15 years one-stop China custom CNC machining parts factory

249 |

Published by VMT at Jun 25 2025 | Reading Time:About 7 minutes

249 |

Published by VMT at Jun 25 2025 | Reading Time:About 7 minutes

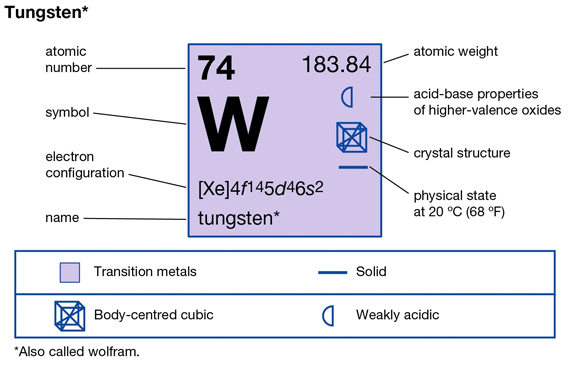

Tungsten is often associated with unmatched strength, extreme durability, and exceptional resistance to wear. But if you're designing CNC machining parts or sourcing components for harsh environments, a critical question emerges—does tungsten rust? The fear of metal degradation, especially rust, can hinder performance and shorten the lifespan of vital equipment. Many industries—from aerospace to jewelry—rely on materials that won’t deteriorate under stress. Fortunately, there’s good news. Tungsten boasts remarkable resistance to rust and corrosion, making it an ideal choice for long-lasting performance. This article explores the anti-rust properties of tungsten metal and answers the key questions engineers, manufacturers, and end-users need to know.

Tungsten does not rust under normal atmospheric conditions due to its high density, corrosion resistance, and stable chemical structure. It forms a protective oxide layer instead of rusting, making it ideal for CNC machining parts in extreme environments.

Understanding whether tungsten rusts is not just a matter of curiosity—it’s vital for anyone using CNC machining services or choosing metals for high-performance applications. This article delves into the science behind tungsten’s corrosion resistance, where and why it might still show signs of oxidation, and how it compares to other metals. Whether you're sourcing from CNC machining factories or specifying materials for long-term use, these insights will guide you in making the best decision.

Key Points (Core Insights of the Article)

Tungsten metal, in its pure form, does not rust the way iron or steel does. This is due to its fundamental chemical and physical properties. Traditional rust, known as iron oxide, forms when iron reacts with water and oxygen, leading to the flaky, reddish-brown corrosion commonly seen on steel. However, tungsten does not contain iron, and therefore, it does not undergo the same oxidation process. Instead of forming rust, tungsten develops a thin, stable oxide layer on its surface when exposed to air. This layer actually protects the metal beneath it from further corrosion—much like aluminum or titanium.

The term "Tungsten Metal Rust" can be misleading because, in practical use, what some mistake for rust is usually superficial discoloration due to minor oxidation under high temperatures or aggressive environments. These changes are typically cosmetic and do not affect the metal’s integrity or performance. Tungsten’s high melting point (3422°C) and extremely high density give it a strong resistance to chemical attack, especially at room temperature or under neutral conditions.

Because of these unique traits, tungsten is favored in industries that require durable CNC machining parts, including aerospace, military, and electronics. CNC machining factories often recommend tungsten when clients need parts that resist wear, heat, and corrosion. So, while no metal is absolutely impervious under all conditions, tungsten stands out for its anti-rust and corrosion-resistant capabilities—making it a premier choice in CNC machining services.

While pure tungsten is highly resistant to rust, there are certain conditions and material compositions under which it may show signs of oxidation or corrosion. The misconception that tungsten rusts often arises when people observe discoloration, surface degradation, or corrosion in tungsten alloys or tungsten carbide components. These occurrences are not the result of tungsten's failure, but of external influences or added elements within the alloy. It's important for engineers and procurement specialists in CNC machining factories to understand these exceptions. Knowing why and when Tungsten Metal Rust might appear helps ensure the correct grade and form of tungsten is selected for specific CNC machining parts used in harsh or reactive environments.

Alloying Elements

One of the main reasons tungsten rust might occur is due to alloying. Pure tungsten is extremely resistant to corrosion, but when combined with other metals—especially those that oxidize easily—the overall corrosion resistance may diminish. For example, tungsten carbide often includes a binder such as cobalt or nickel. These binder materials can oxidize or corrode under certain environmental conditions, leading to surface degradation that may mistakenly be identified as Tungsten Metal Rust. In applications where corrosion resistance is critical, such as marine environments or acidic industrial conditions, the purity of the tungsten alloy must be considered. CNC machining services that work with tungsten components should ensure the alloy selection matches the environmental demands. For maximum corrosion resistance, high-purity tungsten or alloys with stable, non-reactive binders are preferred.

Environmental Conditions

Environmental exposure plays a significant role in whether tungsten shows signs of oxidation. Under normal atmospheric conditions, tungsten remains inert and protected by a stable oxide film. However, in highly reactive environments—such as those containing chlorine, high humidity, saltwater spray, or acidic vapors—even high-grade tungsten alloys may suffer surface degradation. Moisture in combination with heat or pollutants can trigger chemical reactions on the surface of alloys, especially if the tungsten is not pure. Although this reaction is not “rust” in the traditional iron-oxide sense, it still leads to changes in appearance and possibly performance over time. For clients using CNC machining services to produce tungsten parts for outdoor or chemically aggressive environments, protective coatings or inert enclosures may be recommended to mitigate risk.

Extremely High Temperature Conditions

Tungsten is renowned for its ultra-high melting point—over 3400°C—which makes it ideal for high-temperature applications. However, at temperatures above 400°C in the presence of oxygen, tungsten begins to oxidize, forming tungsten oxides such as WO₃. This process isn’t the flaky rust seen in iron but can still lead to a loss of material and deterioration of surface integrity over time. These oxide layers are usually stable at moderate temperatures, but in thermal cycling or continuous exposure to high heat, they may crack or spall off, exposing fresh tungsten to further oxidation. For components produced through CNC machining services that are expected to endure extreme heat—such as aerospace nozzles, electrodes, or furnace parts—it is crucial to apply proper design specifications and consider protective atmospheres to limit this form of Tungsten rust-like degradation.

Presence of Iron Content

In some manufacturing cases, tungsten alloys or components may include trace amounts of iron—either as a deliberate alloying element or as a contaminant. When iron is present, it introduces a vulnerability: true rust (iron oxide) can form if exposed to moisture and oxygen. This rust will not originate from the tungsten itself, but from the iron within the composite. Over time, rust can migrate or create micro-cracks in the surrounding structure, accelerating surface breakdown. In such cases, it becomes easy to misinterpret the appearance of Tungsten Metal Rust, when in fact it’s iron-induced corrosion. CNC machining factories that work with tungsten should use strict quality control and avoid contamination with rust-prone elements, especially when machining CNC parts for corrosive or long-term applications.

Table: Possible Reasons Why Tungsten May Appear to Rust

| Factor |

Explanation |

Impact on CNC Machining Parts |

| Alloying Elements |

Tungsten combined with binders like cobalt or nickel may corrode, even if pure tungsten is rust-resistant. | Risk of surface corrosion or discoloration in tungsten carbide parts; select high-purity or stable alloy binders. |

| Environmental Conditions |

High humidity, saltwater, acid vapors, or chlorine exposure can cause surface oxidation, especially on alloyed tungsten. | Consider protective coatings or proper storage for tungsten CNC parts exposed to harsh environments. |

| High Temperatures |

Above ~400°C, tungsten can form stable oxides (e.g., WO₃) in oxygen-rich environments. | May result in gradual surface degradation or performance loss in high-heat applications like aerospace components. |

| Iron Contamination |

Presence of iron, either alloyed or as a contaminant, can lead to true rust (iron oxide) under moist conditions. | Appearance of rust may not be from tungsten; ensure clean processing and avoid iron in critical CNC machining parts. |

Tungsten’s natural resistance to corrosion and oxidation makes it highly valuable across numerous industries that demand durable and long-lasting components. Because Tungsten Metal Rust is virtually non-existent under most conditions, it has become a material of choice for applications where traditional metals would degrade. Its ability to withstand heat, moisture, and aggressive chemicals, along with its exceptional hardness and density, offers clear advantages for both structural and functional uses. These qualities are especially important when manufacturers rely on CNC machining services to deliver precision parts that must maintain integrity over time. The following applications highlight where tungsten’s anti-rust properties truly shine, especially in sectors like jewelry, electronics, and high-stress industrial uses.

Jewelry Such as Rings

One of the most common commercial uses of tungsten’s corrosion resistance is in the jewelry industry, particularly in tungsten rings and wedding bands. Tungsten is popular because it does not tarnish, fade, or rust like silver or low-grade stainless steel. Unlike softer metals, tungsten retains its luster and polish even after years of daily wear. Consumers choose it not only for its strength and weight but also for its rust-proof and hypoallergenic properties. Because jewelry is frequently exposed to sweat, water, lotions, and varying climates, using a rust-resistant material is essential. Even under constant contact with moisture, Tungsten rust does not form, making it one of the most durable metals for long-term personal accessories. When produced through high-quality CNC machining services, tungsten jewelry parts achieve flawless finishes that resist scratches and corrosion better than almost any other metal.

Light Bulb Filaments

Tungsten has been used for over a century in light bulb filaments due to its exceptional heat tolerance and resistance to oxidation at moderate temperatures. In the vacuum or inert gas environment of a light bulb, tungsten can glow white-hot without deteriorating, making it ideal for long-term use. Its anti-rust nature ensures that the filament remains intact even after thousands of heating and cooling cycles. Despite the development of LED and CFL technologies, tungsten filaments are still used in specialty lighting and applications where heat and brightness are critical. Manufacturers sourcing CNC machining parts for such components rely on tungsten for its reliability under intense thermal stress, where conventional metals would break down or rust.

X-Ray Tubes

Tungsten’s resistance to corrosion and high atomic number make it an essential component in X-ray tubes, particularly in the anode targets that generate X-rays. These parts must endure extreme heat, radiation, and vacuum conditions without degrading. In such sensitive environments, the presence of Tungsten rust or oxidation could impair the accuracy or safety of medical imaging equipment. Tungsten's stability under such conditions guarantees longer component life and consistent performance. CNC machining factories that specialize in medical equipment manufacturing often utilize tungsten components because of their dimensional precision, wear resistance, and immunity to chemical degradation.

Electrodes

In industries such as welding, electronics, and arc lamps, tungsten electrodes are used extensively because of their stability and corrosion resistance. Tungsten electrodes maintain electrical conductivity and mechanical strength even in chemically aggressive environments. Unlike other metals that oxidize rapidly and reduce current efficiency, tungsten remains stable, resisting both heat and Tungsten Metal Rust over time. This is especially critical in TIG welding applications, where arc stability and longevity are essential. Manufacturers turn to specialized CNC machining services to produce precise, consistent tungsten electrodes that perform reliably in challenging industrial conditions.

Penetrating Objects, Armor-Piercing Rounds, etc.

Tungsten’s high density and rust resistance make it ideal for applications requiring deep penetration and extreme mechanical performance—such as armor-piercing projectiles, kinetic energy penetrators, and drilling tools. Unlike steel-based alternatives that may rust or deform under harsh conditions, tungsten maintains structural integrity over extended periods and exposure. In the defense and mining industries, where environmental factors like humidity, salt spray, or acidic soils are common, tungsten outperforms due to its anti-rust properties. CNC machining factories are often contracted to produce high-precision, complex tungsten parts for military-grade munitions and industrial cutting tools, where performance and durability are critical.

Table: Applications of Tungsten’s Anti-Rust Properties

| Application |

Why Tungsten is Used |

Anti-Rust Benefit |

CNC Machining Relevance |

| Jewelry (Rings, Bands) |

Durable, retains shine, hypoallergenic | Tungsten does not rust, fade, or corrode under daily wear conditions | Machined into high-polish, scratch-resistant CNC machining parts for jewelry design |

| Light Bulb Filaments |

High melting point, stable in inert gas environments | No oxidation or degradation in sealed bulbs | Precision CNC machining services create thin, uniform filament wires |

| X-Ray Tubes |

Withstands heat and radiation, high atomic number | Resists chemical breakdown, ensuring imaging consistency | Used in high-spec CNC machining factories for medical-grade components |

| Electrodes |

Maintains electrical conductivity and shape under high temperatures | Does not oxidize or corrode, ensuring stable arc performance | Essential for TIG welding and electronic CNC machining parts |

| Penetrating Objects, Tools |

High density, strength, durability in extreme environments | Resists rust in humid, acidic, or outdoor conditions | Critical in defense and mining CNC machining factories for munitions and cutting tools |

Tungsten’s reputation as an anti-rust metal stems from its unique atomic structure and chemical stability, which distinguish it from rust-prone metals like iron. Rust, in the traditional sense, is a form of iron oxide that forms when iron reacts with moisture and oxygen. Tungsten, on the other hand, does not contain iron and therefore does not produce Tungsten Metal Rust as commonly perceived. Instead, when tungsten is exposed to air at room temperature, it forms a very thin, adherent layer of tungsten oxide (WO₃). This oxide layer is stable, non-porous, and acts as a protective barrier, preventing further oxidation—a behavior similar to that of aluminum and titanium.

One of the primary reasons tungsten does not rust is due to its very low reactivity in neutral or mildly acidic environments. Unlike reactive metals that degrade rapidly in air, water, or humidity, tungsten maintains its integrity for decades, even in demanding industrial or environmental conditions. Additionally, tungsten’s extremely high melting point (3422°C) and dense crystalline structure make it physically resistant to atmospheric attacks that typically lead to rusting in softer, more porous metals.

This makes tungsten ideal for producing long-lasting CNC machining parts used in aerospace, defense, electronics, and even jewelry. CNC machining factories often recommend tungsten in applications where corrosion could compromise performance or safety. Its exceptional anti-rust characteristics reduce the need for frequent replacements, coatings, or surface treatments, thereby lowering long-term maintenance costs. This combination of chemical stability, protective oxide formation, and environmental resistance is why tungsten rust is rarely a concern—and why tungsten remains a top choice in CNC machining services for high-performance applications.

While tungsten does not rust in the traditional sense, it can oxidize—especially when exposed to high temperatures or harsh chemical environments. Oxidation is a surface-level chemical reaction where oxygen bonds with the metal, forming tungsten oxide. At room temperature, this process is minimal and results in the formation of a thin, stable oxide layer that actually protects the underlying metal from further degradation. This layer is not flaky or corrosive like iron rust, but it may alter the surface's appearance slightly, depending on the environment and exposure level.

Under normal conditions—such as typical indoor or moderate outdoor use—pure tungsten retains its natural gray sheen for many years without significant changes. However, when exposed to elevated heat (over 400°C) or chemically aggressive environments (such as acidic vapors or saltwater spray), oxidation may cause discoloration, typically darkening the surface or forming a bluish or brownish tint. These changes are superficial and do not affect the structural strength or performance of the material. Nonetheless, in applications where aesthetics are critical, such as tungsten rings or polished components, even minor surface changes may be undesirable.

In CNC machining factories, tungsten parts are often machined to a fine finish, and in some cases, coated or polished to maintain their luster. For industries that demand both corrosion resistance and visual appeal—like consumer electronics or luxury accessories—machined tungsten surfaces can be further treated to reduce oxidation and maintain long-term brightness. So while Tungsten Metal Rust doesn’t occur, it’s accurate to say that tungsten can oxidize and lose its shine under specific conditions—but this process is slow, controllable, and often purely cosmetic.

Tungsten is one of the most durable and corrosion-resistant metals, especially in environments below its oxidation threshold. However, oxidation can gradually influence its performance, particularly when exposed to extremely high temperatures or reactive atmospheres. Unlike traditional rust, which causes pitting and flaking in metals like iron, tungsten oxidation results in the formation of a thin layer of tungsten trioxide (WO₃) on the surface. This oxide layer initially protects the core material, but under certain extreme conditions—such as continuous thermal cycling or prolonged oxygen exposure above 500°C—it may begin to compromise the metal’s durability.

The primary impact of oxidation on tungsten is surface deterioration rather than internal structural weakness. Over time, the oxide layer may become brittle and spall off, especially in dynamic environments involving vibration or impact. This exposes fresh tungsten underneath, restarting the oxidation cycle. In aerospace, electronics, or high-heat industrial settings, this process can reduce component life and dimensional stability. For these reasons, CNC machining services often factor in environmental exposure when manufacturing tungsten-based components. Where applicable, coatings or protective atmospheres are employed to prevent oxidation-related damage.

Despite this, Tungsten Metal Rust is not a concern in the conventional sense. Tungsten's core durability remains exceptional compared to many engineering metals, especially when processed and used correctly. In most real-world applications, the effects of oxidation are either minimal or manageable with proper design and machining practices. Manufacturers who rely on CNC machining factories for tungsten parts can optimize durability by selecting pure tungsten grades, minimizing surface exposure to high-temperature oxygen, and incorporating thermal barriers when necessary.

Many people use the terms rust and corrosion interchangeably, but in the field of materials science—and especially in CNC machining services—they have distinct meanings. Rust specifically refers to the oxidation of iron or iron-containing alloys, such as steel, in the presence of moisture and oxygen. This process produces iron oxide, the familiar reddish-brown substance that flakes off and weakens metal over time. Rust is highly destructive and compromises both the appearance and structural integrity of iron-based materials.

Corrosion, on the other hand, is a broader term that encompasses any chemical reaction between a material and its environment that leads to material degradation. This includes the oxidation of metals like aluminum, copper, titanium, and tungsten—even if the visible effects are not as severe as rust. In the case of tungsten, the reaction forms a thin oxide layer rather than flaky rust, and this oxide layer generally serves to protect the underlying metal from further damage. As such, while tungsten does not rust, it may still corrode slightly under extreme conditions, such as high heat or chemical exposure.

Understanding this difference is crucial when selecting materials for high-performance CNC machining parts. When a customer asks, "Does tungsten rust?", the correct answer is no—it corrodes in a non-destructive manner. That’s why tungsten is ideal for demanding applications in aerospace, medical, or marine environments. CNC machining factories working with tungsten can assure clients of its superior anti-rust behavior and long-term resistance to typical corrosive forces that plague other metals.

While tungsten is renowned for its exceptional resistance to rust and corrosion, many other common metals oxidize readily under normal environmental conditions. Understanding how these metals behave compared to tungsten highlights why tungsten is often the preferred choice for demanding applications requiring durability and minimal corrosion, including CNC machining parts made in specialized CNC machining factories.

Silver

Silver is highly reactive to sulfur compounds and oxygen in the air, leading to the formation of silver sulfide on its surface—a process known as tarnishing. This tarnish appears as a dark, dull layer that diminishes silver’s shine and aesthetic appeal. While tarnishing is a form of oxidation, it differs from rust because silver does not form iron oxide. Despite this, the tarnish can degrade silver’s surface over time, requiring frequent polishing, especially for jewelry or electronic contacts. Unlike tungsten, silver’s oxidation is more visible and can impact functionality.

Iron

Iron is the classic example of a metal that rusts. When exposed to moisture and oxygen, iron undergoes an electrochemical reaction forming iron oxide (rust), which flakes off and weakens the metal structure. This rusting process not only affects appearance but also compromises the mechanical integrity of iron and steel parts. This is why iron-based components require protective coatings, paints, or alloys to resist rust. In contrast, tungsten rust does not occur, making tungsten a far more durable choice for corrosion-prone environments.

Titanium

Titanium is often praised for its corrosion resistance, but it still oxidizes easily in the presence of oxygen to form a stable oxide layer—titanium dioxide (TiO₂). This oxide layer, similar to tungsten’s oxide film, is very adherent and protective, preventing further corrosion. Unlike rust, titanium oxide does not flake or degrade over time, making titanium highly resistant to most corrosive environments, including seawater. The behavior of titanium oxidation is closer to tungsten’s than to iron’s, though titanium is generally lighter and less dense.

Gold

Gold is a noble metal and is highly resistant to oxidation and corrosion under normal environmental conditions. It rarely tarnishes or oxidizes because of its low chemical reactivity. This inertness is why gold is widely used in electronics and jewelry. While gold does not rust or corrode, it is much softer and less durable than tungsten, which limits its use in high-wear applications. Tungsten’s hardness combined with its anti-rust properties offers advantages where strength is also a priority.

Cobalt

Cobalt oxidizes more readily than tungsten and titanium, forming cobalt oxide layers under exposure to oxygen and moisture. This oxide can affect both the appearance and performance of cobalt-based materials, especially when used in alloys or binders within tungsten carbide parts. Since cobalt is often used as a binder metal in CNC machining parts involving tungsten, its oxidation properties must be carefully managed. Excessive oxidation can cause surface degradation sometimes mistaken for Tungsten Metal Rust, emphasizing the need for precise alloy control in manufacturing.

Table: Oxidation Characteristics of Common Metals Compared to Tungsten

| Metal |

Oxidation Behavior |

Impact on Durability |

Comparison to Tungsten |

| Silver |

Tarnishes easily due to reaction with sulfur and oxygen, forming silver sulfide (black tarnish). | Surface discoloration, requires regular polishing. | Less corrosion resistant than tungsten; tarnishes visibly. |

| Iron |

Rusts rapidly in presence of moisture and oxygen, forming flaky iron oxide that weakens metal structure. | Severe structural degradation over time. | Tungsten does not rust, making it far more durable in moist environments. |

| Titanium |

Forms a stable, adherent oxide layer (TiO₂) that protects from further corrosion. | Highly corrosion-resistant; oxide layer is protective. | Similar anti-rust behavior to tungsten, but lighter. |

| Gold |

Does not oxidize or tarnish under normal conditions due to chemical inertness. | Extremely durable and corrosion-resistant but soft. | Tungsten is harder and better suited for high-wear applications. |

| Cobalt |

Oxidizes in moist oxygen environments forming cobalt oxides, which may degrade surface appearance and properties. | Can cause surface degradation; critical in tungsten alloys. | Oxidizes more readily than tungsten; binder oxidation can affect tungsten carbide parts. |

Will Tungsten Carbide Rust?

Tungsten carbide is widely regarded for its exceptional hardness and wear resistance, making it a staple in industries requiring durable CNC machining parts. However, the question of whether tungsten carbide rusts is common among engineers and manufacturers. The answer is nuanced—tungsten carbide itself does not rust because it does not contain iron, the metal responsible for traditional rust. However, most tungsten carbide materials are composites, typically consisting of tungsten carbide grains bonded with a metal binder, usually cobalt or sometimes nickel.

The presence of cobalt in tungsten carbide introduces the potential for corrosion. Cobalt, unlike tungsten carbide, can oxidize and corrode when exposed to moisture and oxygen, particularly in harsh environments. This surface corrosion can sometimes be mistaken for Tungsten Metal Rust, but it primarily affects the binder phase rather than the carbide grains. As cobalt corrodes, it can weaken the overall structure, leading to reduced mechanical performance and a roughened surface.

To mitigate this, manufacturers and CNC machining factories often apply protective coatings or select cobalt-free binders for applications exposed to corrosive environments. Additionally, controlling environmental exposure—such as limiting humidity and avoiding contact with acids or salts—helps prolong the life of tungsten carbide parts. Thanks to these precautions, tungsten carbide remains a reliable choice for cutting tools, wear parts, and precision components where resistance to corrosion and wear are critical.

In summary, while pure tungsten carbide does not rust, the binder metals in its composition can corrode under certain conditions. Proper material selection, protective treatments, and maintenance are essential to preserve the corrosion resistance of tungsten carbide CNC machining parts.

Tungsten’s impressive corrosion resistance arises from its unique physical and chemical properties that set it apart from many other metals. Unlike iron or steel, which readily rust due to oxidation forming flaky iron oxide, tungsten forms a dense, adherent oxide film on its surface. This oxide layer, primarily tungsten trioxide (WO₃), acts as a protective barrier that prevents oxygen and moisture from penetrating deeper into the metal, effectively stopping further corrosion.

Another key factor in tungsten’s corrosion resistance is its high melting point of 3422°C, one of the highest among all metals. This extreme thermal stability means that tungsten maintains its structural integrity and chemical stability even in harsh, high-temperature environments that might accelerate corrosion in other metals. Furthermore, tungsten’s dense atomic structure and low reactivity to most acids and bases reduce its susceptibility to chemical attack.

In industrial contexts such as CNC machining services, this corrosion resistance translates into longer-lasting, reliable components that perform consistently over time without surface degradation. Whether tungsten is used in aerospace parts, electronic components, or precision tools, its ability to withstand chemical and environmental stressors with minimal oxidation or corrosion is a significant advantage. Additionally, tungsten’s anti-corrosion properties reduce maintenance needs and help ensure the safety and durability of finished CNC machining parts.

Overall, tungsten’s combination of a protective oxide layer, thermal stability, and chemical inertness makes it inherently resistant to rust and corrosion, reinforcing its reputation as a metal of choice for demanding industrial and commercial applications.

While pure tungsten is extremely resistant to rust and corrosion, tungsten alloys—especially those combined with more reactive elements—can exhibit oxidation under certain environmental conditions. The risk of oxidation primarily depends on the composition of the alloy and the presence of binder or secondary metals such as cobalt, nickel, iron, or copper. These alloying elements, while added to improve machinability, toughness, or other mechanical properties, often introduce oxidation susceptibility that pure tungsten does not possess.

For example, tungsten carbide is a popular alloy used in tooling and wear parts, but it often contains a cobalt binder. Under moist or chemically aggressive conditions, the cobalt phase can oxidize or corrode, which may weaken the structure or alter the surface—a phenomenon sometimes misidentified as Tungsten Metal Rust. Similarly, tungsten-nickel-iron alloys, widely used in radiation shielding and military applications, may be prone to corrosion due to the iron content, especially if exposed to high humidity or salt-laden air.

Tungsten-copper alloys, used for heat sinks and electrical contacts, generally resist oxidation well, but copper can still tarnish over time, affecting electrical conductivity. The key to minimizing oxidation in these alloys is proper environmental control, surface treatment, or material selection tailored to the application. CNC machining factories producing CNC machining parts from tungsten alloys must account for these variables and recommend the most appropriate alloy based on the operating environment.

In short, while tungsten itself does not rust, its alloys can oxidize depending on their secondary components. Careful material engineering and protective design help preserve the strength, longevity, and corrosion resistance of tungsten alloy components in demanding environments.

When evaluating metals for high-performance applications, it's essential to compare them across key properties such as corrosion resistance, durability, heat tolerance, and structural integrity. Tungsten stands out for its extraordinary density, high melting point, and resistance to rust and corrosion, especially when compared with commonly used metals such as iron, titanium, stainless steel, and aluminum.

Iron and its alloys, including carbon steel, are particularly vulnerable to rust. In the presence of oxygen and moisture, iron forms iron oxide—a flaky, destructive substance that weakens the metal over time. This is the classic example of metal rust, which tungsten completely avoids. Tungsten rust is virtually non-existent because it forms a stable oxide layer that protects the material rather than destroys it.

Stainless steel, especially grades like 316, offers much better corrosion resistance than carbon steel, but it can still corrode in saltwater or acidic environments. Tungsten, in contrast, maintains its integrity even under harsh chemical exposure and at much higher temperatures, making it ideal for CNC machining parts in extreme industrial settings.

Titanium is known for its excellent strength-to-weight ratio and corrosion resistance. Like tungsten, it forms a protective oxide film, but it is significantly lighter and softer. Tungsten’s superior hardness and high-temperature stability make it more suitable for applications where wear resistance is paramount.

Aluminum, while lightweight and corrosion-resistant, is too soft for many demanding applications and lacks the thermal resistance of tungsten. In contrast, CNC machining services that require parts for aerospace, defense, or high-friction environments often recommend tungsten for its combination of mechanical strength and rust resistance.

In summary, while several metals offer degrees of corrosion resistance, tungsten’s anti-rust performance, density, and heat tolerance position it as one of the most reliable materials for mission-critical CNC machining parts produced in top-tier CNC machining factories.

Table: Tungsten vs. Other Metals – Corrosion Resistance and Performance Comparison

| Metal |

Corrosion Resistance |

Durability / Hardness |

Heat Tolerance |

CNC Machining Application Suitability |

| Tungsten |

Exceptional – forms stable oxide, no traditional rust | Extremely high – among the hardest metals | Excellent – melting point over 3400°C | Ideal for aerospace, military, high-wear, and heat-intensive CNC machining parts |

| Iron |

Poor – rusts quickly in moisture-rich environments | Moderate – degrades quickly without coatings | Moderate – oxidizes at high temperatures | Limited without coatings; prone to Tungsten rust-like corrosion |

| Stainless Steel |

Good – resists rust better than iron, varies by grade | High – especially in hardened variants | Good – commonly used in structural components | Widely used in CNC machining services, but less wear-resistant than tungsten |

| Titanium |

Excellent – forms strong protective oxide layer | Moderate – strong but not as hard as tungsten | Very good – stable at high temperatures | Preferred for lightweight, corrosion-resistant CNC machining parts |

| Aluminum |

Good – self-passivating oxide layer protects surface | Low – soft and easily deformed | Fair – not suitable for very high heat | Best for lightweight applications; not ideal for heavy-duty CNC machining |

Tungsten's unique combination of high density, extreme hardness, excellent corrosion resistance, and high-temperature strength makes it an ideal material for a wide range of demanding applications. Unlike many common metals that suffer from rust or surface degradation, tungsten rust is virtually non-existent due to the formation of a protective oxide layer. This makes tungsten highly valued in sectors where durability and reliability are critical. Industries that depend on CNC machining parts produced to exact tolerances often choose tungsten to ensure longevity, mechanical integrity, and resistance to environmental wear. Below are key industries that greatly benefit from the specialized properties of tungsten.

Aerospace Industry

The aerospace industry requires materials that can withstand extreme conditions—high heat, pressure, and exposure to corrosive environments—while maintaining structural integrity. Tungsten excels in these applications due to its exceptional resistance to oxidation and thermal degradation. It's commonly used in balance weights, radiation shields, and high-temperature engine parts. In contrast to metals like iron or aluminum, which may corrode or weaken under repeated thermal cycles, tungsten maintains its form and function. Aerospace-grade CNC machining services rely on tungsten for producing components that must endure long-term stress without failure, and without the concern of Tungsten Metal Rust impacting performance. Its high density also helps stabilize flight systems by reducing component vibration and enhancing control.

Manufacturing

In the manufacturing sector, tungsten plays a critical role in tooling and machining. Tungsten carbide—a tungsten alloy—is widely used in cutting tools, drill bits, and dies because of its extreme hardness and resistance to wear. When materials must be shaped, cut, or stamped with precision, tool longevity becomes essential. Tungsten’s corrosion resistance ensures tools do not degrade quickly, even when exposed to coolants, lubricants, or humid workspaces. This results in reduced downtime and more consistent production output. Many CNC machining factories choose tungsten-based tooling to deliver precise, repeatable cuts with minimal surface wear, especially when producing complex CNC machining parts in metals, plastics, or composites.

Tungsten is also indispensable in the electronics industry. Its high melting point and excellent electrical conductivity make it ideal for components such as filaments, electrodes, and heat sinks. Unlike materials that may oxidize and fail when subjected to high current or heat, tungsten remains stable and conducts reliably. In microelectronics, where miniaturization and heat management are critical, tungsten is used for thin-film applications and interconnects. Moreover, because Tungsten rust does not occur in standard operating conditions, it’s a preferred material for long-lasting, reliable circuitry. Electronics manufacturers partnering with CNC machining services often specify tungsten when designing components that must endure thermal and electrical stress over time.

Table: Key Industries That Benefit from Tungsten’s Properties

| Industry |

Application Areas |

Why Tungsten is Used |

CNC Machining Relevance |

| Aerospace |

Balance weights, engine parts, radiation shielding | High-temperature strength, non-corrosive, dense, stable under thermal stress | Ideal for precision CNC machining parts exposed to extreme flight conditions |

| Manufacturing |

Cutting tools, dies, drill bits, forming tools | Extreme hardness, wear resistance, corrosion resistance from coolants/lubricants | Used extensively in tooling produced by CNC machining factories |

| Electronics |

Filaments, electrodes, heat sinks, circuit interconnects | Excellent conductivity, thermal stability, no Tungsten rust under standard use | Suitable for micro-sized, high-performance CNC machining parts |

While tungsten offers superior strength, heat resistance, and corrosion protection, it is not without its limitations. Understanding these restrictions is critical for manufacturers, engineers, and procurement teams who want to leverage the material effectively—especially when ordering CNC machining parts made from tungsten or its alloys.

One major consideration is tungsten’s brittleness, particularly in its pure form. Despite its hardness, tungsten lacks ductility, meaning it can crack or fracture under high impact or stress without warning. For this reason, applications requiring flexibility or shock absorption may not be ideal for pure tungsten. Tungsten alloys, such as tungsten-nickel or tungsten-copper, offer better mechanical resilience but may introduce corrosion risks if binder metals like cobalt or iron are present—raising the potential for surface degradation that might resemble Tungsten rust.

Another factor is machinability. Tungsten is a notoriously difficult material to machine due to its hardness and density. It requires specialized CNC machining services, high-grade tooling, and optimized parameters to produce precision components without tool wear or failure. Not all CNC machining factories are equipped to handle tungsten efficiently, and those that do often require extended lead times and higher production costs. The increased tool wear also adds to the operational expense.

Weight is another consideration. Tungsten’s density is higher than nearly any other metal, which is advantageous in some contexts (e.g., vibration damping or ballast) but limiting in others, such as lightweight structural designs or aerospace applications with strict weight budgets.

Finally, cost and sourcing can be challenges. Tungsten is more expensive than many other metals, and supply is often dependent on a small number of global producers. This can lead to price fluctuations and procurement delays, especially for high-purity grades needed in aerospace or electronics.

In summary, while Tungsten Metal Rust is not a concern, proper planning around brittleness, machinability, cost, and sourcing is essential to maximize the performance and longevity of tungsten-based CNC machining parts.

Tungsten has an exceptionally high density of approximately 19.25 grams per cubic centimeter (g/cm³), making it one of the densest naturally occurring elements on Earth—second only to osmium and slightly denser than uranium. To put this in perspective, tungsten is almost twice as dense as steel and significantly denser than lead. This property gives tungsten an unmatched advantage in applications that require maximum mass in minimum volume, such as aerospace counterweights, kinetic energy penetrators, radiation shielding, and high-precision CNC machining parts.

In engineering, a high-density material like tungsten provides several functional benefits. For example, in aerospace and defense, dense tungsten components can balance rotating systems, improve projectile penetration, or provide compact shielding from X-rays and gamma radiation. In contrast to metals like aluminum or titanium, which may offer lightweight benefits, tungsten provides inertia and stability, which is critical in high-performance systems.

The high density also contributes to its corrosion resistance. A tightly packed atomic structure resists penetration by moisture and corrosive agents, further minimizing any risk of Tungsten rust or chemical breakdown. Combined with its high melting point and hardness, this makes tungsten an ideal material for CNC machining services tasked with producing parts for environments where both mass and durability are critical.

However, due to this density, tungsten parts can be heavier and more expensive to manufacture and transport. Therefore, CNC machining factories must carefully assess whether the application justifies the use of such a heavy-duty material. When used appropriately, tungsten’s density plays a central role in ensuring performance, stability, and longevity of the final product.

Tungsten holds the record for the highest melting point of all pure metals, sitting at an extraordinary 3422°C (6192°F). This exceptional thermal property is one of the key reasons tungsten is chosen for high-performance applications where extreme heat is a constant factor. In environments where other metals soften, deform, or oxidize, tungsten retains its structural integrity, resists corrosion, and remains dimensionally stable.

This ultra-high melting point is especially advantageous in industries like aerospace, electronics, metal fabrication, and defense, where components must endure extreme temperatures. Tungsten is commonly used in rocket nozzles, arc welding electrodes, and heating elements. Its ability to remain solid and maintain performance even at temperatures that would liquefy steel or titanium makes it irreplaceable in certain roles.

From a CNC machining services perspective, this thermal resilience presents both an opportunity and a challenge. Tungsten's high melting point means it can be used in parts exposed to intense heat without fear of warping or breakdown. However, it also means that tungsten is difficult to process using conventional methods. CNC machining factories must employ specialized tools and slower feed rates to work with tungsten effectively, as its hardness and brittleness can lead to tool wear and machining complexity.

Furthermore, the high melting point also contributes to tungsten’s resistance to rust and corrosion. Unlike iron or other base metals, tungsten doesn’t break down or oxidize rapidly at elevated temperatures. It forms a stable oxide layer instead of flaking away as Tungsten Metal Rust, which preserves its structural surface in most thermal conditions.

In summary, tungsten's exceptional melting point of 3422°C is a defining feature that reinforces its value in high-heat, high-stress environments—making it one of the most reliable choices for CNC machining parts that must survive the harshest conditions.

Tungsten in its pure form is not magnetic. It is classified as paramagnetic, which means it exhibits very weak magnetic properties only in the presence of an external magnetic field—and even then, the effect is minimal. Once the magnetic field is removed, pure tungsten does not retain any magnetism. This non-magnetic behavior makes tungsten ideal for applications where magnetic interference must be avoided, such as in sensitive electronic components, medical imaging equipment, or magnetic shielding.

However, it's important to note that tungsten alloys may behave differently. If tungsten is alloyed with magnetic elements such as iron, cobalt, or nickel, the resulting material can exhibit varying degrees of magnetism. For example, tungsten-nickel-iron alloys, often used in counterweights and shielding components, can be mildly magnetic depending on the proportions of the alloying elements. This distinction is essential when selecting materials for applications in magnetic fields or precision electronics, where even slight magnetism can cause operational interference.

In terms of CNC machining parts, the non-magnetic nature of pure tungsten is a key advantage. It allows for the manufacturing of components that function reliably in MRI systems, navigation instruments, and telecommunications equipment without affecting signal accuracy or electromagnetic sensitivity. CNC machining services often specify pure tungsten or carefully controlled alloys to ensure that parts meet both mechanical and electromagnetic requirements.

In summary, while tungsten metal rust is not a concern and its corrosion resistance is excellent, its lack of magnetism further enhances its suitability for specialized industrial, aerospace, and electronic applications—especially those requiring non-magnetic, corrosion-resistant CNC machining parts.

Tungsten stands as one of the most resilient and reliable metals available today, particularly for industries that demand strength, heat resistance, and long-term durability. A common question—“Does tungsten rust?”—can now be answered with clarity: tungsten does not rust in the traditional sense. Instead of forming flaky, corrosive iron oxide like steel or iron, tungsten forms a stable and protective oxide layer that helps preserve its surface and structure. This resistance to tungsten rust makes it highly suitable for extreme environments, from aerospace and electronics to manufacturing and defense.

Even when alloyed with other metals like cobalt or iron, tungsten retains much of its corrosion resistance—though careful attention must be paid to binder elements that could introduce oxidation. Understanding these nuances is critical for engineers and manufacturers working with CNC machining parts, as it helps ensure material longevity and optimal performance. Whether used in high-speed tooling, heat-intensive components, or precision electronics, tungsten offers unmatched advantages in both structural and chemical stability.

However, as this article has explored, Tungsten Metal Rust is just one consideration. The metal’s high density, melting point, brittleness, machinability challenges, and cost must also be factored in during material selection. Partnering with experienced CNC machining services and qualified CNC machining factories ensures that tungsten components are designed, machined, and finished to exacting standards—maximizing performance while minimizing risks.

In conclusion, tungsten is not just rust-resistant; it is an elite engineering material that brings together strength, stability, and resilience. When used correctly and machined with precision, tungsten delivers long-term value across a wide range of critical applications.

1. How long does it take for tungsten to rust?

Tungsten does not rust like iron or steel. Instead, it forms a thin, protective oxide layer that prevents traditional rusting. Under normal conditions, tungsten remains corrosion-free indefinitely.

2. Will tungsten rust in water?

No, tungsten is highly resistant to rusting in water due to its protective oxide layer. It does not degrade or corrode like iron when exposed to moisture.

3. Will tungsten rings rust?

Tungsten rings do not rust. They retain their shine and structural integrity over time, making them popular for durable jewelry.

4. Will tungsten carbide rings rust?

Pure tungsten carbide doesn’t rust, but some tungsten carbide rings contain binder metals like cobalt, which may corrode under certain conditions if exposed to harsh environments.

5. Will tungsten rust in salt water?

Tungsten itself is resistant to corrosion, but salt water is highly corrosive. Tungsten alloys with reactive binders might degrade if exposed long-term to salt water without protection.

6. Are tungsten rings durable?

Yes, tungsten rings are extremely durable, scratch-resistant, and maintain their finish better than many other metals.

7. Can tungsten jewelry get wet?

Tungsten jewelry can safely get wet without rusting or tarnishing. It’s ideal for everyday wear, including exposure to water.

8. Can tungsten rings be worn all the time?

Yes, tungsten rings are designed for constant wear due to their hardness and resistance to corrosion, making them suitable for everyday use.

9. Will tungsten rust when exposed to water?

No, tungsten does not rust from water exposure because it forms a protective oxide layer that resists corrosion.

10. Will tungsten fade or rust?

Tungsten does not fade or rust under normal conditions. It keeps its color and finish over time unless subjected to extreme environments.

11. Which is better, tungsten or titanium?

Both metals are corrosion-resistant. Tungsten is harder and denser, offering better wear resistance. Titanium is lighter and more ductile, often preferred for lightweight applications.

12. Is tungsten rust-proof?

Yes, tungsten is effectively rust-proof due to its stable oxide surface layer that prevents traditional rust formation.

13. Will tungsten rust outdoors?

Tungsten does not rust outdoors as it withstands exposure to moisture and oxygen without corroding.

14. Will tungsten rings rust?

Tungsten rings do not rust. Their durability and corrosion resistance make them excellent for long-term wear.

15. Will tungsten products change color over time?

Tungsten generally maintains its color and luster, but prolonged exposure to harsh chemicals or extreme conditions may cause slight surface changes.

16. Why is tungsten used in wedding rings or wedding bands?

Tungsten’s hardness, scratch resistance, and corrosion resistance make it a popular choice for wedding bands that retain their appearance over time.

17. What is the difference between industrial-grade tungsten and jewelry-grade tungsten?

Industrial-grade tungsten focuses on mechanical properties for wear and heat resistance, while jewelry-grade tungsten is refined for aesthetic quality, polish, and comfort.

18. Does tungsten react with oxygen at room temperature?

Tungsten forms a very thin and stable oxide layer at room temperature that protects it from further oxidation, preventing rust or corrosion.