15 years one-stop China custom CNC machining parts factory

444 |

Published by VMT at Jun 26 2025 | Reading Time:About 9 minutes

444 |

Published by VMT at Jun 26 2025 | Reading Time:About 9 minutes

In today’s precision-driven manufacturing world, producing complex, high-quality parts quickly and affordably is more important than ever. But without the right equipment, many factories struggle with inconsistency, inefficiency, and rising production costs. The solution? A powerful, versatile, and reliable machining process — the milling machine. By understanding what a milling machine is, how it works, and why it's essential, manufacturers can take full control of their CNC machining parts production and significantly enhance performance.

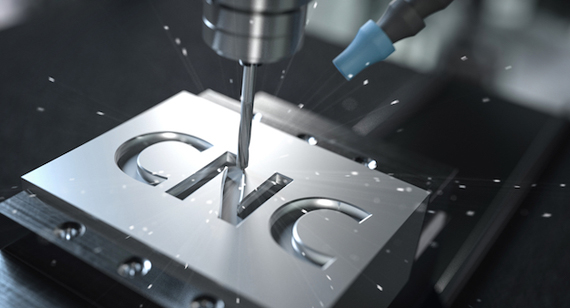

A milling machine is a precision tool used in CNC machining services to cut, shape, and drill solid materials like metal, plastic, and wood. Using rotary cutters, it removes material to achieve complex geometries and tight tolerances, making it vital for industries such as aerospace, automotive, medical, and mold making.

To fully appreciate the role of milling machines in the CNC machining factory environment, this article dives into everything you need to know — from the definition and working principles to types, advantages, applications, and cost. Whether you're a procurement specialist, engineer, or manufacturer, this guide will help you evaluate whether investing in milling machines is the right move for your business.

A milling machine is a mechanical device used to remove material from a workpiece using rotary cutters. Unlike a lathe, which rotates the part, the milling machine keeps the workpiece stationary and rotates the cutting tool. It plays a core role in CNC machining services by allowing the precise shaping of parts made from metals, plastics, wood, ceramics, and composites. Modern CNC milling machines automate this process, boosting productivity and ensuring repeatability for medium to high-volume production runs.

These machines are used across numerous industries including aerospace, automotive, medical, electronics, and mold making — especially when manufacturing parts that demand tight tolerances, intricate contours, or high consistency.

The evolution of milling machines dates back to the early 19th century. In the 1810s, Eli Whitney designed a milling machine to manufacture standardized gun parts. Over time, the technology advanced with improvements in cutter geometry, power transmission, and precision. By the mid-20th century, CNC (Computer Numerical Control) systems transformed traditional mills into automated workhorses. Today, CNC milling machines dominate the manufacturing landscape due to their ability to produce complex geometries at high speeds and with remarkable precision.

1. Part Design

Every milling operation begins with a digital blueprint. A CAD (Computer-Aided Design) model defines the part’s shape, dimensions, and features. This digital file is then translated into machine-readable G-code using CAM (Computer-Aided Manufacturing) software, preparing it for the milling process.

2. Machine Settings

The milling machine operator (or CNC system) sets spindle speed, feed rate, tool paths, and cutting depth according to the material and design requirements. These settings ensure efficient and safe machining.

3. Workpiece Fixtures

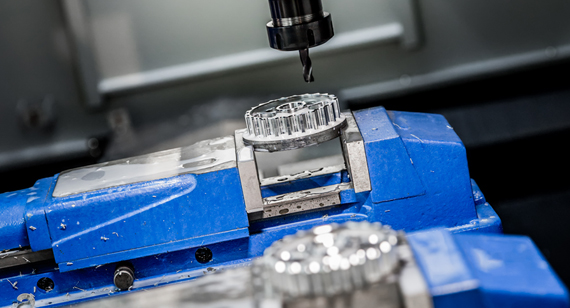

The workpiece is securely mounted on the machine table using fixtures or vises to prevent vibration and movement during machining. Proper clamping is essential for achieving dimensional accuracy.

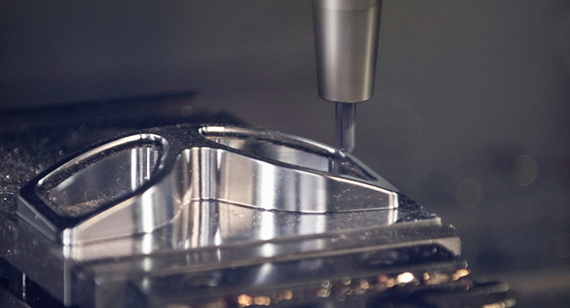

4. Milling Process

Once the program runs, the rotary cutting tool (end mill, face mill, etc.) spins at high speed and moves along programmed paths, removing material layer by layer. Depending on the part complexity, multiple tools may be used in a single operation.

5. Part Inspection

After machining, the part undergoes dimensional and visual inspection. Precision measuring instruments like calipers, micrometers, and CMM (Coordinate Measuring Machines) confirm that the CNC machining parts meet design specifications.

Milling machines are fundamental equipment in any CNC machining factory. They are used for cutting, shaping, drilling, slotting, and finishing various materials—especially metals and hard plastics. These machines operate by rotating a multi-point cutting tool against a workpiece to remove material and produce components with precise dimensions and complex geometries.

Main Functions of a Milling Machine:

| Function |

Explanation |

| Material Removal |

Removes excess material from a solid block (workpiece) to achieve a desired shape. |

| Surface Finishing |

Creates smooth, flat, or contoured surfaces with high accuracy. |

| Slotting and Grooving |

Cuts slots, grooves, keyways, and similar features in a part. |

| Drilling and Boring |

Performs drilling, boring, and reaming operations with precise alignment. |

| Thread Milling |

Creates internal and external threads with high consistency. |

| Contour Milling |

Follows complex curves and profiles, essential in mold making and dies. |

What Are Milling Machines Used For?

Milling machines are used in a wide range of industries, including:

| Industry |

Application |

| Automotive |

Producing engine parts, gear housings, brackets, and transmission components. |

| Aerospace |

Machining lightweight, high-strength parts like wing structures and turbine blades. |

| Medical |

Manufacturing surgical tools, implants, and orthopedic parts with high precision. |

| Electronics |

Producing heat sinks, enclosures, and custom circuit board components. |

| Tool and Die Making |

Creating molds, dies, and fixtures with tight tolerances. |

| Defense |

Fabricating parts for military vehicles, weapons, and communication equipment. |

| General Manufacturing |

Producing components for consumer goods, machinery, and construction tools. |

In Summary

Milling machines are essential for turning raw materials into accurate, high-quality CNC machining parts. Their functions—such as shaping, cutting, and drilling—are foundational to industries that require durability, consistency, and customization. Whether for prototyping or mass production, a milling machine is a powerful tool for delivering reliable machining services.

Understanding the main components of a milling machine is essential for engineers, machinists, and anyone involved in CNC machining services. Each part of the milling machine plays a critical role in ensuring accuracy, stability, and operational efficiency. These parts work together to shape and machine various materials with high precision, particularly in a CNC machining factory where performance and reliability matter.

1. Base

The base is the bottom-most part of the milling machine and acts as the machine’s foundation. It supports the entire weight and ensures stability during operation. Typically made of cast iron, the base absorbs vibration and helps maintain structural integrity. Some designs integrate coolant reservoirs and chip collectors into the base for improved machining efficiency.

2. Column

Mounted vertically on the base, the column is a rigid structure that supports the spindle and other upper components. Inside the column is the spindle motor and the vertical movement system. It serves as the backbone of the machine, providing strength and alignment to the moving parts. In CNC milling machines, the column may also contain electronics and wiring for the machine’s control system.

3. Knee

The knee is a vertically adjustable casting that slides up and down the column. It supports the saddle and table, allowing vertical positioning of the workpiece. In CNC machining, the knee plays a crucial role in setting depth for complex operations, especially when machining multi-axis parts.

4. Lifting Screw

Connected to the knee, the lifting screw is responsible for moving the knee up or down along the column. In manual milling machines, it is operated by a handwheel; in CNC systems, it is motor-driven. This screw provides precise vertical control, vital for setting accurate cutting depths and enabling tight tolerances in CNC machining parts.

5. Saddle

The saddle sits atop the knee and moves horizontally (left and right) along the Y-axis. It supports the worktable and allows side-to-side positioning of the workpiece. Its movement helps achieve complex profiles and dimensions, which are especially important in mold machining and surface milling operations.

6. Table

Mounted on the saddle, the table is where the workpiece is fixed, often using clamps or a vise. It moves longitudinally along the X-axis, enabling linear cutting operations. In CNC machining factories, automated tables can move in multiple directions, allowing the production of parts with intricate geometries.

7. Spindle

The spindle holds the cutting tool and rotates at variable speeds depending on the material and operation. It’s one of the most vital components in a milling machine. In CNC milling machines, the spindle speed is automatically controlled and can be adjusted in real time for optimal cutting performance. It ensures that CNC machining services produce smooth finishes and precise cuts.

8. Arbors

Arbors are shafts attached to the spindle used to hold long or specialized cutting tools. They extend the functionality of the spindle, particularly in horizontal milling machines, where longer cutters are used to perform simultaneous multi-surface operations.

9. Cantilever

The cantilever is primarily seen in some specialized milling machines like the overarm horizontal type. It supports the arbor and provides extra rigidity, ensuring stability during heavy or high-speed machining. This component helps reduce tool vibration and enhances dimensional accuracy.

10. Spindle Box

The spindle box (also called the headstock) houses the spindle, bearings, and gear mechanisms. It controls the speed, direction, and power transmission to the spindle. In CNC machines, it integrates with electronic controllers and sensors, ensuring optimal machining performance, particularly during high-precision operations.

Conclusion

Each component of the milling machine plays a crucial role in delivering efficient, accurate, and high-quality machining results. Whether you're working in a CNC machining factory or operating a standalone milling machine, understanding these parts ensures better performance and helps extend the machine’s life. A solid grasp of these components is fundamental to delivering precise and consistent CNC machining services.

Milling machines have become a cornerstone of modern manufacturing and CNC machining services due to their exceptional versatility and precision. From aerospace parts to consumer electronics, they play a pivotal role in shaping raw materials into finished components. However, like any equipment, they come with both advantages and limitations. Understanding these can help buyers, engineers, and project managers determine whether investing in or outsourcing to a CNC machining factory is the right choice for their specific needs.

Advantages of Milling Machines

1. Versatile

Milling machines are renowned for their versatility. They can perform a wide range of operations—face milling, side milling, contouring, slotting, drilling, tapping, and gear cutting. Whether it’s a vertical or horizontal milling machine, or even a high-end CNC milling center, these machines adapt to various materials such as steel, aluminum, plastic, or composites. This versatility allows manufacturers to produce simple flat surfaces or complex 3D contours using the same equipment, making it a flexible choice for both prototyping and full-scale production.

2. High Precision

Milling machines offer exceptional precision, which is critical in today’s competitive manufacturing landscape. Tolerances within ±0.01 mm are achievable with high-quality machines and skilled operators. CNC milling machines, in particular, use computer-controlled systems to ensure accuracy and repeatability in mass production. This level of precision is essential for industries like aerospace, medical, and automotive where safety and performance depend on exact specifications.

3. Processing Complex Parts

Modern milling machines, especially 4-axis and 5-axis CNC models, can manufacture parts with highly complex geometries. Components with undercuts, compound angles, or curved surfaces that are impossible to produce with traditional methods can be machined with ease. This ability is a key advantage when creating molds, dies, and custom components that require detailed contouring or precise internal features.

4. Improve Efficiency

Milling machines significantly boost manufacturing efficiency. CNC milling allows for continuous operation, 24/7, with minimal supervision. Advanced tooling, automation, and integrated software reduce cycle times and material waste. Additionally, multiple machining operations can be performed in a single setup, reducing the need for secondary processes. This increased efficiency helps reduce production costs and lead times, especially for CNC machining factories working on high-volume orders.

Disadvantages of Milling Machines

1. High Cost

One of the major disadvantages is the high initial investment. Advanced CNC milling machines, especially multi-axis models, can be costly to purchase and install. In addition to the machine itself, businesses must invest in tooling, software, and skilled labor. For small-scale operations or low-volume production, the cost may outweigh the benefits unless outsourcing to a CNC machining service provider is considered.

2. Complex Operation

Operating a milling machine—particularly CNC models—requires specialized knowledge and training. Machine programming, tool selection, setup procedures, and maintenance protocols all demand technical skill. Errors in programming or setup can lead to costly downtime, part rejection, or even machine damage. This complexity adds a learning curve, especially for businesses new to CNC machining.

3. Equipment Maintenance

Regular maintenance is essential to keep milling machines in optimal condition. This includes lubrication, cleaning, calibration, and inspection of mechanical and electronic components. Neglecting maintenance can reduce accuracy, increase wear on parts, and lead to unexpected breakdowns. For CNC machining factories, this means dedicating time and resources to scheduled maintenance, which can temporarily impact production.

4. Environmental Impact

Milling operations can produce considerable waste in the form of chips, lubricants, and energy consumption. While many CNC machining services have implemented eco-friendly practices, the environmental footprint is still a concern. Proper disposal of cutting fluids and recycling of metal shavings are necessary to minimize impact, adding to operational costs and regulatory compliance efforts.

Conclusion

Milling machines offer unparalleled versatility and precision, making them an essential tool in modern manufacturing. While the advantages are significant—especially when paired with professional CNC machining services—potential users must also weigh the costs, operational complexity, and environmental considerations. By understanding both the strengths and limitations, businesses can make informed decisions whether to invest in equipment or partner with a specialized CNC machining factory.

Here's a table summarizing the advantages and disadvantages of milling machines in manufacturing, written in a customer-friendly and clear format:

| Category |

Details |

| Advantages | |

| Versatile | Can perform various operations such as face milling, slotting, drilling, and contouring on different materials. |

| High Precision | Achieves tolerances up to ±0.01 mm, ideal for industries requiring exact specifications like aerospace and medical. |

| Processing Complex Parts | Capable of machining intricate geometries, undercuts, and compound surfaces using multi-axis CNC milling machines. |

| Improve Efficiency | Supports automation and multiple operations in one setup, reducing cycle time and increasing productivity. |

| Disadvantages | |

| High Cost | CNC milling machines and related equipment involve significant upfront investment and operational costs. |

| Complex Operation | Requires skilled programmers and operators; errors in setup or code can lead to quality issues or downtime. |

| Equipment Maintenance | Needs routine maintenance and inspections to maintain performance and avoid breakdowns. |

| Environmental Impact | Produces waste (chips, fluids) and consumes energy; requires eco-conscious practices to manage environmental footprint. |

The performance and precision of a milling machine are largely determined by its technical parameters. These parameters define how the machine interacts with the workpiece and tool, and they must be carefully selected based on the material type, part design, and production goals. Understanding these specifications allows CNC machining factories to optimize cutting conditions, reduce tool wear, and achieve higher-quality CNC machining parts. Whether you're running a vertical, horizontal, or CNC milling machine, the correct setup of these parameters is critical to successful operation.

1. Speed (Spindle Speed - RPM)

Spindle speed, measured in revolutions per minute (RPM), determines how fast the cutting tool rotates. It’s crucial because it affects the heat generated, the quality of the cut, and the overall machining time.

For example, a CNC machining factory might set the spindle at 10,000 RPM for aluminum but only 3,000 RPM for hardened steel.

2. Tool Diameter

Tool diameter influences surface finish, cutting stability, and machining efficiency. Larger tools remove material faster but require more power and space, while smaller tools offer finer detail and precision.

Tool diameter must be matched to the geometry of the part and the required surface finish in CNC machining services.

3. Cutting Speed (Vc)

Cutting speed is the rate at which the tool cuts through the material, typically measured in meters per minute (m/min). It depends on the tool material and the type of workpiece material.

Formula:

Vc = (π × D × n) / 1000

Where:

Higher cutting speeds improve productivity but may shorten tool life if not properly managed.

4. Feed Speed (Feed Rate - mm/min)

Feed speed indicates how fast the workpiece is fed into the tool. It’s a key factor in chip removal rate and surface quality.

This is especially important when milling complex CNC machining parts where precision and surface finish are critical.

5. Cutting Depth

Cutting depth determines how deep the tool cuts into the material per pass. There are two types:

Deeper cuts increase material removal rates but also the force on the tool, so they require powerful machines and rigid setups.

Summary Table: Key Milling Machine Parameters

| Parameter |

Unit |

Definition |

| Spindle Speed | RPM | Tool rotation rate |

| Tool Diameter | mm | Diameter of the milling tool |

| Cutting Speed | m/min | Rate of material removal at the cutting edge |

| Feed Speed | mm/min | Rate of workpiece movement under the tool |

| Cutting Depth | mm | Depth of material removed per pass (axial/radial) |

Understanding these parameters helps manufacturers produce reliable, high-precision CNC machining parts with consistent quality. For deeper guidance on machine setup or to explore VMT’s advanced CNC machining services, check out our related guides and product pages.

Milling machines come in a wide variety of configurations to meet the diverse demands of CNC machining services. Each type has its own structure, operating orientation, and application strengths. Whether it's for prototyping, precision part production, or heavy-duty material removal, understanding the different types helps CNC machining factories choose the most suitable equipment for their production goals. Below is an overview of the most common types of milling machines and their core specifications.

What is a Vertical Milling Machine?

A vertical milling machine has a vertically oriented spindle. The cutting tool moves up and down, and the workpiece is typically clamped on a horizontal table. It’s ideal for precision parts and fine detailing.

What is a Horizontal Milling Machine?

In a horizontal milling machine, the spindle is mounted horizontally, allowing the cutting tool to approach the workpiece from the side. This setup is more stable for heavy-duty work.

What is a CNC Milling Machine?

CNC (Computer Numerical Control) milling machines are automated, programmable systems that offer high precision, repeatability, and flexibility. These machines can be vertical, horizontal, or multi-axis.

What is a Universal Milling Machine?

A universal milling machine combines the capabilities of both horizontal and vertical mills. It can rotate the table and adjust tool angles, offering enhanced flexibility.

What is a Bed Milling Machine?

A bed-type milling machine has a fixed bed and a moving table. It offers strong rigidity and supports heavy workpieces and large-scale machining operations.

Summary Comparison Table

| Type |

Spindle Speed (RPM) |

Table Size (mm) |

Max Workpiece Weight (kg) |

Best Use/Application |

| Vertical Milling Machine |

3,000–12,000 | 800×400 – 1500×600 | 300–800 | Precision detailing, die work, fine machining |

| Horizontal Milling Machine |

2,000–6,000 | 1000×400 – 1600×700 | 500–1200 | Grooving, slotting, heavy cuts |

| CNC Milling Machine |

6,000–24,000 | 600×400 – 2000×800 | 300–1500 | High-precision parts, automated multi-axis operations |

| Universal Milling Machine |

3,000–8,000 | 1000×400 – 1600×600 | 500–1000 | Angular milling, toolroom jobs |

| Bed Milling Machine |

1,500–6,000 | 1500×700 – 3000×1000 | 1000–3000 | Large parts, mold machining, heavy industry |

Want to learn more about which machine best fits your CNC machining needs? Visit our other pages on milling machine structure, CNC machining services, and types of machining operations to get expert insights.

Let us know your production requirements—VMT's CNC machining factory is ready to assist with selecting the right equipment and process for your project.

Milling machines are highly adaptable tools in the field of manufacturing. Their classification can vary based on how the tool interacts with the workpiece, the type of milling operation performed, the direction of the spindle, and the machining objective. Understanding these types helps customers choose the right process for producing CNC machining parts with precision, speed, and cost-effectiveness.

Based on Cutting Direction

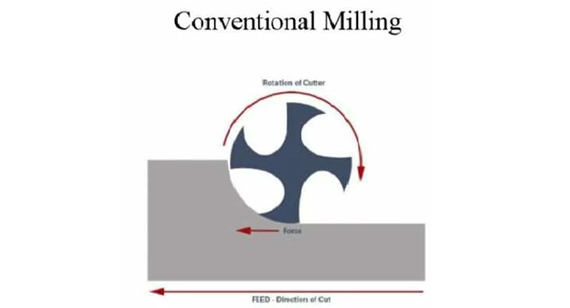

Upward Milling (Conventional Milling)

In this process, the cutter rotates against the direction of feed. The chip thickness starts at zero and increases, which puts more pressure on the workpiece and requires a tighter clamping setup.

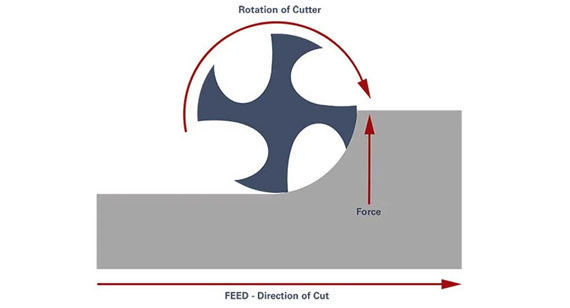

Downward Milling (Climb Milling)

The cutter rotates in the same direction as the feed. Chip thickness starts high and decreases, producing better surface finishes and extending tool life.

Based on Operation Type

These operations define how material is removed from the workpiece using various cutting strategies:

| Operation Type |

Function |

| Face Milling |

Produces flat surfaces perpendicular to the cutter axis |

| General Milling |

Multi-purpose operation to shape any part geometry |

| Side Milling |

Cuts along the sides of the workpiece to form vertical features |

| Keyway Milling |

Used to produce slots or keyways in shafts or hubs |

| Contour Milling |

Follows irregular part geometry to create 3D contours |

| Thread Milling |

Cuts threads into parts using helical interpolation |

| Gear Cutting |

Specialized operation for manufacturing gears |

| Angular Milling |

Cuts at specific angles using single or multiple cutters |

| Forming Milling |

Uses specially shaped cutters to form complex profiles |

| Slot Milling |

Cuts grooves or slots into the material surface |

| Straddle Milling |

Simultaneous cutting on both sides of the workpiece |

| Group Milling |

Uses multiple cutters for parallel surfaces or repetitive features |

Based on Tool Direction

| Type |

Description |

| Horizontal Milling |

The spindle is horizontal, ideal for slotting, facing, or heavy material removal |

| Vertical Milling |

The spindle is vertical; used for die-making, profiling, and contouring |

Each direction determines how the cutter approaches the material, affecting chip removal, rigidity, and finish.

Based on Machining Purpose

Rough Milling

Used to remove large volumes of material quickly. Surface finish is not prioritized. It focuses on speed and cutting efficiency.

Fine Milling

Performed at the finishing stage, where surface quality, tolerance, and precision matter.

Summary

By understanding these types, manufacturers and clients can optimize their CNC machining process according to specific project needs. Whether it's upward milling for tough materials or fine milling for aesthetic finishes, each method has a place in modern CNC machining services.

Interested in how different operations impact part quality and cost?

Check out our pages on CNC machining operations, milling machine structure, or explore precision machining services at VMT for more guidance.

Milling machines are incredibly versatile tools used across industries—from aerospace to furniture production. One of their biggest strengths is the wide variety of materials they can process. Whether you're manufacturing CNC machining parts or working on a custom prototype, knowing which materials are compatible with milling operations is key to choosing the right CNC machining services or factory partner. Let’s explore the categories of materials that can be milled efficiently and what makes each suitable.

Metals and Alloys

Milling machines are widely used for cutting metals, thanks to their precision and power.

| Material |

Use Case |

| Steel | Industrial parts, gears, frames |

| Copper | Electrical components, heat exchangers |

| Aluminum | Lightweight structural parts, aerospace and automotive applications |

| Brass | Decorative parts, fittings, and plumbing |

| Tin | Low-melting applications, alloys |

| Titanium | High-strength aerospace and medical parts |

| Stainless Steel | Corrosion-resistant parts in medical, food, and marine industries |

Milling machines can easily cut these metals using high-speed steel or carbide tools with proper feeds and speeds.

Plastics

Plastics are easier to machine and often used for rapid prototyping or lightweight applications.

| Plastic Type |

Common Applications |

| ABS | Consumer electronics, automotive dashboards |

| Nylon | Wear-resistant parts, gears, and bearings |

| UPVC | Pipes, window frames, fittings |

| HDPE | Cutting boards, tanks, piping components |

Plastics require careful speed settings to avoid melting or poor surface finishes.

Ceramics

While more brittle and abrasive, ceramics can still be milled using specialized tools.

| Ceramic |

Applications |

| Tiles | Custom finishes, construction |

| Porcelain | Dental prosthetics, sanitary fixtures |

| Alumina | Electrical insulators, biomedical components |

| Glass | Optical devices, decorative applications |

Advanced CNC machining services use diamond-coated tools and coolant for better results.

Composites

These materials combine properties of different substances for enhanced strength or weight reduction.

| Composite |

Common Uses |

| Fiberglass | Structural panels, boat hulls, enclosures |

| Carbon Fiber | High-performance sports gear, aerospace, automotive |

Due to fiber structure, milling composites requires dust control and tool durability.

Wood

Wood remains a popular material in furniture, prototypes, and art. Milling machines adapted for woodworking handle:

| Wood Type |

Applications |

| Softwood | Construction, framing, low-cost models |

| Hardwood | Furniture, cabinetry, high-end applications |

| Laminate | Countertops, panels |

| Engineered Wood | Plywood, MDF for mass production |

CNC routers and standard milling machines both serve well for wood with the right tooling.

Summary

From metals to composites, a milling machine's cutting ability depends on tooling, machine power, and processing parameters. When planning CNC machining parts production, selecting the correct material ensures both performance and cost-effectiveness.

Want help choosing the right material for your design?

Explore our CNC machining materials guide, or contact our CNC machining factory experts to get tailored advice for your project.

In CNC machining, the effectiveness and precision of milling depend heavily on the cutting tools used. Different tool types are designed to perform specific operations, each contributing to improved surface finish, cutting efficiency, and geometric accuracy. Understanding these tools is essential whether you're managing a CNC machining factory or sourcing CNC machining services for custom parts. Below is a comprehensive guide to the most commonly used milling tools and their respective functions.

End Mills

End mills are the most versatile and commonly used cutting tools in milling machines. These tools are used for both peripheral and slot cutting. They come in a variety of shapes, including square-end, round-end, and ball-end styles.

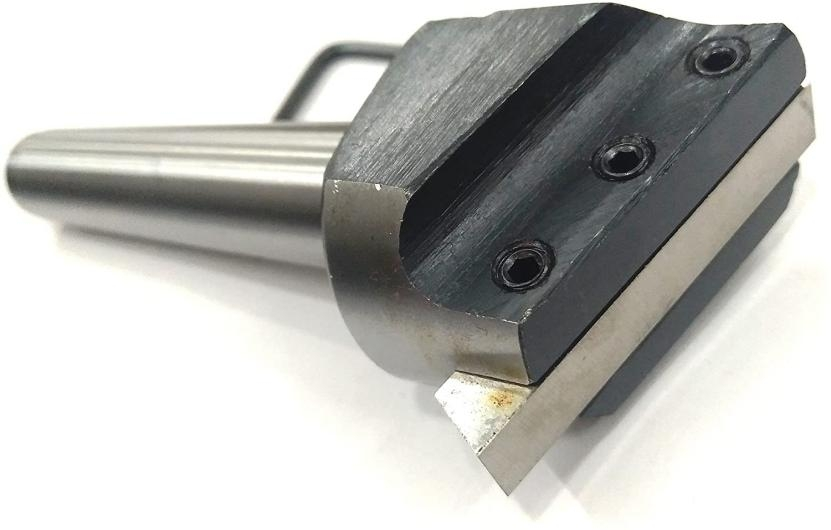

Face Mills

Face mills are designed to cut with the face (top edge) of the tool rather than the sides. These tools are typically large and have multiple replaceable inserts.

Shell Mills

Shell mills are similar to face mills but have a hole in the center for mounting on an arbor. They are used for heavy-duty face milling applications.

Slab Mills

Slab mills are cylindrical tools used primarily for heavy cutting on horizontal milling machines. They are ideal for removing large volumes of material quickly.

T-Slot Mills

T-slot mills are designed to create T-shaped slots, commonly used in machine tool tables.

Slot Drills

Slot drills resemble end mills but are specifically designed for plunge cutting and creating keyways or slots.

Ball End Mills

Ball end mills have a hemispherical end and are used for 3D contouring and curved surface machining.

Fly Cutters

Fly cutters are single-point tools used on manual and CNC machines to machine large, flat surfaces.

Thread Mills

Thread mills are used to cut threads into a workpiece. Unlike taps, they mill threads using CNC path control.

Chamfer Mills

Chamfer mills are used to bevel edges or remove burrs from milled parts.

Summary

Each milling tool serves a specific role in shaping, finishing, or detailing CNC machined parts. Choosing the right tool ensures accuracy, surface quality, and operational efficiency—key factors in high-performance CNC machining services.

Here's a clear and professional table outlining the different cutting tools used in milling, along with their applications and advantages:

| Tool Name |

Applications |

Advantages |

| End Mills |

Profile milling, contouring, slotting, plunging | Versatile, precise, suitable for various materials and operations |

| Face Mills |

Surface finishing, machining flat surfaces | High material removal rate, excellent surface finish |

| Shell Mills |

Heavy-duty face milling on large surfaces | Durable, efficient for large-scale material removal |

| Slab Mills |

Planing large flat surfaces | High-efficiency, ideal for horizontal milling |

| T-Slot Mills |

Cutting T-shaped slots for fixtures and workholding setups | Specialized for slot geometry, useful for fixtures |

| Slot Drills |

Cutting blind holes, slots, keyways | Good chip evacuation, accurate for deep cuts |

| Ball End Mills |

3D contouring, sculpted and curved surfaces | Smooth finishes on complex geometries, ideal for mold and die applications |

| Fly Cutters |

Finishing flat surfaces, low-speed large area finishing | Economical, excellent surface finish |

| Thread Mills |

Internal and external threading | Precise thread depth control, flexible thread pitch options |

| Chamfer Mills |

Edge finishing, deburring, chamfering holes and part edges | Enhances aesthetics, removes sharp edges, ideal for final part preparation |

This table offers a quick, at-a-glance understanding of each cutting tool's function and benefit—ideal for CNC machining professionals, procurement teams, or engineers comparing tooling options.

Milling machines play a critical role across a broad range of industries, thanks to their versatility and precision in shaping materials. From producing intricate components to large-scale manufacturing, milling machines enable efficient and high-quality machining, making them indispensable in modern manufacturing environments.

In the automotive sector, milling machines are extensively used to manufacture engine parts, transmission components, brake systems, and chassis parts. The precision machining ensures that parts meet stringent safety and performance standards. CNC machining parts created with milling machines contribute to lighter, stronger, and more fuel-efficient vehicles.

Aerospace Industry

Aerospace manufacturing demands exceptionally high precision and tight tolerances. Milling machines are used to fabricate aircraft structural parts, turbine blades, and landing gear components. The ability to work with exotic alloys and complex geometries makes milling indispensable for aerospace parts that must withstand extreme conditions.

Metalworking Industry

Milling machines are a cornerstone of metalworking, used for cutting, shaping, and drilling metal workpieces. They produce machine tools, industrial equipment components, and metal molds. Their capacity to process a wide variety of metals, including stainless steel and titanium, supports diverse manufacturing needs.

The electronics industry uses milling machines for creating precise enclosures, heat sinks, connectors, and circuit board components. The demand for miniaturization and high precision is met effectively by CNC machining services that utilize milling machines to produce intricate electronic parts.

Furniture and Woodworking Industry

Milling machines are vital in woodworking for shaping, slotting, and contouring wood pieces. They are used to manufacture furniture components, decorative moldings, and cabinetry. Milling provides the flexibility to produce both mass-produced and custom wood products with fine finishes.

Construction Industry

In construction, milling machines fabricate parts for heavy machinery, tools, and building infrastructure components. Their ability to handle large workpieces and tough materials makes them essential for producing durable and reliable construction equipment.

Mold Making Industry

Precision is paramount in mold making, where milling machines are used to carve detailed molds for plastics, metals, and composites. These molds are critical for mass production of automotive parts, household goods, and packaging materials, ensuring consistent quality and accuracy.

Energy Industry

Milling machines contribute to the energy sector by manufacturing components for turbines, generators, and drilling equipment. The ability to machine hard metals and alloys supports the production of parts designed for durability and high performance in energy generation and exploration.

In the medical field, milling machines produce surgical instruments, implants, prosthetics, and dental appliances. The precision and surface finish achievable with CNC machining parts are crucial for ensuring biocompatibility and functionality in medical devices.

Research and Development

R&D departments rely on milling machines for prototyping and testing new designs. Their flexibility allows rapid iteration of parts, aiding innovation across industries. Milling machines help turn concepts into functional prototypes, accelerating product development cycles.

Here is the table summarizing the Industry Applications of Milling Machines in Manufacturing:

| Industry |

Applications of Milling Machines |

| Automotive Industry |

Manufacturing engine parts, transmission components, brake systems, and chassis parts with high precision and durability. |

| Aerospace Industry |

Producing aircraft structural parts, turbine blades, landing gear components; machining exotic alloys with tight tolerances. |

| Metalworking Industry |

Cutting and shaping metal workpieces, creating machine tools, industrial components, and metal molds. |

| Electronic Industry |

Fabricating precise enclosures, heat sinks, connectors, and circuit board components for miniaturized electronic devices. |

| Furniture & Woodworking |

Shaping, slotting, and contouring wood for furniture, decorative moldings, cabinetry, both custom and mass-produced. |

| Construction Industry |

Producing parts for heavy machinery, tools, and building infrastructure components with the ability to handle large pieces. |

| Mold Making Industry |

Carving detailed molds for plastics, metals, and composites used in automotive, household, and packaging production. |

| Energy Industry |

Manufacturing components for turbines, generators, and drilling equipment, machining hard metals for durability. |

| Medical & Dental Industry |

Producing surgical instruments, implants, prosthetics, and dental appliances requiring precision and biocompatibility. |

| Research & Development |

Rapid prototyping and testing of new designs, facilitating innovation and accelerating product development cycles. |

Here’s a clear and concise breakdown of the advantages and limitations of milling machines compared to other machining operations:

| Advantages of Milling Machines |

Limitations of Milling Machines |

| Versatile machines: Milling machines can perform a wide variety of tasks such as cutting, drilling, slotting, and shaping different materials. This versatility makes them suitable for diverse manufacturing needs. | Costs: Milling machines, especially CNC models, can be expensive to purchase and maintain, making the initial investment high for some manufacturers. |

| Precise tolerances: They deliver high precision and accuracy, essential for producing complex parts with tight dimensional tolerances. | Space requirements: Milling machines require considerable floor space due to their size and the need for safe operation zones. |

| Consistency: Automated milling ensures repeatability, producing consistent and uniform parts across large production runs. | Tools: Milling operations often require a wide range of cutting tools, which adds to tooling costs and inventory management challenges. |

| Automation: CNC milling machines enable automation, reducing manual labor, increasing productivity, and minimizing human error. | Limited accessibility: Milling machines may have limited access to complex internal features compared to other specialized machining methods. |

| Flexibility: Milling can handle various materials—from metals to plastics—making it adaptable for many industries. | |

| Quality results: The combination of precision, versatility, and automation results in high-quality finished products suitable for critical applications. |

The cost of purchasing a new milling machine varies widely, influenced by several key factors that directly affect the machine’s capabilities, precision, and overall value. For businesses and CNC machining factories looking to invest, understanding these cost drivers is crucial to making an informed decision that balances budget with operational needs.

Mill Type:

Different milling machines—such as vertical, horizontal, CNC, or universal mills—have varying price points. CNC milling machines generally cost more due to their automation, precision, and versatility compared to manual mills.

Number of Axes:

The number of axes impacts both the complexity and price. Basic milling machines often have 3 axes (X, Y, Z), while advanced CNC machines can have 4, 5, or even more axes, allowing for more complex machining operations but also driving up the cost.

Machine Size:

Larger machines with bigger worktables and higher load capacities typically come at a higher price. The size directly influences the types of parts that can be machined and the overall factory floor space requirements.

Brand:

Reputable brands with proven reliability, quality, and after-sales support usually command premium prices. Investing in a well-known brand can reduce downtime and maintenance costs over the machine’s lifespan.

Control System:

The sophistication of the control system, such as basic CNC controllers versus advanced multi-axis controllers with enhanced software capabilities, also impacts the price. More advanced controls offer better automation, precision, and ease of use.

Excerpt:

New milling machine prices vary significantly based on type, size, control systems, and brand reputation. Understanding these factors helps manufacturers select equipment that meets production demands without overspending.

Transition:

To make a smart investment in milling machines for CNC machining parts production, it’s essential to evaluate how each factor aligns with your specific manufacturing goals and budget constraints. Let’s explore the different types of milling machines and their cost implications next.

Here's a clear table summarizing the factors affecting the cost of a new milling machine:

| Factor |

Description |

Impact on Cost |

| Mill Type |

Vertical, horizontal, CNC, universal, etc. | CNC and specialized mills cost more |

| Number of Axes |

3-axis, 4-axis, 5-axis or more | More axes increase price |

| Machine Size |

Worktable size and maximum workpiece capacity | Larger machines are pricier |

| Brand |

Manufacturer reputation, quality, and support | Well-known brands command premium |

| Control System |

Basic CNC controllers vs. advanced multi-axis control systems | Advanced controls raise cost |

Milling machines are known for their durability and long service life when properly maintained. On average, a well-maintained milling machine can last between 15 to 30 years or even longer. The actual lifespan depends on several factors including the machine’s build quality, frequency of use, operating conditions, and maintenance routines.

High-quality CNC milling machines from reputable CNC machining factories tend to have a longer lifespan due to their robust construction and advanced control systems. Routine maintenance such as lubrication, timely replacement of worn parts, and proper cleaning significantly extends the machine’s operational life.

Moreover, technological advancements mean that older milling machines can often be retrofitted with newer CNC controls, further prolonging their usability in modern manufacturing environments.

In summary, investing in a milling machine with reliable CNC machining services and committing to regular upkeep can ensure the machine remains productive and accurate for decades, making it a valuable asset in any CNC machining factory.

Maintaining a milling machine is generally manageable but requires consistent attention and proper procedures to ensure long-term performance and accuracy. Milling machines, especially CNC milling machines, involve several mechanical and electronic components that must be regularly checked and serviced.

Routine maintenance tasks include lubricating moving parts, cleaning the machine surfaces to prevent debris buildup, inspecting tool holders and spindles for wear, and ensuring the coolant system functions properly. CNC machining services and CNC machining factories emphasize maintenance schedules to minimize downtime and costly repairs.

While basic upkeep such as cleaning and lubrication is straightforward, more complex maintenance—like calibrating controls or repairing electrical components—might require skilled technicians. Therefore, while a milling machine is not overly difficult to maintain, operators and maintenance personnel must be trained adequately to perform these tasks effectively.

Overall, with proper maintenance protocols and timely servicing, milling machines can maintain high precision and reliability, reducing unexpected breakdowns and enhancing production efficiency.

Milling machines are critical to modern manufacturing, offering precision, versatility, and reliability in producing complex parts. However, their optimal performance heavily depends on regular maintenance and proper care. Neglecting routine maintenance can lead to premature wear, reduced accuracy, machine downtime, and costly repairs. By following structured maintenance practices, manufacturers can extend the machine's service life, maintain consistent machining quality, and ensure a safer working environment.

This guide outlines the key steps and best practices for maintaining and caring for milling machines, including both manual and CNC models.

Regular Inspection of the Milling Machine Lubrication System

Proper lubrication is essential to prevent excessive wear and overheating of moving parts. Operators should routinely inspect the lubrication system to ensure oil reservoirs are filled, delivery lines are unblocked, and oil is reaching critical components like the spindle, guideways, and lead screws. Any leakage, discoloration, or contamination in the lubricant should be addressed immediately. Automated lubrication systems should be tested regularly to verify their functionality and timing.

Key Tips:

Keep the Surface of the Milling Machine Clean

Cleanliness is fundamental to milling machine care. Chips, dust, coolant residue, and debris can accumulate and interfere with moving parts, sensors, or surface finishes. After each shift or job, operators should clean the table, T-slots, and protective covers using brushes, cloths, or compressed air (where appropriate). Avoid using water or inappropriate solvents that could lead to corrosion.

Key Tips:

Pay Attention to the Working Environment of the Milling Machine

The environment surrounding the milling machine significantly influences its longevity and performance. Excessive humidity, temperature fluctuations, and airborne contaminants can contribute to rust, electronics malfunctions, or mechanical wear. Placing the machine in a clean, temperature-controlled area with stable power supply helps minimize risks.

Key Tips:

Regular Maintenance and Overhaul of the Milling Machine

Periodic in-depth maintenance and professional overhauls are crucial for identifying wear and mechanical issues that aren't visible during daily inspections. Depending on usage, machines should undergo scheduled servicing that includes replacing worn bearings, aligning axes, calibrating positioning systems, and checking backlash or play in moving parts.

Key Tips:

CNC Software Update and Data Backup

For CNC milling machines, software updates and data management are equally important as mechanical maintenance. Updated software ensures compatibility, accuracy, and security, while regular data backup prevents loss of critical programs and settings in the event of a system failure.

Key Tips:

Here is a clean and professional summary table outlining the key maintenance areas for milling machines:

| Maintenance Area |

Purpose |

Best Practices |

| Lubrication System Inspection |

Prevents wear, overheating, and mechanical failure | Check oil levels daily; use recommended lubricants; inspect for leaks and contamination |

| Surface Cleaning |

Ensures precision, avoids debris buildup and corrosion | Clean surfaces, chip trays, and filters after each job; avoid corrosive cleaners |

| Working Environment Monitoring |

Reduces external risks like rust, overheating, and system failure | Maintain stable temperature and humidity; keep workspace ventilated and dust-free |

| Regular Maintenance & Overhaul |

Prolongs machine life, preserves accuracy, reduces breakdowns | Schedule periodic servicing; track maintenance logs; replace worn parts |

| CNC Software Update & Data Backup |

Maintains control accuracy and safeguards digital operations | Keep software/firmware updated; back up machining programs and parameters regularly |

Choosing the right milling machine is a critical decision that impacts production efficiency, machining precision, and long-term investment returns. Whether you're investing in a manual or CNC milling machine, understanding key factors like control systems, machine type, power, and configuration ensures the machine aligns with your specific manufacturing needs. Below are the main considerations to guide your selection process.

Control System

The control system determines how the machine is programmed and operated. CNC systems offer automation, repeatability, and complex part machining, while manual control is better suited for low-volume or prototype work. For CNC machines, evaluate the software’s compatibility, ease of programming, and after-sales support.

Machine Type

Milling machines come in various types, such as vertical, horizontal, gantry, or 5-axis CNC. The selection depends on the type of part, required accuracy, and production complexity. Vertical milling machines are ideal for general-purpose jobs, while horizontal and 5-axis machines are better for complex geometries and high-volume production.

Workpiece Size

The physical dimensions of your typical workpiece must align with the machine's table size, travel range, and overall working envelope. Undersized machines limit flexibility, while oversized machines may increase cost and space requirements unnecessarily.

Machine Power

Spindle power and torque affect the material removal rate and machining capabilities. More power is required for harder materials like stainless steel or titanium. Inadequate power can lead to tool wear and surface defects.

Budget

Your budget affects not only the initial purchase but also operating costs, tooling, maintenance, and training. Consider the total cost of ownership rather than just the upfront price. Balancing cost with long-term ROI is key.

Manufacturing Quality

Build quality influences accuracy, stability, and lifespan. Machines made with high-grade cast iron, precision-ground ways, and premium ball screws will perform better over time. Check for certifications or third-party quality assurances.

Configuration

Machine configuration includes tool changers, coolant systems, chip conveyors, and automation options like pallet changers or robotic arms. These features enhance productivity and reduce manual labor. The right configuration depends on your production volume and workflow needs.

Summary Table

| Factor |

What It Affects |

What to Consider |

| Control System |

Automation, ease of use, compatibility | CNC vs. manual, software ecosystem, post-sale support |

| Machine Type |

Machining capability and flexibility | Vertical, horizontal, gantry, or multi-axis machine types |

| Workpiece Size |

Machine size, table dimensions, axis travel | Must fit the largest part you plan to machine |

| Machine Power |

Machining harder materials, cutting speed | Higher spindle horsepower and torque for tougher jobs |

| Budget |

Total cost of ownership and ROI | Balance initial cost with maintenance, tooling, and reliability |

| Manufacturing Quality |

Accuracy, repeatability, and long-term durability | Material quality, construction, brand reputation |

| Configuration |

Productivity, automation, and ease of operation | Tool changers, coolant systems, chip removal, automation capabilities |

Buying a milling machine involves more than just comparing prices—it's about finding the right source that matches your technical needs, budget, and after-sales expectations. Whether you're a first-time buyer or upgrading your current setup, it's important to understand the pros and cons of each purchasing channel. Milling machines are available through various platforms including online marketplaces, offline distributors, used equipment resellers, and even through milling service providers if ownership isn’t required.

Online Market

The online market offers a fast, convenient way to browse and compare a wide range of milling machines from global manufacturers. Platforms like Alibaba, Amazon, eBay, and industry-specific sites such as Thomasnet or DirectIndustry feature both new and used machines.

Advantages:

Considerations:

Offline Market

Buying through local distributors or showrooms allows you to inspect machines physically, ask detailed questions, and receive personalized service. Offline channels are especially useful for large industrial machines where support and installation are critical.

Advantages:

Considerations:

Used Machine

Used milling machines are a cost-effective solution for buyers with budget constraints. You can find them through online auction sites (like MachineTools.com, Surplex, or Exapro), second-hand dealers, or even directly from manufacturers upgrading their equipment.

Advantages:

Considerations:

Milling Service

If your milling needs are occasional or project-based, consider outsourcing to a CNC machining service provider instead of buying a machine. Many companies offer contract milling with high-end equipment and expert operators.

Advantages:

Considerations:

Summary Table

| Buying Option |

Best For |

Key Benefits |

Points to Watch |

| Online Market |

Broad selection and fast comparison | Convenience, variety, global access | Supplier trust, import fees, after-sales service |

| Offline Market |

Local support and hands-on inspection | Physical inspection, expert advice | Fewer choices, potentially higher costs |

| Used Machine |

Budget-conscious buyers | Cost savings, quick availability | Wear & tear risk, outdated technology |

| Milling Service |

Occasional or one-time machining needs | No machine ownership, high precision access | Outsourcing cost, less process control |

Operating a milling machine can be moderately difficult for beginners, but with proper training and practice, most users can become proficient. Manual machines require hands-on skill, while CNC milling machines rely more on programming knowledge and digital control.

Detailed Explanation:

The difficulty of operating a milling machine depends on several factors, including the type of machine, the complexity of the part being produced, and the user’s experience level. Here's a breakdown of what to expect:

1. Manual Milling Machines:

Manual machines require mechanical skill and precision hand-eye coordination. Operators must:

Learning curve: Moderate to high, especially for beginners with no machining background.

2. CNC Milling Machines:

CNC machines are more automated and rely on software to control the machining process. While they reduce the need for manual operation, they require:

Learning curve: Moderate. Easier for those with CAD/CAM or programming experience.

3. Training and Support Matter:

With structured training, even newcomers can learn to operate a milling machine safely and effectively. Many manufacturers and technical schools offer courses, certifications, or on-the-job training programs.

Conclusion:

While milling machines are not “plug and play,” they are not excessively difficult to operate—especially with proper instruction. The key is to combine technical knowledge, hands-on practice, and safety awareness. Once learned, milling becomes a highly rewarding and in-demand skill in the manufacturing industry.

The potential dangers of milling machines include contact with rotating parts, flying chips, entanglement, tool breakage, and electrical hazards. Hidden dangers may involve improper tool clamping, undetected wear, or software errors in CNC systems—all of which can lead to injury or part failure if not properly addressed.

Detailed Breakdown of Dangers

1. Contact with Moving Parts

Operators can accidentally touch rotating cutters, spindles, or lead screws.

2. Flying Chips and Debris

High-speed cutting generates hot metal chips that can cause eye or skin injuries.

3. Entanglement Hazards

Loose clothing, hair, or gloves can be caught in moving parts.

4. Tool Breakage and Ejection

Improper clamping or excessive feeds can cause tool breakage and projectile hazards.

5. Electrical Hazards

Faulty wiring, exposed circuits, or power surges may cause shocks or fires.

Hidden Dangers

6. Improper Tool or Workpiece Setup

Misaligned fixtures, loose bolts, or incorrect offsets may not be immediately obvious but can cause crashes or part defects.

7. Undetected Wear or Damage

Worn-out bearings, backlash, or cracks may not show visible symptoms until failure.

8. Software or Programming Errors (CNC)

Incorrect G-code, post-processing errors, or software bugs can result in unexpected tool paths.

9. Noise and Vibration

Excessive machine noise or vibration could indicate mechanical issues and affect operator health.

Summary Table

| Hazard Type |

Specific Danger |

Prevention Measures |

| Mechanical Contact |

Contact with rotating parts | Use guards, follow lockout/tagout procedures |

| Flying Debris |

Metal chips, tool breakage | Wear PPE, use chip shields |

| Entanglement |

Hair, clothing, gloves in moving parts | Avoid loose clothing, tie hair, don’t wear gloves |

| Tool Setup Errors |

Poor clamping, misalignment | Verify setup, use torque tools, simulate CNC programs |

| Electrical Hazards |

Shock, short circuit | Regular electrical inspections, use certified machines |

| Software Errors (CNC) |

Unexpected tool motion | Validate G-code, simulate before cutting |

| Wear and Tear |

Undetected machine/component failure | Implement scheduled maintenance and monitoring |

In conclusion, milling machines are indispensable tools in modern manufacturing, offering unmatched versatility, precision, and efficiency across a wide range of industries. From automotive and aerospace to electronics and woodworking, their ability to process complex parts with consistent quality makes them a cornerstone of CNC machining services and CNC machining factories worldwide. While they come with certain challenges such as cost, maintenance, and operational complexity, the benefits far outweigh these limitations for businesses seeking high-precision CNC machined parts. Understanding the types, technical parameters, and applications of milling machines empowers manufacturers to select the right equipment tailored to their specific needs.

Ultimately, investing in milling machines is a strategic decision that enhances productivity, innovation, and competitiveness in today’s fast-evolving industrial landscape.

Milling machines are powerful tools central to modern manufacturing, but their performance, longevity, and safety rely heavily on informed operation and proper management. Whether you're choosing the right model, learning to operate it, maintaining it for long-term use, or understanding where to buy one, each step demands careful consideration.

Routine maintenance—such as lubrication checks, environmental controls, and CNC software updates—ensures consistent accuracy and reduces the risk of breakdowns. Choosing the right machine involves evaluating control systems, machine type, power, size, and budget to meet your specific production needs. While operating a milling machine can be challenging at first, with the right training and safety awareness, both manual and CNC machines become accessible tools for professionals and beginners alike.

Finally, recognizing and mitigating potential hazards—from visible mechanical risks to hidden software and setup dangers—is essential for safe and efficient operation. By approaching milling machines with a combination of technical knowledge, preventative care, and safety discipline, you can ensure optimal results and long-term value in any machining environment.

1. What is the difference between a milling machine and a lathe?

A milling machine rotates a cutting tool to remove material from a stationary workpiece, while a lathe spins the workpiece against a stationary cutting tool. Milling is ideal for flat surfaces and complex shapes; lathes are best for cylindrical parts.

2. What is the difference between a milling machine and a router?

Milling machines are more rigid and designed for cutting metals and harder materials, while routers are lighter, typically used for wood, plastics, and soft materials. CNC routers operate at higher speeds but with less torque and precision.

3. What is the difference between a milling machine and a drilling machine?

A drilling machine makes vertical holes using a fixed tool, whereas a milling machine can cut in multiple directions (X, Y, and Z) and perform complex operations like contouring and slotting.

4. What is the difference between a milling machine and a machining center?

A machining center is an advanced CNC milling machine with automatic tool changers, enclosures, and sometimes multi-axis capabilities. It offers higher automation and productivity than standard milling machines.

5. Is CNC a milling machine?

CNC (Computer Numerical Control) refers to the control system. A CNC milling machine is a type of milling machine operated using CNC programming for high precision and automation.

6. Where are milling machines used?

Milling machines are used in automotive, aerospace, electronics, metalworking, medical, and manufacturing industries for producing precision parts, dies, molds, and components.

7. What are the three types of mills?

The three main types of milling machines are:

8. What is the difference between grinding and milling?

Milling removes material using a rotating cutter with teeth, while grinding uses an abrasive wheel for fine finishes and tight tolerances. Grinding is often used for surface finishing; milling is used for shaping and cutting.

9. Why is milling better than drilling?

Milling offers greater flexibility by allowing cuts in multiple directions and the ability to create complex shapes, slots, and contours—unlike drilling, which is limited to making round holes.

10. Are grinders the same as milling machines?

No. Grinders use abrasive wheels for precision surface finishing, while milling machines use toothed cutters to remove bulk material and shape parts. They serve different manufacturing purposes.

11. What are the three types of grinders?

The main types of grinders are:

12. What is the difference between machining and milling?

Machining is a broad term for material removal processes, including turning, drilling, grinding, and milling. Milling is one specific type of machining focused on rotary cutting tools.

13. Are milling and polishing the same?

No. Milling removes material to shape the part, while polishing smooths the surface finish after machining. Polishing is typically a final finishing step.

14. Which is better, down milling or reverse milling?

Down milling (climb milling) generally provides better surface finish and tool life but requires a rigid machine. Reverse milling (up milling) is safer on older or less rigid equipment.

15. How to calculate cutting speed?

Cutting speed (V) is calculated using the formula:

Where:

16. Which is better, lathe or milling machine?

It depends on the application. A lathe is better for turning round parts, while a milling machine excels at flat surfaces and complex geometries. Many machine shops use both for versatility.