15 years one-stop China custom CNC machining parts factory

419 |

Published by VMT at Aug 08 2025 | Reading Time:About 9 minutes

419 |

Published by VMT at Aug 08 2025 | Reading Time:About 9 minutes

Manufacturers and product designers constantly search for ways to improve the durability, aesthetics, and corrosion resistance of stainless steel CNC machined parts. While anodizing is a common surface treatment for aluminum, many are unsure whether this technique applies to stainless steel. The confusion stems from stainless steel’s naturally passive oxide layer and its distinct chemical structure. This lack of clarity can lead to costly errors or missed opportunities when working with CNC machining services. The good news? There are ways to achieve an anodized-like finish on stainless steel—if you understand the process. Let’s demystify the challenges, possibilities, and solutions when it comes to anodized stainless steel CNC machined parts.

Stainless steel can be anodized, but the process is more complex than with aluminum. Due to its passive oxide layer, stainless steel requires specialized electrolytes and tightly controlled conditions. Alternatively, finishes like PVD, passivation, and coating offer similar results with fewer challenges. For most CNC machining factories, these alternatives are more cost-effective and visually consistent.

While anodizing stainless steel is technically feasible, it's not the first choice for many CNC machining services due to the complexity, cost, and inconsistent results. Yet with increasing demands for high-performance and visually distinctive components, engineers are exploring all possible surface treatments. Whether you're sourcing anodized CNC machined parts or considering an alternative finish for your stainless steel components, understanding these options will help you make the best decision for your project. Keep reading to discover how anodizing compares to other methods—and what’s best for your application.

Looking for the right surface treatment for your next product? Explore our comprehensive guides on PVD coatings, electropolishing, and passivation for stainless steel. These pages detail how each method affects appearance, corrosion resistance, and cost—especially when working with stainless steel CNC machined parts. Click through to see which finishing process suits your product and budget best.

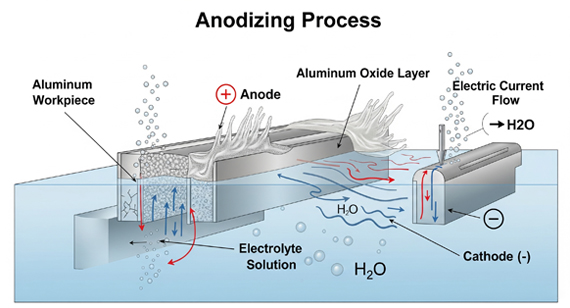

Anodizing is an electrochemical surface treatment process that enhances the natural oxide layer on metals—most commonly aluminum. By immersing the metal in an electrolyte bath and applying an electrical current, the surface oxidizes in a controlled manner, forming a thicker and more durable oxide layer. This anodized layer is chemically bonded to the metal substrate, making it highly resistant to corrosion, wear, and environmental degradation. Unlike paint or plating, anodizing doesn’t peel or chip; it becomes an integral part of the base metal.

The primary purpose of anodizing is to improve the metal’s surface hardness, resistance to corrosion, and overall appearance. The process can also make the material more receptive to coloring, offering design flexibility for applications requiring both performance and visual appeal. These characteristics make anodizing particularly popular for aerospace components, architectural materials, and consumer electronics.

While aluminum is the most commonly anodized metal, other materials such as titanium, magnesium, and zinc can also undergo this process. However, when it comes to anodized stainless steel, the process is more specialized due to the metal’s naturally passive surface. In the context of CNC machining services, anodized CNC machined parts are often requested for aluminum components, but some applications demand a stainless steel alternative that mimics the anodized look while maintaining the performance of stainless steel.

Understanding the anodizing process is essential for engineers and buyers who are selecting surface finishes for high-performance parts. Whether working with aluminum or exploring finishes for stainless steel CNC machined parts, knowing what anodizing truly means helps ensure better results from CNC machining factories.

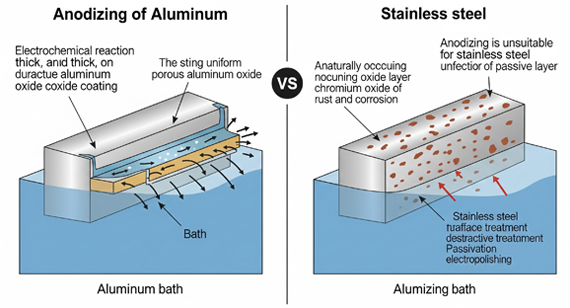

Yes, stainless steel can technically be anodized—but it’s not as straightforward as anodizing aluminum. Unlike aluminum, which forms a porous and consistent oxide layer ideal for coloring and surface treatment, stainless steel has a naturally stable and passive chromium oxide film that resists further oxidation. This characteristic makes the anodizing process on stainless steel far more complex, requiring specialized electrolytes, precise voltage control, and strict process parameters. Even under optimal conditions, the results can be unpredictable in terms of color uniformity, surface finish, and adhesion.

Traditional sulfuric acid anodizing, commonly used for aluminum, is generally ineffective on stainless steel. Instead, stainless steel may undergo a modified anodizing process using phosphoric or organic acid baths to alter its surface oxide layer. The outcome can result in some improvement in appearance and corrosion resistance, but it's rarely as durable or aesthetically pleasing as anodized aluminum. Moreover, the color options are limited, and achieving consistency across multiple anodized stainless steel CNC machined parts is challenging.

In most CNC machining factories, anodizing stainless steel is not offered as a standard service due to these limitations. Instead, alternative finishing methods such as PVD coating, passivation, or electropolishing are more commonly recommended. These processes deliver similar functional benefits—such as corrosion resistance, improved surface hardness, and enhanced aesthetics—while maintaining the integrity and consistency required for high-precision stainless steel CNC machined parts.

For clients seeking anodized CNC machined parts with both durability and design appeal, it’s important to weigh the pros and cons of anodizing stainless steel. In many cases, consulting experienced CNC machining services can help determine whether anodizing or an alternative surface treatment is the best fit for your application.

While the idea of anodized stainless steel offers exciting potential for combining performance and aesthetics, the reality is far more complicated. Stainless steel, unlike aluminum, doesn’t naturally lend itself to anodizing due to its inherent material properties. CNC machining services and engineers often discover that attempts to anodize stainless steel result in inconsistent outcomes, high costs, and limited scalability. Understanding these challenges is crucial before committing to anodized stainless steel CNC machined parts—especially when surface performance and visual consistency are critical.

Oxide Layer Stability

Stainless steel already forms a thin, passive oxide layer—primarily chromium oxide—that protects it from corrosion. This passive layer is stable and self-healing, making additional anodizing chemically redundant in many cases. However, to anodize stainless steel, this native layer must first be modified or removed to allow for new oxide growth. This destabilization can be difficult to control and may lead to surface irregularities or weakened protective properties. CNC machining factories that attempt anodizing stainless steel often need specialized setups and experience to manage this layer safely, which limits widespread adoption.

Corrosion Issues

Ironically, one of the most significant risks of anodizing stainless steel is increased corrosion. If the anodizing process is not precisely controlled, it can lead to pitting, intergranular corrosion, or contamination—especially in marine or high-humidity environments. Unlike aluminum anodizing, which enhances corrosion resistance, stainless steel anodizing can compromise it. As a result, CNC machining services often recommend alternatives like passivation or PVD coating, which enhance corrosion protection without altering the base material’s integrity. For industries that demand durable anodized CNC machined parts, especially in harsh conditions, this drawback is a major consideration.

Cost and Complexity

Anodizing stainless steel is not just technically difficult—it’s also expensive. The specialized equipment, customized electrolytes, tight voltage control, and expert handling make the process labor-intensive and time-consuming. For CNC machining factories, offering this service means investing in niche capabilities that are often not economically viable for small to mid-size batches. Additionally, the low yield rate—due to failures in consistency or quality—further drives up production costs. For customers seeking anodized stainless steel CNC machined parts, these challenges often make the process cost-prohibitive compared to more accessible alternatives.

Surface Uniformity

Another major challenge is achieving a consistent, uniform appearance. Anodized aluminum is known for its smooth, even finish and vibrant color options. In contrast, anodized stainless steel surfaces often appear blotchy, dull, or inconsistent across parts. This variation results from uneven oxide formation, material grain orientation, and microstructural differences. When producing multiple stainless steel CNC machined parts, this inconsistency can be especially problematic—especially for visible or cosmetic components. CNC machining services that prioritize visual quality generally recommend alternative coatings or treatments when surface uniformity is essential.

When considering surface treatments for stainless steel CNC machined parts, anodizing stands out as a process with both promise and complexity. While it’s widely used for aluminum, anodizing stainless steel offers unique functional and visual enhancements—along with notable trade-offs. Understanding both the advantages and disadvantages is essential for engineers, product designers, and procurement teams working with CNC machining services. Below is a breakdown of what anodizing stainless steel can—and can’t—offer in real-world applications.

Advantages of Anodizing Stainless Steel

Although anodizing stainless steel is more complex than anodizing aluminum, it can provide distinct benefits when performed correctly. For specific applications—especially where corrosion resistance, appearance, or electrical insulation is critical—anodized stainless steel can be a viable solution. For those sourcing anodized CNC machined parts, understanding these advantages helps evaluate whether the additional processing is worth the investment.

Enhanced Corrosion Resistance

One of the primary benefits of anodizing is its ability to improve corrosion resistance. While stainless steel is already corrosion-resistant due to its passive oxide layer, the anodizing process—when optimized—can further enhance this property by building a thicker, more robust barrier. This added layer offers increased protection in harsh environments, including marine or industrial applications. For customers seeking durable anodized stainless steel CNC machined parts, this can mean longer service life and fewer replacements over time.

Greater Wear Resistance

In applications where parts are exposed to friction, abrasion, or mechanical wear, anodizing can improve surface hardness. The anodic oxide layer acts as a protective shield, reducing surface degradation and extending the part’s usability. This is especially valuable for precision components or enclosures made from stainless steel that require both strength and long-term stability. CNC machining factories that specialize in producing wear-resistant components may recommend anodizing for parts requiring extra durability without sacrificing dimensional accuracy.

Improved Appearance

Anodized stainless steel offers a visually striking finish that can range from matte to glossy, depending on the process. This aesthetic upgrade is popular in consumer electronics, architecture, and decorative components where appearance matters. While the color range is more limited than anodized aluminum, a well-executed anodized finish on stainless steel adds a premium, professional look. For customers ordering stainless steel CNC machined parts that will be visible to end users, this cosmetic benefit can justify the additional process step.

Enhanced Electrical Insulation

Anodizing also introduces a non-conductive oxide layer, offering excellent electrical insulation. In applications involving electrical enclosures or sensitive electronics, this property can be a major advantage. It helps prevent short circuits and reduces the risk of arcing between components. In such cases, anodized stainless steel CNC machined parts become not only functional but safer and more compliant with industry regulations. CNC machining services working with electronic OEMs often factor this into their surface finish recommendations.

Disadvantages of Anodizing Stainless Steel

Despite its benefits, anodizing stainless steel comes with notable limitations. These drawbacks are often the reason why CNC machining services and factories recommend alternative finishing methods, particularly when cost, consistency, and scalability are key priorities. Before committing to anodized stainless steel CNC machined parts, it’s important to weigh these disadvantages carefully.

Increased Cost

Anodizing stainless steel is significantly more expensive than anodizing aluminum or using other surface treatments like passivation or PVD coating. The specialized equipment, skilled labor, and tightly controlled processing environment make it a high-cost solution. For CNC machining factories, this results in longer lead times and higher part pricing—especially for small to medium production runs. Customers must consider whether the functional gains outweigh the additional expense, particularly in price-sensitive industries.

Limited Color Options

Unlike anodized aluminum, which can be dyed in a wide spectrum of colors, anodized stainless steel has limited color capability. The natural oxide layer formed on stainless steel does not accept dyes well, making vibrant, consistent coloring nearly impossible. This constraint reduces design flexibility for parts that need both high performance and visual appeal. For this reason, CNC machining services often suggest alternative processes—such as PVD—for clients requiring custom finishes or branding colors.

Maintenance Requirements

Although anodized stainless steel can be more resistant to environmental damage, it may still require ongoing maintenance to preserve its appearance and functionality. Over time, exposure to UV, chemicals, or abrasion can degrade the oxide layer, especially if it wasn’t sealed properly during the anodizing process. This means that anodized CNC machined parts may need regular inspections, cleanings, or even reprocessing—adding to long-term maintenance costs.

Limited Applicability

Perhaps the most critical limitation is that anodizing is not suitable for all types of stainless steel or part geometries. Some alloys do not respond well to the process, and complex parts with tight tolerances may suffer dimensional changes or inconsistencies. Additionally, not all CNC machining factories have the capability or experience to handle anodized stainless steel properly. This limits the scalability of the process for mass production, making it more of a niche solution for specialized components.

Here is a clear and professional comparison table summarizing the advantages and disadvantages of anodizing stainless steel. This format makes it easy for engineers, sourcing managers, and decision-makers to quickly evaluate whether anodized stainless steel CNC machined parts are the right choice for their applications.

Advantages and Disadvantages of Anodizing Stainless Steel

| Advantages |

Description |

| Enhanced Corrosion Resistance |

Builds a thicker, more durable oxide layer than the native passive film, offering superior protection in aggressive environments like marine or chemical applications. |

| Greater Wear Resistance |

Improves surface hardness, making stainless steel CNC machined parts more resistant to abrasion and mechanical damage. Ideal for high-friction components. |

| Improved Appearance |

Offers a premium matte or glossy finish, enhancing the aesthetic appeal of visible parts used in consumer products, architecture, or electronics. |

| Enhanced Electrical Insulation |

Forms a non-conductive oxide layer, providing electrical insulation for components used in electronic housings or sensitive equipment. |

| Disadvantages |

Description |

| Increased Cost |

Requires specialized electrolytes, precise voltage control, and experienced handling—raising overall manufacturing costs compared to other surface treatments. |

| Limited Color Options |

Lacks the wide color range seen in anodized aluminum. Dyeing is difficult and inconsistent, reducing design flexibility. |

| Maintenance Requirements |

Over time, the oxide layer can degrade from UV exposure, chemicals, or wear—requiring regular maintenance or surface restoration. |

| Limited Applicability |

Not suitable for all stainless steel grades or part geometries; complex shapes and certain alloys may react unpredictably or yield inconsistent results. |

Anodizing stainless steel is a specialized and intricate process that differs significantly from anodizing more common materials like aluminum. While it can improve corrosion resistance, wear performance, and appearance, it also presents unique technical challenges that require strict process control. This is why most CNC machining factories do not offer stainless steel anodizing as a standard service. However, understanding each step of the process is essential for professionals who are considering anodized stainless steel CNC machined parts, especially in high-performance industries such as aerospace, medical, or marine.

Surface Pretreatment

The first step in anodizing stainless steel is surface preparation. This involves removing any existing oxide layer, machining oil, dirt, or residual contaminants from the surface. A clean and uniform base is essential to ensure even oxide formation during the anodizing process. Pretreatment may include abrasive blasting, polishing, degreasing, or ultrasonic cleaning. CNC machining services often carry out this step immediately after machining to prevent contamination and oxidation during handling or storage. Without proper pretreatment, anodized CNC machined parts may exhibit blotchy finishes or fail to meet performance standards.

Rinsing

After pretreatment, the parts are rinsed with deionized water to eliminate any residual cleaning agents or debris. This step is critical to avoid contamination of the electrolyte bath. Multiple rinsing stages may be used to ensure that the surface is completely clean before proceeding. For stainless steel CNC machined parts, especially those with tight tolerances or complex geometries, high-pressure or ultrasonic rinsing methods may be required to reach all surfaces.

Acid Cleaning (Optional)

In some cases, an acid cleaning step may be added using a diluted solution of nitric acid or phosphoric acid. This removes any remaining passive chromium oxide film that naturally forms on stainless steel surfaces. The goal is to expose a fresh metallic surface to promote consistent anodic oxidation. However, this step must be carefully controlled to prevent pitting or over-etching, which can damage the integrity of the parts. CNC machining factories with experience in stainless steel anodizing typically tailor the acid concentration and exposure time based on the alloy and part geometry.

Rinsing

Following acid cleaning, the parts undergo a second thorough rinsing cycle. This eliminates all acid residues and prevents cross-contamination in the next stage. High-purity deionized water is preferred to maintain process stability. Skipping or rushing this step can lead to surface discoloration or poor oxide adhesion during anodizing.

Electrolyte Preparation

Anodizing stainless steel requires a custom electrolyte solution, often a mixture of sulfuric acid, phosphoric acid, or organic acids—unlike aluminum anodizing, which uses a standard sulfuric acid bath. The electrolyte must be formulated based on the specific stainless steel grade and intended finish. Proper temperature control and agitation are necessary to ensure even current distribution. CNC machining services that offer anodizing typically maintain proprietary electrolyte formulas tailored for high consistency and repeatability.

Anodizing

The anodizing stage involves submerging the stainless steel CNC machined parts in the electrolyte bath while applying a direct current. The part acts as the anode, while a cathode is placed in the bath to complete the circuit. The electrical current causes oxygen to bond with the metal surface, forming a controlled oxide layer. This step must be closely monitored in terms of voltage, current density, time, and temperature. Variations can lead to surface defects, non-uniform oxide layers, or even part failure.

Rinsing

After anodizing, the parts are rinsed again to remove residual electrolyte from the surface. This helps stop further chemical reactions and prepares the surface for optional sealing or coloring. Clean rinsing is especially important when producing medical or aerospace-grade anodized stainless steel CNC machined parts where contamination cannot be tolerated.

Neutralization (Optional)

Some CNC machining factories include a neutralization step using mild alkaline solutions to balance the pH of the anodized parts. This minimizes the risk of delayed corrosion or electrolyte residue leaching during storage or use. While not mandatory, this step is recommended for high-precision or mission-critical components.

Sealing

Sealing the anodized layer is vital to lock in surface properties and prevent moisture ingress or contamination. This can be achieved through hot water sealing, steam sealing, or chemical sealing depending on the required finish. For anodized CNC machined parts that need enhanced corrosion resistance and color retention, sealing is a non-negotiable final step.

Coloring (Optional)

Coloring anodized stainless steel is more difficult than with aluminum. The oxide layer on stainless steel is less porous and does not absorb dyes easily. However, specialized coloring processes such as electrolytic coloring or thin-film interference methods can be used to produce subtle hues. CNC machining services rarely offer broad color palettes for anodized stainless steel due to process limitations, but black, bronze, and gold finishes are occasionally possible.

Precautions

Anodizing stainless steel requires extreme precision and careful process control. Improper cleaning, electrolyte imbalance, or incorrect voltage can lead to part discoloration, inconsistent oxide layers, or reduced corrosion resistance. For this reason, most CNC machining factories recommend alternative surface finishes like PVD coating, passivation, or electropolishing for stainless steel CNC machined parts. Furthermore, not all stainless steel grades respond equally well to anodizing, and certain part geometries may complicate current distribution during the process.

Manufacturers considering anodized stainless steel should consult experienced CNC machining services with proven expertise in this area. Investing in qualified processing partners reduces the risk of costly rework, scrap, or performance failures in the field.

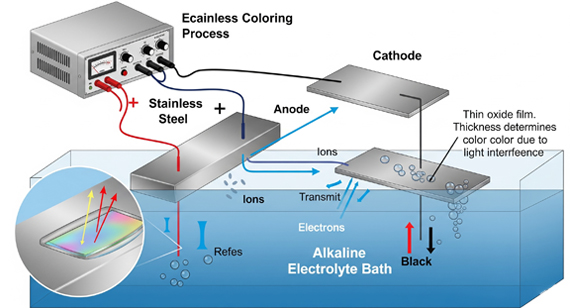

Black anodized stainless steel has become increasingly popular for applications that require both durability and a premium aesthetic. From architectural fixtures and consumer electronics to luxury automotive trim, the bold, dark appearance of black anodizing delivers both function and visual appeal. However, producing a black anodized finish on stainless steel is far more complex than with aluminum. The challenges of coloring, oxide layer formation, and surface uniformity are amplified—making this finish achievable only through precise control and specialized expertise. CNC machining services that offer black anodized stainless steel CNC machined parts typically rely on advanced surface engineering and niche processes tailored for stainless alloys.

Process Overview

The production of black anodized stainless steel involves several tightly integrated steps—each crucial for achieving a durable, uniform, and aesthetically consistent finish. Unlike traditional anodizing for aluminum, this process requires more aggressive pretreatment and custom coloring techniques. Because stainless steel does not naturally absorb dye well, advanced techniques such as electrolytic coloring or physical vapor deposition (PVD) are often layered onto an anodized base to achieve the desired black tone. CNC machining factories that deliver consistent black anodized stainless steel parts must carefully execute every stage of the process with strict quality controls.

Surface Cleaning and Pretreatment

Before any oxidation or coloring can occur, the stainless steel surface must be meticulously cleaned and pretreated. This involves removing machining oils, oxides, and any residual surface contaminants using a combination of degreasing, alkaline cleaning, and acid pickling. For CNC machined parts, this step is particularly critical, as even microscopic residues can interfere with oxide formation and dye adhesion. Mechanical polishing or micro-blasting may also be used to achieve a uniform surface texture, ensuring consistent black coloration later in the process.

Electrolytic Oxidation

Once cleaned, the parts are immersed in a specialized electrolyte solution and subjected to a direct current. This causes an anodic reaction that grows a controlled oxide layer on the stainless steel surface. Unlike anodizing aluminum, which creates a porous oxide layer suitable for dye absorption, stainless steel's oxide layer is much less permeable. Therefore, the black coloration must be achieved either during this stage using metal salt additives or through post-anodizing treatments. The electrolytic oxidation stage must be carefully managed for voltage, temperature, and time to ensure structural integrity and prepare the surface for coloration.

Coloring

Achieving a true black finish on anodized stainless steel is among the most difficult coloring challenges in metal finishing. Since the oxide layer on stainless steel is denser and less porous, traditional organic dyes do not penetrate well. Instead, CNC machining factories often use electrolytic coloring techniques, depositing metal ions such as tin, cobalt, or nickel into the anodic layer to create a black appearance. Alternatively, PVD (Physical Vapor Deposition) or chemical coloring may be applied over the anodized surface to achieve deep black tones. These methods provide better durability and color consistency—particularly important for anodized stainless steel CNC machined parts that serve decorative or consumer-facing roles.

Sealing

The final step is sealing the anodized and colored surface to lock in color, enhance corrosion resistance, and prevent fading over time. Sealing methods may include hot water immersion, steam treatment, or chemical sealing, depending on the desired durability and finish quality. For high-precision stainless steel CNC machined parts, proper sealing also helps maintain tight dimensional tolerances and ensures long-term surface stability, especially in outdoor or high-wear environments.

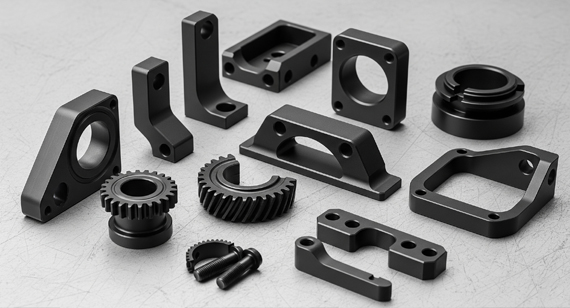

Black anodized stainless steel has carved a niche in industries where aesthetics meet performance. Its deep, matte finish combined with enhanced surface durability makes it a preferred material choice across a broad spectrum of applications. Unlike painted or powder-coated finishes, the anodized surface becomes part of the metal itself, delivering long-lasting color integrity, corrosion resistance, and wear performance. When applied to stainless steel CNC machined parts, black anodizing offers both functional benefits and sleek, modern visual appeal.

In consumer electronics, black anodized stainless steel is often used for device casings, control buttons, and enclosures where a clean, fingerprint-resistant finish is essential. Luxury brands in the tech and accessories sectors favor this surface treatment to convey high-end design language while preserving durability. In architecture and interior design, black anodized finishes are used for door hardware, fixtures, elevator panels, and decorative accents, offering a sophisticated appearance that resists scratching and fading over time.

Automotive and transportation sectors also use black anodized CNC machined parts for trim pieces, dashboard components, and custom interior fittings. These parts must endure regular handling and fluctuating temperatures, making anodized stainless steel an ideal solution. Similarly, in medical device manufacturing, black anodized stainless steel is employed for surgical tools and instrument housings that require low reflectivity and biocompatibility.

CNC machining services that offer black anodized finishes must ensure tight process control and repeatable quality, especially when manufacturing high-volume or customer-facing components. For OEMs and product designers, partnering with CNC machining factories experienced in producing black anodized stainless steel CNC machined parts ensures visual consistency, long-term performance, and reliable delivery timelines.

Here is a clear and professional comparison table showcasing the applications and uses of black anodized stainless steel. This format makes it easy for engineers, procurement teams, and product designers to understand how and where black anodized stainless steel CNC machined parts are commonly applied.

Black Anodized Stainless Steel: Applications and Uses

| Industry |

Application |

Purpose / Benefit |

| Consumer Electronics |

Device casings, control buttons, connectors, housings | Sleek appearance, fingerprint resistance, scratch durability |

| Architecture & Interior Design |

Door handles, elevator panels, light switches, fixtures | Aesthetic appeal, corrosion resistance, color stability |

| Automotive |

Dashboard trims, knobs, interior fittings | Wear resistance, heat tolerance, premium look |

| Medical Devices |

Surgical tools, instrument enclosures | Non-reflective surface, biocompatibility, cleanability |

| Luxury Products |

Watches, phone accessories, writing instruments | High-end matte finish, scratch resistance, lasting color |

| Industrial Equipment |

Control panels, precision enclosures | Enhanced wear protection, corrosion control, electrical insulation |

| CNC Machining Services |

Custom black anodized CNC machined parts | Customizability, brand consistency, robust surface performance |

Rainbow anodized stainless steel has become increasingly popular in industries where visual distinction, luxury appeal, and corrosion resistance are essential. Known for its iridescent, multi-colored surface, this finish is ideal for stainless steel CNC machined parts used in high-end architecture, interior décor, fashion accessories, and premium consumer goods. While the term "anodized" is commonly used, rainbow finishes on stainless steel are typically achieved through specialized surface treatment processes rather than traditional anodizing. These methods produce a striking color spectrum on metal without using dyes or paints, making the finish highly durable and fade-resistant.

Physical Vapor Deposition (PVD) Coating

One of the most widely used techniques for achieving rainbow anodized stainless steel is Physical Vapor Deposition (PVD). In this process, a thin layer of metal-based compounds is vaporized and bonded to the stainless steel surface in a vacuum environment. The resulting layer offers not only a vibrant iridescent effect but also increased hardness, wear resistance, and chemical stability. CNC machining factories that offer PVD-coated stainless steel CNC machined parts typically serve industries requiring long-lasting, decorative finishes—such as architecture, marine hardware, and luxury goods.

Heat Treatment

Another technique for producing rainbow effects is precision-controlled heat treatment. By exposing stainless steel to varying temperatures and atmospheric conditions, an oxide layer forms on the surface, producing interference colors similar to those seen on a soap bubble or oil film. This method creates unique, organic color gradients that cannot be replicated precisely—making each piece visually distinct. While not as abrasion-resistant as PVD, this method is often chosen for artistic installations and decorative anodized CNC machined parts in low-touch environments.

Chemical Coloring

Chemical coloring is a method that uses specific acids and controlled oxidation to manipulate the thickness of the passive oxide layer on stainless steel. This interference layer refracts light to produce the signature rainbow hues without adding pigments. The process is environmentally friendly and produces a corrosion-resistant surface, though it may not be as durable under high friction or frequent handling. CNC machining services applying this method often cater to architectural cladding, elevator panels, and upscale appliances where both aesthetics and durability are required.

Here is a professionally formatted table showcasing the applications and uses of rainbow anodized stainless steel. This layout helps designers, architects, procurement teams, and engineers clearly understand where this vibrant and durable finish adds both functional and aesthetic value.

Rainbow Anodized Stainless Steel: Applications and Uses

| Industry |

Application |

Purpose / Benefit |

| Architecture & Interior Design |

Wall panels, elevator doors, decorative trim, signage | Eye-catching finish, corrosion resistance, long-lasting color vibrancy |

| Luxury Consumer Products |

Watches, jewelry, phone cases, pen casings | Unique multi-color finish, scratch resistance, premium brand appeal |

| Home & Kitchen Appliances |

Faucets, cabinet handles, kitchen hoods, light fixtures | Visual distinction, rust resistance, modern aesthetic |

| Fashion Accessories |

Belt buckles, sunglasses frames, handbag hardware | Trend-forward look, durability, personalized color spectrum |

| Art Installations |

Sculptures, public displays, decorative structures | One-of-a-kind aesthetics, UV stability, surface brilliance |

| Retail & Branding |

Storefront logos, product displays, POS fixtures | Attention-grabbing design, durable finish, color consistency |

| CNC Machining Services |

Custom rainbow anodized CNC machined parts | Brand differentiation, functional decoration, high-performance coatings |

While anodizing is a popular surface treatment for enhancing aluminum parts, it’s less commonly used on stainless steel due to technical limitations such as oxide instability and low color uniformity. However, several alternative surface finishing processes can deliver similar or even superior results for stainless steel CNC machined parts. These methods not only improve corrosion and wear resistance but also enhance surface aesthetics, ensuring compatibility with premium CNC machining services across industries like aerospace, architecture, and consumer goods.

Passivation is a chemical treatment process that removes free iron and enhances the formation of a protective oxide layer on stainless steel. Unlike anodizing, which builds up an artificial oxide film, passivation strengthens the material's natural corrosion resistance without altering its appearance. This method is especially useful for precision CNC machining factories producing parts for medical, food processing, and aerospace industries, where maintaining dimensional accuracy and cleanliness is critical.

Electrolytic Polishing

Electrolytic polishing (or electropolishing) is a surface smoothing technique that removes a microscopic layer of material using electrochemical action. It enhances surface reflectivity, improves corrosion resistance, and eliminates microburrs—making it ideal for anodized CNC machined parts in sanitary and pharmaceutical applications. Unlike anodizing, this process doesn’t introduce coatings or films but results in a clean, bright, and uniform surface.

PVD Coating

Physical Vapor Deposition (PVD) is one of the most popular alternatives to anodizing for stainless steel, especially for aesthetic finishes like black or rainbow coatings. PVD involves vaporizing metal compounds and depositing them onto the stainless steel surface in a vacuum environment. This results in highly durable, decorative layers that resist corrosion, wear, and fading. PVD-coated stainless steel CNC machined parts are widely used in architectural panels, consumer electronics, and automotive trim.

Spraying

Spray coatings, including powder coating and specialized metallic paints, are cost-effective options for enhancing both aesthetics and corrosion resistance. These coatings come in a variety of colors and finishes, including matte, gloss, and textured. Though less durable than PVD or electropolishing, spray finishes can be a practical solution for CNC machining factories producing parts where visual impact and budget efficiency are top priorities.

Coating (Ceramic & Polymer)

Ceramic and polymer-based coatings—such as Teflon, epoxy, or ceramic composites—offer tailored solutions for parts requiring high heat resistance, low friction, or chemical inertness. These coatings are often applied via spraying, dipping, or brushing. While not traditional substitutes for anodizing, they can offer superior functionality for components in harsh environments like oil & gas, marine, or industrial processing.

Here is a clear and professional comparison table summarizing alternative processes for anodized stainless steel, tailored for engineers, buyers, and manufacturing planners evaluating surface finishes for stainless steel CNC machined parts. It includes key factors like durability, aesthetics, cost, and typical applications—ideal for decision-making in CNC machining services and CNC machining factories.

Table: Alternative Surface Finishing Processes for Anodized Stainless Steel

| Process |

Description |

Durability |

Aesthetic Options |

Cost |

Typical Applications |

| Passivation |

Chemical treatment to remove free iron and enhance natural oxide layer | ★★★☆☆ | None (Natural Finish) | ★★☆☆☆ | Medical devices, food equipment, aerospace components |

| Electrolytic Polishing |

Electrochemical process that smooths and brightens the surface | ★★★★☆ | Bright, Mirror Finish | ★★★☆☆ | Pharmaceutical, sanitary piping, surgical tools |

| PVD Coating |

Vacuum-based metal vapor deposition for decorative & functional finishes | ★★★★★ | Black, gold, rainbow, etc. | ★★★★☆ | Architecture, electronics, luxury hardware |

| Spraying |

Paint or powder coating for color and basic protection | ★★☆☆☆ | Wide range of colors | ★☆☆☆☆ | Consumer products, decorative panels, low-cost components |

|

Ceramic/Polymer Coating |

Teflon, epoxy, or ceramic coatings for specialty applications | ★★★★☆ | Usually matte or solid colors | ★★★☆☆ | Oil & gas, marine, industrial, high-friction environments |

Notes:

When it comes to enhancing the durability, corrosion resistance, and aesthetic appeal of stainless steel CNC machined parts, surface treatments play a critical role. Among the many options—anodizing, electroplating, spraying, and PVD coating—each method has unique advantages. Below is a detailed comparison to help decision-makers in CNC machining services and CNC machining factories select the most effective treatment.

Anodizing vs. Electroplating

| Aspect |

Anodizing Stainless Steel |

Electroplating Stainless Steel |

| Process |

Electrochemical oxidation | Electrochemical metal deposition |

| Appearance |

Matte or lightly colored | Bright, shiny metallic finishes (e.g., chrome) |

| Adhesion |

Forms integral oxide layer | Coating sits on surface |

| Corrosion Resistance |

Moderate to high (with sealing) | High (depends on metal used, e.g., nickel) |

| Durability |

Medium | High |

| Color Options |

Limited | Wide, depending on plated metal |

| Cost |

Moderate to High | Moderate |

| Typical Uses |

Decorative hardware, tech enclosures | Faucets, decorative trims, industrial parts |

Anodizing vs. Spraying (Powder/Paint)

| Aspect |

Anodizing Stainless Steel |

Spraying (Paint/Powder Coating) |

| Finish Type |

Thin oxide layer | Coating layer (polymer or resin) |

| Appearance |

Metallic, subdued colors | Vibrant, diverse color palette |

| Corrosion Resistance |

Medium to High (if sealed) | Medium (prone to chipping/flaking) |

| Durability |

Scratch resistant | Prone to wear over time |

| Cost |

Moderate to High | Low to Moderate |

| Maintenance |

Low | Recoating may be required |

| Use Cases |

Premium enclosures, consumer electronics | General appliances, budget parts |

Anodizing vs. PVD Coating

| Aspect |

Anodizing Stainless Steel |

PVD Coating (Physical Vapor Deposition) |

| Technology |

Electrochemical process | Vacuum-based deposition of metallic compounds |

| Aesthetic Appeal |

Subtle metallic finish | High-end, rich colors (e.g., rainbow, black) |

| Hardness |

Moderate | Very high (scratch resistant) |

| Color Variety |

Limited | Extensive, especially decorative colors |

| Adhesion Strength |

Excellent | Excellent |

| Cost |

Moderate to High | High |

| Applications |

Medical equipment, electronics | Watches, jewelry, luxury hardware |

Each method has distinct strengths—anodizing offers good corrosion resistance and surface hardness, electroplating adds metallic luster, spraying is affordable with vibrant color choices, and PVD coating is unmatched for luxury aesthetics and wear resistance.

Yes, you can anodize stainless steel at home, but it is not recommended for beginners due to the complexity, safety risks, and specialized equipment required. Unlike aluminum anodizing, which is relatively straightforward, anodizing stainless steel involves hazardous chemicals, high-voltage DC power supplies, and precise process controls.

What Makes Stainless Steel Anodizing Challenging at Home?

Stainless steel requires strong acids, such as sulfuric acid or hydrofluoric acid, which are corrosive and dangerous to handle without proper training and equipment.

You’ll need a controlled DC power source, usually up to 60V, and a suitable cathode in an acid-resistant anodizing tank. Poor current control can lead to pitting or overheating.

Stainless steel must be polished and degreased meticulously. Any surface contaminants can cause uneven coating or discoloration.

The oxide layer on stainless steel is thinner and harder to dye, unlike aluminum, which easily accepts vibrant colors.

You must use chemical-resistant gloves, face shields, ventilation systems, and possibly a fume hood—equipment that goes beyond most DIY setups.

Alternatives for DIY Enthusiasts

If you're aiming for a unique finish at home, consider these safer alternatives:

Summary: Can You? Technically, Yes. Should You? Probably Not.

While technically feasible, anodizing stainless steel at home is better left to professionals or CNC machining factories with the right facilities. For hobbyists or small-scale projects, safer surface treatments can still achieve great results without the dangers or steep learning curve.

Anodizing is a surface treatment process that creates a durable, corrosion-resistant oxide layer—commonly used on metals like aluminum and, less commonly, stainless steel. But what if you need to reverse the anodizing process to repair, refinish, or repurpose a part?

Yes, anodizing is reversible, but the removal process depends on the material, anodizing type, and desired finish. In industrial settings, anodizing removal is often necessary for rework or secondary processing, especially in CNC machining services.

Chemical Removal

Chemical stripping is the most common and effective method for removing anodized layers:

Note: This method is effective but requires proper chemical handling procedures, personal protection, and environmental safety measures. It’s typically performed in CNC machining factories or professional surface treatment workshops.

Mechanical Removal

Mechanical methods involve physically abrading the surface, including:

These methods are effective for localized removal or when appearance isn't critical. However, they may scratch or deform the base metal, making them unsuitable for precision anodized CNC machined parts.

Electrolytic Removal

Electrolytic de-anodizing uses an electrochemical process to reverse anodizing:

While technically effective, this method is less commonly used due to complexity and limited efficiency compared to chemical stripping.

Conclusion

Yes, anodizing is reversible, and removal can be done chemically, mechanically, or electrolytically—depending on your goals and equipment. However, each method comes with pros, cons, and safety considerations, especially for anodized stainless steel.

For consistent results and to avoid damaging valuable parts, professional CNC machining services or surface treatment providers are recommended.

Hard anodized stainless steel refers to stainless steel that has undergone an enhanced anodizing process, designed to create an extremely durable, wear-resistant, and corrosion-resistant oxide layer on the metal surface. Although anodizing is more commonly associated with aluminum, stainless steel can also be treated using modified hard anodizing or hybrid surface treatment techniques, especially in high-performance CNC machined parts.

This process is ideal for industries requiring superior surface protection—such as aerospace, automotive, and food processing—where equipment must endure harsh environments and frequent use.

What Makes It “Hard”?

“Hard anodizing” refers to the creation of a thicker and denser oxide layer, typically over 25 microns, through a controlled electrolytic oxidation process at lower temperatures and higher voltages. While stainless steel naturally forms a passive oxide layer, hard anodizing artificially thickens and hardens this layer to achieve:

In practice, hard anodized finishes may be achieved using hybrid techniques, combining anodizing principles with PVD coating, passivation, or advanced ceramic treatments.

Applications in CNC Machining

Hard anodized stainless steel is frequently used in:

Due to the precise nature of this surface treatment, many CNC machining factories partner with specialized surface finishing providers to ensure optimal quality and performance.

Summary

Hard anodized stainless steel combines the corrosion resistance of stainless steel with the toughness and longevity of a hard anodized layer. It’s an advanced surface solution tailored for demanding applications—especially in sectors relying on CNC machining services to deliver high-precision, long-lasting components.

When selecting materials for CNC machining parts, clients often face a common question: Should I choose anodized aluminum or stainless steel? Each offers unique advantages, particularly in surface treatments. While anodized aluminum is lightweight and easy to color, stainless steel offers superior strength and corrosion resistance. Understanding the fundamental differences between these two materials helps customers make smarter decisions when partnering with CNC machining factories for their projects.

Anodized Aluminum Alloys

Anodizing aluminum is a widely used surface treatment because of aluminum’s natural ability to form a thick, stable oxide layer. Through an electrochemical process, aluminum parts are transformed into anodized CNC machined components with:

Aluminum is ideal for industries like electronics, aerospace, automotive, and consumer products where weight savings and surface aesthetics are key. The anodizing process can also offer a range of finishes—from matte to gloss—and color options from black to vibrant rainbow tones.

Stainless Steel

Unlike aluminum, stainless steel is naturally corrosion-resistant due to its chromium content. Although stainless steel doesn’t anodize in the same way, it can undergo modified anodizing or alternative surface treatments such as:

Anodized stainless steel is typically used in decorative panels, architectural features, marine applications, and high-wear parts. It offers a sleek, modern appearance combined with outstanding durability. However, the anodizing process for stainless steel is more complex and costly than aluminum.

When selecting between anodized aluminum and anodized stainless steel, consider:

| Feature |

Anodized Aluminum |

Stainless Steel |

| Weight |

Lightweight | Heavy |

| Cost |

Lower | Higher |

| Corrosion Resistance |

Excellent (with anodizing) | Excellent (natural + optional finish) |

| Color Variety |

Wide range | Limited (mainly black or rainbow) |

| Strength |

Moderate | High |

| CNC Machinability |

Easy | Moderate to difficult |

| Common Applications |

Electronics, casings, automotive | Medical, industrial, marine parts |

For aesthetic customization and lightweight parts, anodized aluminum is ideal. For high-load or high-wear environments, stainless steel is the preferred choice—even if it requires specialized CNC machining services.

Anodized aluminum is aluminum that has undergone an electrochemical process to thicken and strengthen its natural oxide layer. This enhancement improves corrosion resistance, wear durability, and allows for vibrant, long-lasting colors. The result? A sleek, protective finish that makes anodized aluminum a go-to material in CNC machining services, architecture, electronics, automotive, and consumer products.

For customers looking to balance performance, weight, and aesthetics, anodized aluminum CNC machined parts offer an attractive, cost-effective solution.

How Anodizing Works

Anodizing aluminum involves immersing the part in an electrolytic bath and passing an electric current through it. This process converts the aluminum surface into a porous oxide layer that can be sealed or dyed. There are three main types of aluminum anodizing:

Key Features of Anodized Aluminum

Applications in CNC Machining

In CNC machining factories, anodized aluminum is a preferred material for components that require precision, durability, and visual appeal. Typical uses include:

Final Thoughts

Anodized aluminum is more than just a pretty surface—it's a high-performance material that brings functional and aesthetic advantages to a wide variety of applications. When working with CNC machining services, anodized aluminum parts help customers achieve both engineering precision and product appeal.

When selecting metal materials for CNC machining parts, it’s essential to understand the differences between anodized steel and stainless steel. While both provide strength and durability, their surface properties, corrosion resistance, and finishing options vary significantly. This knowledge helps engineers and buyers choose the optimal material for their specific applications, ensuring superior performance and cost-effectiveness.

Steel

Steel is a versatile alloy primarily composed of iron and carbon. It is known for its excellent strength, machinability, and affordability. However, standard carbon steel is prone to rust and corrosion unless protected by coatings or treatments.

Anodizing steel is a less common practice compared to aluminum or stainless steel because steel forms an unstable oxide layer that does not provide the same benefits. Instead, steel often undergoes alternative surface treatments such as electroplating, powder coating, or painting to enhance corrosion resistance and wear protection.

For steel CNC machined parts, applying durable surface finishes is critical, especially for outdoor or industrial environments. While anodizing is rare for steel, it may occasionally refer to specialized electrolytic oxidation processes aimed at improving surface hardness.

Stainless Steel

Stainless steel differs from regular steel by its high chromium content (typically above 10.5%), which forms a stable, self-healing oxide layer that naturally protects against rust and corrosion. This makes stainless steel an excellent choice for applications demanding durability and low maintenance.

Although stainless steel cannot be anodized in the traditional sense like aluminum, it can undergo modified anodizing-like treatments, as well as other surface processes such as:

These treatments improve the surface hardness, appearance, and corrosion resistance of stainless steel CNC machined parts. Stainless steel’s superior resistance to corrosion and wear often justifies its higher cost compared to carbon steel.

Summary

| Feature |

Steel |

Stainless Steel |

| Corrosion Resistance |

Low (needs coatings) | High (natural oxide layer) |

| Surface Treatments |

Electroplating, painting, powder coating | Passivation, PVD, electrolytic coloring |

| Anodizing Feasibility |

Rare and limited | Modified anodizing possible |

| Cost |

Lower | Higher |

| Common Applications |

Structural parts, machinery, tools | Medical devices, food processing, architectural parts |

For projects requiring stainless steel CNC machined parts with enhanced surface finishes, CNC machining services often recommend alternative coatings over traditional anodizing to maximize performance and aesthetics.

Anodizing is a widely used electrochemical process that enhances the surface of certain metals by forming a durable, corrosion-resistant oxide layer. While anodizing is highly effective for some metals, it is not suitable for all. Understanding which metals can be anodized helps customers and manufacturers select the right materials for their CNC machining parts and ensure optimal surface performance with anodized stainless steel CNC machined parts or related products.

Metals That Can Be Anodized

Aluminum

Aluminum is the most commonly anodized metal. Its natural oxide layer is easily thickened and enhanced through anodizing, improving corrosion resistance and allowing for vibrant color options. Aluminum alloys are widely used in anodized CNC machined parts across aerospace, automotive, and electronics industries.

Titanium

Titanium anodizing produces a strong, colorful oxide film with excellent corrosion resistance. The oxide layer’s thickness determines the color spectrum, making anodized titanium popular for medical implants, jewelry, and aerospace components requiring both durability and aesthetics.

Magnesium

Magnesium can be anodized to improve corrosion resistance and surface hardness. Given magnesium’s light weight, anodizing is especially valuable in aerospace and automotive sectors where performance and weight reduction are critical.

Zinc

Zinc anodizing enhances corrosion resistance for applications such as automotive parts and coatings. However, it is less common compared to aluminum or titanium anodizing and requires specialized processes.

Niobium

Niobium is anodized primarily for decorative purposes, producing vibrant colors. This makes it popular in niche markets like jewelry and artistic metalwork.

Tantalum

Tantalum anodizing provides a protective, corrosion-resistant surface ideal for chemical processing equipment and medical devices, where biocompatibility and durability are essential.

Metals That Cannot Be Anodized

Stainless Steel

Despite its excellent corrosion resistance, stainless steel cannot be anodized in the traditional sense. Its natural oxide layer is stable but thin and does not respond well to anodizing processes. Instead, stainless steel parts often receive surface treatments like passivation, PVD coating, or electropolishing to enhance appearance and durability.

Copper

Copper also cannot be anodized due to its chemical properties. Copper parts are typically treated with other surface finishes such as electroplating, patination, or chemical coatings to prevent corrosion and improve aesthetics.

Understanding which metals can be anodized ensures the best choices for CNC machining services and surface finishing. For metals like stainless steel and copper, alternative surface treatments can deliver comparable benefits.

Table: Metals That Can and Cannot Be Anodized

| Category |

Metal |

Anodizing Feasibility |

Common Applications |

| Metals That Can Be Anodized | Aluminum | Yes | Aerospace, automotive, electronics, consumer goods |

| Titanium | Yes | Medical implants, aerospace, jewelry | |

| Magnesium | Yes | Lightweight aerospace and automotive parts | |

| Zinc | Yes (less common) | Automotive coatings, specialty applications | |

| Niobium | Yes | Jewelry, decorative metalwork | |

| Tantalum | Yes | Chemical processing, medical devices | |

| Metals That Cannot Be Anodized | Stainless Steel | No | Uses alternative finishes like passivation, PVD coating |

| Copper | No | Uses plating, patination, chemical coatings |

This table helps engineers and procurement teams quickly identify suitable materials for anodizing and understand alternative finishes for metals where anodizing isn’t feasible.

Selecting the right surface finish is critical to maximizing the performance, durability, and aesthetics of stainless steel CNC machined parts. Different finishes can significantly influence corrosion resistance, wear protection, electrical conductivity, and visual appeal. For manufacturers and buyers relying on CNC machining services, understanding these finishes ensures the final product meets application-specific demands while optimizing cost and manufacturability.

Factors to Consider When Choosing a Surface Finish

Consider whether the part will be exposed to harsh chemicals, moisture, high temperatures, or abrasive wear. For example, parts in marine or medical environments require finishes with superior corrosion resistance like passivation or PVD coating.

If appearance matters—such as in consumer products or architectural components—finishes like electropolishing, black anodized stainless steel, or rainbow PVD coatings offer attractive, durable surfaces that enhance brand appeal.

Some finishes improve surface hardness and wear resistance. Hard anodizing or electropolishing can reduce friction and extend part life in mechanical assemblies.

More complex finishes like PVD or hard anodizing may increase production time and cost. Balancing budget with required performance helps avoid overspending on unnecessary treatments.

Some finishes require specific surface preparation or post-machining treatments. Early consultation with your CNC machining factory ensures seamless integration of finishing steps.

Common Surface Finishes for Stainless Steel CNC Machined Parts

| Surface Finish |

Key Benefits |

Typical Uses |

| Passivation |

Enhances natural corrosion resistance | Medical, food processing, aerospace |

| Electropolishing |

Smooth, bright finish; removes micro burrs | Sanitary applications, decorative parts |

| PVD Coating |

Durable, colorful decorative finish | Luxury goods, consumer electronics |

| Powder Coating/Spraying |

Wide color options; moderate protection | Architectural components, appliances |

| Hard Anodizing (Hybrid) |

Increased hardness and wear resistance | Industrial valves, cookware, heavy-duty tools |

Summary

Choosing the right surface finish for stainless steel CNC machined parts requires balancing environmental demands, aesthetics, performance, and cost. Engaging with experienced CNC machining services and CNC machining factories early in the design phase ensures optimal finishing solutions tailored to your project’s needs.

Why Choose VMT for Your Stainless Steel CNC Machining Needs?

When precision, quality, and reliability matter, VMT CNC machining services stand out as your trusted partner for manufacturing stainless steel CNC machined parts. With years of experience and cutting-edge technology, VMT delivers parts that meet the highest industry standards across aerospace, medical, automotive, and industrial sectors.

Our Expertise

VMT utilizes state-of-the-art 3-axis to 7-axis CNC machining centers, ensuring complex geometries and tight tolerances are handled with ease.

From 304 and 316L to specialty grades, we machine stainless steel alloys tailored to your application’s strength and corrosion resistance requirements.

We offer comprehensive finishing options including passivation, electropolishing, PVD coating, and anodized stainless steel treatments to enhance durability and aesthetics.

Our quality control team implements strict inspections, including CMM measurement and surface analysis, to guarantee every part meets your specifications.

Benefits of Partnering with VMT

Applications

Our stainless steel CNC machined parts serve a broad range of industries, including:

Ready to Get Started?

Contact VMT CNC machining factories today to discuss your project requirements and receive a detailed quote. Experience the difference of working with a trusted partner that delivers precision, durability, and exceptional customer service.

Choosing the right surface treatment for stainless steel CNC machined parts is essential to achieving optimal performance, durability, and aesthetic appeal. While traditional anodizing poses challenges on stainless steel, advanced alternatives such as passivation, PVD coating, electropolishing, and hard anodizing hybrids provide effective solutions tailored to various industrial needs.

At VMT, our comprehensive CNC machining services and expertise in surface finishing ensure that every part meets the highest standards of quality and precision. Whether your project demands enhanced corrosion resistance, superior wear protection, or visually striking finishes, partnering with professional CNC machining factories like VMT guarantees reliable results and competitive advantages.

Investing in the right material and surface finish not only extends the life of your components but also enhances their functionality and value. For manufacturers and engineers seeking trusted expertise in anodized stainless steel CNC machined parts and related services, VMT stands ready to deliver exceptional craftsmanship and support.

1. What are the Disadvantages of Anodized Cookware?

Anodized cookware offers excellent durability and corrosion resistance, but it can be more expensive than untreated cookware. The surface may wear over time, especially with abrasive cleaning, and it has limited color options. Additionally, anodized layers can be damaged by harsh chemicals or metal utensils.

2. How to Tell If Metal is Anodized?

Anodized metal typically has a smooth, matte or colored finish that is integral to the surface (not painted). You can test by checking for scratches—anodized layers won’t peel like paint. Also, anodized aluminum often shows a consistent color and increased hardness compared to untreated metal.

3. How Long Does Anodized Metal Last?

With proper care, anodized metal can last many years—often decades—due to its enhanced corrosion and wear resistance. Its longevity depends on the environment and usage; harsh conditions may reduce its lifespan.

4. Do Magnets Attract Anodized Aluminum?

No. Aluminum, including anodized aluminum, is non-magnetic. Magnets do not attract anodized aluminum or its untreated form.

5. Can 316 Stainless Steel Be Anodized?

316 stainless steel cannot be anodized using traditional aluminum anodizing processes. However, it can undergo alternative surface treatments like passivation, PVD coating, or electrolytic coloring to enhance corrosion resistance and appearance.

6. What Corrodes Anodized Aluminum?

Anodized aluminum is highly corrosion-resistant, but strong alkalis, acids, or abrasive conditions can damage the oxide layer over time. Prolonged exposure to saltwater or industrial pollutants may also degrade the finish if not properly maintained.

7. How to Change the Color of Stainless Steel?

Changing stainless steel color typically involves electrolytic coloring, PVD coating, or chemical treatments rather than anodizing. These processes deposit colored layers or alter the oxide film to achieve hues like black, gold, or bronze.

8. What Metals Cannot Be Powder Coated?

Metals that cannot be effectively powder coated include those with poor surface energy or very smooth finishes, such as some stainless steel grades without proper surface preparation, and certain non-ferrous metals like copper without pretreatment. Proper surface cleaning and roughening improve powder coating adhesion.

9. How Much Does Powder Coating Stainless Steel Cost?

Powder coating costs vary based on part size, complexity, and finish type but typically range from $3 to $15 per square foot. Additional costs may apply for surface preparation and special colors. Volume discounts are common in CNC machining factories.

10. Which is Better, Anodizing or Powder Coating?

Anodizing offers a thinner, harder, and more corrosion-resistant finish integral to the metal surface, ideal for aluminum. Powder coating provides thicker, more colorful, and versatile coatings suitable for various metals, including stainless steel. The choice depends on the application’s durability, aesthetic, and environmental requirements.

11. Why Can't Steel Be Anodized?

Steel cannot be anodized like aluminum because it does not form a stable, adherent oxide layer under anodizing conditions. The oxide on steel is not protective and flakes off easily. Instead, steel relies on other surface treatments like electroplating, passivation, or powder coating to enhance durability.