15 years one-stop China custom CNC machining parts factory

201 |

Published by VMT at Jul 29 2025 | Reading Time:About 7 minutes

201 |

Published by VMT at Jul 29 2025 | Reading Time:About 7 minutes

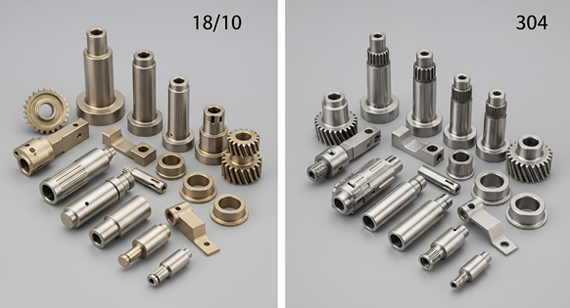

Choosing the right stainless steel for your CNC machining project can be overwhelming. With multiple options like 18-10 and 304 stainless steel available, engineers and buyers often face a dilemma—Which material offers the best balance between strength, corrosion resistance, workability, and cost? Selecting the wrong grade can lead to poor product performance, machining difficulties, or costly replacements.

At VMT CNC Machining, we understand the pressure of selecting materials that meet both technical and financial expectations. That’s why we’ve created this comprehensive guide comparing 18-10 stainless steel and 304 stainless steel—from their composition and properties to their machining behavior and costs—so you can make an informed decision tailored to your project.

18-10 stainless steel and 304 stainless steel are essentially the same alloy, both classified as austenitic stainless steel with similar chromium and nickel content. However, 18-10 emphasizes nickel content for enhanced corrosion resistance and luster. For CNC machining projects, 304 stainless steel offers a more standardized, cost-effective solution, while 18-10 is preferred in high-end consumer or decorative applications.

Now that we’ve outlined the basic comparison, it’s time to dive deeper. What exactly are 18-10 stainless steel and 304 stainless steel? Are they truly the same? How do their differences impact corrosion resistance, weldability, machinability, and cost? This article breaks down everything you need to know to choose the right material for your stainless steel CNC machined parts.

If you're comparing stainless steel grades for CNC machining, you may also be interested in our in-depth guides on 18/8 vs. 18/10 stainless steel, 304 vs. 316 stainless steel, or the complete guide to CNC machining stainless steel parts. These resources provide additional insight to help you optimize your material selection process.

Key Points: 18-10 Stainless Steel vs. 304 Stainless Steel

Determining which is better—18/10 stainless steel or 304 stainless steel—depends on your project’s specific needs. Technically, 18/10 stainless steel is a type of 304 stainless steel with approximately 18% chromium and 10% nickel. The higher nickel content enhances its resistance to rust, pitting, and surface discoloration, which is why it is often used in premium kitchenware, medical instruments, and decorative stainless steel CNC machined parts that demand a polished, long-lasting finish.

On the other hand, standard 304 stainless steel is widely recognized as an industry workhorse. It has nearly the same composition as 18/10 but with slightly less nickel (around 8%). This makes it highly durable, corrosion-resistant, and easier to source at a lower cost. For most industrial and commercial applications—such as structural components, automotive parts, and CNC machining services—304 stainless steel provides the best balance of performance and affordability.

In short: Choose 18/10 stainless steel when superior aesthetics and slightly enhanced corrosion resistance are critical. Choose 304 stainless steel for cost-effective, high-performance solutions in structural or mechanical applications. For most CNC machining factory projects, 304 stainless steel remains the preferred option due to its availability, machinability, and excellent long-term durability.

Comparison Table: 18/10 Stainless Steel vs. 304 Stainless Steel

| Feature |

18/10 Stainless Steel |

304 Stainless Steel |

| Type |

A subtype of 304 stainless steel |

Standard 304 stainless steel |

| Chromium (Cr) Content |

~18% | ~18% |

| Nickel (Ni) Content |

~10% | ~8% |

| Corrosion Resistance |

Slightly higher due to more nickel | Excellent, suitable for most conditions |

| Strength & Durability |

Similar to 304 | Similar to 18/10 |

| Aesthetic Finish |

Shinier and more lustrous | Standard industrial finish |

| Machinability |

Excellent for CNC machined parts | Excellent and widely used in CNC services |

| Weldability |

Good | Good |

| Cost |

Slightly higher | More cost-effective |

| Typical Applications |

Kitchenware, medical tools, decorative parts | Industrial machinery, automotive, structural components |

18/10 stainless steel is an austenitic stainless steel alloy containing approximately 18% chromium and 10% nickel. The chromium provides a protective oxide layer that resists rust and corrosion, while the higher nickel content enhances durability, luster, and resistance to tarnishing. Because of its chemical composition, 18/10 stainless steel is classified within the 300 series stainless steels and is technically a specific grade of 304 stainless steel.

This type of stainless steel is widely used for premium consumer and industrial applications. It is particularly favored for kitchenware, cutlery, medical tools, food processing equipment, and decorative components, where a polished appearance and strong corrosion resistance are essential. The high nickel percentage helps maintain a shiny finish even after repeated exposure to moisture, heat, and cleaning chemicals.

In CNC machining services, 18/10 stainless steel is an excellent material for producing stainless steel CNC machined parts that require both strength and aesthetics. Its good machinability, weldability, and resistance to pitting make it ideal for custom components in food, medical, and marine industries. Partnering with a professional CNC machining factory ensures that 18/10 stainless steel parts are manufactured with precision and optimized surface finishes for both functionality and appearance.

304 stainless steel is one of the most widely used austenitic stainless steel alloys in the world. Its composition typically includes 18–20% chromium and 8–10.5% nickel, along with small amounts of manganese, silicon, and carbon. This balance of elements gives 304 stainless steel excellent corrosion resistance, durability, and formability, making it a versatile choice for countless industrial and commercial applications.

As a 300 series stainless steel, 304 is highly resistant to rust, oxidation, and many chemicals in normal atmospheric conditions. It is commonly used in structural components, industrial machinery, automotive parts, food processing equipment, and piping systems. Its ability to withstand high moisture and moderate heat makes it a preferred material for both indoor and outdoor use.

From a CNC machining perspective, 304 stainless steel is an ideal material for stainless steel CNC machined parts. It offers good machinability, weldability, and durability, allowing CNC machining factories to produce precise, long-lasting components for industries such as medical devices, automotive manufacturing, and consumer products. Additionally, 304 stainless steel is cost-effective and widely available, which is why it is often chosen over 18/10 stainless steel for large-scale or budget-sensitive projects.

Yes, 18/10 stainless steel and 304 stainless steel are essentially the same alloy, but they are labeled differently depending on the context. 304 stainless steel is the official industry designation used in engineering and manufacturing, while 18/10 is a more consumer-facing description that highlights the chromium (18%) and nickel (10%) content of the alloy.

Both are austenitic stainless steels in the 300 series, sharing nearly identical chemical compositions and mechanical properties. The difference lies mainly in nickel emphasis: 18/10 stainless steel explicitly specifies a 10% nickel content, which contributes to its enhanced corrosion resistance, durability, and luster. Standard 304 stainless steel often contains 8–10.5% nickel, meaning that 18/10 falls within the 304 range but represents its higher-quality composition.

From a CNC machining services perspective, both materials perform almost identically. They offer excellent machinability, weldability, and corrosion resistance, making them reliable for stainless steel CNC machined parts across industries such as food processing, medical devices, and industrial equipment. The choice between the two usually depends on marketing needs, aesthetic requirements, and cost considerations rather than major performance differences.

Although 18/10 stainless steel and 304 stainless steel share many similarities, there are subtle differences that can influence material selection for your CNC machining projects. Both are austenitic stainless steels with excellent corrosion resistance, durability, and workability. However, variations in nickel content, surface appearance, and cost can make one more suitable than the other depending on the application. Understanding these key differences helps engineers, manufacturers, and CNC machining factories make informed choices for stainless steel CNC machined parts.

1. Nickel Content

The most significant difference lies in the nickel percentage.

This slightly higher nickel content makes 18/10 more desirable for applications where premium appearance and rust resistance are critical, such as cutlery, decorative components, and medical tools.

2. Corrosion Resistance

Both steels perform excellently in most environments, but 18/10 stainless steel offers slightly better corrosion resistance thanks to its higher nickel content.

For stainless steel CNC machined parts, the difference is often negligible unless operating in aggressive or marine environments.

3. Wear Resistance

Wear resistance is similar for both materials because they share the same basic hardness and tensile strength properties. 18/10’s slightly higher nickel content can improve its ability to maintain a smooth, polished surface over time, which is beneficial for consumer products or visible components. For industrial CNC machining, 304 stainless steel is more than capable of handling typical mechanical wear.

4. Oxidation Resistance

Both 18/10 and 304 stainless steels exhibit excellent oxidation resistance, which protects against rust formation in air and water exposure. The additional nickel in 18/10 stainless steel slightly improves its ability to resist discoloration at higher temperatures, making it popular for cookware, food processing equipment, and medical tools that undergo frequent heating and cleaning.

5. Welding

Weldability for both alloys is excellent, as they are austenitic stainless steels with low carbon content. However, a few points are worth noting:

6. Machinability

From a CNC machining perspective, both materials are very similar.

Both require proper cutting tools, cooling, and speeds to optimize tool life and surface finish.

7. Cost

8. Applications

The choice between these two alloys often depends on end use:

In summary, 18/10 is preferred for aesthetics and corrosion-critical applications, while 304 is the practical choice for industrial and cost-sensitive projects.

Table: Key Differences Between 18/10 and 304 Stainless Steel

| Feature |

18/10 Stainless Steel |

304 Stainless Steel |

| Chromium (Cr) Content |

~18% | ~18% |

| Nickel (Ni) Content |

~10% (higher, enhances luster & corrosion resistance) | 8–10.5% (standard range) |

| Corrosion Resistance |

Slightly higher, ideal for marine and food applications | Excellent, suitable for most industrial uses |

| Wear Resistance |

Very good, maintains polished appearance | Very good, suitable for heavy-duty applications |

| Oxidation Resistance |

Excellent, slightly better at high temperatures | Excellent in typical environments |

| Weldability |

Excellent, stable during welding | Excellent, widely used in industrial applications |

| Machinability |

Great for aesthetic and precision CNC machining | Great for cost-effective CNC machined parts |

| Cost |

Slightly higher due to more nickel | More affordable and widely available |

| Common Applications |

Kitchenware, medical tools, decorative parts | Industrial machinery, automotive, piping, CNC parts |

Understanding the advantages and disadvantages of both 18/10 and 304 stainless steel helps manufacturers and engineers select the best material for their specific CNC machining needs. Both grades offer impressive corrosion resistance and durability, but their subtle differences impact cost, appearance, machinability, and application suitability. This section breaks down the strengths and limitations of each to support informed decision-making for stainless steel CNC machined parts.

18/10 Stainless Steel: Advantages and Disadvantages

As a premium grade within the 304 stainless steel family, 18/10 stainless steel combines excellent corrosion resistance with a lustrous finish. It is favored in environments requiring high hygiene standards and aesthetic appeal. However, these benefits come with considerations around cost and availability.

Advantages of 18/10 Stainless Steel

Disadvantages of 18/10 Stainless Steel

304 Stainless Steel: Advantages and Disadvantages

304 stainless steel is the most commonly used stainless steel alloy worldwide, prized for its versatility and balance of cost and performance. While it may not have the exact nickel content of 18/10, it remains highly effective for a wide range of applications.

Advantages of 304 Stainless Steel

Disadvantages of 304 Stainless Steel

Table: Advantages and Disadvantages of 18/10 vs. 304 Stainless Steel

| Aspect |

18/10 Stainless Steel |

304 Stainless Steel |

| Advantages | - Superior corrosion resistance | - Excellent corrosion resistance |

| - Enhanced aesthetic appeal with bright finish | - Widely available and cost-effective | |

| - Good machinability and weldability | - Strong and durable | |

| - Long-term durability in harsh environments | - Good machinability and weldability | |

| Disadvantages | - Higher cost | - Slightly lower corrosion resistance |

| - Limited availability | - Less lustrous finish | |

| - May be over-specified for some industrial uses | - Potential for work hardening during machining |

This table provides a quick, easy-to-understand overview to assist readers in evaluating which stainless steel grade best fits their CNC machining projects.

When selecting between 18/10 stainless steel and 304 stainless steel for CNC machining projects, understanding their chemical composition is essential. Although these materials are very similar, subtle variations in elemental percentages can affect corrosion resistance, machinability, and mechanical properties. This section provides a detailed breakdown of the key chemical elements in both grades, helping manufacturers and engineers evaluate their suitability for various applications.

18/10 and 304 Stainless Steel: Chemical Composition

| Element |

18/10 Stainless Steel (%) |

304 Stainless Steel (%) |

Notes |

| Iron (Fe) |

Balance | Balance | Base metal for both alloys |

| Chromium (Cr) |

~18 | 17.5 – 18.5 | Provides corrosion and oxidation resistance |

| Nickel (Ni) |

~10 | 8 – 10.5 | Enhances corrosion resistance and luster |

| Manganese (Mn) |

1.0 – 2.0 | 1.0 – 2.0 | Improves hot working and strength |

| Silicon (Si) |

0.5 – 1.0 | 0.5 – 1.0 | Enhances oxidation resistance |

| Carbon (C) |

≤ 0.08 | ≤ 0.08 | Controls hardness and strength |

| Nitrogen (N) |

Trace – 0.1 | Trace – 0.1 | Improves strength and corrosion resistance |

| Phosphorus (P) |

≤ 0.045 | ≤ 0.045 | Impurity, kept low to maintain ductility |

| Sulfur (S) |

≤ 0.03 | ≤ 0.03 | Impurity, affects machinability |

This detailed chemical composition highlights how 18/10 stainless steel tends to have a slightly higher nickel content than standard 304 stainless steel, contributing to its enhanced corrosion resistance and finish. Both alloys maintain similar levels of other elements, ensuring comparable mechanical and physical properties for most CNC machining applications.

18/10 and 304 Stainless Steel: Physical Properties

Physical properties significantly influence how stainless steel performs during CNC machining and in end-use applications. Both 18/10 stainless steel and 304 stainless steel share similar physical characteristics due to their closely related compositions. Understanding these properties helps engineers and machinists optimize machining parameters, predict material behavior, and ensure product durability.

Physical Property Comparison Table

| Property |

18/10 Stainless Steel |

304 Stainless Steel |

Notes |

| Density (g/cm³) |

~8.0 | ~8.0 | Typical density for austenitic stainless steels |

| Melting Point (°C) |

1400 – 1450 | 1400 – 1450 | Similar melting range due to same base elements |

| Thermal Conductivity (W/mK) |

~16 | ~16 | Low thermal conductivity common in stainless steel |

| Electrical Resistivity (Ω·m) |

~7.2 × 10⁻⁷ | ~7.2 × 10⁻⁷ | Typical resistivity for 300 series stainless |

| Thermal Expansion |

Moderate | Moderate | Expansion rates similar due to alloy composition |

| Linear Coefficient of Thermal Expansion (10⁻⁶/K) |

16.0 – 17.0 | 16.0 – 17.0 | Indicates dimensional change with temperature |

| Corrosion Resistance |

Excellent, slightly higher | Excellent | 18/10 has marginally improved corrosion resistance |

| Magnetic Properties |

Non-magnetic (austenitic) | Non-magnetic (austenitic) | Both alloys are typically non-magnetic |

| Formability |

High | High | Easily formed and shaped for complex parts |

| Machinability (Annealed) |

Moderate to Good | Moderate to Good | Requires proper tooling and parameters |

Both 18/10 stainless steel and 304 stainless steel exhibit excellent physical properties suitable for precision CNC machining services. Their density, melting point, and thermal characteristics are nearly identical, ensuring consistency in manufacturing processes. The slightly enhanced corrosion resistance of 18/10 stainless steel is due to its higher nickel content, while both grades maintain non-magnetic properties important in specialized applications.

18/10 and 304 Stainless Steel: Mechanical Properties

Mechanical properties define how stainless steel behaves under various forces and conditions, impacting its performance in CNC machining and final applications. Both 18/10 stainless steel and 304 stainless steel share very similar mechanical characteristics due to their comparable chemical composition. This section highlights key mechanical properties such as hardness, tensile strength, ductility, and elasticity, providing essential data to guide material selection for stainless steel CNC machined parts and CNC machining services.

Mechanical Properties Comparison Table

| Property |

18/10 Stainless Steel |

304 Stainless Steel |

Notes |

| Hardness (HRC) |

70 – 90 (varies by treatment) | 70 – 90 (varies by treatment) | Comparable hardness depending on heat treatment and work hardening |

| Hardness (HV) |

200 – 300 | 200 – 300 | Vickers hardness typical range |

| Hardness (HRC/HRB) |

HRC: ~20 – 25 / HRB: ~80 – 90 | HRC: ~20 – 25 / HRB: ~80 – 90 | Rockwell hardness scales |

| Tensile Strength (MPa) |

520 – 750 | 520 – 750 | Ultimate tensile strength range |

| Elongation (Rp0.2/MPa) |

30 – 45% | 30 – 45% | Yield strength elongation |

| Ductility (%) |

40 – 50% | 40 – 50% | Ability to deform without fracture |

| Ultimate Tensile Strength |

520 – 750 MPa | 520 – 750 MPa | Maximum stress before failure |

| Yield Tensile Strength |

210 – 310 MPa | 210 – 310 MPa | Stress at which permanent deformation begins |

| Reduction of Area (Z/%) |

40 – 60% | 40 – 60% | Measure of material’s ability to withstand deformation |

| Heating Temperature (°C) |

Up to ~1200 | Up to ~1200 | Suitable heat treatment temperatures |

| Elastic Modulus (Young’s, GPa) |

~193 – 200 | ~193 – 200 | Measure of stiffness |

| Elongation at Break (%) |

40 – 50% | 40 – 50% | Total strain at fracture |

| Fatigue Strength (MPa) |

240 – 300 | 240 – 300 | Resistance to cyclic loading |

| Shear Strength (MPa) |

~345 | ~345 | Strength under shear forces |

| Shear Modulus (GPa) |

~77 | ~77 | Rigidity modulus |

| Poisson’s Ratio |

~0.27 | ~0.27 | Ratio of transverse to axial strain |

| Reduction of Area (%) |

40 – 60% | 40 – 60% | Consistent with ductility measures |

Both 18/10 stainless steel and 304 stainless steel offer robust mechanical properties that ensure durability and reliability in CNC machining factory environments. Their similar hardness, tensile strength, ductility, and elasticity make them interchangeable for many applications. The choice between the two often depends more on surface finish and corrosion resistance needs rather than mechanical performance.

Heat treatment plays a crucial role in optimizing the mechanical properties and machinability of stainless steels like 18/10 stainless steel and 304 stainless steel. Both belong to the austenitic stainless steel family, which means they are generally non-hardenable by heat treatment in the traditional sense. Instead, their strength and hardness are mostly influenced by cold working and strain hardening during fabrication and CNC machining processes.

Annealing

Both 18/10 and 304 stainless steels undergo annealing, a heat treatment process where the metal is heated to approximately 1010–1120°C (1850–2050°F) and then slowly cooled. Annealing restores ductility, relieves internal stresses, and improves corrosion resistance. For stainless steel CNC machined parts, annealing ensures easier machining and better dimensional stability.

Stress Relieving

Stress relieving is also common for these stainless steels to reduce residual stresses introduced during machining, welding, or forming. Typically performed at lower temperatures (around 480–760°C (900–1400°F)), stress relieving helps prevent warping and cracking in complex CNC machined components.

Work Hardening

Unlike martensitic stainless steels, 18/10 and 304 do not harden by heat treatment but harden through cold working during machining or forming. This work hardening increases surface hardness and strength but can make machining more challenging if not managed properly. CNC machining factories use optimized tooling and cutting parameters to balance machinability with work hardening effects.

Practical Implications for CNC Machining Services

For manufacturers and CNC machining factories working with 18-10 stainless steel CNC machined parts or 304 stainless steel CNC machined parts, understanding the heat treatment behaviors is essential. Proper annealing and stress relieving maximize material performance, while careful control of machining parameters minimizes work hardening issues, ensuring high-quality finished parts with excellent durability and corrosion resistance.

Table: Heat Treatment of 18/10 vs. 304 Stainless Steel

| Heat Treatment Process |

18/10 Stainless Steel |

304 Stainless Steel |

Notes |

| Annealing |

Heated to 1010–1120°C; slow cooling | Heated to 1010–1120°C; slow cooling | Restores ductility, relieves stress, improves corrosion resistance |

| Stress Relieving |

480–760°C to reduce residual stresses | 480–760°C to reduce residual stresses | Prevents warping and cracking in machined parts |

| Work Hardening |

Hardens by cold working, not heat treatment | Hardens by cold working, not heat treatment | Increases hardness during machining; requires careful process control |

| Heat Treatability |

Non-hardenable by traditional heat treatment | Non-hardenable by traditional heat treatment | Strength controlled mainly by cold work |

This table helps readers quickly understand the heat treatment characteristics critical for CNC machining services involving 18/10 and 304 stainless steel parts.

Both 18/10 stainless steel and 304 stainless steel are versatile materials widely used across industries, thanks to their excellent corrosion resistance, strength, and workability. Understanding their typical applications can help manufacturers and designers select the right grade for specific needs, especially when producing stainless steel CNC machined parts through professional CNC machining services.

Applications of 18/10 Stainless Steel

18/10 stainless steel’s higher nickel content and polished finish make it ideal for applications requiring superior corrosion resistance and an attractive appearance. Common uses include:

Applications of 304 Stainless Steel

304 stainless steel is known for its versatility and cost-effectiveness, widely used in both industrial and consumer sectors:

Summary

While both 18/10 and 304 stainless steel are valuable materials for CNC machining, the choice depends largely on the balance between aesthetic demands and budget. For projects requiring superior finish and corrosion protection, 18/10 stainless steel CNC machined parts are preferred. Conversely, 304 stainless steel CNC machined parts remain the industry standard for robust, cost-efficient manufacturing.

Table: Applications and Uses of 18/10 vs. 304 Stainless Steel

| Application Area |

18/10 Stainless Steel |

304 Stainless Steel |

| Kitchenware & Cutlery |

Premium utensils, cookware, tableware | Standard cookware and kitchen appliances |

| Medical Instruments |

Surgical tools, medical devices | General medical equipment |

| Decorative Components |

Jewelry, architectural trims, consumer goods | Structural elements with less aesthetic focus |

| Food Processing |

Equipment requiring high hygiene and corrosion resistance | Tanks, piping, processing machinery |

| Industrial Machinery |

Limited due to cost | Pumps, valves, automotive parts, machinery |

| Chemical Processing |

Select applications with high corrosion needs | Tanks, reactors, chemical handling equipment |

| Construction & Architecture |

Decorative facades, trims | Railings, supports, facade panels |

| CNC Machined Parts |

High-end precision parts with aesthetic and corrosion demands | General durable and cost-effective components |

This table gives a quick overview to help readers understand which stainless steel grade fits their specific CNC machining and manufacturing needs.

Cost is a critical factor when selecting between 18/10 stainless steel and 304 stainless steel, especially in large-scale manufacturing and CNC machining projects. While both materials offer excellent performance, their price differences can impact project budgets and long-term value. This section explores the initial cost comparison and the long-term cost benefits of choosing one over the other, helping decision-makers optimize both quality and expenses for stainless steel CNC machined parts.

Initial Cost Comparison

Generally, 18/10 stainless steel is more expensive than standard 304 stainless steel. This price premium is largely due to its higher nickel content, which drives up raw material costs. Additionally, 18/10 stainless steel is often produced in smaller quantities and stocked less widely, resulting in higher procurement and lead times for CNC machining factories.

In contrast, 304 stainless steel is more widely available and produced in larger volumes, making it a more cost-effective option for manufacturers. This availability translates into lower material prices and shorter supply chains, which benefit projects requiring bulk orders of 304 stainless steel CNC machined parts.

Long-Term Cost Benefits

While the upfront cost of 18/10 stainless steel is higher, its enhanced corrosion resistance and aesthetic longevity can lead to lower maintenance, replacement, and warranty costs over the product’s lifecycle. For applications exposed to harsh environments, such as marine or food processing, the investment in 18/10 stainless steel often pays off through extended service life and fewer failures.

On the other hand, 304 stainless steel offers excellent value for projects where corrosion exposure is moderate, and aesthetic demands are less critical. Its balance of performance and price makes it suitable for durable industrial parts, where frequent replacement or maintenance is less of a concern.

Ultimately, choosing between these materials depends on the specific application requirements, budget constraints, and expected service conditions in CNC machining projects.

Here’s a clear and concise table summarizing the Cost and Pricing comparison between 18/10 and 304 Stainless Steel:

Table: Cost and Pricing Comparison of 18/10 vs. 304 Stainless Steel

| Cost Aspect |

18/10 Stainless Steel |

304 Stainless Steel |

| Initial Material Cost |

Higher due to increased nickel content and lower availability | Lower due to wider production and availability |

| Procurement Lead Time |

Longer, less commonly stocked | Shorter, widely stocked |

| Manufacturing Cost |

Slightly higher machining and processing cost due to work hardening | Generally lower machining cost and easier processing |

| Long-Term Maintenance |

Lower due to superior corrosion resistance and durability | Moderate; may require more maintenance in harsh environments |

| Replacement Frequency |

Less frequent, extends product lifecycle | May require more frequent replacement under aggressive conditions |

| Overall Cost Efficiency |

Better for high-end, corrosion-sensitive applications | Cost-effective for general industrial applications |

This table provides a quick overview to help readers evaluate the financial implications of choosing between these two stainless steel grades in CNC machining projects.

Understanding the national and international standards for stainless steel grades is crucial when specifying materials for CNC machining projects. Both 18/10 stainless steel and 304 stainless steel conform to widely recognized standards, which ensure consistent quality, chemical composition, and mechanical properties.

National Standards

18/10 Stainless Steel: This designation is primarily a consumer or commercial labeling referring to stainless steel containing approximately 18% chromium and 10% nickel. It does not represent a formal standard but falls within the specifications of several recognized grades, mainly 304 stainless steel.

304 Stainless Steel: This is the official grade under many standards, including:

These standards define the chemical composition, mechanical properties, and testing methods for 304 stainless steel, ensuring high quality and reliable performance for stainless steel CNC machined parts.

Equivalent Grades

Because 18/10 stainless steel is largely synonymous with 304 stainless steel, their equivalents in other standards align as follows:

| Standard/Region |

Equivalent Grade for 18/10 and 304 Stainless Steel |

| ASTM | 304 |

| EN (Europe) | 1.4301 (X5CrNi18-10) |

| JIS (Japan) | SUS304 |

| ISO | X5CrNi18-10 |

| UNS (Unified Numbering System) | S30400 |

Importance for CNC Machining

When sourcing materials or specifying stainless steel for CNC machining services, referencing these standards helps ensure the correct grade and quality. Manufacturers and CNC machining factories can reliably meet design requirements and compliance by using standard-grade 304 stainless steel or its equivalents labeled as 18/10 in commercial contexts.

Choosing between 18/10 stainless steel and 304 stainless steel depends on several factors including application requirements, budget, and desired material performance. Both materials offer excellent corrosion resistance and durability, but their subtle differences can significantly impact the success and cost-effectiveness of CNC machining projects. This section guides manufacturers, engineers, and buyers in making informed decisions to select the optimal stainless steel grade for their needs.

When Should I Use 18/10 Stainless Steel?

18/10 stainless steel is the preferred choice when superior corrosion resistance, a bright polished finish, and longevity are critical. It is ideal for:

Though more expensive, 18/10 stainless steel ensures premium quality and longevity, making it a worthwhile investment for projects demanding both performance and appearance.

When Should I Use 304 Stainless Steel?

304 stainless steel is a versatile, cost-effective choice suitable for a wide range of industrial and consumer applications, such as:

Its widespread availability and balanced properties make 304 stainless steel an excellent all-around material for durable, efficient stainless steel CNC machined parts.

Here’s a clear, professional table summarizing when to use 18/10 stainless steel versus 304 stainless steel for your article:

Table: When to Choose 18/10 vs. 304 Stainless Steel

| Criteria |

Use 18/10 Stainless Steel |

Use 304 Stainless Steel |

| Corrosion Resistance |

Needed for high corrosion environments like marine, food processing, medical | Suitable for moderate corrosion environments |

| Surface Finish |

High polish, bright, and lustrous finish required | Standard finish; less emphasis on aesthetic shine |

| Application Type |

Premium kitchenware, medical instruments, decorative parts | General machinery, automotive, architectural components |

| Budget |

Higher budget for premium quality and longevity | Cost-sensitive projects requiring reliable performance |

| Exposure to Chemicals/Moisture |

Frequent exposure to acids, salts, and moisture | Moderate exposure, typical industrial or indoor use |

| Machining Project Scale |

Smaller, precision CNC machining projects with aesthetic demands | Large-scale CNC machining requiring cost efficiency |

This table helps readers quickly decide the best stainless steel grade for their specific CNC machining and manufacturing needs.

When comparing 304 stainless steel and Grade 8 stainless steel, it’s important to recognize that these two steels serve very different purposes and possess distinct mechanical properties.

304 stainless steel is an austenitic stainless steel known for its excellent corrosion resistance, good ductility, and balanced strength. Its tensile strength typically ranges between 520 and 750 MPa, making it suitable for a wide range of structural and industrial applications, especially where corrosion resistance is a priority.

On the other hand, Grade 8 stainless steel (often referring to Grade 8 bolts or fasteners) generally falls into the category of high-strength alloy steels or martensitic stainless steels. Grade 8 bolts, for example, are typically made from medium carbon alloy steel that is heat-treated to achieve very high tensile strengths, often exceeding 1,200 MPa (about twice that of 304 stainless steel).

Key Differences:

Conclusion

In terms of pure strength, Grade 8 stainless steel is stronger than 304 stainless steel. However, if corrosion resistance is a key factor, especially for CNC machined parts exposed to moisture or chemicals, 304 stainless steel is usually the better choice. Selecting between these materials depends on balancing strength requirements with environmental conditions and application needs.

Selecting the right stainless steel grade is vital for ensuring the success, durability, and cost-effectiveness of any manufacturing or CNC machining project. Both 18/10 stainless steel and 304 stainless steel are widely used materials with proven performance, but their suitability depends on your project’s specific requirements.

Suitability of 18/10 Stainless Steel

If your project demands:

then 18/10 stainless steel CNC machined parts are highly suitable. Though typically higher in cost, the enhanced nickel content and finish quality justify the investment for premium and precision applications.

Suitability of 304 Stainless Steel

For projects where:

304 stainless steel CNC machined parts provide an excellent balance between performance and affordability. Its wide availability and reliable properties make it the go-to choice for many CNC machining factories and manufacturing processes.

Final Considerations

Ultimately, the choice between 18/10 and 304 stainless steel should be guided by the balance between performance needs, budget constraints, and application environment. Consulting with your CNC machining services provider or factory can help tailor the material choice to your project goals, ensuring optimal results.

VMT is a trusted CNC machining factory specializing in precision manufacturing of 18-10 stainless steel CNC machined parts, 304 stainless steel CNC machined parts, and a wide range of other stainless steel components. With extensive experience and advanced CNC machining services, VMT delivers high-quality parts tailored to your specific project requirements.

Customized Solutions for Diverse Stainless Steel Grades

Whether your project requires the superior corrosion resistance of 18-10 stainless steel or the cost-effective versatility of 304 stainless steel, VMT offers customized machining solutions. Our expert engineers collaborate closely with clients to select the optimal stainless steel grade based on application, environment, and budget, ensuring your parts meet exact performance and quality standards.

Advanced CNC Machining Capabilities

Equipped with state-of-the-art CNC machines, VMT provides:

This enables us to manufacture stainless steel CNC machined parts that deliver excellent mechanical properties, surface finishes, and durability.

Quality Assurance and Compliance

At VMT, quality is paramount. We adhere to international standards and conduct rigorous inspections at every stage of production, including:

These quality controls ensure that every stainless steel part leaving our CNC machining factory meets or exceeds your expectations.

Comprehensive Support and After-Sales Service

Beyond manufacturing, VMT provides comprehensive support, including:

This end-to-end approach makes VMT a reliable partner for your stainless steel CNC machining needs.

By choosing VMT, you gain access to expert craftsmanship, advanced CNC machining services, and consistent quality in 18-10 stainless steel CNC machined parts and 304 stainless steel CNC machined parts, helping your project succeed with precision and reliability.

Choosing between 18/10 stainless steel and 304 stainless steel involves carefully balancing factors such as corrosion resistance, mechanical properties, aesthetic requirements, and budget constraints. While both materials are widely used and offer excellent performance for various applications, 18/10 stainless steel stands out for its higher nickel content, superior corrosion resistance, and polished finish, making it ideal for premium and demanding environments. Meanwhile, 304 stainless steel remains a versatile, cost-effective choice suitable for a broad range of industrial and consumer uses.

For manufacturers and engineers seeking precision and reliability in stainless steel CNC machined parts, understanding the nuanced differences between these grades is essential. Whether you prioritize durability, cost efficiency, or visual appeal, selecting the right stainless steel grade can significantly impact your project's success.

Partnering with an experienced CNC machining factory like VMT ensures access to expert guidance, advanced machining capabilities, and rigorous quality control, delivering high-quality 18-10 stainless steel CNC machined parts and 304 stainless steel CNC machined parts tailored to your specific needs.

Ultimately, informed material selection combined with professional CNC machining services will help you achieve durable, high-performance parts that meet both technical requirements and budget goals.

What is the difference between 304 and 1018 stainless steel?

304 stainless steel is an austenitic stainless steel known for corrosion resistance and durability, widely used in CNC machining and manufacturing. In contrast, 1018 is a low-carbon mild steel with limited corrosion resistance, primarily used in structural applications rather than stainless steel machining.

Is 304 a premium stainless steel?

Yes, 304 stainless steel is considered a premium stainless steel grade due to its excellent corrosion resistance, good mechanical properties, and versatility across industries.

Is 18/10 stainless steel the same as 304 or 316?

18/10 stainless steel typically refers to stainless steel with about 18% chromium and 10% nickel, which aligns closely with the composition of 304 stainless steel. It is not the same as 316 stainless steel, which contains higher molybdenum for enhanced corrosion resistance.

Is 18/8 stainless steel the same as 304?

Yes, 18/8 stainless steel is another common name for 304 stainless steel, indicating roughly 18% chromium and 8% nickel content.

What are the uses of 1018 steel?

1018 steel is mainly used for structural and mechanical parts where corrosion resistance is not a priority, including shafts, pins, and gears.

Is 18/10 stainless steel better than 304 stainless steel?

They are essentially the same grade, with 18/10 referring to the chromium and nickel percentages in 304 stainless steel. Differences usually come down to manufacturing processes and finishing.

How can I tell if it's 304 or 316 stainless steel?

316 stainless steel contains molybdenum, offering better corrosion resistance, especially against chlorides. Lab testing, material certificates, or magnetic response tests can help differentiate them.

Which is stronger, 18/8 or 316 stainless steel?

316 stainless steel generally has better corrosion resistance but similar mechanical strength compared to 18/8 (304) stainless steel.

Does 304 stainless steel rust?

304 stainless steel is highly corrosion-resistant but can rust under extreme conditions, especially if exposed to chlorides or poor maintenance.

Which is more expensive, 304 or 316 stainless steel?

316 stainless steel is more expensive due to added molybdenum and improved corrosion resistance.

Is 304 stronger than 316?

Their strength is comparable, though 316 offers better corrosion resistance rather than significantly higher strength.

Which is better, 316 or 18/8 stainless steel?

316 is better for corrosive environments, especially marine or chemical applications. 18/8 (304) is suitable for general use.

Which is stronger, 18-10 or 18/8 stainless steel?

Both terms refer to similar stainless steel grades with slightly different nickel content; mechanical strength is essentially the same.

What is another name for 304 stainless steel?

Common names include 18/8 stainless steel, 18/10 stainless steel, SUS304, and A2 stainless steel.

Which is better, 304 stainless steel or 18/8?

They are essentially the same grade, with 18/8 indicating chromium and nickel percentages typical of 304 stainless steel.