15 years one-stop China custom CNC machining parts factory

291 |

Published by VMT at Sep 03 2025 | Reading Time:About 7 minutes

291 |

Published by VMT at Sep 03 2025 | Reading Time:About 7 minutes

Many engineers and designers wonder: Is cast iron magnetic? This question often arises when choosing materials for CNC machined parts or industrial applications. The problem is that magnetism in metals isn’t always obvious. The good news is that cast iron’s magnetic ability can be explained through its structure, composition, and behavior under different conditions.

Yes, cast iron is magnetic due to its high iron content and ferromagnetic atomic structure. However, its magnetism varies with type—gray, white, ductile, or alloyed cast iron—and environmental factors like temperature or impurities. Cast iron can attract magnets, but its strength depends on composition and processing.

Now that we know cast iron generally shows magnetic properties, let’s explore its different types, the science behind cast iron metal magnetism, and how it compares to other ferrous materials.

Yes, cast iron is magnetic, but the degree of its magnetism depends on the type of cast iron and its internal structure. Since cast iron is primarily composed of iron, a ferromagnetic material, it naturally shows strong magnetic behavior. The high iron content means that cast iron’s atomic structure allows its electrons to align into magnetic domains, giving it the ability to attract magnets. However, the presence of carbon, silicon, and other alloying elements influences how strong that magnetism appears. For example, gray cast iron may exhibit weaker magnetic properties compared to white or ductile cast iron because of differences in graphite distribution.

In practical terms, cast iron’s magnetic ability makes it useful for applications where interaction with magnetic fields is required. For instance, in CNC machining factories, magnetic clamping systems can be used to secure certain types of cast iron during machining. But not every cast iron component responds equally well, so engineers must carefully match material type with machining needs.

Cast iron is a family of iron-carbon alloys that typically contain between 2–4% carbon, along with varying amounts of silicon, manganese, and trace impurities. It is widely used in manufacturing because of its excellent castability, wear resistance, and durability. Unlike wrought iron or mild steel, cast iron is brittle, which makes it less suitable for bending or forging but highly effective for components requiring rigidity and vibration damping.

From a magnetic perspective, cast iron is considered a ferrous material, meaning it is rich in iron and generally capable of interacting with magnetic fields. Its atomic structure and the arrangement of its magnetic domains largely determine its magnetism. This makes cast iron metal magnetism an important factor in industries such as CNC machining services, where precision parts may need to respond to electromagnetic forces or remain unaffected by magnetic interference.

In CNC machining factories, cast iron is often selected for machine bases, housings, and structural components due to its stability and reduced vibration. Knowing whether cast iron is magnetic can help engineers make the right decisions about tool compatibility, electromagnetic applications, and overall project performance.

Cast iron is not a single uniform material but rather a family of iron-carbon alloys, each with distinct mechanical properties and magnetic behavior. Its magnetism depends heavily on carbon form, graphite distribution, and alloying elements. Understanding how white, gray, malleable, ductile, alloy, and high-silicon cast irons behave magnetically helps engineers choose the right material for CNC machined parts, especially when magnetic clamping or induction heating processes are involved.

White Cast Iron

White cast iron is characterized by its hard and brittle structure due to the presence of iron carbides rather than free graphite. Because of its high iron and carbide content, white cast iron exhibits strong ferromagnetic properties. Its electrons align well into magnetic domains, which allows it to attract magnets effectively. However, its brittleness makes it less common in applications where machining flexibility is needed. In CNC machining factories, white cast iron’s magnetism is an advantage when using magnetic fixtures, but extra care must be taken due to tool wear caused by its hardness.

Gray Cast Iron

Gray cast iron is one of the most widely used types, known for its excellent machinability and vibration damping. Its microstructure contains graphite flakes, which interrupt the continuity of the metallic matrix. This reduces the overall alignment of magnetic domains, making gray cast iron less magnetic than white cast iron. While it still responds to magnets, its magnetic ability is moderate rather than strong. For CNC machining services, this means gray cast iron can sometimes be held magnetically, but clamping strength may not be as reliable compared to other ferromagnetic materials.

Malleable Cast Iron

Malleable cast iron is produced by heat-treating white cast iron to transform brittle carbides into more ductile graphite clusters. This process improves mechanical strength and toughness while retaining good iron content. Magnetically, malleable cast iron shows moderate ferromagnetism, stronger than gray cast iron but generally weaker than white cast iron. Its improved ductility makes it more practical for parts that require both magnetic response and machinability. CNC machining factories often select malleable cast iron for automotive and pipe fittings where controlled magnetism and toughness are both desirable.

Ductile Cast Iron (Nodular)

Ductile cast iron, also called nodular cast iron, contains graphite in spherical or nodular form. This structure enhances tensile strength and impact resistance while maintaining ferromagnetism due to its high iron content. The spherical graphite distribution allows better alignment of magnetic domains compared to gray cast iron, making ductile cast iron more magnetic overall. In CNC machining services, ductile iron’s combination of strong magnetism and superior mechanical properties makes it a preferred choice for producing components such as gears, crankshafts, and machine bases.

Alloy Cast Iron

Alloy cast iron is enhanced with additional elements such as nickel, chromium, or molybdenum to improve wear resistance, corrosion resistance, or heat resistance. These alloying elements often interfere with magnetic domain alignment, reducing the overall magnetism of the material. While the base iron is ferromagnetic, high levels of alloying can make cast iron less responsive to magnets. In CNC machining factories, alloy cast iron is chosen more for its durability than its magnetism, which is typically weaker compared to unalloyed types.

High Silicon Cast Iron

High silicon cast iron is designed for superior corrosion resistance, particularly in acidic environments. The increased silicon content modifies the microstructure and reduces ferromagnetic behavior. Compared to gray or ductile cast iron, high silicon cast iron exhibits significantly weaker magnetism, sometimes approaching nonmagnetic characteristics. This makes it unsuitable for magnetic clamping but excellent for specialized applications like chemical pumps or marine equipment. For CNC machined parts, high silicon cast iron is chosen where corrosion resistance outweighs magnetic ability.

Table: Types of Cast Iron and Their Magnetic Properties

| Type of Cast Iron |

Microstructure |

Magnetism |

CNC Machining Considerations |

| White Cast Iron |

Hard iron carbides, little to no graphite | Strongly ferromagnetic | High tool wear due to hardness; suitable for magnetic clamping but brittle. |

| Gray Cast Iron |

Graphite flakes in a ferrite/pearlite matrix | Moderate magnetism (weaker than white iron) | Good machinability; weaker magnetism requires testing before magnetic fixturing. |

| Malleable Cast Iron |

Heat-treated carbides into graphite clusters | Moderate to good ferromagnetism | Balanced toughness and magnetism; practical for automotive and fittings. |

| Ductile (Nodular) Iron |

Graphite in spherical/nodular form | Strong magnetism, better than gray iron | Excellent mechanical strength; works well with magnetic clamping but can increase tool wear. |

| Alloy Cast Iron |

Iron with nickel, chromium, molybdenum, etc. | Variable, often reduced due to alloying | Chosen for durability/corrosion resistance; magnetism weaker and must be verified. |

| High Silicon Cast Iron |

High silicon content, corrosion-resistant | Weak magnetism, sometimes nearly nonmagnetic | Excellent for chemical/marine use; not suitable for magnetic clamping in CNC machining. |

The magnetism of cast iron arises from its internal structure and chemical composition. Cast iron’s magnetic ability is not a coincidence; it is rooted in fundamental material science. By examining its iron content, electron arrangement, atomic structure, and magnetic domains, we can better understand why this common engineering material can attract magnets. This knowledge is especially important in CNC machining services, where the magnetic properties of ferrous materials affect machining techniques and clamping methods.

High Iron Content

The primary reason cast iron is magnetic is its high proportion of iron, typically between 90–95% of its composition. Iron is a classic ferromagnetic element, meaning its atoms can align in response to an external magnetic field. Because cast iron contains such a large amount of this metal, its base material strongly supports magnetism. Even when carbon and silicon are added to alter its properties, the iron base ensures that most types of cast iron metal magnetism remain noticeable. This high iron content is what allows magnets to attract cast iron frying pans, pipes, and CNC machined parts.

Electron Arrangement

On an atomic level, magnetism is influenced by how electrons are arranged in each atom. In iron, the electron shells are not fully paired, leaving unpaired electrons in the d-orbitals. These unpaired electrons generate tiny magnetic fields, and when many atoms align together, they form a larger magnetic effect. Cast iron retains this electron arrangement because of its iron base. The way electrons align within the crystalline lattice explains why ferrous materials like cast iron can be magnetized, while non-ferrous metals such as copper or aluminum cannot.

Ferrous Materials

Cast iron is categorized as a ferrous material because of its high iron content. Ferrous metals are distinct from non-ferrous metals in that they generally display ferromagnetism. This makes cast iron comparable to wrought iron and steel in terms of magnetic properties, although the exact magnetism differs depending on carbon form and alloy composition. In CNC machining factories, knowing whether a workpiece is ferrous or non-ferrous is crucial because ferrous materials can be magnetically clamped, while non-ferrous ones cannot. Cast iron’s classification as ferrous explains why it is generally magnetic, though not as consistent as low-carbon steels.

Atomic Structure

The atomic structure of cast iron plays a central role in its magnetism. Iron atoms arrange themselves in a body-centered cubic (BCC) or face-centered cubic (FCC) structure depending on temperature and carbon content. In cast iron, the dominant structure at room temperature is the BCC form, which allows for the alignment of magnetic domains. The presence of graphite inclusions (flakes, nodules, or clusters depending on cast iron type) interrupts this atomic continuity, weakening magnetism in some types like gray cast iron. Despite these interruptions, the iron lattice maintains enough order to produce noticeable magnetic behavior in most cases.

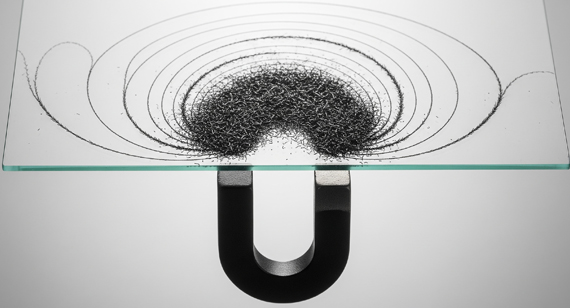

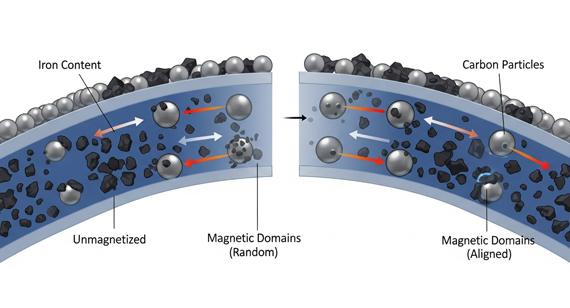

Magnetic Domains

Magnetism in cast iron doesn’t just depend on individual atoms—it also depends on magnetic domains, which are microscopic regions where atoms align their magnetic fields in the same direction. In cast iron, these domains can naturally align when exposed to an external magnet, giving the material its ferromagnetic properties. However, the presence of graphite in gray or malleable cast iron can fragment these domains, lowering the material’s overall magnetism. In contrast, ductile and white cast irons, with fewer interruptions, display stronger magnetic domain alignment and therefore stronger magnetic ability.

Table: Reasons Why Cast Iron is Magnetic

| Factor |

Explanation |

Effect on Magnetism |

| High Iron Content |

Cast iron is 90–95% iron, a ferromagnetic element. | Ensures strong base magnetism; iron-rich structures are easily attracted to magnets. |

| Electron Arrangement |

Iron atoms have unpaired d-orbital electrons that generate magnetic fields. | Allows atoms to align under a magnetic field, creating cast iron’s magnetic ability. |

| Ferrous Materials |

Cast iron is a ferrous metal, unlike non-ferrous metals (copper, aluminum). |

Classifies cast iron as generally magnetic, though less consistent than pure steels. |

| Atomic Structure |

Body-centered cubic (BCC) crystal structure supports domain alignment; graphite interrupts it. | Strong magnetism in white/ductile iron; weaker in gray or high-silicon cast iron. |

| Magnetic Domains |

Groups of aligned atoms form domains; graphite or impurities can disrupt them. | Domains align with external magnets, giving cast iron its observable ferromagnetic properties. |

Yes, cast iron can attract magnets, but the strength of this attraction depends on the specific type of cast iron and its microstructure. Since cast iron is a ferrous material composed primarily of iron, it is naturally capable of interacting with external magnetic fields. When a magnet is brought near cast iron, the magnetic domains inside the material tend to align with the external field, creating a force of attraction. This makes everyday items such as cast iron frying pans, stoves, and pipes responsive to magnets.

However, the degree of attraction varies. White cast iron and ductile (nodular) cast iron, with fewer graphite interruptions, show stronger magnetic ability. In contrast, gray cast iron and high-silicon cast iron, which contain more graphite or alloying elements, tend to exhibit weaker magnetic responses. This means a magnet may stick firmly to one type of cast iron but only lightly to another.

For CNC machining services, this distinction matters greatly. Many machining factories rely on magnetic clamping to hold workpieces in place. If a material like gray cast iron is chosen without confirming its magnetism, the clamping may be insufficient, leading to machining errors or higher costs.

When discussing whether magnetic metals are more potent, we need to distinguish between mechanical strength and magnetic strength. A metal’s magnetism does not directly determine how strong or durable it is. For example, cast iron has good magnetic ability because of its high iron content, yet it is brittle and much weaker in tensile strength compared to steel. On the other hand, steel—particularly low-carbon or tool steel—may have similar or even stronger magnetic properties while also being mechanically tougher.

Magnetic potency depends on how well the metal’s atomic structure supports the alignment of magnetic domains. Iron, cobalt, and nickel are inherently ferromagnetic, meaning they naturally exhibit strong attraction to magnets. Cast iron, being an iron-based alloy, falls into this category, but the presence of carbon and graphite inclusions weakens its overall magnetic potency compared to pure iron or certain steels. This is why a magnet often sticks more strongly to steel than to cast iron.

In CNC machining factories, this difference matters. If a workpiece requires magnetic clamping, materials with higher magnetic permeability—such as low-carbon steel—provide more reliable holding force than gray cast iron. That said, cast iron’s magnetic ability is still sufficient for many applications, provided the right type of cast iron is selected.

Although cast iron is generally magnetic due to its high iron content, several external and internal factors influence how strongly it responds to a magnetic field. Engineers and CNC machining factories must understand these variables to avoid unexpected results during manufacturing or when using magnetic clamping systems. The most significant factors include temperature, material purity, crystal structure, magnetic field strength, and the addition of alloying elements.

Temperature

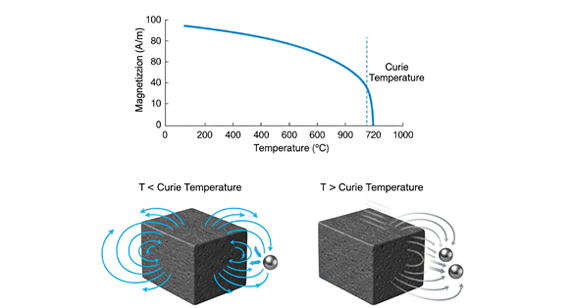

Temperature is one of the most critical factors affecting cast iron’s magnetism. As temperature rises, thermal energy disrupts the alignment of magnetic domains within the material. Eventually, cast iron reaches a threshold called the Curie temperature, beyond which it loses its ferromagnetic properties and becomes paramagnetic. This means it can no longer retain strong magnetism. For cast iron, this transition typically occurs around 770°C (similar to pure iron). In CNC machining services, where heat is generated during cutting or grinding, localized heating may reduce the effectiveness of magnetic clamping.

Purity

The purity of cast iron greatly influences its magnetic behavior. Cast irons with fewer impurities and higher concentrations of iron exhibit stronger magnetism. However, real-world cast iron always contains carbon, silicon, manganese, and other trace elements. These additions disrupt the atomic uniformity and weaken magnetic alignment. For CNC machined parts, variations in purity can explain why two seemingly similar cast iron components respond differently to magnets. High-quality, purer cast irons are more consistent and reliable when magnetic clamping or electromagnetic induction is required.

Crystal Structure

The crystal structure of cast iron plays a key role in its magnetic ability. Iron atoms typically arrange themselves in a body-centered cubic (BCC) lattice at room temperature, which supports ferromagnetism. However, the distribution of carbon in cast iron—either as graphite flakes, nodules, or clusters—can distort this lattice. Gray cast iron, for instance, has flake graphite that interrupts crystal continuity, reducing magnetic strength. White and ductile cast irons, with more uniform structures, maintain stronger ferromagnetic behavior.

Magnetic Field

The strength and orientation of the external magnetic field directly affect how well cast iron becomes magnetized. A weak field may only align a small number of magnetic domains, resulting in minimal attraction. Conversely, a strong magnetic field can fully align domains, creating a stronger magnetic response. In CNC machining factories, powerful electromagnetic chucks are used to secure ferrous materials like cast iron during machining operations. However, the uneven graphite distribution in some cast irons can still lead to inconsistent clamping forces, even under a strong field.

Alloying Elements

The addition of alloying elements such as nickel, chromium, molybdenum, or silicon alters cast iron’s mechanical and magnetic properties. While these elements improve corrosion resistance, heat resistance, and wear performance, they typically weaken magnetism by disturbing the atomic alignment necessary for ferromagnetism. For example, high silicon cast iron is almost nonmagnetic, making it unsuitable for magnetic clamping. In contrast, low-alloy cast irons retain reasonable magnetic ability while benefiting from enhanced durability.

Table: Factors Affecting Cast Iron’s Magnetism

| Factor |

Explanation |

Effect on Magnetism |

| Temperature |

Heat disrupts alignment of magnetic domains; above Curie temperature (~770°C), cast iron becomes paramagnetic. | Magnetism decreases with heat; lost completely past Curie point. |

| Purity |

Higher iron content = stronger magnetism; impurities or excessive carbon/silicon weaken alignment. | Pure cast iron responds strongly; recycled or impure grades show weaker, inconsistent magnetism. |

| Crystal Structure |

Iron’s BCC structure supports magnetism, but graphite flakes/nodules disrupt atomic continuity. | White and ductile cast iron: stronger; gray cast iron: weaker due to graphite interruptions. |

| Magnetic Field |

External field strength determines how many domains align. | Strong fields = stronger attraction; weak fields = limited magnetization. |

| Alloying Elements |

Additions of Ni, Cr, Mo, Si improve durability but disturb magnetic domain alignment. | More alloying = weaker magnetism; high-silicon cast iron is nearly nonmagnetic. |

Ferromagnetism is the property of certain metals, such as iron, cobalt, and nickel, to exhibit strong attraction to magnets due to the alignment of their atomic magnetic moments. Since cast iron is predominantly made of iron, it naturally falls into the ferromagnetic category. However, unlike pure iron, which has a uniform structure and strong magnetic response, cast iron’s magnetism is influenced by its carbon content, graphite distribution, and alloying elements.

In white and ductile cast irons, the relatively uniform iron matrix allows magnetic domains to align more easily, resulting in stronger ferromagnetic behavior. Gray cast iron, on the other hand, contains graphite flakes that break up the iron lattice and disrupt domain alignment, which weakens its overall magnetism. This means that while cast iron is ferromagnetic, it is not as consistently magnetic as pure iron or low-carbon steels.

For CNC machining services, this difference is significant. Pure ferromagnetic materials like low-carbon steel provide strong, reliable holding power when magnetic clamping systems are used. Cast iron, while ferromagnetic, may show variations depending on the specific type. Engineers working in CNC machining factories must therefore understand the differences between cast iron’s magnetic ability and the ideal ferromagnetism of pure iron when designing or processing CNC machined parts.

The Curie temperature is the critical point at which a ferromagnetic material loses its permanent magnetic properties and becomes paramagnetic. For iron and most cast irons, this occurs at approximately 770°C (1,418°F). Below this temperature, the atomic magnetic domains in cast iron align, allowing it to be strongly attracted to magnets. However, once the Curie point is exceeded, thermal energy disrupts this alignment, and cast iron can no longer maintain ferromagnetic behavior.

Different types of cast iron may show slight variations in Curie temperature due to differences in alloying elements, carbon content, and microstructure. For example, high-silicon or alloyed cast irons may experience a slightly reduced Curie temperature compared to pure iron.

In CNC machining and industrial applications, this means cast iron components retain magnetic properties under normal operating conditions but may lose magnetism in high-temperature environments, such as furnaces or high-friction systems. Engineers should account for this when designing magnetic clamping setups or heat-resistant CNC machined parts.

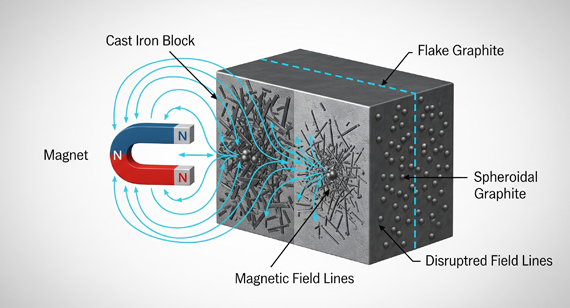

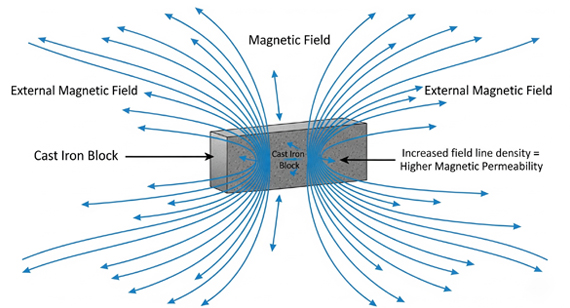

Magnetic permeability is a material’s ability to support the formation of magnetic fields within itself. It essentially measures how easily magnetic flux can pass through the material. Cast iron, being a ferrous material with high iron content, has relatively high magnetic permeability, but this value varies depending on the type of cast iron and its microstructure.

For example, gray cast iron has graphite flakes that disrupt magnetic domain alignment, lowering its permeability compared to white cast iron or ductile iron, which contain more continuous iron phases. Alloying elements such as silicon, nickel, or chromium can also significantly alter permeability, sometimes reducing magnetic response by hindering electron alignment.

In practical CNC machining and manufacturing, understanding the magnetic permeability of cast iron is crucial. It affects how parts interact with magnetic clamps, sensors, or induction systems. Components with higher permeability are better suited for electromagnetic applications, while lower permeability types may require alternative fixturing methods.

The magnetic moment of a material refers to the strength and orientation of its internal magnetic dipoles, which arise from electron spin and orbital motion. In cast iron, the magnetic moment is primarily determined by the presence of unpaired electrons in the 3d orbitals of iron atoms. These unpaired electrons create localized magnetic moments that, when aligned in domains, give cast iron its ferromagnetic properties.

However, cast iron’s magnetic moment is not uniform across all types. For instance, gray cast iron, with graphite flakes, interrupts the continuity of magnetic domains, resulting in a weaker net magnetic moment compared to white cast iron or ductile iron, which have more compact iron matrices. Additionally, alloying elements such as silicon or nickel can reduce the effective magnetic moment by disturbing electron configurations.

In practical CNC machining and material selection, understanding the magnetic moment of cast iron helps engineers determine how strongly a part will interact with external magnetic fields, which is essential for magnetic clamping, testing, or electromagnetic induction applications.

While cast iron is naturally ferromagnetic, it does not retain strong magnetism indefinitely without proper treatment. Permanent magnetization involves aligning the magnetic domains within the iron and “locking” them in place. This process is particularly useful in CNC machined parts, electromagnetic devices, and industrial components where long-lasting magnetic performance is required. Understanding the proper steps can ensure efficiency, reduce costs, and maintain the integrity of the cast iron material.

Choosing the Right Iron Material

Not all cast irons respond equally well to permanent magnetization. White cast iron and ductile (nodular) iron are excellent choices due to their continuous iron matrix and minimal graphite disruption, which allows magnetic domains to align efficiently. In contrast, gray cast iron and high-silicon cast iron are more challenging to magnetize permanently because graphite flakes or high alloying content interrupt domain continuity. Selecting the appropriate material at the outset is crucial to achieve strong and stable magnetization.

Preparing the cast iron surface enhances magnetization. Removing rust, scale, or oil ensures uniform magnetic field penetration. Common methods include mechanical polishing, sandblasting, or chemical cleaning. Smooth, clean surfaces help prevent domain misalignment and improve the efficiency of the magnetization process, particularly for CNC machined parts that require precise magnetic performance.

Applying a Strong Magnetic Field

Once the material is prepared, a strong external magnetic field is applied to align the magnetic domains. This is often achieved using electromagnets or specialized magnetizing coils. The field strength must be sufficient to overcome internal resistance caused by graphite or alloying elements. The orientation of the field is also important; aligning the field along the part’s primary axis ensures maximum magnetization.

In some cases, heat treatment is used before or during magnetization to enhance domain alignment. Heating the cast iron slightly (below the Curie temperature) can reduce internal stress and make domain rotation easier. This step is optional but can improve magnetization results, especially for challenging alloys or complex-shaped parts.

Cooling

After magnetization, the cast iron must be cooled gradually to lock the magnetic domains in place. Rapid or uneven cooling can introduce stress or misalignment, reducing the effectiveness of permanent magnetization. Controlled cooling ensures stable magnetic performance over time, which is critical for components used in CNC machining or electromagnetic applications.

Removing the Magnetic Field

Finally, once the magnetic domains are properly aligned, the external magnetizing field is gradually removed. Sudden removal can disturb the domain alignment and weaken the permanent magnetism. The cast iron should now retain a strong, stable magnetic field suitable for industrial use.

Table: Steps to Permanently Magnetize Cast Iron

| Step |

Description |

Tips / Cautions |

| 1. Choosing the Right Material |

Select cast iron with minimal graphite disruption (white or ductile cast iron preferred). | Avoid gray or high-silicon cast iron if strong permanent magnetism is required. |

| 2. Surface Treatment |

Clean the surface of rust, oil, and scale using mechanical polishing, sandblasting, or chemical cleaning. | Ensure machining tolerances are not damaged; clean surfaces improve domain alignment. |

| 3. Applying a Strong Magnetic Field |

Use electromagnets or magnetizing coils to align magnetic domains along the desired axis. | Field strength must overcome alloying or graphite interruptions; proper orientation is critical. |

| 4. Heat Treatment (Optional) |

Slightly heat the cast iron (below Curie temperature) to reduce internal stress and facilitate domain rotation. | Never exceed ~770°C; overheating will demagnetize the iron. |

| 5. Cooling |

Gradually cool the cast iron to lock magnetic domains in place. | Avoid rapid or uneven cooling to prevent domain misalignment and stress formation. |

| 6. Removing the Magnetic Field |

Slowly remove the external magnetizing field once domains are aligned. | Sudden removal can weaken magnetism; verify magnetic strength after removal for consistency. |

Testing the magnetism of cast iron is essential to determine whether it meets the requirements for magnetic clamping, electromagnetic applications, or permanent magnetization. Because cast iron’s magnetic ability varies by type—white, gray, ductile, or high-silicon—it is important to verify the actual performance rather than assume it based on composition.

Common Methods to Test Magnetism

Using a Handheld Magnet

The simplest method is to bring a strong permanent magnet close to the cast iron surface. The degree of attraction indicates relative magnetism. White and ductile cast irons typically show strong adherence, while gray or high-silicon cast irons may only show weak attraction.

Magnetic Flux Measurement

Industrial-grade testing can be performed using gaussmeters or fluxmeters. These instruments measure the magnetic flux density, providing a quantitative assessment of magnetism. This method is particularly useful in CNC machining factories for ensuring magnetic clamping systems will hold workpieces reliably.

Electromagnetic Testing

Electromagnetic coils can be used to temporarily magnetize the cast iron and observe its response. The induced magnetic field and the resulting alignment of magnetic domains indicate the material’s inherent ferromagnetic properties.

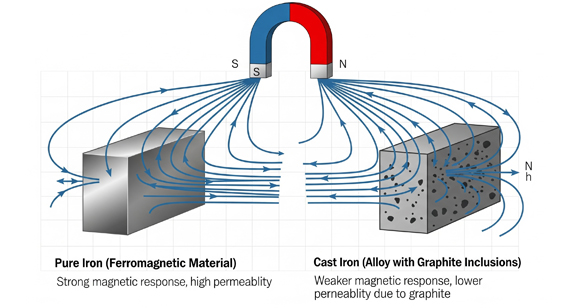

Cast iron exhibits ferromagnetism, but its magnetic ability varies depending on type and composition. Comparing cast iron’s magnetic properties to other metals such as steel, wrought iron, and stainless steel helps engineers and CNC machining factories make informed material choices. Understanding these differences is crucial for applications that rely on magnetic clamping, electromagnetic induction, or permanent magnetization.

Magnetism of Cast Iron vs. Steel

Steel, particularly low-carbon steel, generally has a more uniform and stronger magnetic response than cast iron. While cast iron’s magnetic ability is influenced by graphite flakes and alloying elements, steel has fewer interruptions in its iron lattice, allowing more consistent alignment of magnetic domains. In CNC machining services, steel workpieces often provide more reliable holding under magnetic clamps, whereas cast iron may require careful selection of type—such as white or ductile iron—to achieve similar magnetic performance.

Magnetism of Cast Iron vs. Wrought Iron

Wrought iron, with very low carbon content and a fibrous microstructure, exhibits excellent ferromagnetic properties. Its uniform iron matrix allows magnetic domains to align easily, making it slightly more magnetic than many cast irons. Ductile or white cast iron can approach wrought iron’s magnetism, but gray or high-silicon cast iron falls short. CNC machining factories need to consider wrought iron when consistent magnetic response is required, though cast iron is often chosen for cost-effectiveness and machinability.

Magnetism of Cast Iron vs. Stainless Steel

Most stainless steels, especially austenitic types like 304, are largely nonmagnetic due to their crystal structure and high alloying content. Ferritic and martensitic stainless steels may show some magnetism, but their response is weaker than ferrous cast iron. This contrast explains why a magnet sticks strongly to cast iron pans or pipes, but barely to common stainless steel kitchenware. In CNC machining, choosing cast iron over stainless steel is essential when magnetic fixtures or sensors are involved.

Magnetic vs. Nonmagnetic Cast Iron

Not all cast irons are equally magnetic. White and ductile (nodular) cast irons exhibit strong magnetic ability due to a continuous iron matrix, while gray or high-silicon cast irons have weaker magnetism because graphite flakes and alloying elements disrupt domain alignment. Selecting the right type of cast iron is critical for CNC machined parts that rely on magnetic performance.

Cast Iron and Other Materials

Compared to non-ferrous metals like aluminum, copper, or brass, cast iron is highly magnetic. This makes it suitable for applications involving magnetic clamping, induction heating, or permanent magnetization. However, engineers must balance magnetic performance with other properties such as corrosion resistance, machinability, and mechanical strength when choosing materials for CNC machining services.

Table: Comparison of Cast Iron and Other Materials’ Magnetism

| Material |

Magnetism |

CNC Machining Relevance |

| Cast Iron (White/Ductile) |

Strong ferromagnetism; domains align well | Suitable for magnetic clamping, induction, and permanent magnetization in CNC machined parts. |

| Cast Iron (Gray/High-Silicon) |

Weak magnetism; graphite flakes disrupt domains | May require testing; less reliable for magnetic clamping or electromagnetic applications. |

| Steel (Low-Carbon) |

Very strong and uniform ferromagnetism | Excellent for magnetic fixtures; consistent holding power in CNC machining services. |

| Wrought Iron |

Strong ferromagnetism, very uniform | Highly reliable magnetic response; good for magnetic fixtures and specialized industrial parts. |

| Ferritic/Martensitic Stainless Steel |

Moderate magnetism (depends on type) | Can work with magnetic clamping but less predictable; must verify for CNC processes. |

| Austenitic Stainless Steel (304, 316) |

Essentially nonmagnetic | Not suitable for magnetic clamping; alternative fixturing needed in CNC machining. |

| Non-Ferrous Metals (Al, Cu, Brass) |

Nonmagnetic | Cannot be held with magnets; requires mechanical clamping for machining. |

Cast iron’s combination of ferromagnetic properties, high wear resistance, and machinability makes it an essential material in a wide range of industrial, mechanical, and consumer applications. Its versatility stems from the ability to tailor types and alloy compositions to meet specific mechanical and magnetic requirements.

Industrial Machinery

Cast iron is widely used in the construction of machine bases, frames, and heavy equipment because of its excellent damping capacity, which reduces vibration during operation. Magnetic properties allow for the integration of magnetic clamping systems, especially in CNC machining factories, where precise holding of ferrous workpieces is essential. White and ductile cast irons are particularly suitable for these applications due to their stronger magnetic response.

Pipes, Valves, and Fittings

Due to its corrosion resistance and durability, cast iron is commonly used for water and sewage pipes, valves, and fittings. The material’s ferromagnetism allows for magnetic inspection methods to detect internal defects without destructive testing. High-silicon and alloyed cast irons are often chosen for chemical or marine environments despite their lower magnetic response.

Cookware and Kitchenware

Cast iron cookware, such as frying pans, griddles, and dutch ovens, benefits from both thermal properties and magnetism. The magnetic ability allows induction stovetops to efficiently transfer energy to the pan, demonstrating the practical application of cast iron’s magnetic properties in daily life.

Automotive and Heavy Equipment Components

In automotive and heavy machinery, cast iron is used for engine blocks, brake drums, flywheels, and gear housings. Ductile iron is preferred for components requiring a combination of strength, toughness, and magnetic response. In CNC machining, the magnetic ability aids in alignment and positioning of workpieces during production, improving efficiency and precision.

Electromagnetic and Magnetic Devices

Cast iron’s ferromagnetic nature allows it to be incorporated into electromagnetic devices, magnetic sensors, and industrial magnets. Permanent magnetization of selected cast iron components is used in certain industrial automation and CNC setups, demonstrating its versatility beyond structural applications.

Cast iron is a versatile material whose magnetism and mechanical properties make it essential across industrial, automotive, and consumer applications. Its magnetic ability stems from high iron content, electron arrangement, atomic structure, and magnetic domains, though the degree of magnetism varies with cast iron type, purity, alloying elements, and temperature. White and ductile cast irons exhibit strong ferromagnetic behavior, while gray and high-silicon cast irons show weaker responses.

Understanding cast iron’s magnetic properties is crucial for CNC machining factories and engineers, especially when using magnetic clamping, electromagnetic induction, or permanent magnetization techniques. Testing and selecting the right type of cast iron ensures reliable performance, reduces production errors, and optimizes machining efficiency. Comparing cast iron with other materials such as steel, wrought iron, and stainless steel highlights its unique balance of magnetic ability, durability, and machinability.

Whether for CNC machined parts, industrial machinery, automotive components, cookware, or magnetic devices, cast iron remains a dependable, cost-effective, and widely used material. By understanding its properties and limitations, manufacturers can fully leverage its cast iron metal magnetism to achieve optimal results in both magnetic and mechanical applications.

1. Is cast iron more magnetic than steel?

Cast iron can be magnetic, but its strength varies by type. Low-carbon steel generally exhibits more consistent and stronger magnetism due to fewer graphite disruptions in its structure. White and ductile cast irons may approach steel’s magnetic response, while gray or high-silicon cast irons are weaker. In CNC machining, steel often provides more reliable magnetic clamping than most cast irons.

2. Does a magnet attract cast iron?

Yes. Cast iron is a ferrous material, so it can be attracted to a magnet. The degree of attraction depends on the type: white and ductile cast irons show strong attraction, while gray or high-silicon cast irons respond more weakly.

3. Is cast iron suitable for electromagnetic induction?

Yes, cast iron can be used in electromagnetic induction applications, especially types with strong magnetic properties such as white or ductile iron. However, gray or high-silicon cast irons may require stronger fields or additional design considerations to achieve optimal induction efficiency.

4. What metals are not attracted to magnets?

Non-ferrous metals like aluminum, copper, brass, and austenitic stainless steel are typically nonmagnetic. These materials do not exhibit ferromagnetism and cannot be held by magnetic clamps used in CNC machining.

5. Is white cast iron magnetic?

Yes, white cast iron is magnetic. Its continuous iron matrix allows magnetic domains to align easily, giving it strong ferromagnetic properties suitable for magnetic clamping, permanent magnetization, and electromagnetic applications.

6. What sticks to cast iron?

Magnets, low-carbon steel, and other ferrous materials stick to cast iron. The strength of adhesion depends on the cast iron type: stronger in white or ductile cast iron, weaker in gray or high-silicon variants.

7. Is a cast iron frying pan magnetic?

Yes. Most cast iron cookware, including frying pans, is strongly magnetic. This property allows them to work efficiently on induction stovetops, which rely on the ferromagnetic response of the material.

8. Is wrought iron magnetic?

Yes, wrought iron is highly magnetic due to its uniform, low-carbon iron structure. It is slightly more magnetic than many types of cast iron and is excellent for applications requiring consistent ferromagnetic properties.

9. Is cast iron pipe magnetic?

Yes. Cast iron pipes are generally magnetic because they are made from ferrous materials. The strength of their magnetic response depends on their specific composition and carbon content.

10. What type of iron is nonmagnetic?

Austenitic stainless steel and some high-alloy irons are essentially nonmagnetic. These materials have crystal structures or alloying elements that prevent magnetic domain alignment, making them unsuitable for magnetic clamping or induction without special modifications.

11. Can a magnet attract cast iron?

Yes. A magnet can attract cast iron due to its ferrous nature. The attraction is strongest in white and ductile cast irons, while gray or high-silicon cast irons may respond only weakly, depending on purity, structure, and temperature.