15 years one-stop China custom CNC machining parts factory

88 |

Published by VMT at Aug 07 2025 | Reading Time:About 2 minutes

88 |

Published by VMT at Aug 07 2025 | Reading Time:About 2 minutes

Many industries rely on metals with specific magnetic properties for applications in electronics, aerospace, automotive, and medical devices. Yet, confusion often arises when dealing with lighter metals like magnesium—especially in CNC machining. Some clients assume that all metals must have strong magnetic reactions, leading to incorrect material choices. This can result in design flaws, operational issues, or higher costs. So the question arises: is magnesium magnetic, or does it behave differently under magnetic fields?

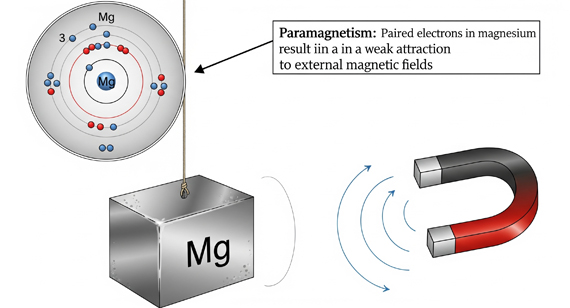

Magnesium is not magnetic in the conventional sense. It is classified as a paramagnetic material, which means it exhibits very weak magnetism only in the presence of a strong external magnetic field. In typical applications—including magnesium CNC machined parts—magnetism is virtually negligible, making it a practical choice for non-magnetic component manufacturing.

Understanding whether magnesium is magnetic is essential for choosing the right material for CNC machined parts, especially when magnetic sensitivity is a concern. Whether you're sourcing from CNC machining factories or evaluating materials for electronic housings, knowing the magnetic behavior of magnesium ensures better engineering decisions. Let's explore its properties in detail.

Magnesium is a lightweight metal, known for its high strength-to-weight ratio and excellent machinability, making it a popular choice for CNC machining services. As the eighth most abundant element in the Earth's crust, magnesium is commonly found in minerals like dolomite and magnesite. Its low density (1.74 g/cm³) and high thermal conductivity make it highly desirable in aerospace and electronics industries. CNC machining factories often use magnesium for structural components where weight reduction is essential, without sacrificing durability. Due to its relatively low melting point (around 650°C), magnesium is easier to cast and machine compared to other metals like titanium or steel.

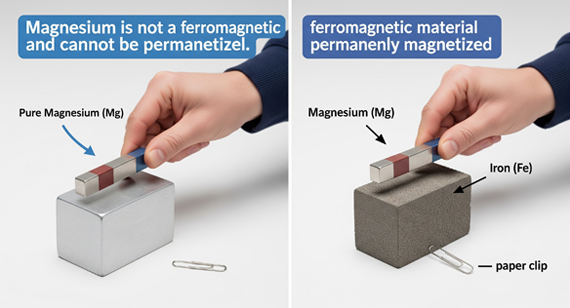

When people ask, “Is magnesium magnetic?”, they’re usually referring to whether magnesium responds to standard magnets or exhibits ferromagnetism. The answer is no—magnesium is not ferromagnetic. Instead, it’s paramagnetic, meaning it reacts weakly to magnetic fields but doesn’t retain magnetism. In other words, if you bring a magnet close to magnesium, it won’t attract like steel does. For industries relying on non-magnetic CNC machined parts, this makes magnesium an excellent material choice. CNC machining services often prioritize magnesium for components used in MRI machines, sensors, or electronics, where non-magnetic properties are essential.

Magnesium falls under the category of non-magnetic materials, a classification that includes aluminum, titanium, and copper. These metals do not exhibit strong magnetic behavior and are often selected for applications where magnetic interference must be avoided. CNC machining factories use non-magnetic metals like magnesium to produce parts for electronic devices, communication systems, and medical equipment. Compared to ferromagnetic materials, non-magnetic metals do not interfere with magnetic fields, which helps improve the accuracy and performance of sensitive instruments. Understanding magnesium’s placement in this category helps engineers select the right metal for CNC machined parts with precision and confidence.

Paramagnetism Properties of Magnesium

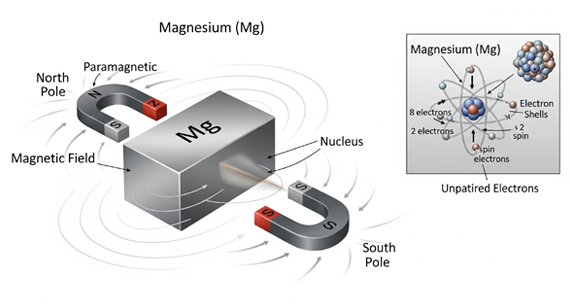

Magnesium’s magnetism falls into a category called paramagnetism. This means it is only weakly attracted to an external magnetic field and does not become permanently magnetized. Here's how its physical and mechanical properties affect its behavior.

Melting Point

Magnesium has a relatively low melting point (about 650°C), which makes it easier to process during CNC machining. Its thermal behavior does not significantly affect its magnetic characteristics, but it contributes to its machinability and usability in temperature-sensitive applications.

Density of Magnesium

With a density of only 1.74 g/cm³, magnesium is lighter than most metals used in CNC machined parts. Its low density correlates with weak magnetic properties, as lighter atomic structures typically have fewer unpaired electrons that contribute to magnetism.

Strength of Magnesium

Magnesium alloys can achieve good tensile strength while maintaining low weight. This strength-to-weight ratio makes it ideal for aerospace and automotive applications, even though it doesn’t offer magnetic properties.

Hardness of Magnesium

The relatively low hardness of magnesium (around 30-100 HB, depending on the alloy) contributes to its machinability. Its softness, however, does not affect its magnetic nature, which remains weak regardless of hardness.

Mechanical Properties of Magnesium

Magnesium’s elasticity, tensile strength, and fatigue resistance contribute to its wide use in CNC machining services. While these traits make it ideal for lightweight structural applications, none contribute significantly to magnetism.

Physical Properties of Magnesium

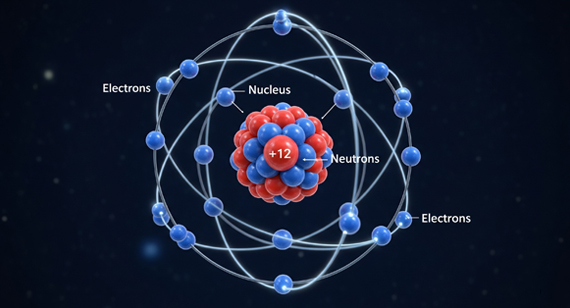

Magnesium’s atomic structure includes two electrons in its outer shell. These electrons pair up, which minimizes magnetic behavior. This atomic arrangement helps classify magnesium as paramagnetic rather than ferromagnetic or diamagnetic.

Although magnesium is paramagnetic, certain external conditions can influence the degree of its magnetic response. Understanding these factors is vital for high-precision applications.

Temperature

As temperature increases, the magnetic susceptibility of paramagnetic materials like magnesium decreases. High heat causes electron motion that disrupts the weak magnetic alignment, making magnesium even less responsive to magnetic fields.

Crystal Structure

Magnesium’s hexagonal close-packed (HCP) crystal structure plays a role in its magnetic behavior. The tight packing reduces the likelihood of unpaired electron spins, which are essential for stronger magnetism.

Magnetization

Unlike ferromagnetic metals, magnesium cannot retain magnetization after the external magnetic field is removed. Its magnetization is temporary, weak, and non-permanent—making it safe for applications that require non-magnetic properties.

Impurities

Certain impurities introduced during processing might alter magnesium’s magnetic response slightly. However, in high-quality CNC machined parts sourced from professional CNC machining factories, the impurity levels are controlled, ensuring consistent non-magnetic performance.

Not all types of steel are magnetic. Austenitic stainless steels, like 304 and 316, are non-magnetic due to their face-centered cubic crystal structure. In contrast, ferritic and martensitic steels are magnetic. Understanding this distinction helps clarify that magnetism is not solely about being a “metal”—rather, it depends on atomic structure and electron configuration.

Is Magnesium a Non-Magnetic Metal?

Yes, magnesium is classified as a non-magnetic metal due to its weak paramagnetic behavior. It neither exhibits strong attraction to magnets nor retains any magnetism. This trait makes it suitable for environments where magnetic interference is problematic, such as in aerospace instrumentation or electronics casings manufactured via CNC machining services.

Is Magnesium Paramagnetic or Diamagnetic?

Magnesium is paramagnetic. This means it has unpaired electrons but doesn’t retain magnetism without an external field. Diamagnetic materials, like bismuth, repel magnetic fields. Magnesium, in contrast, shows a very slight attraction when exposed to a strong magnet, confirming its paramagnetic nature.

Due to its non-magnetic behavior, magnesium is widely used in applications requiring zero magnetic interference. Common examples include electronic device housings, satellite components, MRI-compatible tools, and drone parts. CNC machining factories often machine magnesium parts for such sectors. When designing CNC machined parts for precision instruments, choosing a non-magnetic material like magnesium ensures stability, safety, and functionality.

No, magnesium cannot be permanently magnetized. It does not retain any magnetic field after exposure. This characteristic sets it apart from ferromagnetic materials like iron or cobalt. CNC machining services often prefer magnesium for components that operate near magnetic-sensitive equipment, where retaining magnetic charge would be a liability.

Magnesium oxide (MgO), a compound formed from magnesium and oxygen, is also non-magnetic. Its ionic structure doesn't support magnetic behavior. While it is commonly used in insulation and refractory materials, MgO has no magnetic application and is completely safe for non-magnetic component design.

Magnesium is not magnetic in the way most people assume. As a paramagnetic material, it shows only weak attraction to external magnetic fields and does not retain magnetism. These properties make magnesium highly valuable for non-magnetic CNC machined parts used in precision industries. For clients looking for reliable CNC machining services or sourcing from experienced CNC machining factories, magnesium offers an excellent balance of strength, machinability, and non-magnetic performance.

Is Magnesium a Magnet?

No, magnesium is not a magnet. It does not exhibit ferromagnetic properties and cannot generate or retain a magnetic field. While magnesium is a metal, it is paramagnetic, meaning it shows only a very weak attraction to external magnetic fields and does not behave like traditional magnets.

Does a Magnet Attract Magnesium?

A magnet does not strongly attract magnesium. Due to its paramagnetic nature, magnesium may respond slightly in the presence of a very strong magnetic field, but in normal conditions, it is effectively non-magnetic. That’s why magnesium CNC machined parts are often used in environments where magnetic interference must be avoided.

Which Metals are Magnetic?

Metals that exhibit ferromagnetism—such as iron, cobalt, and nickel—are considered magnetic. These metals can be magnetized and will strongly attract magnets. In contrast, magnesium, aluminum, copper, and titanium are non-magnetic or weakly paramagnetic, making them ideal for non-magnetic applications, including CNC machined parts in electronics and aerospace.

Is Magnesium a Strong Metal?

Magnesium is considered strong relative to its weight, with a high strength-to-weight ratio. However, in terms of absolute strength, it is softer and less durable than steels or titanium. For lightweight CNC machined parts, magnesium provides excellent structural performance where minimizing weight is more critical than maximizing strength.

Is Magnesium a Metal or a Nonmetal?

Magnesium is a metal, specifically an alkaline earth metal in Group 2 of the periodic table. It exhibits typical metallic properties such as electrical conductivity, luster, and malleability. These properties make magnesium suitable for CNC machining services, especially when lightweight, conductive, and non-magnetic materials are required.

Is Magnesium a Ferromagnet?

No, magnesium is not a ferromagnet. Ferromagnetic materials can be magnetized and retain their magnetic field. Magnesium, on the other hand, is paramagnetic, meaning it shows only minimal, temporary magnetic behavior under a strong external magnetic field, and does not retain any magnetism.

Is Gold Magnetic?

Gold is not magnetic. It is classified as diamagnetic, meaning it slightly repels magnetic fields. Like magnesium, gold is used in applications where magnetic neutrality is required. However, gold differs from magnesium in price, density, and corrosion resistance.

Does Magnesium Conduct Electricity?

Yes, magnesium does conduct electricity. It has decent electrical conductivity, although not as high as copper or silver. This makes it suitable for components that need moderate conductivity but non-magnetic behavior, such as magnesium CNC machined parts used in electronic housings or EMI-sensitive assemblies.

Can Magnesium Explode?

Under certain conditions, magnesium can ignite and burn—especially in fine powder form. While it does not "explode" spontaneously, magnesium reacts strongly with fire and produces high-temperature flames. When handled properly, CNC machining factories can safely machine magnesium into solid components without explosion risks.

What Are the Disadvantages of Magnesium Metal?

Magnesium's primary disadvantages include:

However, it remains highly valuable for non-magnetic CNC machined parts thanks to its lightweight and machinability. Proper alloying and surface treatments can address many of its weaknesses.

What Four Elements are Magnetic?

The four elements with strong magnetic properties (ferromagnetism) are:

These elements are commonly used in magnets and magnetic materials. Magnesium is not one of them, as it is paramagnetic and used for non-magnetic applications in CNC machining services.

What Type of Metal is Magnesium?

Magnesium is an alkaline earth metal, belonging to Group 2 of the periodic table. It is lightweight, silvery-white, and moderately reactive. Because it is non-magnetic, highly machinable, and structurally efficient, magnesium CNC machined parts are widely used in aerospace, automotive, and electronics industries.