15 years one-stop China custom CNC machining parts factory

81 |

Published by VMT at Aug 05 2025 | Reading Time:About 6 minutes

81 |

Published by VMT at Aug 05 2025 | Reading Time:About 6 minutes

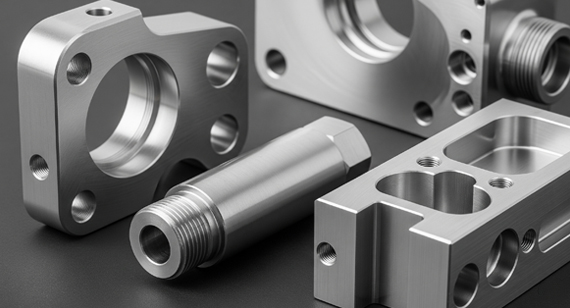

Choosing the right stainless steel for CNC machining can be overwhelming—especially when comparing popular grades like 416 and 316. Many engineers and purchasers struggle to balance machinability, corrosion resistance, and cost. One wrong choice can lead to project delays, cost overruns, or part failure. That’s why it’s critical to understand the unique differences between 416 stainless steel and 316 stainless steel.

VMT, a trusted name in stainless steel CNC machining services, knows that each material serves different applications and offers specific advantages. This article compares the two grades in depth, providing you with clear, actionable insights to make informed decisions on selecting the right stainless steel CNC machined parts.

416 stainless steel is a free-machining martensitic alloy ideal for applications requiring high precision and low corrosion exposure. In contrast, 316 stainless steel is an austenitic grade known for superior corrosion resistance, making it suitable for marine and chemical environments. Choosing between them depends on machinability needs, environment, and cost.

Understanding the core properties of each stainless steel type is the first step toward making the right choice. From chemical composition to mechanical performance, the distinctions between 416 and 316 stainless steel go beyond surface-level features. This article will guide you through every critical factor—ensuring your CNC machining projects meet both technical and economic requirements.

To explore how these materials affect performance, longevity, and cost-efficiency in real-world applications, continue reading. And if you’re considering custom stainless steel CNC machined parts, don't miss the insights from VMT’s CNC machining factory experts at the end of the article.

416 stainless steel is a free-machining martensitic stainless steel that belongs to the 400 series of stainless steels. It is specifically designed for exceptional machinability, making it one of the easiest stainless steels to process using CNC machining services. Due to its sulfur content, which enhances chip formation during cutting, 416 stainless steel is a popular choice for high-volume production of precision parts with tight tolerances. Common applications include gears, shafts, fasteners, valve components, and other stainless steel CNC machined parts that require fine detail and high-speed manufacturing.

While 416 stainless steel offers excellent machinability, it has moderate corrosion resistance compared to austenitic grades like 316. It performs best in environments where the risk of chemical or saltwater exposure is low. It is magnetic, can be hardened through heat treatment, and has good tensile strength, making it ideal for mechanical applications in automotive, firearms, and industrial equipment sectors.

CNC machining factories favor 416 stainless steel because it reduces tool wear and machining time, translating to lower production costs. However, it's not suitable for applications involving severe corrosion, such as marine or food-grade environments, due to its relatively low chromium and nickel content. When corrosion resistance is not a top priority but machining efficiency is, 416 stainless steel CNC machined parts are a smart and economical solution.

416 stainless steel is part of the martensitic stainless steel family and is commonly compared to several other stainless steel grades in terms of machinability and mechanical properties. One of its closest equivalents is UNS S41600, which is its Unified Numbering System (UNS) designation. In European standards, it aligns with EN 1.4005. In Japan, it corresponds to SUS416, and in the British standard system, it is often referred to as BS 416S21.

From a material performance perspective, 416 stainless steel is often compared to other free-machining steels like 303 stainless steel. However, while 303 is an austenitic grade with better corrosion resistance, 416 offers superior hardness and strength due to its martensitic structure, along with better machinability. It can also be considered a lower-corrosion alternative to 420 stainless steel when high machinability is required.

In terms of industry usage, CNC machining factories often regard 416 stainless steel as the go-to material for producing stainless steel CNC machined parts where mechanical strength and fast turnaround times are critical but where exposure to harsh corrosive environments is limited. For components like bushings, bolts, spindles, and motor shafts, 416 stainless steel CNC machined parts provide an ideal balance of performance and cost.

When evaluating material equivalency, it's important to consider the application requirements, such as heat treatment capabilities, hardness, and corrosion exposure. Although equivalent in standards or classification, not all materials offer the same field performance. Consulting CNC machining service providers like VMT can help ensure the right steel grade is selected based on your project's specific demands.

316 stainless steel is an austenitic chromium-nickel stainless steel alloy containing 2–3% molybdenum, which significantly enhances its resistance to corrosion—especially against chlorides and other industrial solvents. It is one of the most corrosion-resistant standard stainless steels available and is widely used in harsh environments such as marine, chemical processing, food handling, and medical applications.

Unlike martensitic steels like 416, 316 stainless steel cannot be hardened by heat treatment. However, it offers excellent formability, weldability, and toughness even at cryogenic temperatures. Its chemical stability and durability make it the preferred material for critical parts exposed to saltwater, acidic environments, or repeated sterilization.

From the perspective of CNC machining services, 316 stainless steel is more challenging to machine than 416 due to its work-hardening properties and high ductility. It requires slower cutting speeds, more rigid tooling setups, and often leads to increased machining costs. Despite this, CNC machining factories continue to manufacture 316 stainless steel CNC machined parts when reliability, hygiene, or resistance to corrosion is a top priority.

Common applications for 316 stainless steel CNC machined parts include valves, pump components, marine hardware, surgical tools, and chemical processing equipment. It also has a low magnetic permeability, making it ideal for environments where magnetism can be problematic. For industries where safety, hygiene, and long-term durability are critical, 316 stainless steel offers a trusted, high-performance solution.

The answer depends entirely on the application. Neither 416 stainless steel nor 316 stainless steel is inherently “better” in all situations—they each offer distinct advantages tailored to specific performance demands. Understanding the differences between the two helps CNC machining service users make smarter decisions based on priorities like corrosion resistance, machinability, strength, and cost.

For projects where ease of machining, high-volume production, and tight tolerances are the top priorities, 416 stainless steel is the better option. It is highly machinable—often regarded as one of the most machinable stainless steels available—which means shorter cycle times, lower tool wear, and reduced machining costs. This makes 416 stainless steel CNC machined parts ideal for mechanical components such as shafts, bushings, gears, and firearm parts where exposure to harsh environments is limited.

In contrast, 316 stainless steel excels in applications where corrosion resistance and durability in harsh environments are essential. Thanks to its molybdenum content, 316 is far more resistant to chlorides, saltwater, and acidic chemicals than 416. It’s the preferred choice in marine, chemical, pharmaceutical, and food processing industries. Although it’s more difficult to machine, 316 stainless steel CNC machined parts offer longevity and safety in critical applications.

In summary, choose 416 stainless steel for precision, budget-conscious machining in non-corrosive environments. Choose 316 stainless steel when corrosion resistance, long-term strength, and material integrity are critical. CNC machining factories like VMT help clients evaluate both material types to determine which stainless steel CNC machined parts will deliver the best results for their unique project.

Here's a clear and professional comparison table for 416 stainless steel vs. 316 stainless steel, focusing on the key factors buyers and engineers consider when choosing materials for CNC machined parts.

416 Stainless Steel vs. 316 Stainless Steel: Which Is Better?

| Category |

416 Stainless Steel |

316 Stainless Steel |

| Machinability |

Excellent – one of the most machinable stainless steels | Fair – work-hardens quickly, requires slower speeds |

| Corrosion Resistance |

Moderate – not suitable for marine or acidic environments | Excellent – ideal for marine, chemical, and medical uses |

| Magnetism |

Magnetic – due to martensitic structure | Non-magnetic – austenitic microstructure |

| Heat Treatment |

Can be hardened by heat treatment | Cannot be hardened by heat treatment |

| Weldability |

Poor – high sulfur content affects welds | Good – easily weldable with appropriate filler metals |

| Tensile Strength |

Moderate to high (after hardening) | High – retains strength at elevated temperatures |

| Applications |

Gears, shafts, firearm components, fasteners | Valves, marine parts, medical devices, food-grade equipment |

| Cost |

Lower – budget-friendly for non-corrosive settings | Higher – premium due to alloying elements and corrosion resistance |

| Formability |

Limited – more brittle, less ductile | Excellent – highly ductile and formable |

| Ideal Use Case |

High-speed precision machining in dry or clean environments | Harsh environments, especially with salt, chemicals, or acids |

This table summarizes the core differences and provides a side-by-side view of each grade’s performance. It helps buyers and engineers at CNC machining factories quickly assess which material is better for their specific stainless steel CNC machined part requirements.

While both 416 and 316 stainless steels fall under the broader category of stainless steel, their internal compositions and performance capabilities differ significantly. These differences affect their suitability for various applications, particularly when it comes to CNC machining services. From corrosion resistance and machinability to strength and thermal characteristics, each alloy serves distinct roles in the manufacturing of stainless steel CNC machined parts.

Understanding these differences is essential for engineers, procurement teams, and product designers who work closely with CNC machining factories. Making an informed material selection not only affects the functionality of the final product but also influences overall cost, machining speed, and long-term durability.

Let’s begin the comparison with one of the most important differentiators: chemical composition

416 Stainless Steel vs. 316 Stainless Steel: Chemical Composition

The chemical composition of a stainless steel alloy determines its corrosion resistance, mechanical strength, heat tolerance, and machinability. While both 416 and 316 stainless steels contain iron and chromium as their base elements, the presence (or absence) of other alloying elements like nickel, molybdenum, and sulfur leads to vastly different material behaviors. This is especially important when evaluating the two materials for use in CNC machined parts or assessing their compatibility with CNC machining services.

Here’s a detailed breakdown of their chemical composition:

Chemical Composition Table

| Element |

416 Stainless Steel (% by weight) |

316 Stainless Steel (% by weight) |

| Carbon (C) |

≤ 0.15 | ≤ 0.08 |

| Iron (Fe) |

Balance | Balance |

| Chromium (Cr) |

12.0 – 14.0 | 16.0 – 18.0 |

| Nickel (Ni) |

≤ 1.25 | 10.0 – 14.0 |

| Manganese (Mn) |

≤ 1.25 | ≤ 2.0 |

| Molybdenum (Mo) |

— | 2.0 – 3.0 |

| Silicon (Si) |

≤ 1.0 | ≤ 1.0 |

| Nitrogen (N) |

— | ≤ 0.10 |

| Phosphorus (P) |

≤ 0.06 | ≤ 0.045 |

| Sulfur (S) |

≥ 0.15 (enhanced machinability) | ≤ 0.03 |

Analysis

The high sulfur content in 416 stainless steel is key to its excellent machinability, making it a top choice for CNC machining factories focused on high-speed, precision production. However, that same sulfur reduces its corrosion resistance, limiting its use in wet or chemical environments.

316 stainless steel, on the other hand, contains significant levels of nickel and molybdenum, which significantly boost its resistance to pitting and crevice corrosion—especially in marine or chloride-heavy settings. This makes it a leading material for 316 stainless steel CNC machined parts used in medical, food-grade, or offshore applications.

416 Stainless Steel vs. 316 Stainless Steel: Physical Properties

Physical properties play a critical role in determining how stainless steels perform under thermal, mechanical, and environmental stress. When evaluating materials for stainless steel CNC machined parts, manufacturers must consider factors like density, conductivity, corrosion resistance, and machinability. These properties influence not only the manufacturing process but also the functionality and lifespan of the final component. Whether you're sourcing from CNC machining factories or engineering parts for critical applications, understanding how 416 stainless steel and 316 stainless steel differ in their physical behavior is essential for making the right material choice.

Physical Properties Comparison Table

| Property |

416 Stainless Steel |

316 Stainless Steel |

| Density |

~7.75 g/cm³ | ~7.99 g/cm³ |

| Melting Point (°C) |

1480 – 1530 | 1370 – 1400 |

| Thermal Conductivity (W/m·K) |

~24.9 at 100°C | ~16.3 at 100°C |

| Electrical Resistivity (Ω·m) |

~0.57 × 10⁻⁶ | ~0.74 × 10⁻⁶ |

| Linear Thermal Expansion (10⁻⁶/K) |

~9.9 | ~16.0 |

| Corrosion Resistance |

Moderate – suitable for dry environments | Excellent – resistant to chlorides & acids |

| Wear Resistance |

Good – improved when heat-treated | Moderate – not ideal for abrasion |

| Oxidation Resistance |

Fair – lower at high temperatures | High – excellent at elevated temperatures |

| Welding |

Poor – not recommended due to sulfur | Excellent – widely used in welded structures |

| Magnetic Properties |

Magnetic | Non-magnetic (in annealed condition) |

| Formability |

Poor – less ductile and formable | Excellent – highly ductile and malleable |

| Machinability (Annealed) |

Excellent – best among stainless steels | Moderate – work hardens during machining |

Analysis

When it comes to physical properties, 416 stainless steel offers superior machinability and thermal conductivity, making it ideal for high-speed production of stainless steel CNC machined parts. Its magnetic properties and ability to be hardened through heat treatment make it suitable for mechanical components that demand precision and strength without extreme corrosion exposure.

In contrast, 316 stainless steel demonstrates far better corrosion resistance, oxidation stability, and formability—key factors for applications in marine, medical, and food-processing industries. Although more challenging to machine, its performance under extreme environments justifies its use in high-value CNC machining services.

For CNC machining factories focused on performance-driven components that must withstand aggressive environments, 316 stainless steel is the preferred material. However, for cost-effective machining where corrosion is not a primary concern, 416 stainless steel CNC machined parts provide excellent value.

416 Stainless Steel vs. 316 Stainless Steel: Mechanical Properties

Mechanical properties are vital when selecting stainless steel grades for CNC machining services, as they determine how the material behaves under stress, strain, and repeated use. Whether producing precision stainless steel CNC machined parts for high-performance machinery or corrosion-resistant components, understanding the differences in hardness, tensile strength, ductility, and fatigue resistance between 416 stainless steel and 316 stainless steel ensures optimal material selection for each application.

Mechanical Properties Comparison Table

| Property |

416 Stainless Steel |

316 Stainless Steel |

| Hardness (HRC) |

24 – 30 (annealed), up to 50 (hardened) | 70 – 90 HRB (annealed) |

| Hardness (HV) |

230 – 300 | 150 – 250 |

| Tensile Strength (MPa) |

650 – 850 | 515 – 720 |

| Elongation at Yield (Rp0.2/MPa) |

~0.2% – 0.3% | 40% |

| Ductility (%) |

10 – 15 | 40 – 60 |

| Ultimate Tensile Strength (MPa) |

620 – 900 | 580 – 750 |

| Yield Tensile Strength (MPa) |

310 – 690 | 205 – 310 |

| Reduction of Area (Z/%) |

30 – 40 | 60 – 70 |

| Heating Temperature (°C) |

980 – 1050 | Not typically heat-treated |

| Elastic (Young’s) Modulus (GPa) |

~200 |

~193 |

| Elongation at Break (%) |

10 – 20 | 40 – 60 |

| Fatigue Strength (MPa) |

Moderate (variable by heat treatment) | High – suitable for cyclic loading |

| Shear Strength (MPa) |

~450 – 600 | ~450 |

| Shear Modulus (GPa) |

~75 | ~77 |

| Poisson’s Ratio |

~0.27 | ~0.30 |

| Reduction of Area |

Moderate | High |

Analysis

416 stainless steel displays higher hardness and tensile strength, especially after heat treatment, making it suitable for applications requiring wear resistance and structural integrity. However, its ductility and elongation are limited compared to 316, restricting its use in applications demanding flexibility.

In contrast, 316 stainless steel offers excellent ductility and elongation, combined with moderate strength, making it ideal for components that experience repeated deformation or cyclic loads. Its superior fatigue strength and reduction of area highlight its durability in dynamic environments.

For manufacturers and CNC machining factories, choosing 416 stainless steel CNC machined parts means prioritizing mechanical strength and machinability in less corrosive environments. When corrosion resistance and mechanical flexibility are paramount, 316 stainless steel CNC machined parts are the preferred choice.

When deciding between 416 stainless steel and 316 stainless steel for CNC machined parts, understanding their respective advantages and disadvantages is crucial. Each alloy offers unique benefits and limitations that impact manufacturing processes, cost, and end-use performance. This section provides a clear overview of the strengths and weaknesses of both materials, helping engineers and procurement teams working with CNC machining services and factories make informed choices for their stainless steel CNC machined parts.

416 Stainless Steel: Advantages and Disadvantages

416 stainless steel is widely recognized for its outstanding machinability and mechanical strength, making it a favored choice for specific industrial applications. However, its limitations in corrosion resistance and weldability restrict its use in certain environments.

Advantages of 416 Stainless Steel

Disadvantages of 416 Stainless Steel

316 Stainless Steel: Advantages and Disadvantages

316 stainless steel is highly valued for its superior corrosion resistance and versatility across demanding industries. While it offers many benefits, it also comes with challenges, especially in machining and cost.

Advantages of 316 Stainless Steel

Disadvantages of 316 Stainless Steel

This comprehensive comparison of advantages and disadvantages enables manufacturers, designers, and buyers to match material properties to their project demands accurately. Whether cost-efficiency or corrosion resistance is the priority, both 416 stainless steel CNC machined parts and 316 stainless steel CNC machined parts have defined roles in CNC machining factories and services.

summarizing the advantages and disadvantages of 416 stainless steel and 316 stainless steel:

416 Stainless Steel vs. 316 Stainless Steel: Advantages and Disadvantages

| Aspect |

416 Stainless Steel |

316 Stainless Steel |

| Advantages | - Excellent machinability, ideal for fast, high-volume CNC machining | - Superior corrosion resistance, especially in marine and chemical environments |

| - Good mechanical strength, can be heat treated for wear resistance | - Good formability and weldability, enabling complex part fabrication | |

| - Magnetic properties useful for specific industrial applications | - Non-magnetic in annealed condition, suitable for sensitive applications | |

| - Cost-effective, lower material cost | - High durability in harsh environments and elevated temperatures | |

| - Quick production turnaround due to ease of machining | - Long-term reliability in food, medical, and offshore applications | |

| Disadvantages | - Moderate corrosion resistance, unsuitable for highly corrosive or marine environments | - Lower machinability; work-hardens, increasing tooling wear and machining time |

| - Poor weldability because of high sulfur content | - Higher material and machining costs | |

| - Limited formability and ductility | - Longer production lead times due to machining challenges | |

| - Magnetic nature may be a limitation for some applications | - Slight magnetic properties may develop after cold working |

This table helps clarify the trade-offs between the two stainless steel grades, supporting informed decisions for customers seeking stainless steel CNC machined parts through CNC machining services and CNC machining factories.

Heat treatment plays a crucial role in determining the mechanical properties and performance of stainless steel CNC machined parts. The ability to modify hardness, strength, and toughness through controlled heating and cooling processes differentiates 416 stainless steel and 316 stainless steel significantly.

416 stainless steel is a martensitic stainless steel, which means it can be heat treated to improve hardness and tensile strength. Typically, 416 undergoes annealing to soften the material for machining, followed by quenching and tempering to achieve the desired mechanical properties. This heat treatment flexibility makes 416 stainless steel CNC machined parts highly adaptable for applications requiring enhanced wear resistance and strength. Heat treatment temperatures for 416 range from approximately 980°C to 1050°C, followed by rapid cooling.

On the other hand, 316 stainless steel is an austenitic stainless steel that cannot be hardened by conventional heat treatment processes. Instead, its mechanical properties rely primarily on cold working and alloy composition. Annealing of 316 stainless steel is usually performed at around 1040°C to 1120°C to relieve stress and restore ductility after machining or forming operations. This annealing improves corrosion resistance but does not increase hardness significantly. For CNC machining factories producing 316 stainless steel CNC machined parts, this means the material requires careful machining strategies to accommodate its toughness and work-hardening behavior.

In summary, heat treatment offers a decisive advantage to 416 stainless steel in terms of hardness and wear resistance customization, making it suitable for parts requiring mechanical strength optimization. Conversely, 316 stainless steel’s strength comes from its inherent corrosion resistance and ductility, with heat treatment primarily used for stress relief and improved corrosion performance.

416 Stainless Steel vs. 316 Stainless Steel: Heat Treatment

| Aspect |

416 Stainless Steel |

316 Stainless Steel |

| Heat Treatability |

Can be heat treated (martensitic) | Cannot be hardened by heat treatment (austenitic) |

| Common Heat Treatment Processes |

Annealing, quenching, tempering | Annealing (stress relief) |

| Annealing Temperature |

~840°C – 900°C (softening for machining) | ~1040°C – 1120°C (stress relief and recrystallization) |

| Hardening Temperature |

~980°C – 1050°C (followed by rapid cooling) | Not applicable |

| Effect of Heat Treatment |

Increases hardness, tensile strength, wear resistance | Relieves internal stresses, improves corrosion resistance |

| Purpose of Heat Treatment |

To optimize mechanical properties and machinability | To restore ductility and reduce residual stress after machining/forming |

| Impact on Machinability |

Improves machinability after annealing, harder after tempering | Stress relief annealing prevents work hardening during machining |

This table clearly contrasts the heat treatment capabilities and purposes of 416 and 316 stainless steel, helping customers and engineers at CNC machining factories select the best material for their stainless steel CNC machined parts.

Choosing between 416 stainless steel and 316 stainless steel largely depends on the intended application and environmental conditions. Each material’s unique properties make it suited for specific industries and parts, particularly when manufactured as stainless steel CNC machined parts through advanced CNC machining services.

416 stainless steel is widely used in applications where high machinability and mechanical strength are paramount, but corrosion resistance demands are moderate. Its free-machining capability makes it an excellent choice for precision components such as gears, shafts, fasteners, valve components, and firearm parts. Industries like automotive, manufacturing, and machinery benefit from 416 stainless steel CNC machined parts, especially when components need to withstand wear and mechanical stress without exposure to harsh corrosive environments.

In contrast, 316 stainless steel is preferred in environments requiring exceptional corrosion resistance and durability. It is extensively used in marine, chemical processing, pharmaceutical, food processing, and medical industries. Typical 316 stainless steel CNC machined parts include pumps, valves, surgical instruments, marine hardware, and chemical containers. The alloy’s resistance to saltwater, acids, and extreme temperatures makes it indispensable for parts operating in aggressive or sanitary conditions.

CNC machining factories often recommend 416 stainless steel when manufacturing cost-effective, mechanically strong parts with low corrosion risk, while 316 stainless steel is chosen for applications prioritizing corrosion resistance and hygiene. For clients seeking stainless steel CNC machined parts tailored to specific performance criteria, consulting with CNC machining service providers like VMT ensures optimal material and process selection.

summarizing the applications and uses of 416 stainless steel versus 316 stainless steel:

416 Stainless Steel vs. 316 Stainless Steel: Applications and Uses

| Applications |

416 Stainless Steel |

316 Stainless Steel |

| Typical Uses |

Gears, shafts, fasteners, valve components, firearm parts | Pumps, valves, surgical instruments, marine hardware, chemical containers |

| Industries |

Automotive, manufacturing, machinery | Marine, chemical processing, pharmaceutical, food processing, medical |

| Environmental Suitability |

Moderate corrosion environments, dry or clean settings | Harsh, corrosive, acidic, and marine environments |

| Mechanical Requirements |

High machinability and wear resistance | Superior corrosion resistance and durability |

| Hygiene and Sterility Applications |

Not typically used | Widely used in food, pharmaceutical, and medical industries |

| Cost Considerations |

Cost-effective for non-corrosive applications | Higher cost justified by superior corrosion resistance |

This table highlights the distinct use cases and industries where each stainless steel grade excels, guiding customers and engineers in selecting the best material for their stainless steel CNC machined parts.

Cost is a critical factor when selecting materials for stainless steel CNC machined parts, especially in large-scale manufacturing. Both the initial material cost and the long-term financial implications should be carefully weighed. CNC machining services and factories must balance upfront expenses with the expected performance and maintenance costs over a component’s lifecycle. This section compares the initial cost and long-term benefits of 416 stainless steel and 316 stainless steel to help customers make informed purchasing decisions.

Initial Cost Comparison

Typically, 416 stainless steel is more affordable than 316 stainless steel. The lower alloy content, especially the reduced levels of nickel and molybdenum, significantly decreases the raw material price. Additionally, 416’s excellent machinability reduces tooling wear and machining time, translating into lower manufacturing costs for stainless steel CNC machined parts. This cost advantage makes 416 an attractive option for applications where corrosion resistance is less critical.

In contrast, 316 stainless steel commands a higher price due to its premium alloy composition that includes nickel and molybdenum. These elements contribute to superior corrosion resistance and durability but increase material costs. Furthermore, the more challenging machining process of 316 stainless steel CNC machined parts often results in longer production times and higher labor costs.

Long-Term Cost Benefits

While 416 stainless steel offers lower upfront costs, 316 stainless steel can provide better long-term value in corrosive or harsh environments. The superior corrosion resistance reduces maintenance, replacement frequency, and downtime, especially in marine, chemical, and food processing applications. These factors can translate into substantial savings over the lifecycle of the product.

Moreover, the durability of 316 stainless steel CNC machined parts often prevents costly failures and improves safety and reliability, which are critical in many industrial applications.

Ultimately, the choice between 416 and 316 stainless steel should consider not only initial manufacturing budgets but also the expected operating environment and maintenance requirements to optimize total cost of ownership.

Here’s a concise and clear table comparing the cost and pricing aspects of 416 stainless steel versus 316 stainless steel:

416 Stainless Steel vs. 316 Stainless Steel: Cost and Pricing

| Cost Aspect |

416 Stainless Steel |

316 Stainless Steel |

| Initial Material Cost |

Lower — due to reduced nickel and molybdenum content | Higher — premium alloying elements increase raw material cost |

| Machining Cost |

Lower — excellent machinability reduces tool wear and time | Higher — work-hardening requires slower machining, increasing labor and tooling costs |

| Production Lead Time |

Shorter — faster machining speeds and less complexity | Longer — slower machining and careful processing required |

| Maintenance Costs |

Potentially higher — moderate corrosion resistance may lead to more frequent replacements or repairs | Lower — superior corrosion resistance reduces maintenance and replacement frequency |

| Total Cost of Ownership |

Cost-effective for non-corrosive environments or short-term use | More cost-efficient for harsh or corrosive environments due to longevity and reliability |

This table helps customers and engineers at CNC machining factories quickly evaluate cost trade-offs between 416 and 316 stainless steel for their stainless steel CNC machined parts.

To ensure quality and consistency, stainless steel grades like 416 and 316 are specified by various national and international standards. These standards define the chemical composition, mechanical properties, and processing requirements. For CNC machining factories and service providers, knowing these equivalent grades helps ensure compliance and compatibility across different markets.

National Standards and Equivalent Grades Comparison

| Standard/Specification |

416 Stainless Steel |

316 Stainless Steel |

| ASTM (American Society for Testing and Materials) |

ASTM A276 Grade 416 | ASTM A276 Grade 316 / 316L |

| UNS (Unified Numbering System) |

UNS S41600 | UNS S31600 (316) / UNS S31603 (316L) |

| JIS (Japanese Industrial Standards) |

JIS SUS 416 | JIS SUS 316 / SUS 316L |

| DIN (German Institute for Standardization) |

DIN 1.4005 | DIN 1.4401 (316) / DIN 1.4404 (316L) |

| EN (European Standard) |

EN 10088-3 (similar grades) | EN 10088-3 (similar grades) |

| ISO (International Organization for Standardization) |

ISO 683-17 | ISO 683-17 |

This table assists engineers, manufacturers, and procurement professionals in identifying the correct stainless steel grades based on internationally recognized standards for stainless steel CNC machined parts.

Selecting the right stainless steel grade is critical to ensuring the performance, durability, and cost-effectiveness of stainless steel CNC machined parts. Both 416 and 316 stainless steels offer distinct advantages tailored to specific applications and environments. Understanding their differences helps engineers, designers, and procurement teams make informed decisions, especially when working with CNC machining services and factories that demand precision and reliability.

When Should I Use 416 Stainless Steel?

416 stainless steel is ideal for applications that prioritize high machinability and mechanical strength with moderate corrosion resistance requirements. It is the preferred choice when rapid, cost-effective production of precision components is needed. Typical scenarios include:

This makes 416 stainless steel CNC machined parts a popular option for automotive, industrial machinery, and equipment manufacturing.

When Should I Use 316 Stainless Steel?

316 stainless steel is best suited for applications demanding superior corrosion resistance, especially in harsh or corrosive environments. It excels where longevity, hygiene, and durability are paramount. Common use cases include:

For customers requiring stainless steel CNC machined parts with exceptional resistance to corrosion and chemical exposure, 316 stainless steel is the preferred material choice in CNC machining services and factories.

This clear guidance enables manufacturers and clients to align material selection with project requirements, optimizing performance and cost in stainless steel CNC machined parts production.

How to Choose Between 416 and 316 Stainless Steel?

| Criteria |

416 Stainless Steel |

316 Stainless Steel |

| Primary Use |

Mechanical parts requiring high machinability and strength | Corrosion-resistant parts for harsh and corrosive environments |

| Corrosion Resistance |

Moderate; suitable for dry or mild environments | Excellent; ideal for marine, chemical, and medical applications |

| Machinability |

Excellent; fast and cost-effective CNC machining | Moderate; work hardens, requiring slower machining |

| Magnetic Properties |

Magnetic | Non-magnetic (annealed condition) |

| Heat Treatment Capability |

Can be heat treated to increase hardness | Cannot be hardened by heat treatment; annealing for stress relief |

| Typical Applications |

Gears, shafts, fasteners, valve components | Marine hardware, surgical instruments, chemical processing parts |

| Cost Consideration |

Lower initial and machining costs | Higher initial and machining costs, but better long-term value |

| Suitability for Food & Medical |

Not recommended | Widely used due to hygiene and corrosion resistance |

| Environmental Suitability |

Best for non-corrosive or mildly corrosive environments | Best for highly corrosive and extreme environments |

This table helps customers, engineers, and procurement teams working with CNC machining factories quickly determine the most suitable stainless steel grade for their stainless steel CNC machined parts.

When comparing 416 stainless steel and Grade 8 steel, it’s important to understand that these two materials serve different purposes and have distinct mechanical properties.

416 stainless steel is a martensitic stainless steel known for its excellent machinability, moderate corrosion resistance, and ability to be heat treated for increased hardness and strength. After proper heat treatment, 416 stainless steel can reach tensile strengths of approximately 650 to 850 MPa, with hardness up to 50 HRC, making it suitable for wear-resistant parts and precision components.

Grade 8 steel, on the other hand, is a high-strength alloy steel commonly used for fasteners such as bolts and nuts. It typically offers tensile strength above 1,200 MPa and a hardness range of 33 to 39 HRC. Grade 8 steel is designed primarily for high-load structural applications rather than corrosion resistance.

In terms of pure strength, Grade 8 steel is generally stronger than 416 stainless steel, especially in tensile strength and yield strength. However, 416 stainless steel offers the advantage of corrosion resistance and machinability, which Grade 8 steel lacks.

For applications requiring high mechanical strength without corrosion exposure, Grade 8 steel is often preferred. Conversely, if moderate corrosion resistance, good machinability, and reasonable strength are required—such as in precision CNC machining services—416 stainless steel CNC machined parts provide a balanced solution.

Choosing between 416 stainless steel and 316 stainless steel depends largely on the specific requirements of your project, including environmental conditions, mechanical demands, and budget considerations. Both stainless steel grades are widely used in CNC machining services and factories, but their properties make them better suited for different applications.

If your project demands high machinability, mechanical strength, and cost efficiency, and the parts will be used in moderate or non-corrosive environments, then 416 stainless steel CNC machined parts are likely the best fit. This grade is excellent for precision components such as gears, shafts, and fasteners, especially when quick production turnaround and heat treatment options are essential.

On the other hand, if your project requires exceptional corrosion resistance, durability in harsh environments, and non-magnetic properties, 316 stainless steel CNC machined parts are the superior choice. This stainless steel excels in marine, chemical processing, food, and medical applications where exposure to corrosive substances and stringent hygiene standards are common.

Ultimately, the right material choice depends on balancing performance with budget. Consulting with experienced CNC machining services can help evaluate your project’s needs and recommend the most suitable stainless steel grade, ensuring your parts meet quality, reliability, and cost goals.

At VMT, we specialize in delivering high-quality stainless steel CNC machined parts tailored to meet the diverse needs of industries ranging from automotive to medical, marine to manufacturing. Whether your project requires 416 stainless steel CNC machined parts known for superior machinability or 316 stainless steel CNC machined parts prized for corrosion resistance, VMT provides comprehensive CNC machining services backed by advanced technology and expert craftsmanship.

Our CNC machining factories are equipped with state-of-the-art equipment capable of precision milling, turning, drilling, and finishing processes that guarantee dimensional accuracy and surface quality. With strict quality control and adherence to international standards, we ensure every part meets or exceeds client specifications.

VMT’s team of experienced engineers collaborates closely with customers to select the right stainless steel grade, optimize design for manufacturability, and streamline production schedules. Our deep understanding of material properties and machining techniques enables us to deliver cost-effective solutions without compromising performance.

By choosing VMT as your trusted partner, you gain access to reliable, efficient, and flexible CNC machining services tailored to produce durable, high-performance stainless steel parts that fit your exact application requirements.

Choosing between 416 stainless steel and 316 stainless steel depends on the specific demands of your project, including environmental conditions, mechanical requirements, and budget considerations. 416 stainless steel excels in applications requiring excellent machinability, good mechanical strength, and cost-effective production, making it ideal for parts used in moderately corrosive or dry environments. Conversely, 316 stainless steel stands out for its superior corrosion resistance, durability in harsh environments, and suitability for sanitary or marine applications.

For manufacturers and clients seeking precision and reliability, working with experienced CNC machining factories and service providers like VMT ensures the selection of the most appropriate stainless steel grade. By aligning material properties with application needs, VMT delivers high-quality, durable stainless steel CNC machined parts that meet exacting standards.

Whether your priority is machining efficiency or corrosion resistance, understanding the differences between 416 and 316 stainless steel empowers informed decisions that optimize performance, cost, and longevity. Partnering with trusted CNC machining services guarantees expert guidance and quality production tailored to your unique requirements.

What is the Difference Between 416 and 316L?

416 stainless steel is a martensitic grade known for excellent machinability and moderate corrosion resistance, while 316L is a low-carbon austenitic stainless steel with superior corrosion resistance, especially in harsh environments. 316L is often chosen for applications needing weldability and enhanced corrosion protection.

Does 416 Stainless Steel Rust?

416 stainless steel can rust if exposed to highly corrosive or marine environments because it has lower corrosion resistance compared to grades like 316 stainless steel. Proper coatings or maintenance are recommended to prevent rust.

Is 416 Stainless Steel Food-Grade?

Generally, 416 stainless steel is not considered food-grade due to its moderate corrosion resistance. For food processing applications, 316 stainless steel CNC machined parts are preferred for hygiene and corrosion resistance.

What Are the Differences Between 304, 316, and 416?

304 and 316 are austenitic stainless steels with excellent corrosion resistance; 316 offers higher corrosion resistance due to added molybdenum. 416 is martensitic, offering better machinability and strength but less corrosion resistance than 304 and 316.

What Grade Is High-Quality Stainless Steel?

Grades such as 316 and 316L are considered high-quality due to their excellent corrosion resistance, durability, and suitability for demanding environments. Selection depends on specific application needs.

Is 416 Stainless Steel Magnetic?

Yes, 416 stainless steel is magnetic because of its martensitic structure, unlike 316 stainless steel, which is generally non-magnetic in its annealed state.

Which Type of Stainless Steel Is Best?

The best type depends on the application: 416 stainless steel for machinability and mechanical strength; 316 stainless steel for corrosion resistance and durability in harsh environments.

Why Is 316 More Expensive Than 304?

316 stainless steel contains molybdenum and higher nickel content, which increase corrosion resistance but also raise material costs compared to 304 stainless steel.

What Are the Strength Grades of Stainless Steel?

Strength varies by grade and heat treatment. Martensitic grades like 416 have higher hardness and tensile strength after heat treatment, while austenitic grades like 316 offer lower strength but higher ductility.

Can 416 Stainless Steel Be Hardened?

Yes, 416 stainless steel can be hardened through heat treatment processes such as quenching and tempering to improve hardness and wear resistance.

Is 316 Stainless Steel Magnetic?

316 stainless steel is generally non-magnetic in the annealed state, but slight magnetism may develop after cold working or welding.

Which Grade of Stainless Steel Is the Most Affordable?

Grades like 304 and 416 are generally more affordable compared to 316 due to their lower alloying content.

Is 416 Stainless Steel Suitable for Knives?

Yes, 416 stainless steel is often used for knife blades due to its good hardness and machinability, though it may require protective coatings for corrosion resistance.

Is 416 Stainless Steel Easy to Machine?

Yes, 416 stainless steel is prized for its excellent machinability, making it ideal for precision CNC machining services and factories.

What Does the "L" in 316L Stainless Steel Stand For?

The "L" denotes "Low Carbon," indicating reduced carbon content that improves weldability and reduces the risk of sensitization and corrosion along welds.

Is 416 Stainless Steel Better Than 304 Stainless Steel?

"Better" depends on use: 416 offers superior machinability and hardness; 304 provides better corrosion resistance and is preferred for general-purpose applications.