CNC machining tolerances for nickel alloys even under stress. Its ability to form stable compounds with other metals makes it ideal for producing materials that resist oxidation and wear at both high and low temperatures.

Related reading: Explore our CNC Machining Services for Nickel Alloys to learn how precision manufacturing improves material performance.

Nickel alloys are metals that combine nickel with other elements such as chromium, copper, molybdenum, or iron to improve strength, corrosion resistance, and heat stability. These high-performance nickel alloys are engineered to perform under extreme conditions—making them essential in aerospace engines, chemical reactors, and power generation systems.

In CNC machining, nickel alloys offer a balance between toughness and precision. They maintain dimensional accuracy under high stress and temperature, allowing for consistent CNC machining tolerances for nickel alloys in critical parts. Common types include Inconel (nickel-chromium), Monel (nickel-copper), and Hastelloy (nickel-molybdenum), each tailored to specific environments and applications.

Related resource: Learn how advanced nickel alloy CNC machining improves durability in harsh environments — visit our CNC Machining Parts page.

Nickel alloys come in several categories, each designed to meet different industrial needs. These alloys are created by combining nickel with elements like chromium, copper, molybdenum, iron, or titanium to enhance strength, corrosion resistance, or thermal stability.

In CNC machining, understanding each alloy’s composition helps you select the right tools and parameters for optimal results. For example, nickel-chromium alloys excel in high-temperature strength, while nickel-copper alloys perform best in marine environments. The table below summarizes the major types, their key elements, properties, and common models used in nickel alloy CNC machining.

| Nickel Alloy Type |

Key Elements |

Properties |

Common Model Types |

| Nickel-Chromium |

Nickel (Ni), Chromium (Cr) | Excellent oxidation and heat resistance; high strength at elevated temperatures | Inconel 600, Inconel 625, Inconel 718 |

| Nickel-Copper |

Nickel (Ni), Copper (Cu) | Outstanding resistance to seawater and acids; good ductility | Monel 400, Monel K-500 |

| Nickel-Molybdenum |

Nickel (Ni), Molybdenum (Mo) | Exceptional resistance to reducing environments and strong acids | Hastelloy B2, Hastelloy B3 |

| Nickel-Iron |

Nickel (Ni), Iron (Fe) | Controlled thermal expansion; excellent magnetic and mechanical stability | Invar 36, Kovar, Alloy 42 |

| Nickel-Chromium-Iron |

Nickel (Ni), Chromium (Cr), Iron (Fe) | Superior heat resistance and oxidation control; used in turbines and heaters | Incoloy 800, Incoloy 825 |

| Nickel-Titanium |

Nickel (Ni), Titanium (Ti) | Shape memory and superelasticity; ideal for medical and precision components | Nitinol 55, Nitinol 60 |

See also: CNC Milling of Nickel Alloys — learn how to achieve tighter tolerances and smoother finishes on high-performance materials.

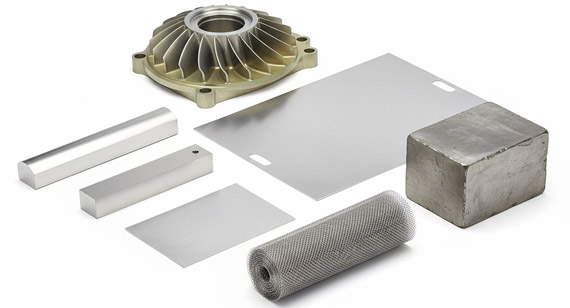

Nickel alloys are available in two main forms: wrought and cast. Each has distinct characteristics that influence their machinability, strength, and cost.

Wrought nickel alloys are mechanically worked into shape through forging, rolling, or extrusion. They offer superior mechanical properties, tighter CNC machining tolerances for nickel alloys, and are preferred for precision parts. Cast nickel alloys, on the other hand, are melted and poured into molds, providing design flexibility and lower manufacturing costs but with slightly reduced strength and ductility.

When selecting the right material for nickel alloy CNC machining, it’s important to balance mechanical performance, production method, and cost considerations.

| Category |

Manufacturing Process |

Key Properties |

Advantages |

Typical Applications |

| Wrought Nickel Alloys |

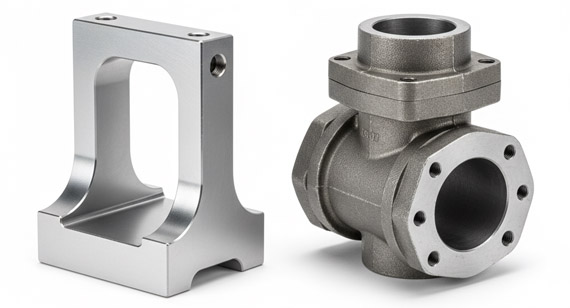

Formed through hot/cold working such as forging, rolling, or extrusion | High strength, excellent ductility, uniform structure | Better mechanical properties, consistent microstructure, ideal for precision machining | Aerospace engine parts, turbine blades, pressure vessels |

| Cast Nickel Alloys |

Produced by melting and pouring into molds, followed by solidification | Good corrosion resistance, moderate strength | Lower cost, complex shape capability, minimal post-processing | Pump housings, valves, chemical processing equipment |

Nickel alloys are categorized into several groups based on their composition and primary performance characteristics. Each group is formulated to meet specific needs—such as corrosion resistance, heat resistance, or strength under high stress. Understanding these classifications helps you select the right material for nickel alloy CNC machining, ensuring both durability and precision in finished parts.

| Group |

Composition Characteristics |

Primary Properties |

Typical Applications |

| Group A – Nickel-Copper Alloys |

Nickel (Ni) + Copper (Cu) | Excellent resistance to seawater and acids; good ductility | Marine hardware, pumps, valves, and heat exchangers |

| Group B – Nickel-Chromium Alloys |

Nickel (Ni) + Chromium (Cr) | High oxidation and heat resistance; maintains strength at elevated temperatures | Gas turbines, exhaust systems, and high-temperature fasteners |

| Group C – Nickel-Molybdenum Alloys |

Nickel (Ni) + Molybdenum (Mo) | Superior resistance to reducing acids and chloride corrosion | Chemical reactors, distillation columns, and piping systems |

| Group D – Nickel-Iron Alloys |

Nickel (Ni) + Iron (Fe) | Controlled thermal expansion and magnetic stability | Precision instruments, electronic components, and glass-to-metal seals |

| Group E – Nickel-Chromium-Iron Alloys |

Nickel (Ni) + Chromium (Cr) + Iron (Fe) | Excellent high-temperature strength and corrosion resistance | Furnace parts, superheater tubes, and aerospace structures |

See also: Learn how CNC machining services for nickel alloys help you achieve reliable performance across all alloy groups — visit VMT CNC Machining.

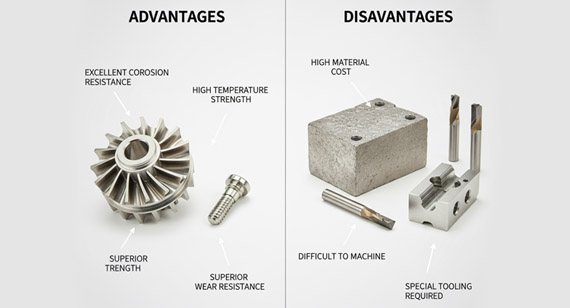

Nickel alloys are widely used in demanding industries because of their exceptional performance under extreme conditions. However, while these high-performance nickel alloys offer many benefits, they also present challenges during CNC machining due to their toughness and work-hardening characteristics. Understanding both sides helps you plan effectively and control production costs.

| Advantages |

Disadvantages |

| Excellent Corrosion Resistance – Ideal for marine, chemical, and high-temperature environments. | Difficult Machinability – High toughness leads to rapid tool wear and requires specialized cutting tools. |

| High-Temperature Strength – Retains mechanical properties even at 1000°C or higher. | Work Hardening – Nickel alloys quickly harden during machining, causing tool chatter or poor finish. |

| Durability and Fatigue Resistance – Perfect for aerospace and energy systems that face stress cycles. | High Machining Cost – Requires carbide or ceramic tools, slow feed rates, and advanced cooling systems. |

| Dimensional Stability – Maintains precise CNC machining tolerances for nickel alloys under stress. | Heat Generation – Excessive heat buildup during machining can damage tools or parts. |

Related content: Learn how advanced nickel alloy CNC machining techniques improve efficiency and extend tool life — explore our Precision CNC Machining Services.

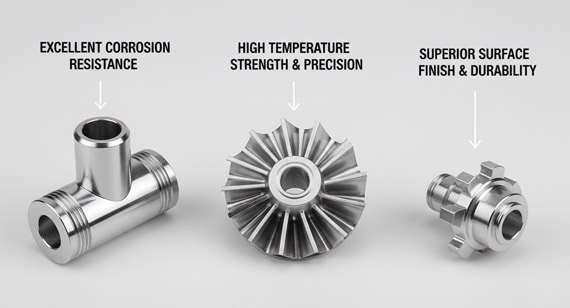

Nickel alloys are known for their ability to perform reliably under harsh environments—combining strength, corrosion resistance, and thermal stability. These unique characteristics make them ideal for industries like aerospace, chemical processing, and marine engineering. When properly managed through CNC machining of nickel alloys, they deliver exceptional precision and durability even under extreme operating conditions.

Nickel Alloys: Chemical Properties

Nickel alloys stand out for their resistance to oxidation, acids, and alkalis. The high nickel content stabilizes the material’s structure, while elements like chromium, molybdenum, and copper enhance corrosion resistance and chemical stability. This allows these alloys to maintain integrity when exposed to aggressive chemicals or high-pressure environments.

Tip: For chemical processing applications, select nickel-molybdenum or nickel-copper alloys — both excel in acid-resistant environments and offer cost-effective CNC machining services for nickel alloys.

Nickel Alloys: Physical Properties

Physically, nickel alloys provide an outstanding balance of strength, ductility, and heat resistance. They retain their structure at temperatures that would weaken most metals and resist deformation under mechanical stress—making them ideal for precision CNC machining and critical applications requiring exact tolerances.

| Property |

Description |

| Density |

Approximately 8.5 g/cm³ — relatively high, contributing to durability and toughness. |

| Melting Point |

Around 1350–1450°C — supports high-temperature machining and service use. |

| Thermal Conductivity |

Low to moderate — heat dissipates slowly, requiring careful coolant management. |

| Electrical Conductivity |

Moderate — allows use in electrical and electronic components. |

| Magnetic Behavior |

Some nickel-iron alloys are magnetic; others remain non-magnetic, depending on composition. |

Nickel alloys are indispensable across industries where strength, corrosion resistance, and heat stability are critical. Their performance in extreme environments makes them a top choice for CNC machining factories producing high-precision parts for aerospace, chemical, marine, and medical fields. By selecting the right alloy, you can optimize both performance and the cost of nickel alloy CNC machining.

Aerospace

Nickel-based superalloys like Inconel 718 and Incoloy 800 are used in jet engines, turbine blades, and exhaust systems. They maintain structural integrity at temperatures above 700°C and resist oxidation. Precision CNC machining of nickel alloys ensures consistent tolerances for these high-stress components.

Chemical Processing

In chemical plants, nickel-molybdenum and nickel-copper alloys (such as Hastelloy and Monel) withstand acids, alkalis, and saltwater corrosion. These alloys are ideal for reactors, heat exchangers, and valves where exposure to aggressive substances is constant.

Oil & Gas

Nickel alloys such as Inconel 625 and Hastelloy C-276 are widely used in offshore drilling, valves, and pipelines. Their high strength and resistance to sulfide stress cracking ensure reliability under high pressure and temperature.

Nickel-titanium (Nitinol) alloys are used in stents, guidewires, and orthodontic devices due to their shape memory and biocompatibility. Their elasticity and strength make them ideal for precision CNC machining of small, complex geometries.

Nickel-iron alloys like Invar 36 and Kovar are used in precision electronic components and semiconductor equipment because of their controlled thermal expansion. These materials maintain stable dimensions under temperature fluctuations.

Marine

Nickel-copper (Monel) alloys are essential for marine pumps, propeller shafts, and seawater valves. They resist corrosion from saltwater and marine organisms, extending equipment life in harsh ocean environments.

Precision Instruments

Nickel alloys with tight thermal expansion control are perfect for measuring instruments and precision fixtures. They ensure consistent accuracy even in environments with varying temperatures and pressures.

Explore more: Visit VMT CNC Machining Services to see how we deliver precision across aerospace, marine, and medical applications.

Table:Nickel Alloys: Applications

Nickel alloys are widely used across many industries due to their exceptional high-temperature strength, corrosion resistance, and workability. The following table summarizes the key applications of different types of nickel alloys:

| Nickel Alloy Type |

Key Applications |

Industry Examples |

| Nickel-Chromium (Ni-Cr) |

High-temperature components, heating elements, gas turbine parts | Aerospace, power generation, industrial furnaces |

| Nickel-Copper (Ni-Cu) |

Seawater systems, chemical processing equipment, heat exchangers, pumps, and valves | Marine engineering, chemical processing, shipbuilding |

| Nickel-Iron (Ni-Fe) |

Magnetic materials, low-expansion alloys, electrical instrument parts | Electronics, electrical, instrumentation |

| Nickel-Molybdenum (Ni-Mo) |

Corrosion-resistant components for strong acid environments, chemical vessels, reactors | Chemical, petrochemical, pharmaceutical industries |

| Nickel-Titanium (Ni-Ti) |

Shape memory components, medical implants, actuators, and sensors | Medical, automotive, robotics, electronics |

| Nickel-Chromium-Iron (Ni-Cr-Fe) |

High-temperature bolts, pressure vessels, nuclear power components | Nuclear energy, power generation, petrochemical |

| Nickel-Based Superalloys (e.g., Inconel, Hastelloy) |

Jet engine blades, gas turbines, turbine casings, chemical reactors | Aerospace, energy, chemical processing |

Nickel is notoriously difficult to machine compared to standard metals like aluminum or mild steel. Its toughness, work-hardening tendency, and low thermal conductivity make cutting and shaping more challenging. Without proper tooling and optimized parameters, you can experience rapid tool wear, surface damage, and poor CNC machining tolerances for nickel alloys.

Despite these challenges, with the right approach, you can achieve precision and efficiency. Using carbide or ceramic cutting tools, controlling feed rates, and applying high-pressure cutting fluids are essential for successful CNC machining of nickel alloy parts.

Nickel alloys are considered challenging to machine due to their high strength, work-hardening behavior, and low thermal conductivity. These factors cause tools to wear faster and generate heat near the cutting zone, which can affect surface finish and dimensional accuracy. CNC machining tolerances for nickel alloys require careful planning to avoid defects such as burrs, chatter, or micro-cracking.

Machinability varies among different nickel alloys:

With proper tooling, coolant management, and cutting parameters, you can achieve high-quality finishes and maintain precision CNC machining even on the toughest nickel alloys.

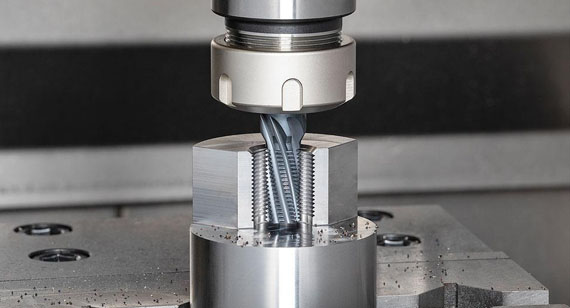

Nickel alloys require specialized machining due to their toughness, work-hardening, and heat retention. Using the right method ensures precision, reduces tool wear, and maintains CNC machining tolerances for nickel alloys.

CNC Turning is commonly used for cylindrical parts. It allows precise shaping but requires careful control of speed, feed, and tool selection to prevent work hardening.

Tool Material Considerations for Turning

Selecting the proper tool material is critical when machining nickel alloys. The right tool improves surface finish, maintains dimensional accuracy, and extends tool life.

Tip: Always match tool material to alloy type and cutting conditions. Using HSS for tough nickel alloys can lead to rapid wear and increased machining cost.

CNC Milling and Sawing

Milling and sawing are essential for shaping nickel alloy parts with complex geometries. These methods allow high precision and good surface finishes when proper tools and parameters are used.

Heavy-Duty Milling

Heavy-duty milling is used for removing large amounts of material efficiently. Carbide or ceramic cutters are preferred due to their hardness and heat resistance. Proper speed and feed control prevent excessive heat and maintain CNC machining tolerances for nickel alloys.

Carbon Cutting Saws

Carbon cutting saws are commonly used for cutting nickel alloy bars and billets to size before further machining. They offer high precision and reduce stress on the material.

Grinding and Honing Techniques

Grinding and honing are used to achieve precise dimensions and smooth surface finishes on nickel alloys. These finishing methods are critical for maintaining CNC machining tolerances for nickel alloys and improving part performance.

Best Practices for Nickel Grinding

Tip: Regularly dress grinding wheels to ensure consistent cutting efficiency and surface finish.

Centerless Grinding and Honing

Tip: Combine grinding and honing for parts requiring tight tolerances and superior surface finish in precision CNC machining applications.

Advanced CNC Machining Techniques

Advanced CNC machining techniques help you handle tough nickel alloys efficiently while maintaining precision and reducing tool wear. Proper planning, tool selection, and simulation are key to success.

Planning

Tip: Always simulate complex operations before actual machining to minimize scrap and reduce costs.

Forming

Forming methods shape nickel alloys without traditional cutting.

Tip: Choose forming methods based on part geometry and tolerance requirements.

Broaching

Broaching efficiently creates keyways, holes, and profiles.

Tip: Ensure proper alignment and lubrication to prevent tool wear and maintain CNC machining tolerances.

Drilling (High-Speed and Heavy-Duty)

Drilling is used for holes of various sizes and depths.

Tip: Use proper coolant and moderate speeds to prevent heat buildup and maintain precision machining.

Reaming

Reaming ensures hole diameter accuracy and smooth finishes.

Tip: Always verify hole diameter after reaming to maintain tight tolerances.

Tapping

Tapping creates internal threads accurately.

Tip: Pre-drill accurately and apply consistent lubrication to maintain thread quality.

Threading can be performed using various methods depending on the part and tool.

Tip: Always select the correct tool pitch and cutting speed for nickel alloy CNC machining to prevent chatter and tool damage.

Advanced tools make machining nickel alloys easier, more precise, and efficient. Selecting the right tool can reduce work hardening, improve surface finish, and extend tool life.

Helical End Mills

Helical end mills provide smooth cutting and efficient chip evacuation. They reduce cutting forces and help maintain precision CNC machining tolerances for nickel alloys.

Specialty Tools

Specialty tools are designed for complex geometries or hard-to-machine alloys. Examples include profile cutters, thread mills, and custom-shaped inserts.

Carbide and C-Grade Inserts

Carbide and C-grade inserts offer high hardness, heat resistance, and long tool life. They are ideal for high-performance nickel alloys in CNC turning and milling operations.

Proper cutting fluids and optimized cutting speeds are critical for machining nickel alloys. They reduce heat, prevent work hardening, extend tool life, and maintain CNC machining tolerances for nickel alloys.

Importance and Types of Cutting Fluids

Cutting fluids improve cooling, lubrication, and chip removal. Choosing the right fluid enhances efficiency and part quality.

Tip: Always ensure consistent coolant flow and avoid overheating during CNC milling and turning of nickel alloys.

Optimizing Cutting Speeds

Cutting speed and feed rates directly impact tool wear and surface finish. Adjusting these parameters improves efficiency without compromising part quality.

Tip: Start with recommended speed/feed charts for the specific nickel alloy and adjust based on observed tool wear and finish.

Variable Speed Cutting in Nickel Machining: Specifications and Advantages

Using variable speeds allows adaptation to different part geometries and alloy types, improving efficiency and surface finish.

Tip: Use high-speed machining for fine features and low-speed for bulk removal to balance efficiency and tool life.

Machining nickel alloys requires careful preparation and strict safety measures to protect operators, tools, and workpieces. Proper planning ensures precision, reduces accidents, and extends tool life during CNC machining of nickel alloy parts.

Preparing for Effective Machining

Tip: Skipping these preparatory steps can lead to tool damage, workpiece defects, and increased cost of nickel alloy CNC machining.

Key Considerations for Machining Safety

Tip: Always inspect workpiece setup and support before cutting, especially for long or thin sections.

Machining Nickel Alloys at High Temperatures

Tip: When machining at high temperatures, balance speed with tool life and surface finish to maintain precision CNC machining tolerances for nickel alloys.

Machining nickel alloys can be challenging. Common mistakes often lead to poor surface finish, tool wear, and increased costs in CNC machining of nickel alloy parts.

Common Mistakes

Tip: Monitor cutting conditions closely to prevent hardening, sticking, or overheating.

Preventative Measures

Tip: Combining the right tools, fluids, and parameters ensures consistent surface quality and reduces machining costs.

Proper preparation is key to achieving precision and efficiency when machining nickel alloys. Skipping these steps can lead to tool wear, poor surface finish, and higher costs in CNC machining of nickel alloy parts.

Understanding Material Behavior

Know the alloy’s hardness, toughness, and work-hardening tendencies. Understanding these properties helps you select appropriate tools, cutting speeds, and feeds for precision CNC machining.

Tool Inspection and Selection

Check tools for wear, cracks, and sharpness before machining. Choose carbide, ceramic, or coated tools based on the alloy and operation type. Proper tool selection ensures longer life and consistent CNC machining tolerances for nickel alloys.

Machine Setup

Ensure all fixtures, clamps, and alignments are secure. A stable setup prevents vibration, chatter, and dimensional errors during machining.

Coolant System Inspection

Verify that coolant flow, pressure, and quality are sufficient. Proper cooling prevents overheating, reduces work hardening, and improves surface finish.

Machining nickel alloys is demanding due to toughness, work hardening, and heat buildup. Using the right techniques and tools helps you maintain precision CNC machining tolerances for nickel alloys while reducing tool wear and costs.

High-Pressure Coolant

High-pressure coolant improves chip removal, reduces heat, and prevents tool sticking. It is especially effective during deep cuts or heavy material removal.

Choose cutting fluids suitable for nickel alloys. Sulfurized mineral oils or synthetic coolants provide lubrication and temperature control, reducing work hardening and extending tool life.

Climb milling reduces cutting forces and minimizes tool deflection. It produces better surface finishes and lowers the risk of work hardening compared to conventional milling.

Nickel alloys are essential in industries that demand high strength, corrosion resistance, and performance under extreme conditions. While they present machining challenges—such as work hardening, heat generation, and tool wear—these issues can be managed with proper preparation, tool selection, cutting fluids, and advanced CNC machining techniques. By understanding the properties of nickel alloys and applying best practices in CNC milling, turning, and precision machining, you can achieve high-quality, durable components efficiently. Investing in proper planning, simulation, and innovative tooling not only improves part accuracy but also reduces production costs and enhances overall reliability.

1. Is nickel difficult to machine?

Yes. Nickel alloys are tough, prone to work hardening, and have low thermal conductivity, making cutting, turning, and milling more challenging than standard metals. Proper tooling and cutting fluids are essential.

2. Is Inconel the same as nickel alloys?

Inconel is a type of high-performance nickel-chromium-based alloy, so it falls under the broader category of nickel alloys but has specific properties optimized for high-temperature and corrosion resistance.

3. How strong are nickel alloys?

Nickel alloys are very strong, with excellent tensile and yield strength. Their high-temperature stability and corrosion resistance make them ideal for aerospace, chemical, and marine applications.

4. What is the most difficult alloy to machine?

Nickel-based superalloys like Inconel 718 and Hastelloy are among the hardest to machine due to their toughness, work hardening, and heat retention.

5. Why is Inconel 718 difficult to machine?

It work-hardens quickly, has low thermal conductivity, and produces tough chips. This combination wears tools rapidly and requires specialized cutting methods, tools, and coolant strategies.

6. Is titanium stronger than nickel?

Titanium has a high strength-to-weight ratio but lower density than nickel alloys. Nickel alloys generally outperform titanium in high-temperature strength and corrosion resistance.

7. Is Inconel difficult to machine?

Yes. Inconel is extremely tough and prone to work hardening. It requires carbide or ceramic tools, precise feeds and speeds, and high-pressure coolant.

8. What is the best type of cutting fluid for machining nickel alloys?

Sulfurized mineral oils or synthetic coolants are ideal. They provide excellent lubrication, reduce heat, and prevent work hardening during CNC machining of nickel alloy parts.

9. Is Inconel harder than titanium?

Yes. Inconel alloys, such as Inconel 718, are harder and more resistant to heat and corrosion than titanium alloys.

10. Why is Inconel so difficult to weld?

Its high strength and thermal conductivity can cause distortion, cracking, and stress accumulation during welding. Specialized welding techniques and filler materials are required.

11. Can Nickel 99 be machined?

Yes, Nickel 99 (pure nickel) can be machined, but it still requires proper tooling, cutting fluids, and controlled speeds and feeds to avoid work hardening and tool wear.