15 years one-stop China custom CNC machining parts factory

106 |

Published by VMT at Sep 06 2025 | Reading Time:About 3 minutes

106 |

Published by VMT at Sep 06 2025 | Reading Time:About 3 minutes

You’re planning aluminum CNC machined parts and want clean, bright white anodizing. Then you’re told it’s “impossible” or risky. Confusing, right? The issue isn’t the anodizing layer—but how white works with dyes and light. Here’s the practical fix: proven alternatives that deliver durable, white surfaces without ballooning project cost today.

True white anodizing isn’t feasible because anodic pores don’t accept white dye and the oxide’s light-scattering makes whites look gray or chalky. Instead, use powder coating, electrophoretic coating, or PEO/ceramic finishes for durable white on aluminum parts, then specify sealing and gloss to match appearance and corrosion targets.

We’ll explain why white behaves differently in anodizing, when it fails, and the shop-ready alternatives that keep timelines, budgets, and brand color accurate for CNC machined parts at scale.

Anodizing is an electrochemical process that thickens the natural oxide layer on aluminum parts, making the surface harder, more wear-resistant, and more corrosion-resistant. Instead of coating aluminum with an external layer, anodizing transforms the surface itself into a protective barrier. This oxide layer is porous at first, allowing dyes or electrolytic coloring to penetrate before it’s sealed for durability.

Strictly speaking, there is no true white anodized aluminum. The anodizing process creates a transparent or slightly tinted oxide layer. To achieve color, the porous surface is dyed or electrolytically colored before sealing. Since white pigments do not absorb into the anodic pores the way other dyes do, attempts at “white anodizing” usually result in dull gray, off-white, or chalky finishes.

At first glance, anodizing seems like it should work with any color. After all, aluminum anodizing can produce deep blacks, vibrant blues, or bright reds. But white is the exception. The reasons are linked to how light interacts with the anodized layer and how dyes are absorbed into the microscopic pores of aluminum oxide.

Why is white different?

White isn’t a color in the same way blue or red is. Instead, it’s the reflection of all visible wavelengths of light. To achieve “white,” a surface must scatter and reflect light evenly across the spectrum. Anodized aluminum oxide, however, is semi-transparent and tends to distort or mute light rather than reflect it purely.

The nature of white

Because anodized layers are clear to slightly gray, they interact poorly with white pigments. When white pigments are added, they often appear dirty or off-white because the oxide film itself adds a gray undertone. This makes achieving a true, bright white nearly impossible with anodizing alone.

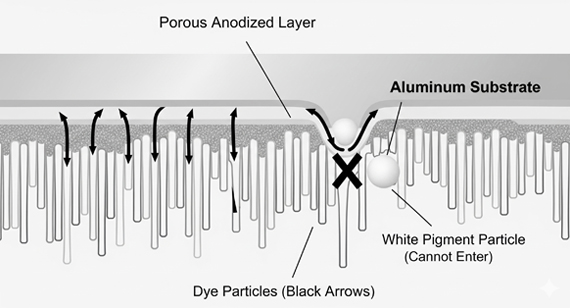

Surface porosity

During anodizing, aluminum forms a porous oxide layer that allows dyes to penetrate before sealing. These pores are well-suited for absorbing colored dyes, but they are not effective at holding or scattering white pigments. As a result, white pigments don’t lock in uniformly, leaving the surface patchy or chalky.

Dye absorption

Anodizing relies on dye molecules penetrating into the oxide pores. Black, blue, red, and other colors work well because they absorb specific wavelengths of light. White pigments, however, work by scattering light, not absorbing it. Since anodic pores can’t scatter light effectively, the “white” looks weak or dirty.

Other reasons

Beyond color science, there are also practical reasons:

Tip: Communicate your color goals early. CNC machining factories can recommend the most cost-effective finishing method that meets both function and aesthetics.

Since true white anodizing is not possible, CNC machining factories rely on alternative finishing techniques to achieve a bright white surface on aluminum parts. These methods combine durability, appearance, and cost efficiency, making them suitable for projects that require precise color matching.

Etching

Chemical or acid etching roughens the aluminum surface before further treatment. While etching itself doesn’t create white, it improves adhesion for paints, electrophoresis, or powder coating, ensuring a more uniform and durable white layer.

Sandblasting

Sandblasting uses abrasive particles to texture the aluminum before finishing. It produces a matte, light-gray base that enhances the brightness of applied white coatings. Combined with powder coating or electrophoresis, sandblasted surfaces achieve a clean, even white look.

Electrophoresis

Electrophoretic coating (also called e-coating) deposits an even, thin film of pigment across aluminum parts. Unlike anodizing, it supports pure white finishes with good adhesion and corrosion resistance. It’s especially useful for complex CNC machined parts where powder coating may be too thick.

Spraying

Spraying (liquid paint or powder coating) is the most common method for achieving white aluminum surfaces. Powder coating, in particular, provides excellent color coverage, durability, and chemical resistance. It also allows for gloss, satin, or matte whites depending on project requirements.

Comparison of White Surface Treatment Alternatives

| Method |

Can Achieve White? |

Finish Appearance |

Durability |

Typical Thickness |

Best Use Case |

Notes / Tips |

| Etching |

No (prep only) | Matte base, light gray | Low by itself | Minimal | Pre-treatment before coating | Improves adhesion for coatings; not a standalone finish |

| Sandblasting |

Indirect (prep) | Matte, textured surface | Medium (with coating) | Minimal | Enhance coating brightness | Adds cost; specify gloss level early |

| Electrophoresis |

Yes | Smooth, uniform white | Good corrosion + wear resistance | Thin (10–30 μm) | Small/complex CNC machined parts | Cost-effective for high volumes, precision safe |

| Spraying (Powder Coating) |

Yes | Gloss, satin, or matte white | Excellent mechanical + chemical resistance | Thick (50–150 μm) | Large or visible aluminum parts | Adds coating thickness—adjust tolerances |

White anodizing is often requested by designers, but it remains one of the most difficult surface treatments to achieve on aluminum CNC machined parts. The challenge lies in both the physics of light and the limitations of the anodizing process itself.

Color inconsistency

Unlike other anodized colors, white cannot be reproduced consistently across batches. Different alloys, surface finishes, and pore structures produce shades ranging from grayish to chalky white, making color matching nearly impossible.

Weak dye retention

The anodic oxide layer accepts darker dyes well, but white pigments fail to bond effectively. This leads to fading, patchy tones, or poor coverage, especially under UV exposure.

Higher rejection rate

Because achieving uniform “white” is unreliable, CNC machining factories experience higher rejection rates when attempting white anodizing. This increases cost and lead time.

Limited industrial demand

Since most industries prefer metallic or dark anodized finishes, few facilities develop or optimize white anodizing lines. This limits supplier options and increases processing risk.

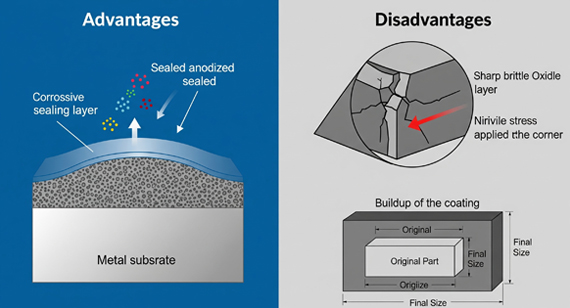

Anodizing remains one of the most popular finishing methods for aluminum CNC machined parts. While it has clear advantages in durability and appearance, it also comes with certain limitations—especially when it comes to achieving pure white finishes.

Advantages of Anodizing

Tip: For aluminum CNC machining services, anodizing is often the most cost-effective way to combine protection and aesthetics in a single process.

Disadvantages of Anodizing

Tip: To minimize cost and risk, stick to standard anodized colors like black, silver, or gray unless brand identity demands custom shades.

Advantages and Disadvantages of Anodizing

| Aspect |

Advantages |

Disadvantages |

| Durability |

Hard, wear-resistant surface that extends part lifespan | Can still scratch under heavy abrasion |

| Corrosion Resistance |

Protects aluminum parts against oxidation and environmental exposure | Requires proper sealing to be effective |

| Appearance |

Wide range of colors possible (black, red, blue, etc.) | White anodizing not achievable; color matching can vary between batches |

| Environmental Impact |

Thin oxide layer, no peeling or flaking like paint | Uses acids and chemicals that require careful disposal |

| Dimensional Accuracy |

Thin coating (5–25 μm) preserves CNC machining tolerances | Surface prep is critical—scratches remain visible after anodizing |

| Cost Efficiency |

Cost-effective for corrosion + aesthetics in one step | Custom colors and non-standard finishes increase cost and lead time |

| Material Compatibility |

Works well on aluminum, titanium, magnesium | Not suitable for stainless steel, copper, or most steels |

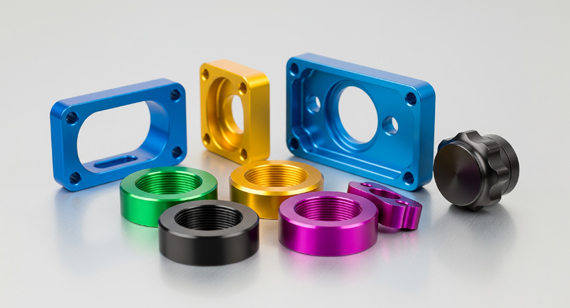

Anodizing is not only about durability—it also allows aluminum CNC machined parts to take on a wide range of colors. The coloring process happens during or after anodizing, when the porous oxide layer is still open and can accept dyes, electrolytic deposits, or other treatments before sealing.

Dyeing

In this method, organic or inorganic dyes penetrate the pores of the anodized layer. After sealing, the color becomes part of the aluminum surface. Common shades include black, red, blue, and gold. However, pure white cannot be achieved with dyeing due to the nature of light reflection.

Electrolyte Coloring

Electrolytic coloring uses metal salts such as tin or cobalt deposited in the pores of the anodized layer through an AC current. This creates metallic-looking colors, especially bronze, champagne, or black. Electrolyte coloring is known for durability and consistent batch results.

One-Piece Coloring

Also called integral coloring, this process combines anodizing and coloring in one step. As the oxide layer forms, metallic salts are co-deposited, giving the aluminum a consistent, metallic shade such as bronze or black. This method is highly durable and commonly used in architectural applications.

Interference Coloring

This technique creates colors by controlling the thickness of the anodized layer and how it refracts light. Instead of pigments, interference produces optical effects, generating vibrant blues, greens, and purples. However, it cannot produce a true white.

Impregnation

In some cases, anodized pores can be impregnated with lubricants, resins, or other compounds instead of dyes. While this doesn’t add decorative color, it enhances functional properties such as wear resistance, electrical insulation, or chemical protection.

Sealing

After coloring or impregnation, the anodized surface must be sealed. Sealing closes the microscopic pores, locking in the dye or deposited material and improving corrosion resistance. Without sealing, the color would fade quickly, and the anodized layer would remain vulnerable to staining or dirt absorption.

Anodized aluminum offers a wide range of colors, though availability depends on the method used (dyeing, electrolytic coloring, or interference). While true white anodizing is not achievable, many other shades are widely used in CNC machined parts across industries.

Standard Colors

Tip: Black anodizing is the most consistent and durable option—ideal for CNC machining services that require repeatable batches.

Specialty & Decorative Colors

Tip: Specialty colors are harder to reproduce consistently across large volumes. Always request color samples before mass production.

Why White Isn’t on the List

White anodizing is not possible because anodic pores cannot hold white pigments or scatter light evenly. When customers request “white anodized aluminum,” it usually refers to anodizing plus an additional coating such as powder coating or electrophoresis.

Colors Available for Anodized Aluminum

| Color / Shade |

How It’s Achieved |

Durability / UV Stability |

Common Applications |

Notes / Tips |

| Clear / Natural Silver |

Transparent oxide layer, no dye | High | Industrial CNC machined parts, enclosures | Shows base alloy finish, scratches remain visible |

| Black |

Organic dye or electrolytic method | Very high | Aerospace, electronics, consumer products | Most consistent and fade-resistant |

| Bronze / Champagne |

Electrolytic coloring with metal salts | High | Architectural frames, automotive trims | Metallic look, widely used outdoors |

| Gold |

Dyeing or electrolytic coloring | Medium to high | Decorative parts, electronics, luxury items | Color shade may vary by batch |

| Blue / Red / Green |

Organic dyeing | Medium | Branding parts, sports equipment, housings | Lighter shades may fade outdoors |

| Gray / Metallics |

Controlled alloy + anodizing bath | High | Industrial design, machine housings | Neutral, professional look |

| Purple / Violet |

Interference coloring | Medium | Decorative and specialty consumer products | Limited availability, higher cost |

| Turquoise / Aqua |

Specialty dyes or interference | Medium | Jewelry, decorative CNC machined parts | Not standard, requires custom order |

| White |

Not achievable with anodizing | N/A | Requires powder coating / electrophoresis | Use anodizing + coating combo for true white |

At VMT, we specialize in aluminum CNC machining combined with high-quality surface treatments, including anodizing. Whether you need natural, black, or custom-colored anodized finishes, our team ensures precise machining, consistent coloring, and reliable corrosion resistance. For projects requiring white finishes, we provide effective alternatives such as powder coating or electrophoresis to achieve your design goals.

By working with a professional CNC machining factory, you eliminate the trial-and-error often seen with unverified suppliers. Our engineers guide you from material selection to surface treatment, helping control costs while guaranteeing functional and aesthetic requirements.

While anodizing is an excellent finishing choice for aluminum CNC machined parts, it comes with one clear limitation: true white anodizing is not possible. The science of light reflection and the structure of anodic pores make pure white unachievable, often leading to gray or chalky results.

The good news is that alternatives like powder coating, electrophoresis, and ceramic (PEO) treatments can provide bright, durable white finishes while preserving the corrosion resistance and longevity of aluminum parts. Choosing the right method depends on your project’s functional needs, tolerance requirements, and budget.

At VMT, our expertise in CNC machining services and anodizing solutions ensures you get high-quality results every time. Whether you need anodized black, natural metallic, or pure white through alternative coatings, we deliver reliable finishing for industries ranging from electronics to aerospace.

1. What metals cannot be anodized?

Anodizing works primarily on aluminum, titanium, and magnesium. Metals like stainless steel, copper, and most steels cannot form a stable anodic oxide layer, so anodizing is ineffective on these surfaces.

2. Why can't stainless steel be anodized?

Stainless steel naturally forms a passive oxide layer, but it doesn’t respond to anodizing like aluminum. Attempts to anodize it won’t produce a durable or colorful layer.

3. Can you anodize with vinegar?

Vinegar is an acid and can slightly etch aluminum, but it cannot create a proper anodized layer. True anodizing requires controlled electrochemical processes with specific electrolytes.

4. What are the dangers of anodizing?

Anodizing involves strong acids (like sulfuric acid) and electrical current. Improper handling can cause chemical burns, toxic fumes, or environmental hazards. Always use certified CNC machining factories with safety protocols.

5. Why is anodized aluminum black?

Black anodized aluminum is achieved by dyeing the porous oxide layer or using electrolytic coloring. Black is one of the most stable and UV-resistant colors for anodizing.

6. Can you anodize any color?

Most colors except true white can be achieved. Darker shades like black, bronze, and blue are easiest. White cannot be achieved due to light reflection and pore absorption limitations.

7. Can you anodize silver?

Silver-colored finishes can be approximated through clear anodizing or interference methods, but pure silver is not typically used for anodizing.

8. Can anodizing be covered up?

Yes. Painted or powder-coated layers can be applied over anodized aluminum, but this may reduce some corrosion resistance benefits.

9. Can copper be anodized? Why can't steel be anodized?

Copper does not form a thick, porous oxide layer suitable for coloring, and steel cannot form a stable anodic oxide like aluminum, so both metals are unsuitable for standard anodizing.

10. Can you anodize welded aluminum?

Yes, but welds may appear darker or uneven due to localized alloy differences. Pre-treatment and careful control of anodizing parameters are necessary for uniform results.

11. Does anodizing prevent rust?

Anodizing protects aluminum from corrosion and oxidation, but it does not make ferrous metals like steel rust-proof. Sealing improves corrosion resistance further.

12. Can you anodize over an old anodized layer?

It is possible but not ideal. Re-anodizing may produce uneven thickness, color variation, or poor adhesion. Often, the old layer must be stripped before re-anodizing.