15 years one-stop China custom CNC machining parts factory

424 |

Published by VMT at Aug 08 2025 | Reading Time:About 7 minutes

424 |

Published by VMT at Aug 08 2025 | Reading Time:About 7 minutes

Choosing the wrong drill bit for a 3/8-16 tap can lead to stripped threads, broken taps, and expensive CNC machining rework. Many engineers, buyers, and CNC machining factories face this challenge daily, especially when working with different materials or customizing CNC machining parts. Fortunately, you don’t need to guess the correct size. By understanding the standard and material-specific requirements, you can ensure optimal fit, thread strength, and production efficiency. In this guide, we’ll walk you through everything you need to know about 3/8-16 tap drill bit sizing.

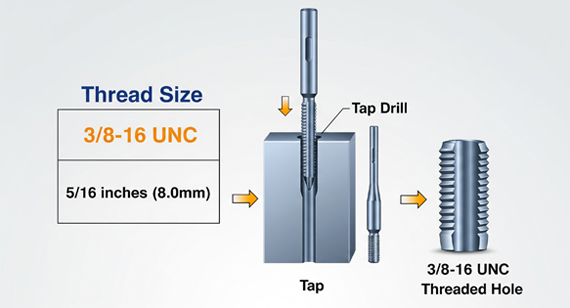

To tap a standard 3/8-16 thread, use a 5/16 inch (0.3125") drill bit. This size ensures a proper thread engagement and minimizes the risk of stripping or tool wear, especially when producing CNC machining parts across various materials.

Understanding the 3/8-16 tap drill bit size is essential not just for machinists, but for engineers, procurement teams, and quality assurance departments alike. Whether you're working with standard alloys or special materials, selecting the correct tap and drill bit size ensures precision, durability, and compatibility with CNC machining services. Let’s explore the reasons behind this size choice and how to adjust it based on the material or project type.

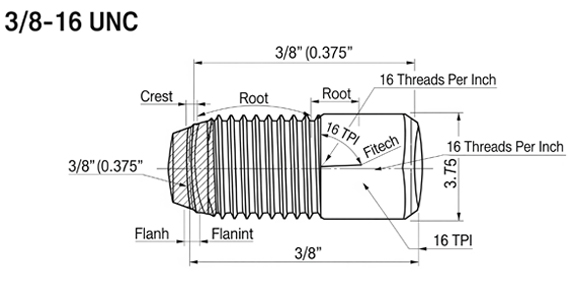

A 3/8-16 tap refers to a fastener size of 3/8 inch in diameter with 16 threads per inch (TPI), which is considered a Unified National Coarse (UNC) thread. The correct tap drill size to pair with a 3/8-16 tap is 5/16" or 0.3125". This size offers the ideal balance between material engagement and tool clearance, which is crucial for maintaining the strength and integrity of the threads. Using a smaller bit may result in excessive material in the hole, making tapping difficult and increasing the chance of breakage. On the other hand, a larger bit can cause shallow or loose threads, compromising the performance of CNC machining parts. In precision-focused CNC machining services, accuracy in tap and drill bit pairing is vital, and this 5/16" sizing is a proven industry standard.

Drilling the correct hole size before tapping ensures clean, properly formed threads. For a 3/8-16 tap, the ideal hole size is 5/16 inches (equivalent to a letter "F" drill bit in the standard drill chart). This specific dimension allows the tap to cut threads deeply enough for structural integrity without overly stressing the tap itself. CNC machining factories often use this size when programming holes for tapped features on components like housings, brackets, or mounting flanges. Drilling too small increases the chance of tool breakage, while too large may cause thread failure. In high-precision CNC machining services, these seemingly minor details make all the difference in part performance and client satisfaction.

When installing a 3/8-16 helical coil (also known as a thread insert), the hole size must accommodate both the coil and the tap that creates the internal thread for the insert. For most standard-length inserts, a 25/64" (0.3906") drill bit is typically used prior to tapping. This larger drill size provides enough clearance for the tap designed for the insert’s outer thread. Helical coils are often used in CNC machining parts to strengthen threads in softer materials such as aluminum or plastic. Therefore, CNC machining services must precisely follow insert manufacturer specs to ensure strong, reusable threads in critical applications.

The 3/8-16 thread size is among the most commonly used in mechanical design and manufacturing, particularly in North America. This popularity comes from its balance between strength, availability, and versatility. It is widely used in structural assemblies, industrial equipment, and custom CNC machining parts. The coarse 16 threads per inch provide better resistance to stripping and cross-threading in softer materials, while still offering sufficient holding power for a wide range of applications. For CNC machining factories, having a standard like 3/8-16 simplifies tooling, reduces setup times, and improves compatibility across product lines, making it a go-to choice in many engineering projects.

When working with a 3/8-16 tap, the standard drill bit size used is 5/16 inches (0.3125"), which corresponds to a letter "F" drill bit. This size offers approximately 75% thread engagement, which is considered ideal for most general-purpose applications, ensuring both thread strength and ease of tapping. This standard is widely adopted across CNC machining factories and is a reliable default for both soft and hard metals, plastics, and composites.

However, not all materials behave the same way under machining operations. This is where custom tap and drill bit sizes come into play. For harder materials such as stainless steel or tool steel, CNC machining services may reduce thread engagement to prevent excessive tap wear or breakage. In such cases, a slightly larger drill bit like 21/64" (0.3281") might be used. Conversely, for softer materials like aluminum or plastics—especially when stronger threads are needed—engineers might choose a slightly smaller drill size to increase thread engagement.

Additionally, if a customer requires tighter tolerances or specific thread fit classes (such as 3B vs. 2B), CNC machining parts may demand a custom-prepared hole size to match the required specification. Customization is often influenced by factors such as coating thickness, thread interference, or surface treatment.

CNC machining services must consider not just the tap and drill pairing, but the full interaction between material properties, tool geometry, and application requirements. This is why advanced CNC machining factories offer both standard and tailored solutions—ensuring precision, consistency, and optimal performance no matter the end-use. Understanding both standard and custom sizing allows teams to make informed decisions and avoid costly thread failures in final assemblies.

Having a reliable tap and drill bit size chart is essential for any CNC machining factory, as it allows machinists, engineers, and quality inspectors to quickly reference the correct sizes for tapping operations. For 3/8-16 threads specifically, both standard and alternative drill bit sizes are used depending on the application, material type, and thread engagement desired.

Below is a detailed tap and drill bit size chart tailored for 3/8-16 taps:

| Thread Size |

Thread Pitch (TPI) |

Tap Type |

Standard Drill Bit Size |

Decimal (inches) |

Letter/Number Equivalent |

Recommended Use |

| 3/8-16 UNC | 16 | Plug Tap | 5/16" | 0.3125" | Letter "F" | General-purpose tapping, ideal for most metals and plastics |

| 3/8-16 UNC | 16 | Spiral Tap | 21/64" | 0.3281" | — | Harder materials, reduced engagement to avoid tap breakage |

| 3/8-16 UNC | 16 | Bottoming Tap | 19/64" | 0.2969" | — | Softer materials, increased thread engagement |

| 3/8-16 Helicoil | 16 | STI Tap | 25/64" | 0.3906" | — | Used before inserting helical coil/thread insert |

This chart helps CNC machining services plan their tapping operations precisely. The standard size of 5/16" (letter F) is the go-to for most CNC machining parts. However, experienced CNC machining factories know that even a few thousandths of an inch difference in drill bit size can significantly affect thread fit and tool longevity—especially when high-volume production or high-tolerance components are involved.

For customers needing CNC machining services, having access to such a chart ensures consistent communication and expectation-setting between design teams and manufacturing partners. It eliminates guesswork and enhances the overall reliability of tapped components in mechanical assemblies.

While the 3/8-16 tap drill bit is widely used, many other thread sizes are essential in CNC machining factories—ranging from fine-pitch threads in electronics to coarse threads in heavy machinery. Below is a quick-reference tap and drill bit size chart for other commonly used UNC and UNF threads in CNC machining services:

| Thread Size | Threads Per Inch (TPI) | Tap Type | Drill Bit Size | Decimal (in) | Letter/Number Size | Application |

| 6-32 UNC | 32 | Plug/Btm | #36 | 0.1065 | #36 | Electronics, light-duty metalwork |

| 8-32 UNC | 32 | Plug/Btm | #29 | 0.1360 | #29 | Small enclosures, brackets |

| 10-24 UNC | 24 | Plug | #25 | 0.1495 | #25 | General mechanical fastening |

| 10-32 UNF | 32 | Fine Thread | #21 | 0.1590 | #21 | Vibration resistance, precision components |

| 1/4-20 UNC | 20 | Plug/Btm | #7 | 0.2010 | #7 | Common bolts, CNC machining parts |

| 5/16-18 UNC | 18 | Plug/Btm | Letter "F" | 0.2570 | F | Medium-duty mechanical parts |

| 3/8-16 UNC | 16 | Plug/Btm | 5/16" | 0.3125 | F | Structural frames, mounting brackets |

| 1/2-13 UNC | 13 | Plug/Btm | 27/64" | 0.4219 | — | Heavy-duty machinery, supports |

| 1/2-20 UNF | 20 | Fine Thread | 29/64" | 0.4531 | — | Automotive, aerospace CNC parts |

| M6 x 1.0 | Metric | Plug | 5.0 mm | 0.1969 | — | European and metric assemblies |

| M8 x 1.25 | Metric | Plug | 6.8 mm | 0.2677 | — | General metric usage |

Tip: Always verify the correct drill bit size based on thread pitch, hole depth, material hardness, and required thread engagement—especially when producing precision CNC machining parts.

Including this tap and drill bit size chart not only increases the article’s usefulness for a broader audience but also improves relevance for CNC machining services offering both metric and imperial threading options. It reflects the diversity of fastener and thread requirements that CNC machining factories must handle daily.

Calculating the correct drill bit size for a tap is a crucial step in ensuring strong, reliable threads—especially when producing CNC machining parts for industries like aerospace, automotive, or medical devices. CNC machining services rely on these calculations to meet tight tolerances and functional specifications without compromising on thread integrity or tool life.

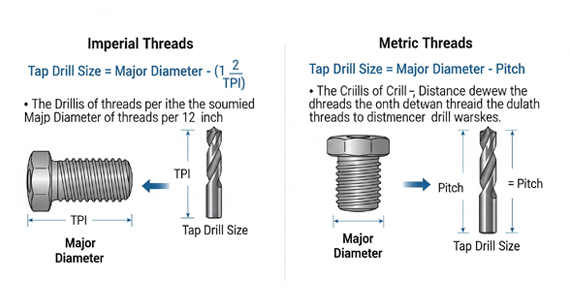

The basic formula for calculating the drill bit size for Unified threads (UNC/UNF) is:

Drill Bit Size = Major Diameter – (1 ÷ Threads Per Inch)

For a 3/8-16 tap, apply the formula:

So:

Drill size = 0.375 - (1 ÷ 16) = 0.375 - 0.0625 = 0.3125"

This confirms the standard drill bit size: 5/16" (0.3125").

For metric threads, use this formula:

Drill Bit Size = Major Diameter – Pitch

Example for M8 x 1.25:

Drill size = 8.00 - 1.25 = 6.75 mm

(Usually rounded to the nearest available drill, such as 6.8 mm.)

This calculation ensures proper thread engagement, which generally ranges from 60–75% for standard engineering practice. Too little engagement can lead to stripped threads, while too much makes tapping harder and increases tool breakage risk—especially in hardened metals.

CNC machining factories often integrate these calculations into CAM software and process sheets. However, manual checking is still essential in prototype work or when working with non-standard materials. Understanding how to calculate tap drill sizes empowers engineers, machinists, and procurement teams to avoid costly mistakes in both design and production.

Choosing the correct drill bit size for tapping isn’t just about looking up a number on a chart—it’s about evaluating the full context of the machining application. CNC machining factories consider several important factors when determining the optimal drill bit size, especially for high-precision CNC machining parts that demand tight tolerances, high strength, and long-term reliability.

1. Start with the Thread Specification

Always begin with the thread type you’re cutting—such as 3/8-16 UNC. Each thread standard (UNC, UNF, metric, etc.) has a specific tap drill size recommendation based on thread pitch and diameter. For example, a 3/8-16 tap typically uses a 5/16" (0.3125") drill bit, which provides approximately 75% thread engagement.

2. Factor in the Material Type

The hardness and machinability of the material directly influence drill bit size selection. In softer materials (like aluminum or plastics), you may reduce the drill size slightly to achieve deeper thread engagement. In harder materials (like stainless steel or titanium), increasing the drill size slightly can reduce cutting forces, minimize tool wear, and avoid tap breakage.

3. Consider the Required Thread Engagement

For most general-purpose applications, 60–75% thread engagement is ideal. However, for load-bearing components or critical assemblies, you may require higher engagement. CNC machining services often consult engineering drawings or customer specs to determine this requirement.

4. Match to Tap Type and Tolerance Class

The type of tap—plug, bottoming, spiral point, etc.—and the desired fit class (like 2B or 3B) may also influence the ideal drill bit size. Tighter fits require more precision, while looser fits may allow for slightly larger pre-drilled holes.

5. Adjust Based on Coatings and Surface Finishes

If your CNC machining parts will undergo plating, anodizing, or coating, you may need to account for the extra thickness by adjusting your drill size accordingly.

6. Use CAM Software or Tap Drill Calculators

Many CNC machining factories rely on CAM systems or tap drill calculators that factor in material, thread pitch, and tolerance levels automatically. This ensures consistency and accuracy—especially for high-volume CNC machining services.

By evaluating these variables together, engineers and machinists can confidently choose the right drill bit size for tapping. This reduces defects, improves thread integrity, and ensures every part produced meets the exacting standards expected from professional CNC machining services.

In CNC machining services, few factors impact thread performance more than selecting the right tap and drill bit size. Whether manufacturing thousands of CNC machining parts or producing a high-value prototype, the precision of these two components directly affects the strength, longevity, and reliability of the finished thread. For CNC machining factories aiming for zero-defect production and customer satisfaction, this choice is not optional—it’s essential.

How an Incorrect Drill Bit Size Affects Thread Quality

Using an incorrect drill bit size when tapping can have immediate and long-term consequences. If the drill bit is too small, the tap will have to cut more material than intended, leading to excessive stress on the tool. This often results in poor chip evacuation, increased torque, and a higher likelihood of tap breakage, especially when machining hard metals like stainless steel.

On the other hand, if the drill bit is too large, the resulting thread will have shallow engagement, leading to weak threads that may strip under load or vibration. In CNC machining parts used in structural or load-bearing applications, this compromises the overall performance and can result in product failure or costly warranty issues.

Incorrect sizing also affects thread class tolerance, which is especially problematic in industries that require strict dimensional accuracy—like aerospace, medical, and automotive. Therefore, CNC machining factories must follow precise specifications and use proper verification tools during setup and inspection stages.

Why Precision Is Critical for Strong, Reliable Threads

In CNC machining, precision equals performance. Threads are responsible for fastening, alignment, and even electrical connectivity in certain applications. If the thread is even slightly off due to incorrect tap or drill sizing, it can result in misalignment, cross-threading, or reduced torque capacity.

Strong and reliable threads rely on balanced engagement—not too tight, not too loose. That balance comes from carefully matching the correct drill bit to the specific tap being used. High-performance CNC machining services often work with a variety of materials—each with different responses to cutting tools. What works for aluminum won’t work the same for hardened steel or composites. That’s why top-tier CNC machining factories apply engineering data, machinist expertise, and real-world testing to ensure every thread performs as expected under operational conditions.

How the Correct Drill Bit Size Prevents Thread Damage

Selecting the right drill bit size before tapping is the most proactive step in preventing thread damage. When the hole is prepared with the correct diameter, the tap encounters optimal cutting resistance, chip flow is smoother, and thread form remains consistent throughout the entire depth of the hole.

This precision drastically reduces the risk of:

By simply matching the correct drill size to the tap—such as using a 5/16" drill bit for a 3/8-16 tap—CNC machining services can extend tool life, improve threading speed, and reduce scrap rates. This ultimately improves delivery times, lowers costs, and enhances overall product quality.

In summary, the right tap and drill bit size isn't just a technical detail—it's a fundamental building block of high-quality CNC machining parts.

Selecting the right drill bit size for a 3/8-16 tap may seem straightforward, but in reality, it requires thoughtful consideration of several factors: thread engagement, material type, tooling conditions, and performance expectations. In the world of CNC machining services, this decision affects everything from thread strength and precision to tool life and part functionality. For CNC machining factories that prioritize quality and repeatability, choosing the correct drill bit size for a 3/8-16 thread is part of a larger commitment to excellence in part manufacturing.

Calculating Tap and Drill Bit Size for 3/8-16 Threads

The standard formula used in the machining industry to calculate tap drill sizes is:

For a 3/8-16 thread:

Drill size = 0.375 - (1 ÷ 16) = 0.375 - 0.0625 = 0.3125"

Thus, the correct drill bit size is 5/16", or letter "F", which ensures around 75% thread engagement—a balanced standard in CNC machining parts for both strength and manufacturability. This calculation is especially useful when customizing parts or validating existing drill and tap pairings on the shop floor.

Common Drill Bit Sizes for 3/8-16 Tapping

While 5/16" (0.3125") is the industry standard for 3/8-16 tapping, there are variations based on application requirements:

| Drill Bit Size |

Decimal (in) |

Use Case |

| 5/16" | 0.3125 | Standard tap size for 3/8-16 UNC threads |

| 21/64" | 0.3281 | For harder materials to reduce cutting force |

| 19/64" | 0.2969 | For soft materials to increase thread engagement |

| 25/64" | 0.3906 | Used for STI (Screw Thread Insert) tapping for helicoils |

CNC machining factories often keep all these sizes on hand to allow flexible response to material types and customer specifications. Experienced machinists understand that even a minor adjustment in drill size can significantly improve tapping efficiency and final part quality.

Adjusting Based on Material Type and Hardness

The material being machined plays a critical role in determining the ideal drill bit size. In softer materials like aluminum, brass, or certain plastics, using a slightly smaller drill bit—such as 19/64"—can increase thread depth and holding strength. However, going too small increases the risk of tap breakage, especially during deep-hole tapping operations.

For harder materials such as stainless steel or alloy steel, using a slightly larger bit like 21/64" reduces cutting resistance, minimizes tap wear, and helps prevent galling. In CNC machining services where large production volumes are involved, optimizing drill size by material type improves process stability and reduces tool change downtime.

Additionally, when tapping holes for helical coil inserts (like in aerospace CNC machining parts), the drill bit size must accommodate the outer thread of the insert, not the nominal bolt thread. That’s why 25/64" is commonly used for 3/8-16 helicoil preparation.

Ultimately, choosing the correct drill bit size for a 3/8-16 tap means balancing engagement, tool performance, and thread quality. By factoring in thread specifications, material hardness, and application needs, CNC machining services can produce high-precision components that meet or exceed customer expectations.

In CNC machining services, one small misstep in drill and tap size selection can compromise the quality of your entire part—leading to production delays, increased scrap, or worse, costly product failures in the field. When dealing with a widely used thread like 3/8-16, it’s easy to assume that any near-size drill bit will do. However, CNC machining factories know that precision matters. Avoiding these common mistakes ensures your CNC machining parts meet functional, structural, and performance requirements every time.

Using an Oversized Drill Bit for 3/8-16 Threads

An oversized drill bit creates a hole that is too large for the 3/8-16 tap to form strong, full-depth threads. This results in shallow threads with reduced holding strength, which are prone to stripping under load or vibration. This mistake often occurs when machinists substitute close-but-not-exact drill sizes, especially when tools are unavailable or mislabeled.

In CNC machining factories, this error can slip through unnoticed until parts reach assembly or field testing—by which time, the cost of rework is far greater. An oversized hole also eliminates the possibility of retapping or using thread inserts without redesign. For mission-critical applications, especially in aerospace or automotive CNC machining parts, this could render the component unusable.

Always confirm that you’re using the standard 5/16" drill bit for 3/8-16 taps, unless specific material or design considerations dictate otherwise.

Using an Undersized Drill and Its Consequences

Conversely, using a drill bit smaller than 5/16" for a 3/8-16 tap increases material resistance during tapping. This can lead to excessive torque, poor chip evacuation, and tap breakage, especially in hard materials like stainless steel or titanium. Broken taps not only ruin the part—they can also damage the workholding setup and require expensive removal procedures.

Even if the tap doesn’t break, forcing it into an undersized hole creates distorted threads, increases friction, and often results in non-conforming parts that must be rejected. In high-precision CNC machining services, consistency is king—so pushing tooling beyond its limits to "force" a thread is never a viable strategy.

Ignoring the Effect of Pitch on Drill Size

Another common oversight is failing to understand how thread pitch affects drill size. The pitch for a 3/8-16 thread is 1/16" or 0.0625", and this directly influences the depth and spacing of the threads. If this value is misread or not factored into calculations, the selected drill bit may be too large or too small.

This is especially problematic when converting between metric and imperial measurements, or when using automatic toolpath generators in CAM software. CNC machining factories that overlook pitch when switching between UNC and UNF threads risk producing incorrect threads that do not meet tolerance or fit class requirements.

To avoid this mistake, always reference trusted tap drill charts, apply the correct calculation formulas, and ensure that pitch is clearly defined in your CNC setup sheets and design drawings.

Precision in CNC machining services often comes down to understanding the fine details—and one of the most misunderstood concepts is the difference between tap drill size and thread size. For buyers, engineers, and machinists working on CNC machining parts, knowing this distinction ensures stronger threads, better fit, and fewer production errors. Whether you're producing high-tolerance components or structural fasteners, grasping this difference is essential for achieving optimal performance and thread engagement in CNC machining factories.

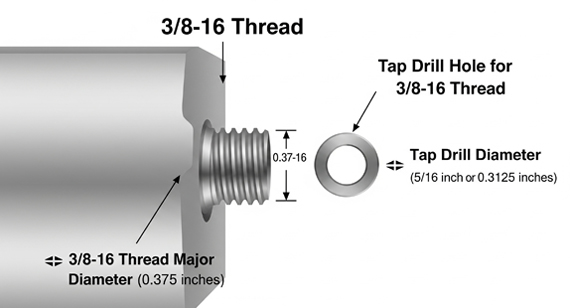

The Difference Between Tap Drill Size and Thread Size

At first glance, many assume that the tap drill size and the thread size are the same. But they serve very different purposes. The thread size refers to the nominal diameter of the finished threaded hole—for example, a 3/8-16 thread has a nominal outer diameter of 0.375 inches and 16 threads per inch (TPI). This is the size of the fastener that will screw into the hole.

The tap drill size, however, is the diameter of the hole you must drill before tapping. For a 3/8-16 thread, the standard tap drill size is 5/16" (0.3125")—which is smaller than the thread's nominal diameter to allow the tap to cut into the material and form the threads.

This intentional difference is what creates strong, defined threads within the hole. If the drill hole were the same size as the thread, the tap wouldn’t have any material to cut, and no functional threads would be formed.

Why Tap Drill Size is Slightly Smaller than Thread Size

The tap drill size is always slightly smaller than the thread size because it must leave enough material for the tap to form the thread's crests and roots. For a 3/8-16 thread, the difference between the 0.375" major diameter and the 0.3125" drilled hole allows the tap to create threads with a suitable depth and surface finish.

This gap—typically equal to 1 ÷ TPI—ensures that threads are strong enough to withstand torque, vibration, and repeated use. The smaller drill size leads to approximately 75% thread engagement, which is considered ideal in most CNC machining parts: strong enough to hold firmly, but not so tight that the tapping process becomes difficult or risks breaking the tool.

CNC machining services calculate and test this offset carefully, especially when creating threaded holes in custom components, where failure is not an option.

How to Select the Proper Tap Drill Size for Optimal Thread Fit

To choose the correct tap drill size for a 3/8-16 thread—or any other thread—you must account for:

For general-purpose applications, the 5/16" drill bit is the go-to choice for a 3/8-16 tap. But in CNC machining factories, experienced machinists will adjust the drill size up or down based on whether the part will undergo plating, heat treatment, or be subject to high loads.

Ultimately, the goal is to match the drill size with the expected thread performance. Too large, and the thread becomes weak. Too small, and you risk damaging tools or parts. Precision in this area is one of the defining traits of high-quality CNC machining services.

In CNC machining services, precision isn’t a luxury—it’s a necessity. Especially when tapping threads like 3/8-16, even minor miscalculations can lead to stripped threads, poor fit, or tool breakage. Whether you're sourcing CNC machined parts from a reliable factory or producing them in-house, mastering the techniques for achieving precision with a 3/8-16 tap drill ensures your threaded components perform reliably in real-world applications.

Ensuring the Correct Hole Depth for 3/8-16 Threads

One of the most overlooked factors in thread quality is hole depth. For a 3/8-16 thread, achieving the correct hole depth ensures full thread engagement and avoids bottoming-out issues that can damage taps or lead to weak thread anchoring.

As a rule of thumb, the drilled hole should be slightly deeper than the intended thread length—typically 1.5 to 2 times the thread’s nominal diameter, or around 9/16" to 3/4" deep, depending on application requirements. This extra depth gives clearance for chips, prevents tap breakage, and allows for full-depth threading.

In high-precision CNC machining factories, hole depth is measured using automated probing systems or pre-calibrated depth stops, ensuring accuracy within microns.

Using the Proper Tapping Tool for Precise Results

Not all taps are created equal. Choosing the right tap is essential for producing clean, consistent threads in a 3/8-16 hole. Factors like the material type (e.g., aluminum, stainless steel, or hardened alloys) will determine whether you should use a spiral point tap, spiral flute tap, or hand tap.

For blind holes, spiral flute taps are preferred, as they lift chips out of the hole. For through holes, spiral point taps push chips forward, reducing binding and breakage.

In professional CNC machining services, machinists also select taps with coatings like TiN or TiCN to improve wear resistance and accuracy, particularly when working with abrasive materials or performing high-volume production.

Using a worn-out or incorrect tap will compromise thread pitch, diameter, and overall fit—jeopardizing the performance of the CNC machining parts being produced.

Calibration Tips for Thread Cutting Consistency

Even with the correct drill size and tap, inconsistencies in machine calibration can lead to faulty threads. That’s why top-tier CNC machining factories perform regular calibration checks on spindle alignment, tapping torque, and tool wear compensation.

Here are key calibration tips for consistent 3/8-16 threads:

These small adjustments—when done consistently—can make a significant difference in the final quality of stainless steel CNC machined parts, aluminum housings, and other threaded components.

When it comes to 3/8-16 tap drill applications, thread engagement is a critical factor in determining the mechanical strength and long-term performance of the finished part. Whether you’re machining stainless steel housings or aluminum brackets, the amount of thread engagement directly influences the load-bearing capacity, vibration resistance, and durability of your CNC machined parts.

What Is Thread Engagement and Why Does It Matter?

Thread engagement refers to how much of the internal thread (in the hole) makes contact with the external thread (on the fastener). For 3/8-16 threads, the ideal engagement is typically 60% to 75%, which balances strength with ease of tapping.

If engagement is too low, the fastener won’t hold under stress; if it's too high, tapping becomes difficult and increases the risk of tap breakage—especially in hard materials.

For CNC machining services focused on quality and repeatability, this means precisely controlling both hole diameter and tap depth to ensure the desired thread engagement without over-stressing the tool or the material.

How Material Type Influences Thread Strength

Different materials require different strategies for achieving optimal thread strength. For example:

This is why experienced CNC machining factories often modify tap drill size based on both the thread and the material—using specialized charts or calculations rather than one-size-fits-all recommendations.

Calculating Thread Engagement for 3/8-16 Threads

To calculate thread engagement, you’ll need:

A commonly used tap drill for 3/8-16 is 5/16" (0.3125"), which typically results in about 65–70% thread engagement, depending on the material.

Formula:

This level of precision, supported by consistent measurement and tooling, is what sets professional CNC machining services apart—ensuring every thread not only fits but performs under load, thermal stress, and time.

Choosing the correct 3/8-16 tap drill size isn’t just about thread type or diameter—it’s also heavily influenced by the material being machined. Whether you're working with soft plastics or high-strength steel, selecting the wrong drill size can lead to poor thread integrity, tool wear, or even part failure. Leading CNC machining factories understand this well, tailoring their tap drill sizes to suit the unique characteristics of each material for strong, reliable CNC machining parts.

Sizing Soft vs. Hard Materials

When tapping soft materials such as aluminum, brass, or plastics, the material deforms more easily, allowing for greater thread forming with less cutting force. In these cases, a slightly larger tap drill size may be used to reduce the chance of over-threading or material pushout. This ensures clean threads while preventing tap breakage.

In contrast, hard materials like stainless steel or titanium resist deformation and demand tighter tolerances. A slightly smaller tap drill is typically used to maintain thread engagement strength, even though this increases tapping resistance. Precision is especially vital in these materials to avoid tap wear and ensure long-term thread durability.

Special Considerations for Metals, Plastics, and Composites

Different materials behave in unique ways under machining:

Professional CNC machining services tailor each approach to the material, ensuring your CNC machined parts are both strong and precise.

Why Material Type Affects Tap Drill Size Selection

Every material has a unique modulus of elasticity, hardness, and thermal behavior. These properties determine how threads will form, how chips will evacuate, and how much engagement can be safely achieved without damage. For example:

This is why experienced CNC machining factories rely on detailed process planning and material-specific charts when selecting tap and drill sizes—ensuring consistency, accuracy, and performance in every part.

When manufacturing CNC machining parts with a 3/8-16 thread, the purpose of the thread greatly influences the optimal tap drill size. Whether the application demands strength under load, airtight sealing, or ultra-precise assembly, choosing the correct drill bit and tap combination ensures the finished part performs as expected. Leading CNC machining services customize thread preparation based on these specific end-use requirements, delivering high-performance results across various industries.

Load-Bearing Applications: Maximize Thread Engagement

In structural or mechanical assemblies where the 3/8-16 thread is subjected to heavy loads, it’s essential to maximize thread engagement. This means using the standard tap drill size of 5/16" (0.3125"), which results in about 75% thread engagement—ideal for tensile and shear strength. For extremely high-load situations or harder materials, CNC experts may even select a slightly smaller drill (e.g., 0.302") to increase holding force, though this must be balanced against the risk of tool breakage.

CNC machining factories take material hardness and application torque into account to ensure the tapped threads won’t strip under force.

Sealing Applications: Tight Fit to Prevent Leaks

When 3/8-16 threads are used in applications involving fluids, gases, or pressure—such as hydraulic ports or air manifolds—sealing becomes a top priority. In these cases, precision is critical, and achieving a tight thread fit is essential.

While the standard drill size is often used, professionals may reduce drill diameter slightly or use tapered taps (such as NPT if appropriate) in conjunction with thread sealant or O-rings. Proper tool calibration and attention to depth control are vital to prevent leaks and maintain system integrity.

Precision Fit Assemblies: Exact Alignment Matters

In assemblies where components must align with tight tolerances—such as sensor mounts, electronic housings, or robotic assemblies—the tapped hole must offer repeatable precision. Here, a slightly larger drill size (e.g., 0.323") may be used to create a looser fit that eases installation, especially in softer materials like plastic or aluminum.

This approach reduces insertion torque and risk of thread galling, especially in high-volume CNC machining parts where consistency and repeatability are crucial.

By tailoring the 3/8-16 tap drill size to match the application—whether for strength, sealing, or precision—CNC machining services ensure every thread delivers maximum performance and reliability. Understanding these nuances helps customers make smarter design and sourcing decisions.

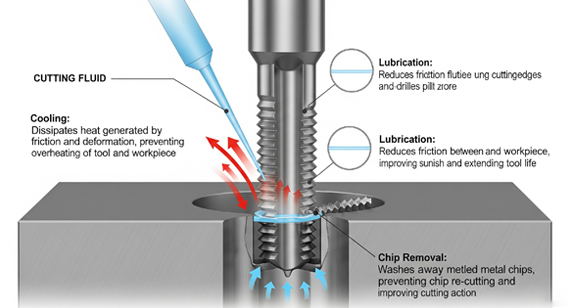

In CNC machining, achieving consistent and accurate threads—especially when using a 3/8-16 tap drill—requires more than just the right tools. Cutting fluids play a critical role in thread formation, tool life, and overall quality of the final CNC machining parts. By reducing friction and dissipating heat, the right cutting fluid ensures smoother tapping, longer tool life, and fewer thread defects. Leading CNC machining services recognize the value of optimized lubrication and make it a standard part of precision operations.

The Importance of Using the Correct Cutting Fluid

Using the correct cutting fluid during 3/8-16 thread tapping prevents galling, thread tearing, and excessive tool wear. This is particularly important when machining tough metals like stainless steel or titanium, where dry tapping can result in thread distortion or broken taps. The cutting fluid not only acts as a lubricant but also aids in flushing away chips from the tapped hole, ensuring uninterrupted cutting action and cleaner threads.

CNC machining factories often tailor fluid selection to the specific material being machined—ensuring that every tapped hole meets the thread quality requirements for strength, fit, and finish.

Common Cutting Fluids for 3/8-16 Tapping

The type of cutting fluid used depends largely on the base material and production volume. Some common options include:

For tapping 3/8-16 threads in softer materials like aluminum or brass, light oil or synthetic fluids typically suffice. In contrast, for steel, stainless steel, or other harder alloys, higher-viscosity straight oils or tapping pastes are preferred to reduce cutting forces and extend tap life.

Precision threads start with precise preparation—and cutting fluid is a key part of that equation. By using appropriate lubrication, CNC machining services ensure longer tool life, reduced waste, and optimal performance of the final threaded components.

In high-precision CNC operations, especially when tapping with a 3/8-16 tap, controlling heat, friction, and chip evacuation is vital. One of the most effective ways to achieve this is by using cutting fluids. These lubricants not only enhance thread quality but also extend the life of taps and reduce wear on drill bits. For manufacturers and engineers aiming to produce reliable CNC machining parts, understanding the role of cutting fluids in minimizing tool wear and thread damage is key to maintaining long-term productivity.

Reducing Friction Between Tap and Workpiece

During tapping, the tap is subjected to significant rotational and axial force. Without sufficient lubrication, this creates high friction between the cutting edges of the tap and the workpiece—leading to rapid tool wear and even tap breakage. Cutting fluids reduce this friction by creating a lubricating barrier, allowing the tap to glide more smoothly through the material. This is especially important when tapping threads in tough materials like steel or titanium, where dry cutting can cause premature tool failure.

Cooling the Cutting Zone

As taps and drill bits work, they generate substantial heat. Excessive heat softens tool steel, reduces hardness, and accelerates edge dulling. Cutting fluids absorb and carry away heat from the cutting zone, helping to preserve the tool’s sharpness and structural integrity. In high-volume CNC machining services, the consistent use of proper coolant can double or even triple tool life, directly impacting cost-efficiency and output quality.

Flushing Chips to Prevent Thread Damage

Another critical benefit of cutting fluids is their ability to flush chips from the tapped hole. Trapped metal chips can cause misalignment, rough thread surfaces, or even gouges within the thread form—leading to thread failure. By keeping the thread path clear, fluids ensure that the 3/8-16 threads are formed cleanly, with uniform pitch and depth.

When CNC machining factories prioritize proper cutting fluid selection and application, the result is a smoother tapping process, reduced rework, and longer-lasting tools—all of which contribute to higher-quality, cost-effective CNC machining parts.

Choosing the correct tap and drill bit size for 3/8-16 threads is not just a matter of following a chart—it’s a foundational step that determines the strength, accuracy, and durability of your threaded components. From calculating the ideal tap drill size, accounting for material hardness, to applying the right cutting fluids, every decision directly influences the performance of your finished CNC machining parts.

An oversized drill can compromise thread engagement, while an undersized one can lead to broken taps and wasted material. Similarly, ignoring factors like material type or cutting fluid use can significantly reduce thread integrity and tooling lifespan. That’s why experienced CNC machining factories place such a high priority on precision at every stage of the tapping process.

Whether you're producing parts in steel, aluminum, or plastic, understanding the science and strategy behind 3/8-16 tapping allows you to achieve consistently reliable results. For businesses seeking high-performance components, partnering with expert CNC machining services ensures that your threaded parts meet both design intent and end-use demands—without costly errors or delays.

What Drill Size Should I Use for Tapping a 7/16 Hole?

To tap a 7/16"-14 UNC thread, the recommended drill bit size is 23/64" (0.3594"). This provides the correct hole diameter to ensure proper thread engagement without stripping or overtightening.

What Size Drill Bit is Required for 8-32 Screws?

For an 8-32 UNC screw, you should use a #29 drill bit (0.1360"). This size ensures enough material for threads to form securely when tapping.

Which Drill Bit is Closest to 37/64?

The closest metric equivalent to a 37/64" drill bit (0.5781") is approximately 14.7mm. If exact sizing is critical, using a proper 37/64" bit is recommended for precision fits in CNC machining parts.

How Big Should Holes Be Drilled When Tapping?

The hole should be slightly smaller than the thread’s major diameter to allow for sufficient thread depth. A general rule is:

Are 3/16 and 7/32 the Same Drill Bit?

No. A 3/16" drill bit is 0.1875", while a 7/32" drill bit is 0.21875". Using the wrong one can lead to improper hole sizing and thread failure.

What Size Drill Bit is Suitable for 6-32 Taps?

For a 6-32 UNC tap, use a #36 drill bit (0.1065"). This size allows for clean thread cutting without compromising thread strength.

What is the Thread Size for 6-32?

The 6-32 designation means a No. 6 screw with 32 threads per inch (TPI). Its major diameter is approximately 0.1380".

How Do I Choose a Drill Bit for Taps?

Choose a bit slightly smaller than the screw's major diameter. Use a tap drill chart for precision, especially for steel CNC machining parts, where tolerances are tight.

What Size Drill Bit is Suitable for 3/16 Taps?

If you're tapping a 3/16"-24 UNF thread, use a #25 drill bit (0.1495"). For 3/16"-32 UNEF, a #26 drill bit (0.1470") is more appropriate.

What is the Thread Size for 3/8-16?

The 3/8-16 specification refers to a 3/8" major diameter with 16 threads per inch. It's a common UNC (coarse) thread used in many industrial and CNC machined components.

How Do I Put a 3/16 Drill Bit into the Drill?

Insert the 3/16" drill bit into the chuck, then twist the chuck clockwise to tighten. Ensure it’s centered and fully secured before powering on the drill.

How Do I Find the Screw Size that Fits the Hole?

Use a thread gauge or screw checker to match the hole with the right screw. Alternatively, test-fit with screws of varying sizes starting from smaller diameters.

How Do I Drill Screw Guide Holes?

Use a drill bit slightly smaller than the screw’s minor diameter. This allows the threads to cut into the material, providing a strong grip without splitting it.

What Size of Drill Bit is Suitable for a No. 8 Tap?

For a No. 8-32 tap, use a #29 drill bit (0.1360"). For No. 8-36 (UNF), use a #30 drill bit (0.1285").