15 years one-stop China custom CNC machining parts factory

87 |

Published by VMT at Sep 20 2025 | Reading Time:About 5 minutes

87 |

Published by VMT at Sep 20 2025 | Reading Time:About 5 minutes

When choosing between stainless steels, it can be tough to know which material best suits your project’s needs. Are you looking for corrosion resistance or strength? Do you need the material to be easy to machine? 304 Stainless Steel and 1018 Stainless Steel each offer distinct advantages, but understanding the key differences is crucial to making the right choice for your application. If you want to get the best value while meeting your specifications, read on to explore their differences.

304 Stainless Steel is highly corrosion-resistant and versatile, ideal for environments exposed to moisture, while 1018 Stainless Steel is softer, easier to machine, and suited for structural and mild applications. The choice depends on whether you prioritize durability or machinability.

Understanding the differences between 304 and 1018 Stainless Steel is important when deciding which material to use in CNC machining. From composition to physical properties, each grade has its strengths and weaknesses. Let’s break down what makes each of them unique and how they compare in various applications.

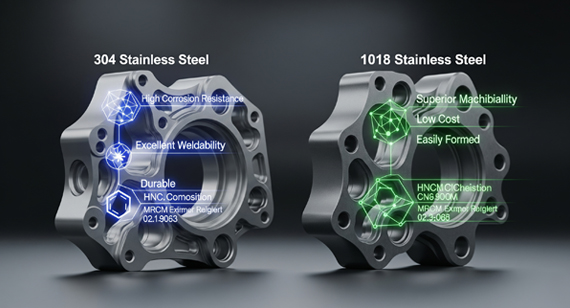

304 Stainless Steel, often referred to as “18/8 stainless steel” due to its composition (18% chromium and 8% nickel), is one of the most widely used types of stainless steel. It’s known for its excellent corrosion resistance, making it suitable for use in environments exposed to moisture, chemicals, and high temperatures. This alloy is also highly versatile, with applications ranging from kitchen appliances and food processing equipment to architectural structures and medical devices. Its ability to resist rust and staining, combined with its ability to maintain structural integrity over time, makes 304 Stainless Steel a go-to material for many industries.

What is Another Name for 304 Stainless Steel?

304 Stainless Steel is commonly referred to as "18/8 stainless steel" due to its specific composition of 18% chromium and 8% nickel. This nickname highlights two of the key elements that give the alloy its excellent corrosion resistance and formability. Additionally, it may also be called "A2 stainless steel," which refers to the material classification in the ISO standard. The name “18/8” is widely recognized, especially in the food and beverage industries, as it indicates the alloy's ability to withstand exposure to moisture and various chemicals.

1018 Stainless Steel is a low-carbon steel alloy commonly used for its excellent machinability and formability. While it doesn't offer the same level of corrosion resistance as 304 Stainless Steel, it is more affordable and easier to machine, making it a popular choice for applications that don’t require high resistance to rust or extreme conditions. The composition of 1018 includes approximately 0.18% carbon, along with trace amounts of manganese and other elements, which give it a balance of strength and ductility. This makes it ideal for structural applications, components like shafts, and parts that require welding.

What Steel is 1018 Steel Equivalent To?

1018 Steel is often considered equivalent to mild steel or low-carbon steel grades in various international standards. In terms of composition and properties, 1018 is similar to A36 steel, which is another popular low-carbon steel commonly used for structural applications. In the European standard, 1018 is equivalent to the C22 grade, which also has a low carbon content and good machinability. While these steels are comparable in strength and formability, they differ in terms of specific standards and regional preferences.

The question of whether 304 Stainless Steel or 1018 Stainless Steel is better depends entirely on the specific requirements of your project. If your focus is on corrosion resistance and durability, 304 Stainless Steel is the superior choice. Its resistance to rust, oxidation, and a wide range of chemicals makes it ideal for applications in the food, medical, and marine industries. However, if your priority is machinability, cost-effectiveness, and ease of fabrication for structural components, 1018 Stainless Steel would be the better option. It’s more affordable and easier to work with in CNC machining but lacks the advanced corrosion resistance of 304.

304 Stainless Steel and 1018 Stainless Steel are widely recognized across various industries, each meeting specific national and international standards. Understanding these standards and equivalent grades can help ensure that you select the right material for your project. Below is a comparison of the national standards and equivalent grades for both materials:

| Material |

National Standards |

Equivalent Grades (USA) |

Equivalent Grades (EU) |

Equivalent Grades (China) |

Equivalent Grades (Japan) |

| 304 Stainless Steel |

ASTM A240, ASTM A276 | AISI 304 | EN 1.4301 | GB/T 4237-2001 | JIS SUS304 |

| 1018 Stainless Steel |

ASTM A108, ASTM A36 | AISI 1018 | EN C22 | GB/T 700-2006 | JIS S10C |

When comparing 304 Stainless Steel and 1018 Stainless Steel, several key differences stand out. These differences play a crucial role in determining which material is best suited for your project. Here's a breakdown of the most significant distinctions:

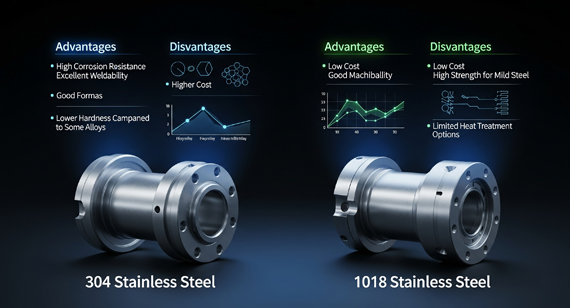

Corrosion Resistance

304 Stainless Steel is highly resistant to corrosion, making it ideal for applications in harsh environments, such as in food processing or marine applications. In contrast, 1018 Stainless Steel has limited corrosion resistance and is more suitable for dry, non-corrosive environments.

Machinability

1018 Stainless Steel is easier to machine due to its lower carbon content. It’s a preferred choice for CNC machining when ease of fabrication is a priority. 304 Stainless Steel, while still machinable, is more challenging to work with because of its higher strength and toughness.

Strength and Durability

304 Stainless Steel offers superior strength and durability, especially in high-stress and corrosive environments. 1018 Stainless Steel is not as strong as 304, but it provides sufficient strength for structural and mild applications.

Formability

Both materials are highly formable, but 304 Stainless Steel offers better formability at higher temperatures. 1018 Stainless Steel is more versatile for cold working, such as bending and forming, due to its lower carbon content.

Cost

1018 Stainless Steel is generally more cost-effective than 304, making it a preferred choice when budget is a key concern and corrosion resistance is not critical.

Both 304 Stainless Steel and 1018 Stainless Steel have unique advantages and disadvantages depending on the specific requirements of your project. Below, we’ve summarized the key pros and cons of each material to help you make an informed decision.

| Feature |

304 Stainless Steel |

1018 Stainless Steel |

| Advantages |

||

| Corrosion Resistance |

Excellent resistance to rust and corrosion, ideal for harsh environments. | Minimal corrosion resistance, suitable for dry conditions. |

| Strength |

High strength and durability, good for structural applications. | Moderate strength, sufficient for light to medium-duty applications. |

| Versatility |

Widely used in a variety of industries, including medical, food, and marine. | Cost-effective and easy to machine, ideal for general-purpose uses. |

| Temperature Resistance |

Excellent performance at high temperatures. | Performs well in low-temperature applications. |

| Weldability |

Excellent weldability for complex structures. | Good weldability, though less suited for high-performance applications. |

| Disadvantages |

||

| Cost |

Generally more expensive than 1018. | More affordable, making it suitable for budget-conscious projects. |

| Machinability |

More difficult to machine due to its toughness. | Easier to machine, but sacrifices some strength and corrosion resistance. |

| Durability in Harsh Conditions |

Limited durability in extremely harsh or corrosive conditions without protective coatings. | Not suitable for exposure to moisture or chemicals. |

| Hardness |

Harder to achieve very fine surface finishes. | Softer, which can lead to more wear and tear under certain conditions. |

When choosing between 304 Stainless Steel and 1018 Stainless Steel, it's important to compare their properties to understand which material will meet your project's specific requirements. This section outlines the chemical composition of both materials, which directly impacts their performance in various applications.

304 Stainless Steel and 1018 Stainless Steel: Chemical Composition

| Property |

304 Stainless Steel |

1018 Stainless Steel |

| Carbon (C) |

0.08% max | 0.18% |

| Chromium (Cr) |

18.0-20.0% | Not present (low-carbon steel) |

| Nickel (Ni) |

8.0-10.5% | Not present |

| Manganese (Mn) |

2.0% max | 0.60-0.90% |

| Silicon (Si) |

0.75% max | 0.10-0.35% |

| Phosphorus (P) |

0.045% max | 0.04% max |

| Sulfur (S) |

0.03% max | 0.05% max |

| Iron (Fe) |

Balance | Balance |

304 Stainless Steel and 1018 Stainless Steel: Physical Properties

The physical properties of 304 Stainless Steel and 1018 Stainless Steel differ significantly, affecting how they perform in various applications. Here, we compare the most important physical characteristics of each material, such as density, melting point, and thermal conductivity.

| Physical Property |

304 Stainless Steel |

1018 Stainless Steel |

| Density |

8.00 g/cm³ | 7.87 g/cm³ |

| Melting Point |

1400-1450°C (2552-2642°F) | 1450°C (2642°F) |

| Thermal Conductivity |

16.2 W/m·K | 50.0 W/m·K |

| Resistivity |

0.072 Ω·mm²/m | 0.076 Ω·mm²/m |

| Thermal Expansion |

17.2 × 10⁻⁶ /°C | 12.0 × 10⁻⁶ /°C |

| Linear Thermal Expansion |

16.0 × 10⁻⁶ /°C | 11.9 × 10⁻⁶ /°C |

| Magnetic Properties |

Non-magnetic (Austenitic) | Magnetic (Ferritic) |

304 Stainless Steel and 1018 Stainless Steel: Mechanical Properties

The mechanical properties of 304 Stainless Steel and 1018 Stainless Steel influence their strength, ductility, and overall performance in various applications. Understanding these properties is essential for selecting the right material based on your project's load-bearing requirements and durability.

| Mechanical Property |

304 Stainless Steel |

1018 Stainless Steel |

| Hardness (HRC) |

18-22 HRC | 50-60 HRC |

| Tensile Strength |

505-750 MPa | 440-550 MPa |

| Yield Strength |

215-505 MPa | 370-460 MPa |

| Elongation at Break |

40-60% | 28-40% |

| Ductility (%) |

Excellent | Moderate |

| Ultimate Tensile Strength |

620 MPa | 460 MPa |

| Shear Strength |

280-370 MPa | 310-400 MPa |

| Shear Modulus (GPa) |

78 GPa | 81 GPa |

| Fatigue Strength (MPa) |

215 MPa | 280 MPa |

| Poisson's Ratio |

0.3 | 0.29 |

Heat treatment a critical role in altering the mechanical properties of both 304 Stainless Steel and 1018 Stainless Steel. However, the heat treatment process and its effects differ between the two materials, given their distinct compositions and intended applications. Below, we compare the heat treatment characteristics for each material.

| Heat Treatment Property |

304 Stainless Steel |

1018 Stainless Steel |

| Annealing Temperature |

1040-1120°C (1904-2048°F) | 780-820°C (1436-1508°F) |

| Quenching |

Water or air quenching | Water or oil quenching |

| Hardening |

Not hardenable by heat treatment due to its austenitic structure | Can be hardened by cold working, but limited response to heat treatment |

| Normalizing |

Typically not necessary, but can be done at 1040-1100°C | Normalized at 870-920°C (1598-1688°F) to improve machinability |

| Stress Relieving |

760-870°C (1400-1600°F) | 540-650°C (1004-1202°F) |

| Tempering |

Not commonly used | Tempering can be done after hardening to reduce brittleness |

Both 304 Stainless Steel and 1018 Stainless Steel are widely used across various industries, but their specific properties make them suited for different types of applications. Below, we explore where each material excels based on its mechanical properties, corrosion resistance, and ease of machining.

| Application Area |

304 Stainless Steel |

1018 Stainless Steel |

| Food Processing |

Highly resistant to corrosion, making it ideal for food-grade equipment, storage tanks, and utensils. | Not suitable due to limited corrosion resistance. |

| Medical Equipment |

Commonly used in surgical instruments, implants, and medical devices due to its biocompatibility and corrosion resistance. | Not typically used in medical applications due to its lack of corrosion resistance. |

| Chemical Processing |

Ideal for equipment exposed to chemicals or extreme environments, such as pumps, valves, and reactors. | Not suitable for chemical processing applications. |

| Automotive Parts |

Used in exhaust systems, mufflers, and other components requiring high strength and corrosion resistance. | Suitable for structural parts like chassis and brackets where corrosion is less of a concern. |

| Construction |

Often used in architectural features, building facades, and structural components exposed to outdoor environments. | Suitable for non-corrosive indoor applications or low-stress structural components. |

| Machinery Components |

Common in applications requiring high durability and resistance to wear, such as bearings, gears, and machine housings. | Used in less demanding machinery components where cost and machinability are a concern. |

| Marine Industry |

Preferred for marine hardware and components exposed to saltwater environments due to its excellent corrosion resistance. | Not ideal due to its susceptibility to rust and corrosion in seawater. |

| CNC Machining |

Used for precision parts in CNC machining due to its ease of welding and formability, though harder to machine than 1018. | Excellent for general-purpose CNC machining, particularly for parts where ease of fabrication is key. |

When deciding between 304 Stainless Steel and 1018 Stainless Steel, cost plays a crucial role in determining the best material for your project. While both materials offer distinct advantages, their pricing differences can impact your overall project budget. Below, we compare the cost factors of 304 and 1018 Stainless Steel to help guide your decision.

These figures are approximate and can vary depending on market conditions, suppliers, and your specific project requirements.

| Cost Factor |

304 Stainless Steel |

1018 Stainless Steel |

| Material Cost (per lb) |

$1.50 - $3.00 per lb |

$0.60 - $1.20 per lb |

| Material Cost (per kg) |

$3.30 - $6.60 per kg | $1.30 - $2.60 per kg |

| Initial Material Cost |

Typically more expensive due to higher alloy content (nickel and chromium) and superior properties. | More affordable, as it is a low-carbon steel with minimal alloying elements. |

| Machining Cost (per hour) | $85 - $150 per hour More difficult to machine due to its strength and toughness, which may result in higher labor and tooling costs. |

$60 - $100 per hour Easier to machine, which can lead to lower machining costs and faster production. |

| Welding Cost (per inch) |

$5 - $8 per inch (based on welding method and filler material) Higher welding costs due to its higher alloy content, requiring more precise techniques and filler material. |

$3 - $5 per inch (less complex welding process) Lower welding costs due to its lower alloy content and simpler welding process. |

| Heat Treatment Cost |

$100 - $200 per part (depends on size and process) | $50 - $100 per part (simple heat treatment processes) |

| Surface Finishing Costs |

$2 - $4 per part (polishing, passivation, coating) | $1 - $2 per part (minimal finishing for surface treatment) |

| Corrosion Resistance Costs |

No additional cost for maintenance due to corrosion resistance Higher upfront cost for materials, but less need for protective coatings or maintenance over time due to superior corrosion resistance. |

Additional coating or maintenance may cost $2 - $5 per part annually Lower initial cost, but may require coatings or frequent maintenance in corrosive environments. |

| Long-Term Durability |

More cost-effective in the long run for applications exposed to corrosive environments, reducing replacement and maintenance costs. | Cheaper upfront, but may incur higher maintenance or replacement costs in harsh environments. |

Choosing between 304 Stainless Steel and 1018 Stainless Steel largely depends on the specific needs of your project. Factors like corrosion resistance, strength, machinability, and cost-effectiveness will guide your decision. Below, we provide guidance on when each material is the better option based on different project requirements.

| Criteria |

304 Stainless Steel |

1018 Stainless Steel |

| When to Choose 304 Stainless Steel |

- When high corrosion resistance is needed (e.g., in food, medical, or marine environments). - For applications exposed to high temperatures. - When long-term durability and minimal maintenance are key. - If the project requires superior strength and formability. |

- When cost is a significant factor, especially for non-corrosive environments. - For structural components that do not require high corrosion resistance. - For applications that require ease of machining and forming. - When low to moderate strength is sufficient. |

| When to Choose 1018 Stainless Steel |

- When working with budget-conscious projects that prioritize initial cost savings. - For parts that need to be easily machined or welded. - For applications that are not exposed to harsh or corrosive conditions. - When high strength or extreme durability is not a critical requirement. |

- When moderate corrosion resistance is acceptable. - For non-corrosive indoor applications. - When ease of processing and low material costs are more important than long-term performance. - For structural and low-stress parts in general-purpose manufacturing. |

When comparing 304 Stainless Steel to Grade 8 stainless steel, it's important to clarify that Grade 8 is a classification of bolts, not a specific material. Grade 8 bolts are typically made of medium carbon steel, often with a hardened and tempered finish, and they are designed for high-strength applications. On the other hand, 304 Stainless Steel is an austenitic stainless steel with good corrosion resistance but relatively lower tensile strength compared to many carbon steels.

Here's a quick comparison:

| Property |

304 Stainless Steel |

Grade 8 Stainless Steel |

| Tensile Strength |

505-750 MPa (73,200-108,000 psi) | 1,200 MPa (174,000 psi) (for bolts made of medium carbon steel) |

| Yield Strength |

215-505 MPa (31,200-73,000 psi) | 1,030 MPa (150,000 psi) |

| Hardness (HRC) |

18-22 HRC | 33-39 HRC (for Grade 8 bolts) |

Choosing between 304 Stainless Steel and 1018 Stainless Steel depends on your project's specific requirements, such as strength, corrosion resistance, and machinability. To make an informed decision, consider the following factors:

| Criteria |

304 Stainless Steel |

1018 Stainless Steel |

| Corrosion Resistance |

Excellent resistance to corrosion, ideal for food, medical, and marine applications. | Moderate corrosion resistance, suitable for indoor or dry applications. |

| Strength |

High tensile and yield strength, making it suitable for structural and high-performance applications. | Lower strength compared to 304, but adequate for general-purpose and non-critical applications. |

| Machinability |

More challenging to machine, requiring specialized tools and techniques. | Easy to machine, making it a good choice for high-volume and complex parts. |

| Weldability |

Excellent weldability, often used in welded assemblies. | Good weldability but may require more care due to its lower carbon content. |

| Cost |

Higher material and processing costs due to its alloy content and superior properties. | More affordable and budget-friendly, especially for less demanding applications. |

| Temperature Resistance |

Performs well at high temperatures and in extreme conditions. | Not recommended for high-temperature environments. |

At VMT, we specialize in delivering high-quality CNC machining services for both 304 and 1018 Stainless Steel parts. Whether you need precision components for demanding industries or cost-effective solutions for general applications, we have the expertise and equipment to meet your requirements. Our factory is equipped with advanced CNC machines that ensure accuracy, efficiency, and the highest standards of quality in every part we produce.

Our Services:

Why Choose VMT for Your CNC Machining Needs?

Applications:

Tip: If you need high-performance parts that require superior corrosion resistance and strength, 304 Stainless Steel is ideal. However, for cost-effective solutions where machining ease and general structural integrity are prioritized, 1018 Stainless Steel is an excellent choice. At VMT, we provide CNC machining services tailored to both materials, ensuring you get the best results for your project.

In conclusion, both 304 Stainless Steel and 1018 Stainless Steel offer unique advantages depending on your project's requirements. 304 Stainless Steel is ideal for applications that demand high corrosion resistance, strength, and durability, making it suitable for industries such as food processing, medical, and marine environments. Its higher material and machining costs are often justified by its long-term performance and minimal maintenance needs.

On the other hand, 1018 Stainless Steel provides a more cost-effective option for projects where corrosion resistance is less critical, and ease of machining is more important. It excels in general-purpose and structural applications, offering good strength and machinability at a lower cost.

Choosing between these two materials ultimately depends on factors such as the environment in which the parts will be used, the required strength, your budget, and the ease of fabrication. Whether you need the superior performance of 304 Stainless Steel or the affordability and machinability of 1018 Stainless Steel, VMT offers CNC machining services tailored to your needs, delivering high-quality, precision parts that meet your specifications.

By understanding the key differences in properties, applications, and costs, you can make an informed decision that aligns with your project’s goals and budget.

1. Which is better, 304 stainless steel or 18-10 stainless steel?

Both 304 Stainless Steel and 18-10 Stainless Steel are essentially the same material. 18-10 refers to the alloy's composition, indicating 18% chromium and 10% nickel, which is typical for 304 Stainless Steel. So, they are interchangeable, and there's no difference in performance between the two.

2. What is stronger than 1018 steel?

Several steels are stronger than 1018 Steel, including 1045 Steel, AISI 4140, and tool steels like D2 and M2. These materials have higher carbon content or alloying elements, giving them greater tensile strength and hardness compared to 1018.

3. Is 1018 good for knives?

1018 Steel is not ideal for knives, as it has low carbon content and lacks hardness and edge retention. Knife steels like 1095, 440C, or D2 are more commonly used because they can be hardened more effectively and hold an edge longer.

4. Is 1018 steel hardenable?

Yes, 1018 Steel can be hardened through heat treatment, though it doesn’t achieve the same hardness as higher-carbon steels. The steel can be carburized to increase surface hardness, but the overall hardness will still be lower than steels like 1045 or tool steels.

5. Is 1018 steel good for welding?

Yes, 1018 Steel is good for welding. Its low carbon content makes it easier to weld without the risk of cracking, and it can be welded using most common techniques, including MIG and TIG welding. However, preheating and proper post-weld heat treatment may be necessary for thicker sections.

6. Does 304 stainless steel rust?

304 Stainless Steel is highly resistant to rust and corrosion due to its high chromium and nickel content. However, it can still corrode in extreme conditions, such as exposure to chlorides (saltwater or harsh chemicals), and under certain conditions like high heat, especially if it’s exposed to inadequate maintenance.

7. Which is better, 18/8 or 304 stainless steel?

18/8 Stainless Steel is essentially the same as 304 Stainless Steel. The 18/8 designation refers to its alloy composition—18% chromium and 8% nickel—which is standard for 304 Stainless Steel. Therefore, they are equally good in terms of quality and performance.

8. Which grade is better, 304 or 316 stainless steel?

316 Stainless Steel is better for environments with high exposure to corrosive elements, such as saltwater or chemicals. It contains molybdenum, which enhances its resistance to corrosion, making it ideal for marine or chemical industries. 304 is still highly corrosion-resistant but doesn’t perform as well in highly corrosive environments.

9. What is the best grade of stainless steel?

The "best" grade depends on the application. For general purposes, 304 Stainless Steel is the most commonly used due to its balance of strength, corrosion resistance, and machinability. For highly corrosive environments, 316 Stainless Steel is better. For heavy-duty applications requiring higher hardness, alloys like 17-4 PH may be preferred.

10. Which is better, 18-10 or 18-0 stainless steel?

18-10 Stainless Steel (18% chromium, 10% nickel) is better than 18-0 Stainless Steel (18% chromium, 0% nickel) in terms of corrosion resistance, strength, and durability. The 10% nickel content in 18-10 gives it better resistance to rust and tarnishing compared to 18-0.