15 years one-stop China custom CNC machining parts factory

192 |

Published by VMT at Sep 05 2025 | Reading Time:About 4 minutes

192 |

Published by VMT at Sep 05 2025 | Reading Time:About 4 minutes

When choosing the right surface treatment for CNC machined parts, many engineers face the same problem: anodizing is widely used but may not offer enough protection, while micro-arc oxidation (MAO), also called plasma electrolytic oxidation (PEO), seems complex and costly. Without clear guidance, project costs rise, and performance expectations are not met.

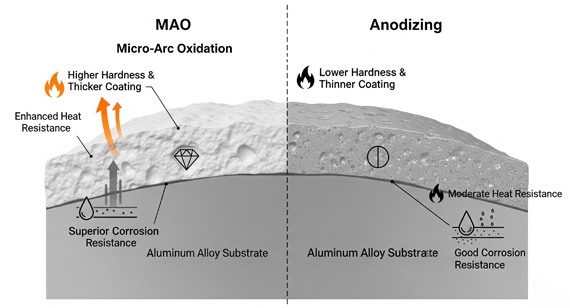

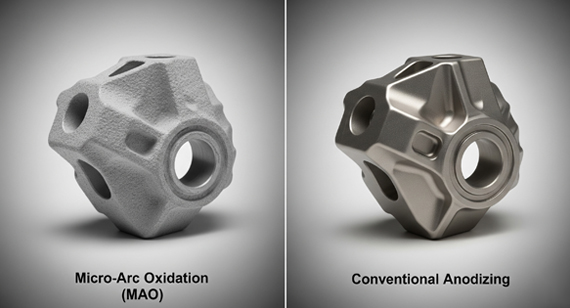

Micro-arc oxidation (MAO) or plasma electrolytic oxidation (PEO) creates thicker, harder, and more wear-resistant ceramic coatings compared to anodizing. While anodizing is ideal for cost-effective corrosion protection, MAO offers superior durability, thermal resistance, and adhesion, making it more suitable for high-performance CNC machined parts.

To help you choose the right process, let’s explore what MAO and anodizing are, their differences, and how they affect CNC machining projects.

Micro-arc oxidation, also called plasma electrolytic oxidation, is an advanced electrochemical process that forms a ceramic oxide coating on lightweight metals such as aluminum, magnesium, and titanium. Unlike traditional anodizing, MAO uses higher voltages, which create plasma micro-discharges on the metal surface. These sparks generate localized high temperatures and pressures, resulting in a dense and extremely hard oxide layer.

This coating improves wear resistance, corrosion resistance, and thermal stability, making MAO ideal for aerospace, automotive, defense, and medical CNC machined parts.

Anodizing is a simpler and more cost-effective electrochemical process that increases the thickness of the natural oxide layer on aluminum and some other nonferrous metals. The process uses lower voltages than MAO, creating a controlled, uniform oxide film.

Anodizing improves corrosion resistance, enhances appearance through coloring, and provides moderate wear resistance. It is widely used in consumer products, electronics, and industrial CNC machined parts where cost control and surface aesthetics are priorities.

Anodizing is a common surface treatment used on aluminum CNC machined parts. It not only improves corrosion resistance but also allows coloring and enhances wear performance. Depending on application needs, there are three main types of anodizing: chromic acid (Type I), sulfuric acid (Type II), and hard anodizing (Type III). Each has unique benefits and limitations.

Type I – Chromic Acid Anodizing

Chromic acid anodizing produces the thinnest oxide layer, usually 0.5–2.5 microns. It is mainly used where fatigue resistance and minimal dimensional change are important, such as aerospace CNC machined parts. The coating is thin and offers good corrosion resistance, but it’s not suitable for heavy wear.

Type II – Sulfuric Acid Anodizing

Sulfuric acid anodizing is the most common method. It creates oxide layers between 5–25 microns and allows coloring, which makes it popular in consumer goods and industrial products. It balances cost, corrosion resistance, and appearance, making it ideal for decorative and general-purpose CNC machined parts.

Type III – Hard Anodizing

Hard anodizing, or Type III, produces much thicker and denser oxide layers (25–150 microns). This makes it suitable for applications that demand high wear resistance, thermal resistance, and long service life. It is commonly used in aerospace, automotive, and defense industries for critical CNC machined components.

| Type |

Electrolyte Used |

Coating Thickness |

Durability / Wear Resistance |

Corrosion Resistance |

Coloring Options |

Cost Level |

Common Applications |

| Type I – Chromic Acid |

Chromic acid | 0.5–2.5 µm | Low | Good | Limited | Medium | Aerospace, fatigue-sensitive parts |

| Type II – Sulfuric Acid |

Sulfuric acid | 5–25 µm | Moderate | Good | Wide range | Low | Consumer goods, industrial parts, decorative finishes |

| Type III – Hard Anodizing |

Sulfuric acid (higher voltage/temp control) | 25–150 µm | High | Excellent | Limited | High | Aerospace, automotive, defense, heavy-wear parts |

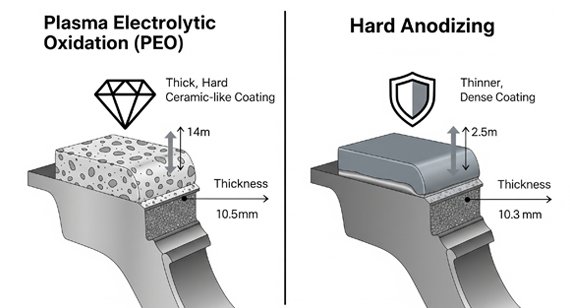

When engineers need strong surface protection for CNC machined parts, two processes often come up: plasma electrolytic oxidation (PEO), also called micro-arc oxidation (MAO), and hard anodizing. Both improve durability, but choosing the wrong one can lead to higher costs, poor performance, or unnecessary machining adjustments.

Plasma electrolytic oxidation (PEO) creates a ceramic-like coating that is harder, thicker, and more heat-resistant than hard anodizing. Hard anodizing is more affordable and provides solid corrosion and wear resistance but doesn’t match PEO’s extreme performance.

Let’s compare PEO and hard anodizing side by side so you can choose the right process for your CNC machining project.

Plasma Electrolytic Oxidation (PEO)

PEO uses very high voltages to generate plasma micro-discharges on the metal surface. These sparks transform the metal into a dense ceramic oxide layer. The coating is extremely hard, wear-resistant, and stable under high temperatures. This makes PEO ideal for aerospace, automotive, and defense CNC machined parts that operate in harsh conditions.

Hard Anodizing

Hard anodizing is a Type III anodizing process using sulfuric acid under controlled temperature and voltage. It produces a thick, dense oxide coating (25–150 µm) that offers strong corrosion resistance and good wear protection. Hard anodizing is cost-effective and widely available, making it popular for industrial and mechanical CNC machined parts.

Key Differences Between PEO and Hard Anodizing

Here’s a straightforward comparison:

| Feature |

Plasma Electrolytic Oxidation (PEO / MAO) |

Hard Anodizing (Type III) |

| Coating Nature |

Ceramic-like, crystalline | Oxide layer, dense |

| Thickness |

50–200 µm (varies) | 25–150 µm |

| Hardness |

Extremely high (up to ceramic level) | High but lower than PEO |

| Heat Resistance |

Excellent (can withstand >1000°C) | Good (limited at high temps) |

| Corrosion Resistance |

Very high | High |

| Cost |

Higher | Moderate |

| Applications |

Aerospace, defense, high-wear CNC machined parts | Industrial, automotive, general CNC machined parts |

When choosing a surface treatment for CNC machined parts, both micro-arc oxidation (MAO), also called plasma electrolytic oxidation (PEO), and anodizing are common options. Each has clear strengths and weaknesses, and knowing the differences helps you pick the right process without wasting time or money.

Key Advantages and Disadvantages

| Process |

Advantages |

Disadvantages |

Common Applications |

| Micro-Arc Oxidation (MAO / PEO) |

Extremely hard ceramic-like layer, excellent wear resistance, high heat stability, strong corrosion protection, good adhesion to base metal | Higher cost, longer process time, requires special equipment, limited suppliers | Aerospace, defense, automotive, medical CNC machined parts |

| Anodizing (Type II / Type III) |

Lower cost, widely available, good corrosion resistance, decorative coloring possible, moderate wear protection | Less wear resistance than MAO, lower heat resistance, thickness and hardness vary by type, may affect part dimensions | Consumer goods, electronics, automotive, industrial CNC machined parts |

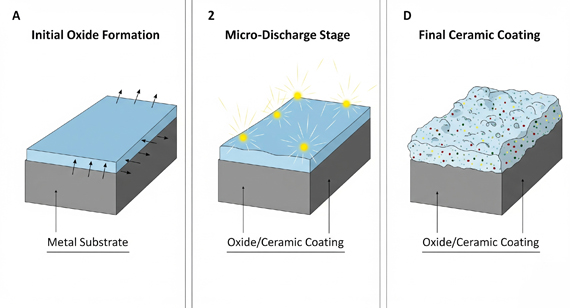

Micro-arc oxidation (MAO), also called plasma electrolytic oxidation (PEO), forms a ceramic-like coating on metals such as aluminum, magnesium, and titanium. The process develops in three main stages. Each stage builds on the previous one to create a dense and durable surface layer.

Stage 1: Substrate Oxidation

The process begins with substrate oxidation. When voltage is applied, a thin oxide film forms on the surface of the metal. This initial layer acts as the foundation for further coating growth. At this point, the film is thin but uniform, ensuring good adhesion to the base material.

Stage 2: Plasma Modification

As the voltage increases, micro-discharges appear on the surface. These sparks generate high temperatures and pressure in localized areas. The energy melts and re-solidifies parts of the oxide film, making the layer thicker and harder. This plasma action is what sets MAO apart from standard anodizing.

Stage 3: Addition of Electrolyte Elements

In the final stage, elements from the electrolyte solution enter the coating through the plasma channels. These additives improve hardness, wear resistance, and sometimes even color. The result is a ceramic-like layer that is well-bonded and highly resistant to wear, corrosion, and heat.

Anodizing is a controlled electrochemical process that thickens the natural oxide layer on metals like aluminum. It protects CNC machined parts from corrosion, adds wear resistance, and can improve appearance. The process follows several key steps, each affecting the quality of the final coating.

1. Cleaning and Pretreatment

Before anodizing, the metal surface must be thoroughly cleaned. Oils, grease, or dirt are removed using alkaline or acidic solutions. Mechanical polishing or chemical etching may also be done to achieve a smooth, uniform finish.

2. Anodizing

The cleaned part is placed in an electrolyte bath, usually sulfuric acid, and connected as the anode. When current is applied, oxygen ions combine with the metal surface, forming an oxide layer. The thickness of this layer depends on voltage, current density, and process time.

3. Coloring (Optional)

Anodized coatings are porous, allowing dyes or metallic salts to be absorbed. This step provides decorative finishes in a wide range of colors. Some industries, such as consumer electronics, use anodizing primarily for aesthetics combined with corrosion protection.

4. Sealing

After anodizing (and coloring, if chosen), the porous oxide layer must be sealed to improve corrosion resistance. Sealing closes the pores and locks in dyes, enhancing durability.

Sealing Methods

Caution: Poor sealing reduces corrosion resistance and causes fading in colored parts.

5. Rinsing and Drying

Finally, the parts are rinsed to remove any remaining chemicals and then dried. This step ensures no residues remain, leaving a clean and finished surface ready for use.

| Step |

Description |

Tips / Cautions |

| 1. Cleaning and Pretreatment |

Remove oils, dirt, and oxides using chemical or mechanical cleaning. Ensures a uniform base surface. | Skipping cleaning leads to weak or uneven coatings. |

| 2. Anodizing |

Place the part in an electrolyte bath (usually sulfuric acid) and apply current. An oxide layer forms on the surface. | Voltage and bath conditions must be controlled to ensure uniform thickness. |

| 3. Coloring (Optional) |

Dye or metallic salts enter the porous oxide layer for decorative finishes. | Darker colors offer better UV stability. |

| 4. Sealing |

Close pores to improve corrosion resistance and lock in colors. Can be hot DI water, medium-temp nickel acetate, or low-temp chemical sealing. | Poor sealing reduces durability and may cause fading. |

| 5. Rinsing and Drying |

Wash away chemical residues and dry the part for final use. | Proper rinsing prevents contamination and extends coating life. |

Micro-arc oxidation (MAO), also called plasma electrolytic oxidation (PEO), is an advanced surface treatment that produces ceramic-like coatings. Compared with conventional anodizing, MAO provides superior durability and performance. Understanding why MAO is often preferred helps engineers select the right process for CNC machined parts.

Advantages of MAO Over Conventional Anodizing

Higher Hardness and Wear Resistance

MAO forms a much harder coating than anodizing. The ceramic-like layer can resist scratches, abrasion, and friction far better, making it ideal for high-wear applications.

Thicker and Denser Coating

MAO coatings are thicker (often 50–200 µm) and denser than conventional anodized layers (usually 5–25 µm). This thickness provides better protection against corrosion, wear, and chemical attack.

Excellent Heat Resistance

MAO coatings can withstand higher temperatures than standard anodized layers, which is critical for aerospace, automotive, and defense applications.

Enhanced Corrosion Protection

The dense and tightly bonded MAO layer prevents corrosive agents from reaching the base metal more effectively than conventional anodizing.

Better Adhesion and Long-Term Durability

MAO coatings bond strongly to the base metal, reducing the risk of peeling or flaking over time, unlike some anodized coatings that may chip under impact.

| Feature |

Micro-Arc Oxidation (MAO / PEO) |

Conventional Anodizing (Type II / III) |

| Coating Hardness |

Extremely hard, ceramic-like, resists wear and scratches | Moderate hardness, less wear-resistant |

| Coating Thickness |

50–200 µm, dense and uniform | 5–25 µm, thinner and less dense |

| Wear Resistance |

Excellent, suitable for high-friction applications | Moderate, may wear faster under heavy use |

| Heat Resistance |

High, stable at elevated temperatures | Limited, can degrade under extreme heat |

| Corrosion Protection |

Superior, tightly bonded to base metal | Good, but less resistant than MAO |

| Durability / Adhesion |

Strong adhesion, long service life, resists peeling | Moderate adhesion, can chip or flake under impact |

| Cost / Equipment |

Higher cost, requires specialized equipment and process control | Lower cost, widely available, simpler process |

| Applications |

Aerospace, automotive, defense, medical CNC machined parts | Consumer electronics, general industrial parts, decorative applications |

The quality of a micro-arc oxidation (MAO) coating depends on several process parameters. Controlling these factors ensures CNC machined parts have uniform thickness, high hardness, and excellent corrosion resistance. Even small changes can affect performance and appearance.

1. Voltage and Current Density

Voltage and current density directly influence the formation of micro-discharges. Higher voltage increases coating thickness and hardness but can also cause surface cracking if uncontrolled.

2. Frequency

The frequency of the applied electrical pulses affects plasma generation and coating microstructure. Higher frequencies can produce smoother coatings, while lower frequencies may create rougher surfaces.

3. Duty Cycle

Duty cycle refers to the ratio of pulse-on time to pulse-off time. It controls energy input and heat accumulation in the coating process. Optimizing the duty cycle prevents overheating and ensures uniform layer formation.

4. Electrolyte Composition

The composition of the electrolyte determines the chemical elements incorporated into the coating. Different ions can enhance hardness, corrosion resistance, or even color.

5. Additives

Additives in the electrolyte, such as silicates or phosphates, modify the coating structure and surface characteristics. They can improve wear resistance or introduce specific functional properties.

6. pH

pH affects the conductivity of the electrolyte and the plasma reaction. Maintaining the correct pH ensures consistent discharge behavior and prevents localized defects in the oxide layer.

| Factor |

Effect on Coating Quality |

Tips / Cautions |

| Voltage and Current Density |

Higher voltage increases thickness and hardness; too high may cause surface cracks | Monitor voltage to balance coating quality and prevent defects |

| Frequency |

Higher frequency produces smoother coatings; lower frequency may create rough surfaces | Incorrect frequency can cause uneven thickness or weak bonding |

| Duty Cycle |

Controls energy input and heat accumulation; affects uniformity | Too high damages substrate; too low produces thin or porous coatings |

| Electrolyte Composition |

Determines elements incorporated; affects hardness, corrosion resistance, and color | Wrong composition can weaken coating or reduce protection |

| Additives |

Modify coating structure and surface properties; improve wear resistance | Select additives based on part application requirements |

| pH |

Influences plasma reactions and conductivity; ensures consistent discharges | pH fluctuations may cause cracks, pores, or uneven thickness |

The quality of an anodized coating on CNC machined parts depends on several key variables. Controlling these factors ensures uniform thickness, optimal hardness, and long-term corrosion resistance. Understanding each variable helps prevent defects and improves process consistency.

1. Electrolyte Composition

The type and concentration of the electrolyte, usually sulfuric acid for Type II or III anodizing, affect the thickness, hardness, and porosity of the oxide layer. Different additives can also improve wear resistance or allow specific coloring.

2. Battery Temperature

Temperature control during anodizing is critical. Higher temperatures can speed up coating formation but may reduce hardness and increase porosity. Lower temperatures produce denser and harder layers but take longer to process.

3. Current Density

Current density influences the growth rate and microstructure of the anodized layer. Higher current density speeds up coating formation but can overheat the part, while lower current density produces slower but more uniform layers.

4. Time

The duration of the anodizing process directly affects the final oxide thickness. Longer times yield thicker coatings, which improves corrosion resistance and wear protection but may slightly alter dimensions.

| Variable |

Effect on Coating Quality |

Tips / Cautions |

| Electrolyte Composition |

Determines thickness, hardness, porosity; additives can improve wear resistance or color | Using the wrong electrolyte can produce weak or uneven coatings |

| Battery Temperature |

Higher temperatures speed coating growth but may reduce hardness; lower temperatures create denser, harder layers | Sudden temperature fluctuations can cause cracks or uneven thickness |

| Current Density |

Higher density increases growth rate; lower density produces slower but more uniform layers | Optimize based on part size, shape, and desired thickness |

| Time |

Longer anodizing time increases oxide thickness, enhancing corrosion and wear resistance | Over-anodizing can cause brittleness or slight dimensional changes |

Choosing between micro-arc oxidation (MAO / PEO) and conventional anodizing depends on the application, environment, and budget. Both processes protect CNC machined parts, but each has strengths and limitations. Understanding these differences helps you pick the right coating for durability, performance, and cost-efficiency.

When to Choose Micro-Arc Oxidation (MAO / PEO)

Tip: MAO is best for aerospace, automotive, defense, or medical CNC machined parts where performance is critical, and budget allows for specialized processing.

When to Choose Conventional Anodizing (Type II / III)

Caution: Anodizing is better suited for parts where extreme wear and heat are not major concerns. Dimensional changes must also be considered for precise CNC machined components.

Recommendation

| Feature |

Micro-Arc Oxidation (MAO / PEO) |

Conventional Anodizing (Type II / III) |

| Wear Resistance |

Extremely high; ideal for high-friction applications | Moderate; hard anodizing improves wear but less than MAO |

| Heat Stability |

Excellent; stable under elevated temperatures | Limited; may degrade under extreme heat |

| Corrosion Protection |

Superior; dense ceramic-like layer resists chemicals and moisture | Good; suitable for general industrial and decorative use |

| Durability / Adhesion |

Strong adhesion; resists peeling or chipping | Moderate adhesion; may chip under impact |

| Cost |

Higher; requires specialized equipment | Lower; widely available |

| Coloring Options |

Limited; mostly functional coatings | Wide range; decorative and functional |

| Best Applications |

Aerospace, automotive, defense, medical CNC machined parts | Consumer goods, industrial parts, electronics, decorative CNC machined parts |

At VMT, we provide professional surface treatment services for CNC machined parts, specializing in both micro-arc oxidation (MAO / PEO) and conventional anodizing. Our expertise ensures parts achieve optimal hardness, corrosion resistance, and dimensional accuracy for a wide range of industrial applications.

Micro-Arc Oxidation (MAO / PEO) Services

VMT’s MAO service creates dense, ceramic-like coatings that significantly improve wear resistance, heat stability, and corrosion protection. We handle aluminum, magnesium, and titanium parts with precise control over voltage, current, electrolyte composition, and process parameters. This ensures consistent quality for aerospace, automotive, and defense components.

Anodizing Services

Our anodizing services include Type II (sulfuric acid), Type III (hard anodizing), and optional coloring and sealing processes. We optimize electrolyte composition, current density, temperature, and time to achieve uniform thickness, high corrosion resistance, and smooth finishes. Anodized parts are ideal for consumer products, electronics, and industrial components.

Why Choose VMT

Tip: Working with a professional service provider like VMT reduces the risk of coating defects, ensures dimensional accuracy, and helps avoid costly rework.

Choosing the right surface treatment for CNC machined parts depends on the application, performance requirements, and budget. Micro-arc oxidation (MAO / PEO) offers superior hardness, wear resistance, heat stability, and long-term durability, making it ideal for high-performance aerospace, automotive, and defense components. Conventional anodizing provides good corrosion protection, decorative options, and lower cost, making it suitable for industrial, consumer, and decorative applications.

At VMT, we provide expert MAO and anodizing services tailored to your CNC machined parts. By carefully selecting the process, controlling parameters, and ensuring precise coating thickness, we help maximize part performance, durability, and aesthetics.

1. What is the difference between oxidation and anodizing?

Oxidation is a natural chemical reaction where a metal reacts with oxygen, forming a thin oxide layer. Anodizing is a controlled electrochemical process that thickens this oxide layer for protection and aesthetics.

2. What is the micro-arc oxidation process?

Micro-arc oxidation (MAO), also called plasma electrolytic oxidation (PEO), uses high-voltage electrical discharges in an electrolyte to create a hard, ceramic-like coating on metals like aluminum, magnesium, and titanium.

3. What is the difference between anodizing and etching?

Anodizing thickens the oxide layer for protection and decoration. Etching removes material or creates texture but does not form a protective oxide coating.

4. Does anodizing prevent oxidation?

Yes. Anodizing creates a dense, controlled oxide layer that protects the metal from natural oxidation and corrosion.

5. Does anodizing wear out over time?

Over time, anodized layers can wear down, especially under friction or impact. Hard anodizing (Type III) lasts longer than standard anodizing (Type II).

6. What metals cannot be anodized?

Most anodizing processes work only on metals like aluminum, titanium, and magnesium. Metals like copper, steel, and brass typically cannot be anodized.

7. Can I dye aluminum without anodizing?

No. Anodizing creates porous oxide layers that absorb dyes. Without anodizing, dye will not bond to the aluminum surface.

8. Why can't I anodize white?

White anodizing requires proper dyeing and sealing. Pure white is difficult because the natural oxide layer tends to be translucent, and improper sealing can cause discoloration.

9. What causes black anodizing to turn purple?

Color changes can occur due to UV exposure, impurities in the dye, or uneven sealing. Proper sealing and high-quality dyes prevent this issue.

10. How do I remove oxide from anodized aluminum?

Oxide layers can be removed using chemical stripping agents or strong alkaline solutions. This process should be handled carefully to avoid damaging the base metal.

11. What is the difference between anodizing and oxidation?

Oxidation is a natural reaction with oxygen; anodizing is a controlled electrochemical process that thickens the oxide layer to improve protection and appearance.

12. Can the anodized layer be removed?

Yes. The anodized layer can be stripped chemically or mechanically, but this exposes the bare metal and removes the protective and decorative benefits.