15 years one-stop China custom CNC machining parts factory

489 |

Published by VMT at Aug 06 2025 | Reading Time:About 6 minutes

489 |

Published by VMT at Aug 06 2025 | Reading Time:About 6 minutes

When designing precision components, every decision matters—especially the type of aluminum you use. Many engineers and procurement teams face confusion when choosing between 6061-T6 and 6061-T651 aluminum. They sound nearly identical, but even small differences in tempering can affect machining performance, dimensional stability, and final product reliability. If you're sourcing aluminum CNC machined parts, the wrong choice can mean costly reworks or structural issues.

Fortunately, this comparative guide helps eliminate that uncertainty. By clearly breaking down the distinctions between 6061-T6 and 6061-T651, you'll learn how their differences in processing, physical and mechanical properties, and applications affect your CNC machining project outcomes.

The main difference between 6061-T6 and 6061-T651 aluminum lies in their stress-relief processes. While both are heat-treated, T651 undergoes additional stretching to reduce internal stresses, making it more dimensionally stable than T6. This makes 6061-T651 the better choice for precision aluminum CNC machined parts requiring tight tolerances.

Understanding the nuances between 6061-T6 and 6061-T651 aluminum tempers is essential for product performance and production efficiency. This article explains everything from heat treatment processes to mechanical properties, machinability, and common applications. Whether you're working with CNC machining factories or sourcing components, you'll find clear, actionable answers below.

Before diving deeper into this comparison, check out VMT’s resources on aluminum CNC machined parts and our guide to choosing the right aluminum alloy for CNC machining. These articles can help frame your material selection strategy from the ground up.

6061 aluminum is one of the most widely used aluminum alloys in modern manufacturing due to its exceptional balance of strength, corrosion resistance, and machinability. Classified as a precipitation-hardened alloy, 6061 belongs to the 6xxx series of aluminum, which primarily uses magnesium and silicon as the major alloying elements. This combination allows the material to form a magnesium silicide structure, which is crucial for heat treatment and strengthening processes. As a result, 6061 aluminum is highly versatile and is frequently chosen for aerospace, automotive, marine, and precision CNC machined parts.

One of the key characteristics of 6061 aluminum is its adaptability to various tempers, including T4, T6, and T651, which provide different balances of hardness, tensile strength, and stress resistance. For example, in its annealed or “O” condition, the alloy is soft and highly formable, making it ideal for complex shaping. After heat treatment into the T6 or T651 tempers, it achieves higher hardness and strength while maintaining a relatively lightweight profile. Its excellent corrosion resistance—especially against moisture and many chemicals—makes it a reliable choice for outdoor or marine environments.

From a machining standpoint, 6061 aluminum is known for its excellent workability. It can be milled, turned, or drilled efficiently, producing high-quality surface finishes for aluminum CNC machined parts. Furthermore, it can be anodized for enhanced corrosion protection and aesthetics. Because of this versatility, CNC machining factories frequently recommend 6061 aluminum for projects that demand both durability and cost-effectiveness. Whether for structural components, industrial equipment, or custom parts, 6061 aluminum remains a cornerstone material in modern engineering and manufacturing.

Aluminum 6061, often abbreviated as Al 6061, is a precipitation-hardened aluminum alloy widely used across industries due to its high strength-to-weight ratio, corrosion resistance, and excellent machinability. Its alloying elements primarily include magnesium (Mg) and silicon (Si), which form magnesium silicide (Mg₂Si), enabling effective heat treatment and strengthening. This alloy is highly popular for manufacturing aluminum CNC machined parts because it can be tailored to different mechanical and physical requirements through tempering processes.

The term “temper” in aluminum processing refers to the specific combination of heat treatment and mechanical operations applied to the alloy to achieve desired hardness, strength, and stability. For 6061 aluminum, the most common tempers are O, T4, T6, and T651.

These tempers allow 6061 aluminum to meet diverse application needs, from structural frameworks to high-precision aerospace parts. In CNC machining factories, selecting the right temper ensures that parts maintain their shape, resist warping, and achieve the required mechanical performance. Whether for automotive frames, marine fittings, or industrial machinery, the temper of 6061 aluminum directly influences the success of the final product.

6061-T6 aluminum is one of the most popular tempers of the 6061 aluminum alloy, known for its excellent combination of strength, corrosion resistance, and machinability. The “T6” designation refers to a specific heat treatment process that significantly enhances the alloy’s mechanical properties. In this temper, 6061 aluminum achieves high tensile strength and hardness, making it an ideal choice for applications that require durability, dimensional precision, and long service life. Industries such as aerospace, automotive, marine, and precision CNC machining frequently use 6061-T6 aluminum to produce structural components, brackets, and custom machined parts.

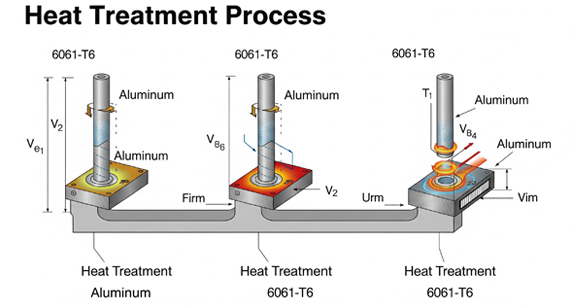

The manufacturing process for 6061-T6 aluminum primarily involves three key steps:

As a result of this process, 6061-T6 aluminum offers a strong balance of lightweight performance, machinability, and resistance to wear and corrosion. Its properties make it highly suitable for producing 6061-T6 aluminum CNC machined parts, where precision and reliability are essential.

Al 6061-T6 is widely recognized as one of the most versatile aluminum alloys for engineering and manufacturing applications. Its combination of moderate weight, high strength, excellent corrosion resistance, and ease of machining makes it a preferred material for industries ranging from aerospace to automotive and marine. For CNC machining factories, 6061-T6 aluminum is often the go-to choice for producing reliable and precise aluminum CNC machined parts. However, like all materials, it comes with both strengths and limitations. Understanding the advantages and disadvantages of 6061-T6 aluminum is crucial for selecting the right material for your specific project.

Advantages of Al 6061-T6

Disadvantages of Al 6061-T6

Despite these limitations, 6061-T6 remains a top choice for aluminum CNC machined parts due to its balance of performance, cost-effectiveness, and availability in CNC machining factories worldwide.

summarizing the advantages and disadvantages of 6061-T6 aluminum:

| Category |

Details |

| Advantages | |

| High Strength-to-Weight Ratio | Provides strong structural performance while remaining lightweight, ideal for aerospace and automotive parts. |

| Good Corrosion Resistance | Resists rusting and environmental damage, even in marine conditions. |

| Excellent Machinability | Easy to machine and ideal for 6061-T6 aluminum CNC machined parts, producing high-quality finishes. |

| Good Weldability | Can be welded using standard processes; post-weld heat treatment may restore strength. |

| Versatility | Suitable for a wide range of applications, making it a popular choice in CNC machining services. |

| Disadvantages | |

| Lower Strength vs. 7075 | Does not match the ultimate strength of higher-performance alloys like 7075-T6. |

| Reduced Formability | Becomes less ductile after T6 tempering; not ideal for deep bends or complex shapes. |

| Residual Stress & Warping | May retain internal stresses that cause distortion during heavy machining operations. |

| Moderate Fatigue Resistance | Less resistant to cyclic loading, requiring careful design for vibration-prone components. |

6061-T651 aluminum is a heat-treated and stress-relieved temper of the 6061 aluminum alloy, designed to offer enhanced dimensional stability for precision applications. The “T651” designation indicates that the material has undergone the same heat treatment as T6 but with an additional stretching process to relieve internal stresses. This extra step makes 6061-T651 particularly valuable for CNC machining factories and manufacturers producing components that require tight tolerances and minimal risk of warping or distortion during or after machining.

Unlike 6061-T6, which can retain residual stresses from quenching, 6061-T651 provides greater stability when exposed to high-speed milling or large-volume material removal. This makes it an excellent choice for aerospace components, automotive structural parts, industrial machinery, and 6061-T651 aluminum CNC machined parts, where maintaining shape and precision is critical.

The manufacturing process for 6061-T651 aluminum alloy involves four primary steps:

Thanks to this process, 6061-T651 aluminum is the preferred choice for precision aluminum CNC machined parts and large components where consistency, stability, and machinability are top priorities.

Al 6061-T651 is one of the most reliable aluminum tempers for applications requiring precision, strength, and dimensional stability. By combining the heat treatment of 6061-T6 with an additional stretching process, T651 aluminum achieves superior stress relief, making it highly suitable for CNC machining factories that produce large or complex components. Engineers often choose 6061-T651 aluminum when high accuracy, low warping risk, and long-term stability are critical for aluminum CNC machined parts. However, like all materials, it has both strengths and limitations that should be considered before selecting it for your project.

Advantages of Al 6061-T651

Disadvantages of Al 6061-T651

Because of its combination of stability, strength, and machinability, 6061-T651 is a top choice for CNC machining services producing precision aluminum components in aerospace, marine, and industrial sectors.

summarizing the advantages and disadvantages of 6061-T651 aluminum:

| Category |

Details |

| Advantages | |

| Enhanced Dimensional Stability | The stretching process relieves internal stresses, reducing warping or distortion during machining. |

| High Strength-to-Weight Ratio | Provides structural strength similar to 6061-T6 while remaining lightweight. |

| Excellent Machinability | Easier to machine with high accuracy, ideal for 6061-T651 aluminum CNC machined parts. |

| Strong Corrosion Resistance | Maintains excellent resistance in marine and outdoor environments. |

| Consistency for Large Components | Performs well in thick plates or long parts, ensuring dimensional reliability in CNC machining. |

| Disadvantages | |

| Higher Cost | Slightly more expensive than 6061-T6 due to additional stress-relief processing. |

| Moderate Formability | Less ductile than softer tempers; not suitable for deep bending or complex forming. |

| Not the Strongest Alloy | Provides good strength but cannot match 7075-T6 for high-stress applications. |

| Welding Considerations | Welding may reduce localized strength; post-weld heat treatment may be required. |

This table clearly communicates the practical pros and cons of 6061-T651 for engineers and buyers evaluating aluminum CNC machined parts and CNC machining services.

Although 6061-T6 and 6061-T651 are the same base aluminum alloy, the difference in their tempering process creates notable distinctions in performance. The “T6” temper is solution heat-treated and artificially aged, offering excellent strength and corrosion resistance. The “T651” temper includes an additional stretching step after quenching, relieving internal stresses for improved dimensional stability during CNC machining. This distinction is crucial for aluminum CNC machined parts, as 6061-T651 is less prone to warping or distortion in large or complex components. By examining their physical properties, machinability, and stress performance, manufacturers can determine which temper best suits their project requirements.

Aluminum 6061-T651 vs. Aluminum 6061-T6: Physical Properties

While both tempers share the same chemical composition, subtle differences in heat treatment and stress relief affect their physical and machining behavior. Here are the key physical properties and performance factors to consider when comparing 6061-T6 and 6061-T651 aluminum for CNC machining services:

| Property |

6061-T6 Aluminum |

6061-T651 Aluminum |

| Density |

2.70 g/cm³ |

2.70 g/cm³ |

| Melting Point (°C) |

~582–652 |

~582–652 |

| Thermal Conductivity (W/m·K) |

167 |

167 |

| Electrical Resistivity (Ω·m) |

3.99 × 10⁻⁸ |

3.99 × 10⁻⁸ |

| Thermal Expansion Coefficient (10⁻⁶/K) |

23.6 |

23.6 |

| Corrosion Resistance |

Very good in most environments | Very good; similar to T6 |

| Wear Resistance |

Moderate |

Moderate |

| Oxidation Resistance |

Excellent |

Excellent |

| Weldability |

Good; post-weld heat treatment may be required to regain full strength | Good; same as T6, but stress relief benefits remain |

| Dimensional Stability |

Moderate; risk of warping in large machined parts |

Excellent; minimized warping due to stress relief |

| Heat Treatment Process |

Solution heat-treated → Quenched → Artificially aged | Solution heat-treated → Quenched → Stretched (1–3%) → Artificially aged |

| Stress Relief |

Moderate; residual stresses may remain | Excellent; stretching process relieves internal stresses |

| Magnetic Properties |

Non-magnetic |

Non-magnetic |

| Formability |

Limited after T6 tempering; better in T4 or O tempers | Similar to T6; not ideal for deep bending or complex forming |

| Machinability (Annealing) |

Very good |

Excellent for precision machining |

This comparison shows that while the two tempers share most physical characteristics, 6061-T651 has a clear advantage in dimensional stability and stress relief, making it the better choice for large, complex, or high-precision aluminum CNC machined parts.

Aluminum 6061-T651 and Aluminum 6061-T6: Mechanical Properties

While 6061-T6 and 6061-T651 aluminum share the same chemical composition and similar overall strength, the additional stress-relief step in 6061-T651 affects how the material performs under machining and load conditions. Both tempers offer high tensile strength, good fatigue resistance, and reliable elasticity, making them suitable for aluminum CNC machined parts in structural, automotive, and aerospace applications. However, 6061-T651 provides improved dimensional stability, which is particularly valuable for precision CNC machining services where tight tolerances are critical. Understanding their mechanical properties helps engineers and manufacturers select the most appropriate temper for a specific project.

Here is a detailed comparison of the mechanical properties of 6061-T6 and 6061-T651 aluminum:

| Mechanical Property |

6061-T6 Aluminum |

6061-T651 Aluminum |

| Hardness (HRC) |

60 HB (~9 HRC) | 60 HB (~9 HRC) |

| Hardness (HV) |

~107 HV | ~107 HV |

| Hardness (HRC/HRB) |

~95 HRB | ~95 HRB |

| Ultimate Tensile Strength (MPa) |

290–310 | 290–310 |

| Yield Tensile Strength (MPa) |

240 | 240 |

| Elongation (Rp0.2 / MPa) |

240 | 240 |

| Ductility (%) |

8–12 | 8–12 |

| Reduction of Area (Z/%) |

~12 | ~12 |

| Elongation at Break (%) |

8–12 | 8–12 |

| Fatigue Strength (MPa) |

~96 | ~96 |

| Shear Strength (MPa) |

~200 | ~200 |

| Elastic (Young’s) Modulus (GPa) |

68–70 | 68–70 |

| Shear Modulus (GPa) |

26 | 26 |

| Poisson’s Ratio |

0.33 | 0.33 |

| Heating Temperature (Max °C) |

170–180 | 170–180 |

Both materials deliver comparable strength and hardness, but 6061-T651’s stress-relieved temper ensures greater stability during high-volume CNC machining or when removing large amounts of material. This makes it a preferred choice in aerospace plates, precision automotive components, and industrial machinery parts produced in CNC machining factories.

Aluminum 6061-T651 and Aluminum 6061-T6: Chemical Composition

Both 6061-T6 and 6061-T651 aluminum share the same chemical composition, as they are different tempers of the same 6061 alloy. The primary alloying elements—magnesium (Mg) and silicon (Si)—form magnesium silicide (Mg₂Si), which is responsible for the alloy’s strength after heat treatment. Trace elements like chromium (Cr), copper (Cu), and titanium (Ti) further enhance corrosion resistance, toughness, and grain structure. Because the chemical makeup does not change between T6 and T651, their mechanical and corrosion properties remain very similar. The main distinction lies in stress relief and dimensional stability, achieved through the stretching process of T651.

Below is the typical chemical composition of 6061 aluminum in both T6 and T651 tempers:

| Element |

Percentage (%) |

| Aluminum (Al) |

95.85 – 98.56 |

| Chromium (Cr) |

0.04 – 0.35 |

| Copper (Cu) |

0.15 – 0.40 |

| Iron (Fe) |

≤ 0.70 |

| Magnesium (Mg) |

0.80 – 1.20 |

| Manganese (Mn) |

≤ 0.15 |

| Silicon (Si) |

0.40 – 0.80 |

| Titanium (Ti) |

≤ 0.15 |

| Zinc (Zn) |

≤ 0.25 |

| Residuals |

≤ 0.15 (total) |

Because the chemical composition is identical, the choice between 6061-T6 and 6061-T651 depends on processing requirements rather than elemental differences. For aluminum CNC machined parts, T651 is often chosen when high precision and dimensional stability are critical, while T6 is suitable for general structural and automotive applications where minimal stress relief is acceptable.

Both 6061-T6 and 6061-T651 aluminum are widely used in engineering, manufacturing, and CNC machining services because of their high strength, good corrosion resistance, and excellent machinability. While they share the same chemical composition, their different tempers make them suitable for slightly different applications. The main distinction lies in dimensional stability: 6061-T651 is stress-relieved and therefore preferred for large or complex aluminum CNC machined parts, whereas 6061-T6 is typically used in general structural components where minor distortion is less critical.

6061-T6 Aluminum Applications:

6061-T651 Aluminum Applications:

In summary, 6061-T6 is ideal for general-purpose use and parts with moderate precision requirements, while 6061-T651 is the better choice for CNC machining factories producing complex or heavy-duty parts that demand high dimensional reliability. Selecting the right temper ensures optimal performance, efficiency, and cost-effectiveness for your project.

Here’s a clear and practical table comparing the applications and uses of 6061-T6 vs. 6061-T651 aluminum for your article:

| Application Category |

6061-T6 Aluminum |

6061-T651 Aluminum |

| Automotive Components |

Frames, engine parts, brackets, and general automotive structures | Precision performance parts, suspension components, and racing applications |

| Aerospace & Aviation |

Aircraft frames, supports, and non-critical structural components | Precision structural parts, wing fixtures, and large plates requiring tight tolerances |

| Marine Equipment |

Boat fittings, docks, and corrosion-resistant marine hardware | Heavy-duty marine fixtures and precision components for minimal warping |

| Industrial Machinery |

Machine frames, supports, and general structural equipment | Tooling, jigs, fixtures, and machine bases requiring high dimensional stability |

| Heavy CNC Machined Parts |

Standard machined components with moderate stress relief needs | Large plates, molds, and complex 6061-T651 aluminum CNC machined parts |

| Consumer Products |

Bicycle frames, sports gear, furniture, and lightweight structural items | Premium custom components needing excellent dimensional reliability |

This table allows readers to quickly identify which alloy temper is best suited for their CNC machining services or project requirements.

Aluminum 6061 is an extremely versatile alloy because it can be processed into multiple tempers, each designed to optimize specific mechanical properties like strength, ductility, and machinability. Tempers are achieved through various heat treatment and mechanical processes, including solution heat treatment, quenching, stretching, and aging. The choice of temper affects how the alloy behaves in CNC machining services, welding, forming, and structural applications. Understanding each temper—its heat treatment and tensile strength—helps manufacturers and CNC machining factories select the best material for their aluminum CNC machined parts.

6061-O Temper

6061-T4 Temper

6061-T62 Temper

6061-T6 Temper

6061-T651 Temper

Since your list repeated T6 and T651, I have included each once with complete details to keep the content accurate and professional.

Here’s a clear and concise table summarizing the other tempers of 6061 aluminum, including their heat treatment methods and tensile strengths, for your article:

| Temper |

Heat Treatment Process |

Tensile Strength (MPa / ksi) |

Key Characteristics |

| 6061-O |

Fully annealed; no heat treatment | ~124 MPa / 18 ksi | Very soft and ductile; excellent for bending and forming, but low strength |

| 6061-T4 |

Solution heat-treated → Naturally aged | ~207 MPa / 30 ksi | Moderate strength with better formability; often used before further heat treatment |

| 6061-T62 |

Solution heat-treated → Artificially aged (slightly different cycle than T6) | ~260 MPa / 38 ksi | Balanced strength and ductility; slightly better machinability than T6 |

| 6061-T6 |

Solution heat-treated → Quenched → Artificially aged | ~290–310 MPa / 42–45 ksi | High strength, good corrosion resistance, and excellent for 6061-T6 aluminum CNC machined parts |

| 6061-T651 |

Solution heat-treated → Quenched → Stretched (1–3%) → Artificially aged | ~290–310 MPa / 42–45 ksi | Same strength as T6 but stress-relieved; excellent dimensional stability for CNC machining services |

This table allows readers to quickly compare the different 6061 tempers, their processing methods, and their tensile strength, making it easy to select the right option for aluminum CNC machined parts.

Choosing between 6061-T6 and 6061-T651 aluminum depends on your project’s dimensional accuracy requirements, part size, machining needs, and cost considerations. Both tempers offer excellent strength, corrosion resistance, and machinability, making them popular for aluminum CNC machined parts in aerospace, automotive, and industrial applications. The key difference lies in stress relief and dimensional stability: 6061-T651 is stretched to remove internal stresses, making it more reliable for large or complex parts where warping could be a problem. In contrast, 6061-T6 is sufficient for most general-purpose components and is more cost-effective. Understanding where each excels ensures optimal performance and manufacturing efficiency.

When Should I Use 6061-T6 Aluminum?

Use 6061-T6 aluminum for:

When Should I Use 6061-T651 Aluminum?

Use 6061-T651 aluminum for:

In summary, 6061-T6 is the cost-effective choice for general-purpose parts, while 6061-T651 is the premium option for high-precision CNC machining projects in CNC machining factories where dimensional stability is essential.

Here’s a clear comparison table for when to use 6061-T6 vs. 6061-T651 aluminum to make the selection process easy for readers:

| Criteria |

6061-T6 Aluminum |

6061-T651 Aluminum |

| Project Type |

General-purpose structural and functional parts | High-precision, heavy-duty, or large-scale components |

| Dimensional Stability |

Moderate; may warp with heavy machining | Excellent; stress-relieved to minimize distortion |

| Machining Requirements |

Suitable for light-to-medium machining | Ideal for heavy milling and 6061-T651 aluminum CNC machined parts |

| Tolerance Needs |

Medium; adequate for standard applications | High; best for tight tolerances and precision parts |

| Material Removal Volume |

Low to moderate material removal | High material removal with minimal risk of warping |

| Cost Consideration |

More cost-effective and widely available | Slightly more expensive due to additional processing |

| Application Examples |

Automotive frames, marine parts, aerospace brackets | Aerospace plates, molds, fixtures, precision industrial machinery |

| Best Use Case |

Standard CNC machining projects | CNC machining services requiring top-level dimensional reliability |

This table gives readers a quick visual guide to select the right alloy temper based on machining complexity, precision, and budget.

When it comes to manufacturing high-quality aluminum CNC machined parts, VMT is a trusted partner for industries that demand precision, durability, and reliability. Whether your project requires 6061-T6 aluminum for cost-effective general components or 6061-T651 aluminum for stress-relieved, high-precision parts, our expert team ensures every detail meets your specifications.

VMT operates state-of-the-art CNC machining factories equipped with advanced milling, turning, and finishing technology, allowing us to handle everything from simple prototypes to complex, large-scale production runs. Our engineers have extensive experience in machining 6061 aluminum in all tempers, guaranteeing excellent surface finishes, dimensional accuracy, and performance.

By choosing VMT, you gain:

Whether you are producing aerospace fixtures, automotive brackets, marine components, or industrial machinery parts, VMT delivers consistent quality and competitive pricing. Contact VMT today to get reliable CNC machining services and high-performance 6061 aluminum CNC machined parts tailored to your needs.

Choosing between 6061-T6 aluminum and 6061-T651 aluminum depends on your project’s precision requirements, machining complexity, and budget. Both tempers share the same chemical composition and offer high strength, good corrosion resistance, and excellent machinability, making them widely used in aluminum CNC machined parts across aerospace, automotive, marine, and industrial applications.

6061-T6 is the go-to option for general-purpose components where cost-efficiency and good mechanical properties are sufficient. It performs well in standard CNC machining projects, automotive brackets, marine fittings, and structural applications.

6061-T651, on the other hand, is the premium choice for high-precision parts, large plates, and heavy milling applications that require maximum dimensional stability. Its stress-relieved condition significantly reduces the risk of warping or distortion, making it ideal for aerospace fixtures, industrial molds, and other critical CNC machining services where tight tolerances are essential.

By understanding the differences in heat treatment, physical properties, and performance, engineers and manufacturers can confidently select the right 6061 aluminum temper for their needs. Partnering with an experienced CNC machining factory like VMT ensures that your aluminum CNC machined parts are produced with superior accuracy, surface finish, and reliability—helping you achieve optimal results in any project.

1. Is 6061-T6 the same as T6511?

6061-T6 and 6061-T6511 are similar but not identical. T6511 indicates the alloy has been solution heat-treated, stress-relieved by stretching, and artificially aged, with a slightly different stretching method than T651. Both provide improved dimensional stability over T6 but may differ in stress relief specifics.

2. Does T651 meet the requirements of T6?

Yes, 6061-T651 meets or exceeds the mechanical properties and strength requirements of 6061-T6. The main difference is that T651 includes a stress-relief stretching step for better dimensional stability.

3. What is the difference between 6061-T651 and 6082-T6?

6061 and 6082 are different aluminum alloys. 6061-T651 has better corrosion resistance and weldability, while 6082-T6 offers higher strength. The choice depends on specific application needs.

4. What is 6061-T651 aluminum used for?

6061-T651 is commonly used in aerospace, automotive, heavy machinery, molds, and fixtures requiring high dimensional stability and resistance to warping during machining.

5. Can you bend 6061-T651 aluminum?

Bending 6061-T651 is possible but limited due to its hardened temper. For extensive forming, softer tempers like 6061-O or T4 are recommended to avoid cracking.

6. What grade of aluminum is T6?

T6 refers to the temper of the aluminum alloy after solution heat treatment and artificial aging. It is not a grade itself but a treatment condition applied to alloys like 6061, 7075, etc.

7. What is the difference between T6 and T61 heat treatments?

T6 is solution heat-treated and artificially aged. T61 is similar but involves controlled cooling after solution heat treatment, offering slightly different mechanical properties for specialized applications.

8. How do you stress relieve 6061-T6 aluminum?

Stress relief is typically done by stretching the material (as in T651 temper) or by low-temperature annealing to reduce internal stresses from machining or fabrication.

9. Is 6061-T6 forged or cast?

6061-T6 aluminum is commonly produced as a wrought product (rolled, extruded, or forged), not cast, to ensure uniformity and superior mechanical properties.

10. What is the yield strength of 7075 T651 aluminum?

7075-T651 aluminum typically has a yield strength of about 503 MPa (73 ksi), significantly higher than 6061 alloys, making it suitable for high-strength aerospace applications.

11. What is the difference between 6061-T651 and 7075 T651?

6061-T651 offers excellent corrosion resistance and weldability with moderate strength, while 7075-T651 provides much higher strength but less corrosion resistance and is harder to weld.

12. What does T6 stand for in aluminum?

T6 indicates that the aluminum alloy has undergone solution heat treatment followed by artificial aging to achieve a stable and high-strength condition.

13. How do you temper aluminum to T6?

Tempering to T6 involves heating the alloy to a high temperature (solution heat treatment), quenching it rapidly, then aging it at a lower temperature for a set period to enhance strength.

14. Can T6 aluminum be welded?

Yes, but welding T6 aluminum often reduces its strength near the weld. Post-weld heat treatment may be necessary to restore full mechanical properties.

15. What is the difference between 6082 T6 and T651?

6082-T6 and 6082-T651 differ mainly in that T651 includes a stress-relief stretching step, enhancing dimensional stability, while T6 does not. Both have similar strength levels.

16. What is the difference between T61 and T63?

T61 and T63 are tempers similar to T6 but with slight variations in aging time and temperature, leading to small differences in strength and ductility tailored for specific engineering requirements.