15 years one-stop China custom CNC machining parts factory

103 |

Published by VMT at Sep 05 2025 | Reading Time:About 2 minutes

103 |

Published by VMT at Sep 05 2025 | Reading Time:About 2 minutes

If you are choosing materials for your next project, 420 SS is a strong and affordable option you might consider. This article will explain to you what 420-SS is made of, main properties and applications. Learn how this material can help you with your project needs.

420 SS is a grade of Stainless Steel that has good hardness, wear resistance and moderate corrosion resistance. It can be heat treated which means you can harden and temper it to get the exact strength and properties you need. It’s a customizable choice for many applications.

When you understand the composition of 420 SS, you will know how well it will perform in your applications. This steel is a mix of several components, each with a specific role.

|

Name |

Role |

Percentage |

|

Chromium |

Adds corrosion resistance and hardenability |

12-14% |

|

Carbon |

Increases hardness and strength |

0.15-0.38% |

|

Manganese |

Improves machinability and workability |

1% max |

|

Silicon |

Acts as a deoxidizer and strengthens steel |

1% max |

|

Phosphorus |

Present in trace amounts as an impurity |

0.04% max |

|

Sulfur |

Controlled to preserve mechanical properties |

0.03% max |

420 SS has a density of 7.7-7.8 g/cm³ that makes it slightly lighter than many other stainless grades. The material also has good dimensional stability and can maintain its shape well under normal operating conditions.

You will appreciate the impressive strength characteristics of 420 SS. In its hardened and tempered condition, it can achieve tensile strengths up to 700 MPa with yield strengths around 500 MPa. This grade of stainless steel has excellent wear resistance and you can heat treat it for different hardness levels.

The thermal conductivity of 420 SS is approximately 24.9 W/m·K at room temperature. It has a coefficient of thermal expansion of 10.4 × 10⁻⁶/°C which might help you when designing parts that will experience temperature variations. The material can handle operating temperatures up to 750°C in oxidizing atmospheres.

420 SS is magnetic in both annealed and hardened conditions which differentiates it from austenitic grades. This magnetic property can be useful for your applications where magnetic separation or electromagnetic compatibility is needed. The permeability can also vary with heat treatment conditions.

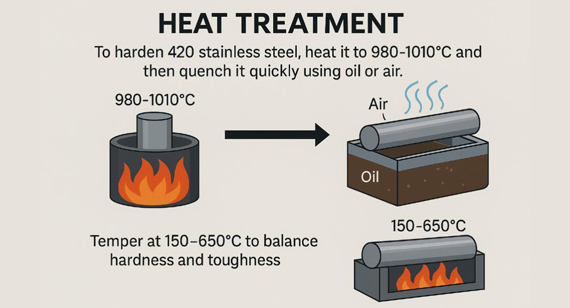

Heat Treatment

To harden 420 SS, you should heat it to 980-1010°C and then quickly cool it using oil or air. You can tamper it at 150-650°C to balance its hardness and toughness for your specific needs.

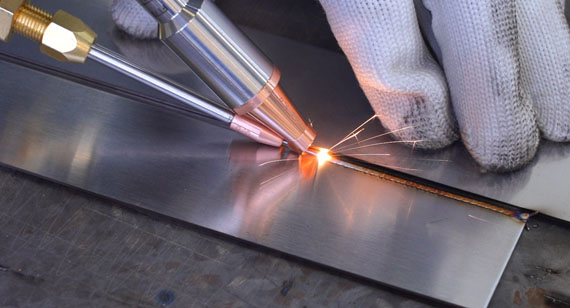

Welding

When welding 420 SS, you can pre-heat it to 200-400°C and apply heat treatment afterward to prevent cracking. Low-hydrogen electrodes and control cooling can be used to keep their strength and properties.

Machining

You can machine 420 SS easily when it’s in the annealed state using standard tools. Use carbide tools, coolant and steady feed rates to avoid hardening.

Cold Working

If you want to cold work 420 SS, start when it is in the annealed state. Since it hardens quickly, you should plan your operations carefully and can be annealed midway if needed.

420 SS is known for its ability to become very hard after heat treatment. You can harden it to levels up to 50 HRC that makes it perfect for tools or parts that face a lot of wear and tear. This is why it can be used to make items like knife blades or cutting tools that need to last a long time.

420 SS gives you solid protection against rust and corrosion caused by air, moisture and mild chemicals. While it is not as resistant as some higher grade stainless steels, it can still work well in many environments. It performs better than regular carbon steel that makes it a good choice for applications where you need modest corrosion resistance.

This steel has good strength and can be used for projects where moderate to high strength is a must. It performs well across various temperatures, so you can use it for tools, machine parts or structural components. If you need a material that balances strength and durability, 420 stainless steel is a dependable option for many different applications.

You’ll find 420 SS easy to fabricate using common tools and techniques. Whether you need to machine, weld or shape it, this material is simple to handle with the right methods. By following proper steps for heat treatment, you can get the best results.

One of the best features of 420 SS is its ability to harden through heat treatment. You can control its hardness, strength and toughness based on your needs. By adjusting processes like quenching and tempering, you can customize its performance. This feature allows you to customize the material to make it perfect for your project.

If you’re looking for a budget-friendly material, 420 SS is a great choice. It costs less than high-alloy stainless steels which makes it a smart pick for projects where extreme corrosion resistance isn’t necessary. You still get good mechanical properties at a lower cost, making 420 SS an affordable and practical option for many applications.

Tempering 420 SS after hardening allows you to adjust its hardness and toughness to fit your needs. By using the correct heat treatment process, you can achieve a good balance between strength and flexibility. Post-tempering improves its overall usability.

If you want to improve the performance of 420 SS even further, you can add surface treatments like coating, plating or nitriding. These treatments can boost its corrosion resistance, wear resistance or even improve its appearance. This makes it easy to adapt the material to fit your specific needs.

When it comes to surgical instruments, 420 SS is what you need because it’s strong, resists rust and keeps sharp edges well. It is used in tools like scissors, forceps and other medical instruments where these qualities matter the most. It is good for situations where tools need to be sterilized often and stay sharp for precise performance.

If you need bearings or bushings that don't wear out faster, you need 420 SS. It is tough, can resists wear and hold its shape over time. You can count on it to perform well in places where other materials, like bronze or carbon steel, might wear out too quickly. 420 SS is useful in moderately corrosive areas that will also help your equipment last longer and reduce the need for maintenance.

For industrial equipment like pumps, valves and manufacturing machinery, 420 SS is your cost-effective material. It has corrosion resistance and strong mechanical properties that makes it good for jobs where you need durability. Whether you are specifying parts for new machines or replacing worn components, this material can help you get a balance of performance and affordability.

If you’re working with plastic injection molding, 420 SS is what you need for less abrasive materials. It is strong and can resist wear, so your molds will last longer and keep a smooth surface finish over time. This will make your production process more efficient and help you create high-quality plastic parts. If you want a reliable material to handle frequent use, 420 SS is a good value for many molding applications.

For tools like screwdrivers, wrenches and other hand tools, 420 SS is a strong and affordable option. It resists rust and corrosion, so your tools will look good and work well for a long time. Whether you are using them daily or occasionally, they can handle regular wear and tear. It also have better durability and appearance compared to tools made from carbon steel.

420 SS is a great material for food processing equipment like utensils, preparation surfaces and machine components. It is easy to clean which is important for meeting food safety standards. Whether you are working in a commercial kitchen or processing facility, this material will make sure your equipment lasts long and stays hygienic.

316 offers superior corrosion resistance, especially in marine and chemical environments, but lacks the hardening capability of 420. You choose 316 for corrosive environments and 420 when hardness and wear resistance are priorities over maximum corrosion protection.

440C provides higher carbon content and superior hardness potential compared to 420. You select 440C for applications requiring maximum hardness and wear resistance, while 420 offers better toughness and easier machinability for general-purpose applications.

17-4 PH delivers higher strength through precipitation hardening and better corrosion resistance than 420. You choose 17-4 PH for high-strength applications in corrosive environments, while 420 provides adequate performance at lower cost for less demanding conditions.

410 contains lower carbon content than 420, resulting in better weldability but lower hardness potential. You select 410 for welded structures where moderate strength is adequate and 420 when higher hardness and wear resistance are required.

420 SS offers an excellent balance of properties for applications requiring moderate corrosion resistance, good mechanical strength and cost-effectiveness. At VMT CNC machining factory, we specialize in precision machining and fabrication of 420 SS and all other grades. Our experienced team can help you optimize your design for manufacturability while maintaining the quality standards your applications demand. Contact us today to discuss your CNC machining and fabrication needs.

Is 420 stainless steel good for knives?

Yes, 420 stainless steel is great for budget-friendly kitchen knives and utility blades. It can hold a decent edge if heat treated properly and resists rust to some extent. However, if you need better edge retention, you might consider higher-grade SS like 440C.

Does 420 stainless steel rust?

420 SS resists rust and corrosion well in normal conditions like daily kitchen use. But in marine environments or when exposed to salty or harsh conditions, it may still rust. Proper cleaning and maintenance will help prevent this.

How does 420 SS compare to 440 SS?

440 SS, especially 440C, has more carbon, making it harder and better at holding an edge. While 420 is easier to work with and tougher, 440C is preferable for premium knives due to its superior hardness.

Can 420 SS be passivated?

Yes, you can passivate 420 SS to improve its resistance to rust. Passivation removes impurities from the surface and strengthens its protective layer which is especially helpful after machining.

What are the machining considerations when working with 420 SS?

When machining 420 SS, it’s best to work on it in its softer, annealed state. Use sharp tools, steady feed rates and plenty of coolant to reduce heat and avoid hardening the material during the process.