15 years one-stop China custom CNC machining parts factory

384 |

Published by VMT at Jul 26 2025 | Reading Time:About 10 minutes

384 |

Published by VMT at Jul 26 2025 | Reading Time:About 10 minutes

Choosing the right knives steel can feel overwhelming. With dozens of options available—each boasting different levels of hardness, edge retention, corrosion resistance, and price—buyers and manufacturers alike often struggle to find the best material for their specific needs. Whether you're crafting precision blades or sourcing CNC machining services for knives steel parts, making the wrong choice can result in subpar performance, rapid wear, or costly replacements.

But there’s good news: with the right knowledge, you can confidently match the ideal knives steel to your application, whether it's everyday carry, kitchen use, or industrial-grade cutting tools. From high-performance stainless steels like S30V and M390 to tough carbon steels like 1095 and CPM-M4, this comprehensive guide covers everything you need to know about knives steels and their suitability for CNC machining.

Read on to discover the best knives steels available today—and how CNC machining factories can help turn the right steel into high-performance cutting tools.

The best knives steels offer a balance of hardness, toughness, corrosion resistance, edge retention, and cost-efficiency. Popular choices include M390, CPM-S35VN, VG-10, and D2 steel. Selecting the right steel depends on intended use, maintenance preferences, and compatibility with CNC machining services for consistent, precision manufacturing.

Knives enthusiasts, manufacturers, and CNC machining specialists alike can benefit from understanding how various steels perform under real-world conditions. This guide not only breaks down key characteristics like wear resistance and corrosion protection, but also explores how each steel behaves during CNC machining processes—especially relevant for producing precision blade components.

To dive deeper into the specifics, let’s start by reviewing the fundamental characteristics that make a steel ideal for knives—and which ones matter most depending on your needs.

Key Points: 37 Knives Steels at a Glance

Before you dive into the detailed breakdown of each steel, here’s a quick summary of what this guide covers:

When selecting the ideal knives steel, five core properties stand out as the primary decision drivers. Each steel type varies across these dimensions, and the ideal balance depends on your knives's intended use—be it for outdoor survival, food preparation, industrial cutting, or collectible craftsmanship. These five characteristics also influence how easily the material can be shaped, machined, and finished using CNC machining services.

Hardness

Hardness refers to a steel's ability to resist deformation under stress, often measured by the Rockwell Hardness Scale (HRC). Harder steels typically hold an edge longer but are more difficult to sharpen and more prone to chipping. For instance, premium stainless steels like CPM-S110V and ZDP-189 offer excellent hardness (often above HRC 60), making them ideal for wear-critical cutting tasks.

In CNC machining factories, high-hardness steels can present tooling challenges and increased wear on cutting tools. However, with proper tooling and feeds/speeds, these materials can be precisely shaped into high-performance knives components. A balance must be struck—too soft, and edge retention suffers; too hard, and the steel may become brittle.

Toughness

Toughness measures a steel’s ability to absorb impact and resist chipping or breaking. This is especially important for outdoor knives and survival blades, which must endure rough use. Tougher steels include CPM-3V and CPM CruWear, which can survive repeated impacts without fracturing.

From a CNC processing perspective, tougher steels often require slower machining speeds and stronger cutting tools. This makes CNC machining services critical for achieving clean profiles and tolerances without inducing micro-cracks or structural fatigue.

Wear Resistance

Wear resistance refers to a knives steel’s ability to withstand abrasion and material loss during cutting or repeated use. This property is especially important for knives that are subjected to tough materials like rope, cardboard, or bone. High wear resistance is typically found in steels with high volumes of hard carbides, such as vanadium or tungsten carbides. Steels like CPM-S90V, M390, and Maxamet are excellent examples—they hold their edge incredibly well due to their superior wear-resistant microstructure.

In CNC machining factories, high wear-resistant steels can be challenging to process due to their hardness and carbide density. Tooling wear increases, requiring advanced CNC machining services equipped with high-end carbide or ceramic tools. Despite the challenges, these steels yield blades with excellent longevity, making them a popular choice for premium knives brands and industrial cutting tools.

For applications requiring long-term sharpness and minimal sharpening, prioritizing wear resistance is a wise choice—particularly if the manufacturing partner can handle the steel’s machining complexities.

Corrosion Resistance

Corrosion resistance is a steel’s ability to resist rust and oxidation, especially when exposed to moisture, salt, or acids. Stainless steel for knives typically includes at least 12–13% chromium, which forms a passive oxide layer that protects the blade. Steels like VG-10, Elmax, and H1 offer outstanding corrosion resistance, making them ideal for kitchen knives, diving knives, and outdoor tools exposed to humid or salty environments.

Stainless steels are generally more forgiving during CNC processing compared to high-alloy tool steels. However, their performance still varies depending on exact chemical composition and heat treatment. CNC machining factories must account for potential work hardening and surface finish requirements when processing stainless steel CNC machining parts.

For users who prioritize ease of maintenance and durability in wet environments, selecting a corrosion-resistant knives steel is essential.

Edge Retention

Edge retention refers to how long a blade maintains a sharp cutting edge under regular use. It’s influenced by a combination of hardness, wear resistance, and microstructure stability. Steels like CPM-20CV, S35VN, and ZDP-189 are known for excellent edge retention, making them suitable for precision cutting applications where frequent sharpening is undesirable.

From a machining standpoint, steels with high edge retention are often harder and contain more wear-resistant carbides, which can make them tougher to cut and finish. This increases CNC machining complexity and tooling costs, but the trade-off is a knives that performs exceptionally over time.

For manufacturers and users seeking long-lasting performance with minimal maintenance, edge retention is a top priority. It’s especially critical in knives used for continuous or repetitive cutting in industrial, culinary, or field environments.

Cost

Cost is always a factor when selecting knives steel—especially for mass production or budget-conscious consumers. High-performance steels like M390 or CPM-S110V can significantly increase the cost of both raw materials and machining due to their complexity and required CNC machining services. On the other hand, more affordable steels like 8Cr13MoV, 420HC, or 1095 offer decent performance at a lower price point and are easier to machine, reducing manufacturing overhead.

For CNC machining factories, lower-cost steels are easier and faster to process, making them suitable for large-batch production of consumer-grade knives. However, the trade-off often lies in reduced performance—whether in corrosion resistance, edge retention, or toughness.

Choosing the right steel requires balancing budget with intended application. Premium knives may justify the investment in exotic steels and high-precision CNC machining, while utility or entry-level knives may benefit more from affordable, easy-to-machine options.

Comparison Table: Key Characteristics of Knives Steel

| Characteristic |

Definition |

Examples of High Performance Steels |

CNC Machining Consideration |

| Hardness |

Resistance to deformation or denting (measured in HRC). | ZDP-189, CPM-S110V, M390 | Harder to machine; may cause more tool wear. |

| Toughness |

Ability to absorb impact without chipping or breaking. | CPM-3V, CPM CruWear, A2 | Tough steels may be slower to machine but are less brittle. |

| Wear Resistance |

Ability to resist abrasion and surface wear over time. | CPM-S90V, Maxamet, K390 | High wear resistance increases tooling wear and machining time. |

| Corrosion Resistance |

Ability to resist rust or oxidation, especially in moist or salty environments. | H1, Elmax, VG-10 | Stainless steels are easier to maintain but may work harden during machining. |

| Edge Retention |

How long a blade stays sharp with use. | CPM-20CV, S35VN, S30V | High edge retention steels require precise, high-quality CNC machining. |

| Cost |

Raw material and machining expenses. | 8Cr13MoV, 420HC (Low) / M390, S110V (High) | Lower-cost steels are easier to machine; high-end steels increase complexity. |

This table helps summarize the factors to consider when choosing the right knives steel for both end-users and CNC machining factories.

There is no one-size-fits-all answer to the question “Which steel is best for knives?”—because the best knives steel depends entirely on the intended application. Whether you're choosing knives steel for daily carry, outdoor survival, culinary use, or industrial tools, selecting the right material involves balancing key properties such as hardness, corrosion resistance, edge retention, and machinability.

For high-end performance and long-term durability, M390 and CPM-S35VN are often considered top-tier options. M390 is a premium stainless steel known for its excellent edge retention, wear resistance, and high corrosion resistance—making it suitable for high-precision knives and CNC machining services that demand tight tolerances. Similarly, CPM-S35VN offers a slightly easier-to-sharpen alternative with great toughness and machinability, which makes it popular among custom knives makers and CNC machining factories.

If budget is a concern, 8Cr13MoV or 420HC are good lower-cost stainless steel for knives that still deliver decent corrosion resistance and easy machinability. These steels are ideal for entry-level blades and are widely used in mass production environments where fast, cost-effective CNC machining is essential.

Outdoor enthusiasts often prefer tougher steels like CPM-3V or D2, which are less likely to chip or crack under harsh use. However, these may be prone to rust if not properly maintained, which should be factored into your decision.

Ultimately, the best knives steel is the one that meets your performance expectations and suits the capabilities of your CNC machining service provider. Choosing the correct steel ensures the blade performs well, lasts longer, and aligns with your budget—whether you’re producing individual steel CNC machining parts or large production batches.

Understanding the different categories of knives steel is crucial for selecting the best material for your specific cutting needs. Knives steels are broadly classified into several types based on their chemical composition and intended performance. These categories include carbon steel, tool steel (low alloy and high alloy), high speed steel, stainless steel, and Damascus steel. Each group has distinct advantages and drawbacks in terms of hardness, corrosion resistance, toughness, and compatibility with CNC machining services.

CNC machining factories often evaluate steel type before processing to ensure the material aligns with the desired finish, tolerance, and manufacturing speed. For example, high carbon steels may be easier to machine but require additional steps to prevent rust, while stainless steel for knives is favored for corrosion-resistant applications and long-term durability.

In this section, we’ll explore the key characteristics, strengths, and trade-offs of each major knives steel category.

Carbon steel is one of the oldest and most widely used materials for knives. It is composed primarily of iron and carbon, without significant amounts of chromium or other alloying elements. The high carbon content gives these steels excellent hardness and edge retention, making them popular for applications where sharpness and cutting power are critical—such as hunting, bushcraft, or chef knives.

However, carbon steels are highly prone to rust and discoloration if not properly maintained. They require regular oiling and drying after each use, especially in humid or salty environments. Popular carbon steels include 1095, 1066, and 1084, which are often used for fixed-blade outdoor knives and traditional culinary tools.

For CNC machining factories, carbon steels are generally easier to cut and shape, resulting in cost-effective production of steel CNC machining parts. Still, post-machining treatments such as coating or bluing are often recommended to improve corrosion resistance.

Low Alloy Tool Steel

Low alloy tool steels are engineered for strength, toughness, and moderate corrosion resistance. These steels contain small amounts of elements like chromium, vanadium, or molybdenum to improve hardenability and wear resistance while maintaining excellent machinability. Examples include steels like 5160 and O1.

These materials are frequently used in tactical knives, survival blades, and other tools that demand impact strength and edge durability. They may not resist rust as well as stainless options, but their performance in extreme use environments makes them a reliable choice for military or outdoor gear.

Low alloy tool steels are well-suited for CNC machining due to their workability and consistency. CNC machining factories often choose these materials for custom knives parts or mid-tier production runs, especially where cost-efficiency and mechanical strength must be balanced.

High Alloy Tool Steel

High alloy tool steels take toughness and wear resistance to the next level by adding greater quantities of elements like vanadium, tungsten, and cobalt. These steels form complex carbides that improve edge retention and durability under heavy-duty usage. D2, CPM-M4, and CruWear are prominent examples.

These steels are often used in premium cutting tools, industrial knives, and hard-use blades where long-term sharpness is vital. While many high alloy steels offer partial corrosion resistance, they may still require coating or maintenance to avoid oxidation.

CNC machining services must be equipped with high-performance tooling and optimized cutting strategies to process high alloy steels efficiently. These steels are tough on tooling but offer high rewards in performance—making them a preferred choice in specialized applications.

High Speed Steel

High speed steels (HSS) are known for maintaining hardness at elevated temperatures, making them ideal for use in high-friction or high-speed cutting environments. Steels like M2 and M42 are common examples used not only in machining tools but also in specialized knives applications that require both heat resistance and wear performance.

Knives made from high speed steel are rare but appreciated for their edge stability and abrasion resistance. They can be brittle compared to other knives steels, which makes them more suitable for precision or light-duty tasks rather than impact-heavy applications.

From a CNC machining perspective, high speed steels are difficult to process and require top-tier equipment, but many CNC machining factories are capable of handling them when the application demands ultra-durable, heat-resistant blades.

Tool Steel

Tool steel is a broad category that includes both low and high alloy steels engineered for shaping, cutting, and punching other materials. Their application in knives varies from utility blades and workshop knives to custom and tactical tools. Popular tool steels include A2, O1, and S7, offering a balance of hardness, toughness, and machinability.

Tool steels are often chosen for knives that require strength and wear resistance under repeated use. While some lack corrosion resistance, their ease of sharpening and edge retention qualities make them dependable choices for field tools and workshop blades.

Tool steels are readily available in most CNC machining factories and are well-known for their dimensional stability and machinability—making them a practical option for steel CNC machining parts.

Stainless steel is the most popular category for consumer and kitchen knives due to its excellent corrosion resistance. By definition, stainless steel contains at least 12–13% chromium, which forms a passive oxide layer that protects the surface from rust and oxidation. Popular stainless steels for knives include VG-10, CPM-S35VN, M390, and 440C.

These steels are favored for culinary knives, EDC (everyday carry) tools, and diving knives due to their resistance to staining and low maintenance requirements. Some stainless steels offer a premium balance of edge retention, hardness, and corrosion resistance—especially powder metallurgy grades like CPM-20CV and Elmax.

For CNC machining services, stainless steels are among the most commonly processed materials. While some types are prone to work hardening, modern CNC machining factories can handle stainless steel CNC machining parts with high precision and consistency, producing blades that are both beautiful and functional.

Damascus Steel Knives

Damascus steel knives are known for their distinctive wavy patterns and blend of performance and aesthetics. Traditionally made by forge-welding multiple types of steel together, modern Damascus knives are often created using high-performance stainless or carbon steel layered for visual effect and functional benefit.

While not a separate steel type in itself, Damascus steel can combine the best attributes of different knives steels—such as the toughness of 1095 with the corrosion resistance of 15N20. The result is a knives that not only performs well but also appeals to collectors and enthusiasts.

Damascus-style billets can be more difficult to machine due to varying hardness within the layers. However, CNC machining factories with experience in Damascus or laminated steels can produce intricate and precise Damascus blade profiles, handles, and decorative components.

Here’s a comparison table summarizing the Common Knives Steel Types, helping readers quickly understand the differences between them in terms of performance and CNC machining compatibility:

Table: Comparison of Common Knives Steel Types

| Steel Type |

Key Characteristics |

Typical Applications |

CNC Machining Considerations |

| Carbon Steel |

High hardness, excellent edge retention, poor corrosion resistance | Hunting knives, chef knives, bushcraft tools | Easy to machine; may require post-processing for corrosion resistance |

| Low Alloy Tool Steel |

Good toughness, moderate wear and corrosion resistance | Tactical knives, survival tools, shop blades | Good machinability; commonly used for custom CNC knives parts |

| High Alloy Tool Steel |

Superior wear resistance, high toughness, moderate corrosion resistance | Industrial knives, premium EDC knives | Harder to machine; requires high-end tooling in CNC machining factories |

| High Speed Steel |

Retains hardness at high temperatures, extreme wear resistance | Specialized knives, cutting tools | Difficult to machine; needs advanced equipment and slower cutting speeds |

| Tool Steel |

Balanced hardness and toughness, varies by grade | Utility knives, workshop blades | Widely used in CNC machining; stable and predictable processing behavior |

| Stainless Steel |

Excellent corrosion resistance, wide performance range depending on grade | Kitchen knives, diving knives, everyday carry | Common in CNC machining services; some grades may work harden |

| Damascus Steel Knives |

Aesthetic appeal, layered performance depending on constituent steels | Custom and collectible knives | Variable hardness can complicate machining; requires experienced handling |

This table helps both technical and non-technical readers compare knives steel categories at a glance and understand their relationship to CNC machining services and steel CNC machining parts production.

Every type of knives steel has its own strengths and weaknesses. Choosing the right one means carefully balancing performance, durability, ease of maintenance, and machinability. For knives manufacturers and users alike, understanding these trade-offs is critical—not just for performance in the field or kitchen, but also during the CNC machining process. Whether working with carbon steel, stainless steel for knives, or exotic layered steels like Damascus, selecting the appropriate steel impacts everything from blade longevity to production cost and efficiency.

In the following sections, we explore the pros, cons, and care tips for each major knives steel type to help you make the most informed decision possible—especially when partnering with CNC machining factories to produce high-precision knives components.

Carbon Steel

Pros and Cons of Using Carbon Steel for Knives

Pros:

Cons:

Carbon steel remains a favorite among outdoor enthusiasts and professional chefs for its sharpness and strength. It’s often used in traditional or bushcraft knives, where rugged edge performance is a priority. From a CNC machining perspective, carbon steel is relatively easy to process, making it a practical choice for steel CNC machining parts in custom or mass production settings.

Maintenance and Maintenance Tips

To extend the lifespan of a carbon steel blade:

Low Alloy Tool Steel

Pros and Cons of Using Low Alloy Tool Steel for Knives

Pros:

Cons:

Low alloy tool steels strike a good balance between performance and affordability. They are used in survival and tactical knives where toughness is essential. These steels are generally CNC-friendly and compatible with most CNC machining services, making them suitable for both custom and OEM knives production.

Maintenance and Maintenance Tips

High Alloy Tool Steel

Pros and Cons of Using High Alloy Tool Steel for Knives

Pros:

Cons:

High alloy tool steels are used in premium knives, industrial cutters, and performance blades. Steels like D2, CPM-M4, and CruWear excel in abrasive tasks. CNC machining factories require robust tooling to handle these steels, but the result is a high-quality steel for knives that performs over the long term.

Maintenance and Maintenance Tips

High Speed Steel

Pros and Cons of Using High Speed Steel for Knives

Pros:

Cons:

Though more common in industrial tools than consumer knives, high speed steels like M2 and M42 can produce ultra-durable cutting instruments. These materials are complex to machine and typically require CNC machining factories equipped with high-end carbide tooling and optimized machining strategies.

Maintenance and Maintenance Tips

Stainless Steel

Pros and Cons of Using Stainless Steel for Knives

Pros:

Cons:

Stainless steel for knives is widely used across kitchenware, EDC tools, and outdoor gear. Premium stainless grades like M390, Elmax, and CPM-S35VN deliver high hardness and wear resistance, while budget steels like 8Cr13MoV or 420HC offer decent performance at a lower cost. Stainless steel CNC machining parts are common in modern production due to their clean finish and corrosion resistance.

Maintenance and Maintenance Tips

Damascus Steel Knives

Pros and Cons of Using Damascus Steel for Knives

Pros:

Cons:

Modern Damascus steel knives are often made from layered high-carbon or stainless steels. The performance depends on the base metals used, but they usually offer a good balance of strength, edge retention, and appearance. Damascus billets can be challenging for CNC machining services due to variable hardness, but experienced CNC machining factories can handle intricate profiles and finishes.

Maintenance and Maintenance Tips

Here is a table summarizing the Common Knives Steels: Pros, Cons, and Maintenance Tips for easy comparison:

| Steel Type |

Pros |

Cons |

Maintenance Tips |

| Carbon Steel |

- Excellent hardness and edge retention - Easy to sharpen - Affordable |

- Prone to rust and discoloration - High maintenance |

- Wipe dry after use - Oil regularly - Store in dry place |

| Low Alloy Tool Steel |

- Tough and durable - Better corrosion resistance than carbon steel - Stable heat treatment |

- Not fully rustproof - Can chip under stress |

- Clean and oil after use - Use blade coatings - Sharpen regularly |

| High Alloy Tool Steel |

- Superior edge retention - High wear resistance - Long tool life |

- Hard to sharpen - Can be brittle - Requires advanced machining |

- Use diamond sharpeners - Store dry - Apply rust inhibitors |

| High Speed Steel |

- Heat-resistant - Extreme wear resistance - Long-lasting edge |

- Brittle - Expensive - Difficult to machine |

- Avoid drops - Use diamond hones - Lightly oil if carbon-based |

| Stainless Steel |

- Rust-resistant - Low maintenance - Food-safe and versatile |

- Some grades dull quickly - High-end types can be costly |

- Rinse and dry - Strop as needed - Avoid dishwashers |

| Damascus Steel |

- Beautiful layered pattern - Balanced performance - Collectible |

- Quality varies - Risk of rust - Expensive to produce |

- Keep dry - Light oiling - Avoid abrasive cleaning |

Choosing the right knives steel can be the difference between a knives that lasts a lifetime and one that fails under pressure. Whether you're a professional chef, outdoor adventurer, or collector, understanding the unique advantages of today’s top-performing steels helps you make smarter buying decisions. This guide highlights nine high-performance steels dominating the knives industry today, analyzing their features, benefits, and ideal applications.

CPM-S110V Steel

What is CPM-S110V Steel?

CPM-S110V is a premium particle metallurgy stainless steel developed by Crucible Industries. It offers exceptional wear resistance and edge retention thanks to its high vanadium and niobium content.

Pros and Cons of Using CPM-S110V Steel for Knives

Advantages:

Disadvantages:

CPM-S90V Steel

What is CPM-S90V Steel?

Another Crucible creation, CPM-S90V is a high-vanadium stainless steel known for wear resistance and cutting performance in premium folding and fixed-blade knives.

Advantages and Disadvantages of Using CPM-S90V Steel for Knives

Advantages:

Disadvantages:

M390 Steel

What is M390 Steel?

M390 is a third-generation powder metallurgy steel produced by Böhler-Uddeholm. It’s engineered for high-end knives where both wear and corrosion resistance are crucial.

Advantages and Disadvantages of Using M390 Steel for Knives

Advantages:

Disadvantages:

K390 Steel

What is K390 Steel?

Böhler’s K390 is a high-speed tool steel with remarkable wear resistance, often chosen for industrial cutting tools and high-performance knives.

Advantages and Disadvantages of Using K390 Steel for Knives

Advantages:

Disadvantages:

ZDP 189 Steel

What is ZDP 189 Steel?

Developed by Hitachi, ZDP 189 is a Japanese powder steel with very high carbon and chromium content, making it ultra-hard and wear-resistant.

Advantages and Disadvantages of Using ZDP 189 Steel for Knives

Advantages:

Disadvantages:

Elmax Steel

What is Elmax Steel?

Elmax is a “super clean” powder metallurgy steel from Uddeholm. It balances corrosion resistance, wear resistance, and toughness, making it popular in survival knives.

Advantages and Disadvantages of Using Elmax Steel for Knives

Advantages:

Disadvantages:

CPM-20CV Steel

What is CPM-20CV Steel?

Produced by Crucible, CPM-20CV is comparable to M390 and CTS-204P. It features a high volume of vanadium carbides and a rich chromium composition for maximum performance.

Advantages and Disadvantages of Using CPM-20CV Steel for Knives

Advantages:

Disadvantages:

CTS-XHP Steel

What is CTS-XHP Steel?

CTS-XHP is a Carpenter Technology steel that blends the characteristics of 440C and D2. It is a high-carbon, high-hardness stainless steel with fine grain for razor edges.

Advantages and Disadvantages of Using CTS-XHP Steel for Knives

Advantages:

Disadvantages:

CTS-204P Steel

What is CTS-204P Steel?

CTS-204P is Carpenter’s equivalent to M390 and CPM-20CV. Known for its balanced performance, it's widely used in high-end folders and EDC knives.

Advantages and Disadvantages of Using CTS-204P Steel for Knives

Advantages:

Disadvantages:

CPM-M4 Steel

What is CPM-M4 Steel?

CPM-M4 is a high-speed tool steel with extreme wear resistance and toughness. It’s not stainless, but it’s a favorite among custom makers for performance-driven knives.

Advantages and Disadvantages of Using CPM-M4 Steel for Knives

Advantages:

Disadvantages:

CPM S35VN

What is CPM S35VN Steel?

CPM S35VN is a premium stainless steel developed by Crucible Industries in collaboration with Chris Reeve Knives. It’s a refined version of S30V, designed to offer better toughness, ease of sharpening, and overall balance.

Advantages and Disadvantages of Using CPM S35VN Steel for Knives

Advantages:

Disadvantages:

CPM-S30V

What is CPM-S30V Steel?

CPM-S30V was once the gold standard for premium knives steels. Created specifically for cutlery, it balances edge retention, toughness, and corrosion resistance exceptionally well.

Advantages and Disadvantages of Using CPM-S30V Steel for Knives

Advantages:

Disadvantages:

154CM

What is 154CM Steel?

154CM is a high-carbon, high-molybdenum stainless steel originally developed by Crucible. It’s known for its wear resistance and good edge-holding capability.

Advantages and Disadvantages of Using 154CM Steel for Knives

Advantages:

Disadvantages:

ATS-34

What is ATS-34 Steel?

ATS-34 is a Japanese equivalent of 154CM, produced by Hitachi. It gained popularity for its fine grain and high hardness, especially in tactical and custom knives.

Advantages and Disadvantages of Using ATS-34 Steel for Knives

Advantages:

Disadvantages:

D2 Steel

What is D2 Steel?

D2 is a semi-stainless tool steel with high wear resistance. It's known for its toughness and ability to hold an edge even under harsh conditions.

Advantages and Disadvantages of Using D2 Steel for Knives

Advantages:

Disadvantages:

VG-10

What is VG-10 Steel?

VG-10 is a high-end stainless steel from Japan, widely used in culinary and EDC knives. It balances edge sharpness, corrosion resistance, and ease of maintenance.

Advantages and Disadvantages of Using VG-10 Steel for Knives

Advantages:

Disadvantages:

H1 Steel

What is H1 Steel?

H1 is a nitrogen-based stainless steel created specifically for extreme corrosion resistance. It’s ideal for saltwater environments, diving knives, and wet conditions.

Advantages and Disadvantages of Using H1 Steel for Knives

Advantages:

Disadvantages:

N680

What is N680 Steel?

N680 is a nitrogen-enriched stainless steel made by Böhler. Designed for high corrosion resistance, it's commonly used in diving and medical knives.

Advantages and Disadvantages of Using N680 Steel for Knives

Advantages:

Disadvantages:

440C

What is 440C Steel?

440C is a high-carbon stainless steel that once defined premium knives performance. It’s still widely used due to its good hardness, wear resistance, and affordability.

Advantages and Disadvantages of Using 440C Steel for Knives

Advantages:

Disadvantages:

AUS-8

What is AUS-8 Steel?

AUS-8 is a Japanese stainless steel known for its toughness and corrosion resistance. It’s a common choice in budget-friendly EDC and tactical knives.

Advantages and Disadvantages of Using AUS-8 Steel for Knives

Advantages:

Disadvantages:

CTS-BD1

What is CTS-BD1 Steel?

CTS-BD1 is a vacuum-melted stainless steel from Carpenter. It offers a great balance of hardness, corrosion resistance, and ease of sharpening, often used in mid-range knives.

Advantages and Disadvantages of Using CTS-BD1 Steel for Knives

Advantages:

Disadvantages:

8Cr13MoV Steel

What is 8Cr13MoV Steel?

8Cr13MoV is a Chinese stainless steel often compared to AUS-8. It’s a budget-friendly option used in many entry-level knives due to its balance of performance and cost.

Advantages and Disadvantages

Advantages:

Disadvantages:

5Cr14MoV Steel

What is 5Cr14MoV Steel?

5Cr14MoV is a low-cost stainless steel typically used in kitchen and utility knives. It offers decent corrosion resistance with easy maintenance.

Advantages and Disadvantages

Advantages:

Disadvantages:

14C28N Steel

What is 14C28N Steel?

14C28N is a Swedish stainless steel made by Sandvik. It’s designed for improved hardness and edge stability while maintaining rust resistance.

Advantages and Disadvantages

Advantages:

Disadvantages:

440A Steel

What is 440A Steel?

440A is a stainless steel with high chromium content, commonly used in low- to mid-tier knives. It's known for corrosion resistance over edge retention.

Advantages and Disadvantages

Advantages:

Disadvantages:

420HC Steel

What is 420HC Steel?

420HC is a modified version of 420 stainless steel with higher carbon, offering better edge performance while maintaining rust resistance. It’s used by brands like Buck Knives.

Advantages and Disadvantages

Advantages:

Disadvantages:

13C26 Steel

What is 13C26 Steel?

13C26 is another Sandvik steel similar to AEB-L. Known for its fine grain structure, it’s capable of taking a very sharp edge.

Advantages and Disadvantages

Advantages:

Disadvantages:

1095 Steel

What is 1095 Steel?

1095 is a high-carbon tool steel widely used in survival, bushcraft, and fixed-blade knives. It excels in toughness and edge retention.

Advantages and Disadvantages

Advantages:

Disadvantages:

1066 Carbon Steel

What is 1066 Carbon Steel?

1066 is a high-carbon steel with even higher hardness potential than 1095, often used in machetes or hard-use knives where toughness is key.

Advantages and Disadvantages

Advantages:

Disadvantages:

420J Steel

What is 420J Steel?

420J is a low-end stainless steel with very high corrosion resistance and low hardness. It’s often used in display knives or kitchen tools.

Advantages and Disadvantages

Advantages:

Disadvantages:

AUS-6 Steel

What is AUS-6 Steel?

AUS-6 is a Japanese stainless steel similar to 420HC. It’s commonly found in entry-level knives and kitchen blades.

Advantages and Disadvantages

Advantages:

Disadvantages:

Maxamet Steel

What is Maxamet Steel?

Maxamet is a proprietary high-speed steel from Carpenter, offering extreme hardness and wear resistance. It’s used in ultra-premium knives.

Advantages and Disadvantages

Advantages:

Disadvantages:

CPM-10V Steel

What is CPM-10V Steel?

CPM-10V is a Crucible tool steel with extreme wear resistance and high vanadium content. Ideal for industrial cutting tools and high-performance knives.

Advantages and Disadvantages

Advantages:

Disadvantages:

CPM CruWear Steel

What is CPM CruWear Steel?

CPM CruWear is a tool steel from Crucible with a balance of toughness, wear resistance, and moderate corrosion protection — often considered a “tougher cousin” to D2.

Advantages and Disadvantages

Advantages:

Disadvantages:

VG-10 Steel

(Note: Already covered in Part 2. Here’s a quick recap.)

What is VG-10 Steel?

VG-10 is a premium Japanese stainless steel used in culinary and EDC knives, known for sharpness and corrosion resistance.

Advantages and Disadvantages

Advantages:

Disadvantages:

Here’s a comprehensive comparison table summarizing the 35 popular knives steels from your outline. It includes key attributes to help customers quickly compare performance and choose the best steel for their needs.

Popular Knives Steels Comparison Table

| Steel Type | Steel Category | Edge Retention | Toughness | Corrosion Resistance | Ease of Sharpening | Notable Use Cases |

| CPM-S110V | Powder Stainless | ★★★★★ | ★★ | ★★★★☆ | ★ | Premium EDC, folding knives |

| CPM-S90V | Powder Stainless | ★★★★★ | ★★☆ | ★★★★☆ | ★ | High-end folders, outdoor knives |

| M390 | Powder Stainless | ★★★★☆ | ★★★ | ★★★★★ | ★★☆ | EDC, tactical, collector's knives |

| K390 | Tool Steel | ★★★★★ | ★★★★ | ★ | ★★ | Utility, hard-use, industrial knives |

| ZDP-189 | Powder Stainless | ★★★★★ | ★★☆ | ★★★ | ★ | Precision slicers, high-end folders |

| Elmax | Powder Stainless | ★★★★ | ★★★★ | ★★★★☆ | ★★★☆ | Outdoor, survival, EDC |

| CPM-20CV | Powder Stainless | ★★★★★ | ★★★ | ★★★★★ | ★★☆ | Premium EDC, all-purpose |

| CTS-XHP | Stainless Tool | ★★★★ | ★★★☆ | ★★★★ | ★★★☆ | Pocket knives, tactical |

| CTS-204P | Powder Stainless | ★★★★★ | ★★★ | ★★★★★ | ★★☆ | Folding knives, premium EDC |

| CPM-M4 | Tool Steel | ★★★★★ | ★★★★★ | ★ | ★ | Combat, hard-use knives |

| CPM-S35VN | Powder Stainless | ★★★★☆ | ★★★☆ | ★★★★☆ | ★★★☆ | Premium all-around knives steel |

| CPM-S30V | Powder Stainless | ★★★★ | ★★★ | ★★★★ | ★★☆ | Classic premium EDC |

| 154CM | Stainless | ★★★☆ | ★★★ | ★★★☆ | ★★★☆ | General-purpose, budget mid-tier knives |

| ATS-34 | Stainless | ★★★☆ | ★★★ | ★★★ | ★★★☆ | Tactical and custom knives |

| D2 | Semi-Stainless | ★★★★☆ | ★★★★ | ★★☆ | ★★ | Outdoor, utility, survival |

| VG-10 | Stainless | ★★★☆ | ★★★ | ★★★★☆ | ★★★☆ | Kitchen, EDC |

| H1 | Nitrogen Stainless | ★★☆ | ★★★ | ★★★★★ | ★★★☆ | Marine, diving knives |

| N680 | Nitrogen Stainless | ★★☆ | ★★☆ | ★★★★★ | ★★★☆ | Water-use, medical knives |

| 440C | Stainless | ★★★☆ | ★★☆ | ★★★☆ | ★★★☆ | Classic folders, budget hunting knives |

| AUS-8 | Stainless | ★★☆ | ★★★ | ★★★☆ | ★★★★ | Budget EDC, tactical knives |

| CTS-BD1 | Stainless | ★★☆ | ★★★ | ★★★★ | ★★★★ | Mid-range kitchen or pocket knives |

| 8Cr13MoV | Stainless | ★★☆ | ★★☆ | ★★★☆ | ★★★★ | Entry-level EDC |

| 5Cr14MoV | Stainless | ★★ | ★★☆ | ★★★★☆ | ★★★★☆ | Kitchen knives, budget blades |

| 14C28N | Stainless | ★★★☆ | ★★★ | ★★★★ | ★★★★ | Mid-tier EDC, culinary |

| 440A | Stainless | ★★☆ | ★★☆ | ★★★★ | ★★★★☆ | Low-end kitchen knives |

| 420HC | Stainless | ★★☆ | ★★★☆ | ★★★★☆ | ★★★★ | Outdoor knives, Buck knives |

| 13C26 | Stainless | ★★★ | ★★★ | ★★★☆ | ★★★★☆ | Razor blades, thin slicing knives |

| 1095 | High Carbon Steel | ★★★★ | ★★★★☆ | ★ | ★★★★★ | Bushcraft, survival fixed-blades |

| 1066 | High Carbon Steel | ★★★☆ | ★★★★☆ | ★ | ★★★★☆ | Choppers, machetes |

| 420J | Stainless | ★ | ★ | ★★★★☆ | ★★★★★ | Display knives, budget kitchen blades |

| AUS-6 | Stainless | ★ | ★★☆ | ★★★☆ | ★★★★★ | Entry-level knives |

| Maxamet | High-Speed Tool | ★★★★★+ | ★☆ | ★ | ★ | Ultra-premium EDC, collectors |

| CPM-10V | Tool Steel | ★★★★★ | ★★☆ | ★ | ★ | Industrial, wear-intensive cutting tools |

| CPM CruWear | Tool Steel | ★★★★☆ | ★★★★★ | ★★☆ | ★★★☆ | Hard-use folders, tactical knives |

Legend:

Conclusion

Each of these knives steels represents a high-performance solution tailored to specific use cases—whether it's edge retention, corrosion resistance, or toughness. If you're investing in a high-end blade, understanding these materials will help you choose the steel that matches your lifestyle, budget, and usage intensity. Whether it's the ultra-hard ZDP 189 for precision cuts or the well-rounded M390 for everyday use, your ideal knives steel is just a decision away.

While high-end steels like CPM S35VN and S30V are known for elite-level edge retention and corrosion resistance, there are plenty of capable and affordable options like 154CM, VG-10, or D2 that still perform admirably in everyday situations. Whether you're buying for the kitchen, outdoor use, or professional tasks, choosing the right knives steel comes down to balancing your budget, usage style, and desired maintenance level.

This section rounds out the spectrum of knives steels — from affordable, corrosion-resistant steels like 8Cr13MoV and AUS-6 to elite-performance options like Maxamet and CPM CruWear. For budget-conscious buyers or kitchen users, steels like 420HC or 14C28N offer tremendous value. Meanwhile, professionals, collectors, and outdoorsmen may gravitate toward CPM-10V or Maxamet for unrivaled performance.

Want a comparison table or help selecting the best steel for your specific use? Let me know—I can tailor a guide just for that!

As knives steel technology continues to evolve, manufacturers and enthusiasts alike are gravitating toward steels that offer elite-level balance — combining edge retention, toughness, and corrosion resistance without major compromises. Two standout performers in this category are Cru-Wear and the revolutionary CPM MagnaCut. These steels are not just trends — they represent the future of knives performance, and understanding their unique qualities helps consumers make smarter, long-term choices.

Cru-Wear Steel

What is Cru-Wear?

Cru-Wear is a Crucible Industries tool steel designed for maximum toughness and wear resistance. It’s often considered a tougher, more corrosion-resistant alternative to D2 and CPM M4. With high vanadium and tungsten content, Cru-Wear is optimized for extreme durability without sacrificing cutting performance.

Advantages and Disadvantages of Using Cru-Wear Steel for Knives

Advantages:

Disadvantages:

Best For:

CPM MagnaCut Steel

What is CPM MagnaCut?

CPM MagnaCut is a groundbreaking stainless steel developed by Dr. Larrin Thomas in collaboration with Crucible Industries. It’s a powder metallurgy steel engineered to deliver the trifecta of knives performance: top-tier edge retention, extreme toughness, and stainless corrosion resistance — without the traditional trade-offs.

Advantages and Disadvantages of Using CPM MagnaCut Steel for Knives

Advantages:

Disadvantages:

Best For:

Final Thoughts on Cru-Wear and CPM MagnaCut

If you’re looking for steel that can handle the extremes — whether that’s wilderness survival, daily carry, or tactical use — Cru-Wear and CPM MagnaCut are standout performers. Cru-Wear offers elite toughness with tool steel reliability, while CPM MagnaCut redefines what's possible in stainless steel performance. For customers who want no-compromise quality, these steels are worth every penny.

Choosing the right knives starts with understanding the steel it’s made from. Not all steels are created equal — each one has unique characteristics that affect performance, maintenance, and longevity. Below are the core properties that define how a knives steel behaves, helping you make informed decisions whether you're buying a kitchen knives, outdoor tool, or EDC folder.

1. Edge Retention

Definition: How long the blade stays sharp during use.

Why it matters:

A knives with high edge retention will stay sharp longer, making it ideal for extended tasks like food prep, field use, or cutting rope and cardboard. Steels like CPM-S110V, M390, and Maxamet excel in this category.

What to look for:

2. Toughness

Definition: The blade’s ability to resist breaking, chipping, or cracking under stress.

Why it matters:

If you plan to use your knives for batoning, prying, or impact cutting, toughness is crucial. Steels like Cru-Wear, CPM-3V, and 1095 offer high durability without brittleness.

What to look for:

3. Corrosion Resistance

Definition: How well the steel resists rust, stains, or discoloration when exposed to moisture, salt, or acidic materials.

Why it matters:

Knives used in kitchens, humid environments, or marine conditions need high corrosion resistance. Stainless steels like H1, VG-10, CPM MagnaCut, and 14C28N offer excellent protection.

What to look for:

4. Sharpenability

Definition: How easy it is to sharpen the blade and restore a fine edge.

Why it matters:

Knives that are difficult to sharpen can be frustrating to maintain. While ultra-hard steels retain their edge, they often require diamond stones or professional tools. Steels like 420HC, AUS-8, and 1095 are easier to sharpen at home.

What to look for:

5. Wear Resistance

Definition: Resistance to abrasion, which directly impacts how fast the edge wears down over time.

Why it matters:

High wear resistance ensures long-term edge stability, especially in harsh environments. Steels like CPM-10V, S90V, and ZDP-189 resist dulling even after repeated heavy use.

What to look for:

6. Hardness (HRC Rating)

Definition: A measure of how hard the steel is, usually shown on the Rockwell Hardness Scale (HRC).

Why it matters:

Harder steels hold a sharper edge but are more brittle. Softer steels are tougher but dull faster. A good everyday balance is around 58–62 HRC.

General HRC Guidelines:

Summary Table: Key Knives Steel Characteristics

| Characteristic |

Improves... |

Trade-Off |

Best Steels Examples |

| Edge Retention |

Long-lasting sharpness | Harder to sharpen | S110V, Maxamet, M390 |

| Toughness |

Resistance to breaking/chipping | May lose edge faster | Cru-Wear, 1095, CPM-3V |

| Corrosion Resistance |

Rust/stain protection | Often softer than tool steels | H1, MagnaCut, VG-10 |

| Sharpenability |

Easy maintenance | Less edge retention | 420HC, AUS-8, 1095 |

| Wear Resistance |

Edge longevity under abrasion | Difficult to reprofile | CPM-10V, ZDP-189, S90V |

| Hardness (HRC) |

Cutting performance | Brittle if too hard | Depends on steel (58–65 HRC) |

Final Thoughts

Every knives steel is a trade-off — there’s no one-size-fits-all. The key is to match the steel’s characteristics to your needs. Whether you want a rust-proof fishing knives, a shaving-sharp kitchen slicer, or a field-ready survival tool, understanding these properties ensures you make the right choice the first time.

Knives steel is more than just “metal” — it’s a carefully balanced recipe of alloying elements, each contributing unique properties. From edge retention to corrosion resistance, every element plays a role in how the knives performs in real-world use. Whether you’re a knives enthusiast, manufacturer, or shopper comparing steels, understanding these chemical components will help you choose the right steel for your cutting needs.

Below is a breakdown of the most important elements found in modern knives steels — what they are, why they’re used, and how they impact performance.

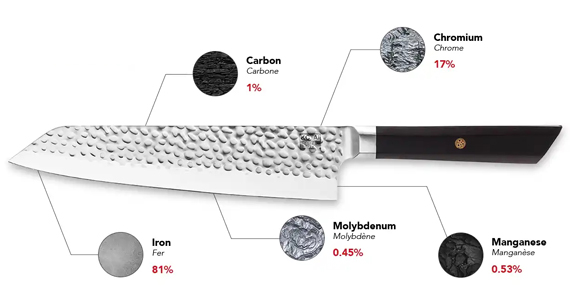

Carbon (C)

Chromium (Cr)

Molybdenum (Mo)

Nickel (Ni)

Vanadium (V)

Cobalt (Co)

Manganese (Mn)

Silicon (Si)

Niobium (Nb)

Tungsten (W)

Sulfur (S)

Phosphorus (P)

Nitrogen (N)

Copper (Cu)

Aluminum (Al)

Boron (B)

Lead (Pb)

Selenium (Se)

Tantalum (Ta)

Zirconium (Zr)

Summary Table: Key Elements in Knives Steels

| Element |

Key Effect on Knives Steel |

Common Steels Featuring It |

| Carbon |

Hardness, edge retention | D2, 1095, S90V |

| Chromium |

Corrosion resistance, hardness | 440C, S30V, VG-10 |

| Molybdenum |

Toughness, strength | CPM-154, Elmax |

| Nickel |

Toughness, corrosion resistance | 316 stainless, some kitchen steels |

| Vanadium |

Edge retention, wear resistance | S110V, M390, S35VN |

| Cobalt |

Strength, heat resistance | M390, VG-10 |

| Manganese |

Hardness, strength | AUS-8, 1095 |

| Silicon |

Toughness, deoxidizing | D2, tool steels |

| Niobium |

Toughness, fine edge stability | S35VN, Vanax |

| Tungsten |

High hardness, wear resistance | CPM-10V, tool steels |

| Sulfur |

Machinability | 416 stainless |

| Phosphorus |

Strength, edge stability | Basic stainless steels |

| Nitrogen |

Corrosion resistance, hardness | H1, LC200N, Vanax |

| Copper |

Antibacterial, corrosion resistance | Marine-grade steels |

| Aluminum |

Strength, deoxidizer | Some tool steels |

| Boron |

Hardenability | Tool steels |

| Lead |

Machinability (non-knives use) | Industrial steels |

| Selenium |

Machinability (rare) | Specialty alloys |

| Tantalum |

Corrosion resistance, thermal stability | Surgical, aerospace alloys |

| Zirconium |

Strength, corrosion resistance (emerging steels) | Custom steels |

Final Thoughts

Knives steel chemistry is a balancing act — adding one element may improve edge retention but reduce toughness. The best knives steels are expertly blended to meet specific needs, whether that’s food-safe corrosion resistance, field-ready toughness, or scalpel-like sharpness.

Understanding these elements will help you choose knives based not just on branding — but on real performance science.

CPM steel stands for Crucible Particle Metallurgy steel, a family of premium high-performance tool steels produced using an advanced powder metallurgy process. Known for outstanding edge retention, toughness, and wear resistance, CPM steels are widely used in high-end knives, industrial tools, and aerospace components.

What Does "CPM" Mean?

CPM is short for Crucible Particle Metallurgy, a proprietary manufacturing process developed by Crucible Industries in the United States.

Traditional steel is made by melting raw materials and casting them into solid ingots. In contrast, CPM steel is made by atomizing molten steel into fine powder, then pressing and sintering that powder into solid bars. This process ensures:

Why Is CPM Steel Better for Knives?

CPM steels are engineered for extreme cutting applications. Compared to conventional steels, they offer:

| Performance Trait |

Advantage of CPM Steel |

| Edge Retention | Finer carbide distribution = longer-lasting sharpness |

| Toughness | Less likely to chip or snap under stress |

| Wear Resistance | Maintains cutting power even in abrasive environments |

| Corrosion Resistance | Superior in CPM stainless grades like CPM-S30V or S35VN |

| Sharpening Precision | Consistent grain = cleaner, more predictable edge geometry |

Popular Types of CPM Knives Steels

| CPM Grade |

Key Feature |

Best For |

| CPM-S30V |

Balanced corrosion & edge retention | Premium EDC, outdoor knives |

| CPM-S35VN |

Improved toughness over S30V | Tactical, survival, and custom knives |

| CPM-S90V |

Extreme wear resistance | High-end slicers, collectors |

| CPM-3V |

Maximum toughness (non-stainless) | Choppers, survival blades |

| CPM-10V |

Industrial-level wear resistance | Cutting tools, specialty knives |

| CPM-M4 |

Tool steel with superior edge holding | High-performance folders, sports use |

| CPM-CruWear |

Tough tool steel, excellent edge holding | Heavy-use knives and bushcraft |

| CPM-MagnaCut |

Stainless + ultra-tough + edge-holding | All-purpose elite knives (new-gen) |

Is CPM Steel Stainless?

Some CPM steels are stainless, while others are non-stainless tool steels. For a steel to be stainless, it must contain at least 13% chromium.

Always check your intended environment (wet, corrosive, outdoor use, etc.) before choosing a CPM grade.

Why Knives Makers Choose CPM Steel

From custom knives artisans to global brands like Spyderco, Benchmade, and Bark River, many choose CPM for:

Final Thoughts

CPM steel isn't just a material — it's a performance upgrade.

When you see "CPM" on a blade, you're looking at a knives crafted for precision, power, and longevity. While it may cost more than standard steels, the durability and edge-holding power make CPM knives a smart long-term investment for professionals and enthusiasts alike.

Austenitic steel is a non-magnetic, corrosion-resistant stainless steel ideal for environments needing rust resistance and formability.

Martensitic steel, on the other hand, is magnetic, hardenable, and stronger, making it better suited for knives, cutting tools, and wear-resistant components.

What is Austenitic Stainless Steel?

Austenitic steel has a face-centered cubic (FCC) crystal structure. It contains high levels of chromium (≥16%) and nickel (8–10%), with low carbon content.

Key Features:

Common Grades:

Best For:

What is Martensitic Stainless Steel?

Martensitic steel has a body-centered tetragonal (BCT) structure and higher carbon content, which makes it heat treatable and hardenable.

Key Features:

Common Grades:

Best For:

Comparison Table: Austenitic vs. Martensitic Steel

| Property | Austenitic Steel | Martensitic Steel |

| Microstructure | Austenite (FCC) | Martensite (BCT) |

| Corrosion Resistance | Excellent | Moderate |

| Hardness (after HT) |

Not hardenable | Very high (with heat treatment) |

| Magnetic? |

No (non-magnetic) | Yes (magnetic) |

| Toughness |

High | Medium |

| Edge Retention |

Low | High |

| Machinability |

Fair | Good (annealed), Hard (hardened) |

| Applications |

Sinks, tanks, cookware | Knives, tools, wear parts |

Which One Should You Choose?

| Application |

Recommended Steel Type |

| Cutting performance & wear resistance | Martensitic |

| Corrosion-critical environments | Austenitic |

| Decorative, food-contact CNC parts | Austenitic |

| Knives blades or surgical tools | Martensitic |

| Forming, bending, or welding projects | Austenitic |

Final Thoughts

Choosing between austenitic and martensitic stainless steel depends on performance needs:

Damascus steel refers to a distinctive type of layered or patterned steel known for its beautiful wavy designs, excellent strength, toughness, and sharpness. Modern Damascus is typically created by forge-welding multiple layers of different steels together, resulting in a blade that combines the best qualities of each layer.

The History of Damascus Steel

The name “Damascus steel” originally described a legendary Middle Eastern steel used from around the 3rd century AD to the 17th century. Historical Damascus blades were famed for their unique watery or “flowing” patterns, exceptional sharpness, and durability.

The exact original process was lost over time, and today’s “Damascus steel” is a modern recreation inspired by those ancient blades, achieved by pattern welding different steel types.

How Is Modern Damascus Steel Made?

Modern Damascus steel is created by forge-welding alternating layers of two or more steels with contrasting properties — for example:

The layered billet is repeatedly heated, hammered, folded, and twisted, creating hundreds of layers. This process:

Characteristics of Damascus Steel

| Feature | Description |

| Unique Pattern | Beautiful flowing, wavy, or ladder-like designs created by layering steel |

| Edge Performance |

Sharp and holds edge well due to high-carbon layers |

| Toughness |

Soft layers add flexibility and resistance to cracking |

| Corrosion Resistance |

Varies depending on steel types used, generally moderate |

| Craftsmanship |

Each blade is unique due to the hand-forging process |

Advantages of Damascus Steel for Knives

Disadvantages to Consider

How to Identify Authentic Damascus

Final Thoughts

Damascus steel is a fusion of art and engineering, blending visual beauty with practical cutting performance. Whether you’re a collector, chef, or outdoor enthusiast, a well-made Damascus knives offers both functional excellence and unmatched aesthetics.

No — even if two blades are made from the same steel grade, their performance, durability, and quality can vary significantly. Factors such as heat treatment, blade geometry, manufacturing process, and finish play critical roles in determining the final blade characteristics.

Why Does the Same Steel Result in Different Blade Quality?

1. Heat Treatment Process

2. Blade Geometry and Design

3. Manufacturing and Quality Control

4. Surface Treatment and Coatings

5. Source and Batch Variations

What This Means for You as a Buyer

Final Thoughts

The steel grade is just the starting point. The expertise behind heat treatment, design, and finishing ultimately determines whether the blade meets your expectations in sharpness, durability, and reliability.

When selecting a knives, steel grade is important but not the only factor influencing performance and user satisfaction. To make the best choice for your needs, consider these additional aspects:

1. Blade Heat Treatment

2. Blade Geometry and Edge Type

3. Intended Use

4. Maintenance Requirements

5. Cost vs. Performance

6. Corrosion Resistance

7. Manufacturer Reputation and Quality Control

8. Aesthetic and Ergonomic Factors

Summary

Selecting the right knives steel is a balance of material properties, intended use, maintenance willingness, and budget. Considering these factors alongside steel grade ensures you get a knives that truly meets your expectations — whether for professional use or personal enjoyment.

Choosing the right knives steel is more than just picking a name or grade—it’s about understanding the unique balance of hardness, toughness, corrosion resistance, and maintenance that best fits your specific needs. Whether you prioritize long-lasting sharpness for demanding outdoor use, easy upkeep for kitchen tasks, or stunning aesthetics for a collector’s piece, knowing the characteristics of different steels empowers you to make informed decisions.

Modern advancements like CPM powder metallurgy steels and innovations such as Damascus layering provide unprecedented performance and style, while classic steels continue to prove their worth through reliable versatility.

Ultimately, a knives’s performance depends not only on the steel itself but also on expert heat treatment, precise blade geometry, and meticulous craftsmanship. Investing in quality steel combined with skilled manufacturing ensures your knives delivers exceptional durability, cutting power, and satisfaction for years to come.

Make your next knives purchase a smart, confident choice — because the right steel is the foundation of every great blade.

1. Is Steel Good for Knives?

Yes. Steel is the primary material used for knives due to its strength, hardness, and ability to hold a sharp edge. Different steel types offer various balances of sharpness, toughness, and corrosion resistance.

2. What Are the Three Types of Steel Knives?

The three main types are:

3. Is 154CM a Good Steel?

Yes, 154CM is a high-quality stainless steel known for excellent edge retention, corrosion resistance, and good toughness. It’s popular in mid to high-end knives.

4. Which is Better, Iron or Steel Knives?

Steel knives are better because steel is an alloy of iron with added elements improving hardness, durability, and corrosion resistance. Pure iron knives are rare and generally inferior for cutting tasks.

5. Can Steel Really Sharpen?

Steel knives can be sharpened effectively using proper sharpening stones or tools. The steel’s hardness affects how easily it can be sharpened and how long the edge will last.

6. What Steels Are the Best Knives Made of?

Some of the best knives steels include CPM-S35VN, M390, S90V, VG-10, and 154CM due to their balance of edge retention, toughness, and corrosion resistance.

7. What Are Cheap Knives Made Of?

Cheap knives often use lower-grade stainless steels like 420, 3Cr13, or AUS-8, which are easier to manufacture and maintain but offer lower edge retention and durability.

8. Is 420 Steel Suitable for Knives?

420 steel is suitable for budget knives and tools requiring corrosion resistance, but it has relatively low hardness and edge retention compared to premium steels.

9. Which Steel Is Best for Knives?

The best steel depends on your needs. For premium knives, CPM-S35VN, M390, and S90V are top choices. For everyday use, steels like VG-10 and 154CM balance performance and cost.

10. What Does 420 Stainless Steel Contain?

420 stainless steel contains about 12–14% chromium, making it corrosion-resistant but generally lower in carbon (~0.15%) compared to higher-grade steels.

11. Which Is Better, 440 Steel or 420 Steel?

Generally, 440 steel (especially 440C) is better than 420 steel in hardness and edge retention, making it more suitable for quality knives.

12. Is S30V Steel Good?

Yes, CPM-S30V is a premium stainless steel known for excellent edge retention, corrosion resistance, and toughness, widely used in high-end knives.

13. Is 3Cr13 Stainless Steel Suitable for Knives?

3Cr13 is a budget stainless steel with decent corrosion resistance and moderate hardness, suitable for entry-level knives but not for heavy-duty use.

14. Is VG-10 Better Than S30V?

VG-10 is a high-quality Japanese stainless steel offering excellent sharpness and corrosion resistance. S30V generally has better wear resistance and toughness, making it superior for heavy or prolonged use.

15. Is D2 Steel Better Than 440C?

D2 is a semi-stainless tool steel with higher carbon and chromium than 440C, offering better wear resistance and edge retention but less corrosion resistance.

16. Will Steel Knives Rust?

Steel knives can rust if not properly maintained, especially high-carbon or non-stainless steels. Stainless steels resist rust better but still require care to prevent corrosion.