15 years one-stop China custom CNC machining parts factory

87 |

Published by VMT at Sep 19 2025

87 |

Published by VMT at Sep 19 2025

Are you looking for a high-performance steel that delivers both toughness and excellent edge retention? If so, CPM S30V stainless steel might be the material you need. Many manufacturers and craftsmen face the challenge of finding a steel that balances durability, resistance to wear, and corrosion resistance—while still being relatively easy to machine. In this article, we’ll explore why CPM S30V has become a go-to material for tools, knives, and high-end products.

CPM S30V stainless steel is a high-performance material known for its superior hardness, corrosion resistance, and edge retention. Often used in premium knives and tools, it combines durability with ease of machining. The steel’s composition includes vanadium, which enhances wear resistance, making it ideal for demanding applications where strength and toughness are essential.

Now that you know the basics of CPM S30V stainless steel, it’s important to dive deeper into its characteristics and understand how it outperforms other steels in various applications. Whether you’re considering it for knives, tools, or CNC machining parts, the unique properties of this steel make it a standout choice. Let’s explore the key traits that make CPM S30V so effective.

CPM S30V stainless steel is a premium grade of steel created through the Crucible Particle Metallurgy (CPM) process. This process results in a fine, uniform distribution of carbides, giving the steel excellent wear resistance and edge retention. Specifically designed for high-performance applications, S30V is commonly used in making knives, cutting tools, and industrial parts where strength and toughness are essential. It offers a unique combination of corrosion resistance, hardness, and durability, making it highly sought after in precision industries like aerospace, medical, and high-end manufacturing.

What Steel is CPM S30V Equivalent To?

CPM S30V stainless steel is often compared to other high-performance steels, such as 154CM, VG10, and D2. It is similar to 154CM in terms of hardness and toughness but has superior wear resistance due to its higher vanadium content. Compared to VG10, CPM S30V offers better edge retention and corrosion resistance, making it a stronger choice for knives and tools that undergo heavy use. When compared to D2, CPM S30V excels in overall toughness and corrosion resistance, thanks to its refined manufacturing process. Though it shares some characteristics with these steels, the unique CPM process enhances S30V’s performance, making it ideal for demanding applications.

Yes, CPM S30V stainless steel is highly suitable for knives, especially those requiring excellent edge retention, corrosion resistance, and toughness. The steel’s vanadium content gives it superior wear resistance, allowing knives to stay sharper longer, even with heavy use. Its resistance to rust and staining makes it a great choice for knives exposed to moisture or harsh environments. Whether for high-end hunting knives, kitchen knives, or everyday carry blades, CPM S30V offers the durability and performance that knife enthusiasts and professionals look for in a steel.

CPM S30V stainless steel is known for its impressive balance of hardness, corrosion resistance, and wear resistance. These characteristics are largely due to its unique chemical composition, which includes vanadium, carbon, and chromium. The CPM (Crucible Particle Metallurgy) process ensures the steel’s fine carbide structure, providing enhanced durability and long-lasting performance in demanding applications.

CPM S30V Stainless Steel: Chemical Composition

CPM S30V’s exceptional performance is due in large part to its unique chemical composition, which is designed to enhance wear resistance, toughness, and corrosion resistance. The combination of carbon, chromium, vanadium, and molybdenum gives the steel its ideal balance of hardness and durability. Here's the breakdown of its chemical makeup:

| Element |

Percentage |

| Carbon (C) |

1.45% |

| Chromium (Cr) |

14.00% |

| Vanadium (V) |

4.00% |

| Molybdenum (Mo) |

2.00% |

| Manganese (Mn) |

0.50% |

| Silicon (Si) |

0.50% |

| Phosphorus (P) |

0.03% |

| Sulfur (S) |

0.03% |

This composition gives CPM S30V its impressive qualities, with vanadium enhancing wear resistance, chromium improving corrosion resistance, and carbon contributing to hardness.

CPM S30V Stainless Steel: Mechanical Properties

CPM S30V stainless steel offers a range of mechanical properties that make it ideal for use in high-performance tools and knives. The combination of hardness, strength, and toughness makes it particularly well-suited for demanding applications. Below is a detailed overview of the key mechanical properties of CPM S30V:

| Property |

Value |

| Hardness (HRC) |

58-60 HRC |

| Tensile Strength |

1,400 MPa |

| Yield Strength |

1,200 MPa |

| Elongation (Rp0.2/MPa) |

10-15% |

| Ductility |

High |

| Fatigue Strength |

850 MPa |

| Poisson's Ratio |

0.30 |

| Elastic Modulus |

200 GPa |

| Shear Modulus |

80 GPa |

| Shear Strength |

950 MPa |

These mechanical properties give CPM S30V steel its durability, wear resistance, and overall toughness, making it an excellent choice for cutting tools and other high-stress applications.

CPM S30V Stainless Steel: Physical Properties

CPM S30V stainless steel not only excels in mechanical properties but also offers distinct physical properties that contribute to its performance in various environments. These properties, such as density, thermal conductivity, and corrosion resistance, are essential for tools and knives that need to withstand extreme conditions. Here's a detailed overview of CPM S30V’s physical properties:

| Property |

Value |

| Density |

7.75 g/cm³ |

| Melting Point |

1,400°C (2,550°F) |

| Specific Heat |

460 J/kg·K |

| Thermal Conductivity |

22.5 W/m·K |

| Thermal Expansion |

9.8 × 10⁻⁶ /°C |

| Linear Thermal Expansion Coefficient |

10.5 × 10⁻⁶ /°C |

| Resistivity |

0.00075 μΩ·m |

| Magnetic Properties |

Non-magnetic |

| Electrical Conductivity |

Low |

| Corrosion Resistance |

Excellent |

| Toughness |

High |

These physical properties contribute to the steel’s versatility in various demanding applications, ensuring long-lasting performance and resistance to wear, corrosion, and thermal damage.

Why Choose CPM S30V Stainless Steel for Knives and Tools?

CPM S30V stainless steel stands out in the world of high-performance materials due to its outstanding combination of hardness, edge retention, corrosion resistance, and toughness. These properties make it a top choice for knives and tools that are used in demanding environments. Here's why CPM S30V is a great choice:

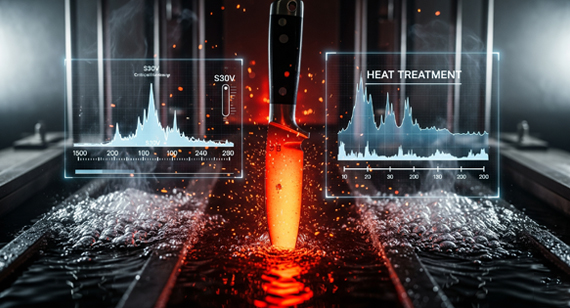

Heat treatment is a crucial step in enhancing the performance of CPM S30V stainless steel, as it influences its hardness, toughness, and overall durability. Proper heat treatment can optimize the steel’s characteristics, ensuring it meets the demands of high-performance knives and tools. Here’s an overview of the typical heat treatment process for CPM S30V:

Proper heat treatment is critical to getting the most out of CPM S30V stainless steel, ensuring optimal performance in tools and knives that require exceptional hardness and durability.

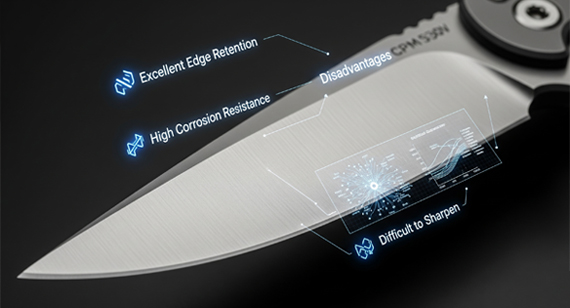

CPM S30V stainless steel is a high-performance material that offers a unique balance of properties suited for knives, tools, and other demanding applications. While it provides numerous advantages in terms of durability, corrosion resistance, and edge retention, it does have some drawbacks to consider. Below is a breakdown of its key advantages and disadvantages:

| Advantages |

Disadvantages |

| Excellent Wear Resistance |

Hard to Machine |

| Due to its vanadium content, CPM S30V maintains a sharp edge for longer, reducing the need for frequent sharpening. | The high hardness of S30V can make it more difficult to machine compared to softer steels, requiring specialized tools and processes. |

| Superior Corrosion Resistance |

Higher Cost |

| S30V is highly resistant to rust and staining, making it ideal for knives and tools exposed to moisture or harsh environments. | CPM S30V is more expensive than many other steels, which could impact project costs, especially for large runs. |

| Balanced Toughness and Hardness |

Requires Precise Heat Treatment |

| Offers a great balance between toughness and hardness, providing excellent durability without being too brittle. | The steel requires precise heat treatment for optimal performance; improper heat treatment can reduce its strength and edge retention. |

| Good Sharpness and Edge Retention |

Not as Tough as Some Steels in Impact Resistance |

| Holds a sharp edge for an extended period, making it ideal for high-performance knives and tools. | While tough, CPM S30V can be more brittle than other steels, like D2, under certain high-impact conditions. |

| Versatile for Various Applications | |

| Suitable for knives, cutting tools, and other precision components used in demanding environments. |

These advantages and disadvantages make CPM S30V a top choice for high-performance tools, but they also require careful consideration when selecting the material for a specific project.

CPM S30V stainless steel is known for its versatility and high performance, making it a popular choice across various industries. Its combination of hardness, corrosion resistance, and edge retention makes it ideal for applications that demand durability and precision. Here’s a look at the primary uses of CPM S30V:

| Application |

Description |

| Knives and Cutting Tools |

Due to its excellent edge retention and corrosion resistance, CPM S30V is commonly used in premium knives, including hunting knives, kitchen knives, and tactical blades. |

| Industrial Tools |

S30V is used in industrial cutting tools such as saw blades, drill bits, and knives that need to maintain sharpness and resist wear over extended periods. |

| Aerospace Components |

Aerospace parts that require high strength and resistance to wear and corrosion, such as components in engines and landing gear, benefit from S30V’s properties. |

| Medical Instruments |

Surgical tools and medical instruments made from CPM S30V offer high durability and corrosion resistance, essential for precision and safety in medical procedures. |

| Automotive Parts |

High-performance automotive components, such as brake pads and gears, utilize S30V for its resistance to wear and fatigue. |

| Outdoor Tools and Equipment |

Tools used in extreme outdoor conditions, like multi-tools, axes, and outdoor knives, benefit from S30V’s ability to withstand rough environments without degrading. |

CPM S30V is particularly well-suited for any application requiring a balance of wear resistance, corrosion resistance, and strength, making it a reliable choice across various industries.

The cost of CPM S30V stainless steel can vary depending on several factors, including the grade of the material, its availability, and the complexity of machining. Below is a general overview of the typical costs involved in the material and machining process for CPM S30V, though prices can fluctuate based on supplier and region.

| Cost Category |

Price Range (USD) |

Description |

| Material Cost (per kg) |

$30 - $50 | The price of raw CPM S30V stainless steel per kilogram varies depending on market conditions and supplier. |

| Material Cost (per pound) |

$13 - $22 | For smaller quantities or when purchasing per pound, prices generally range from $13 to $22. |

| CNC Machining (per hour) |

$100 - $150 | CNC machining services for CPM S30V typically cost between $100 and $150 per hour, depending on the complexity of the parts and the machining process required. |

| Heat Treatment Cost (per part) |

$20 - $50 | Heat treatment, including processes like tempering or cryogenic treatment, can add $20 to $50 per part, depending on the size and specific requirements. |

| Tooling and Setup Costs |

$50 - $200 | Tooling costs can range from $50 to $200, depending on the equipment used and the setup complexity for machining CPM S30V. |

| Surface Finishing (per part) |

$20 - $100 | Polishing, coating, or other finishing processes to ensure surface quality may add an additional $20 to $100 per part. |

| Shipping and Handling (per order) |

Varies based on quantity and location | Shipping costs for CPM S30V steel depend on quantity, location, and delivery time frame. |

While CPM S30V is a premium material and has higher initial costs compared to other steels, its durability and performance in demanding applications often justify the investment. Keep in mind that these prices are general estimates and can vary.

When selecting the right steel for your project, comparing CPM S30V stainless steel to other high-performance alloys is essential to understanding its strengths and weaknesses. Each steel has unique characteristics that make it suited for specific applications. Below is a detailed comparison of CPM S30V stainless steel with other popular steels commonly used for knives, tools, and industrial applications.

CPM S30V vs. 154CM Stainless Steel

| Property |

CPM S30V |

154CM |

| Edge Retention |

Superior | Good |

| Corrosion Resistance |

Excellent | Good |

| Toughness |

High | Moderate |

| Hardness |

58-60 HRC | 58-61 HRC |

| Wear Resistance |

Excellent | Good |

| Common Applications |

Knives, cutting tools | Knives, aerospace, medical tools |

CPM S30V has better edge retention and wear resistance due to its higher vanadium content, making it more suitable for high-performance knives. 154CM is a slightly less expensive option with decent toughness and wear resistance.

CPM S30V vs. 440C Stainless Steel

| Property |

CPM S30V |

440C |

| Edge Retention |

Excellent | Good |

| Corrosion Resistance |

Excellent | Good |

| Toughness |

High | Moderate |

| Hardness |

58-60 HRC | 58-60 HRC |

| Wear Resistance |

Very High | Moderate |

| Common Applications |

Knives, tools, aerospace | Knives, bearings, medical tools |

While CPM S30V offers superior wear resistance, 440C is a cost-effective option for knives and tools but lacks the same level of edge retention and wear resistance as S30V.

CPM S30V vs. VG10 Steel

| Property |

CPM S30V |

VG10 |

| Edge Retention |

Excellent | Good |

| Corrosion Resistance |

Excellent | Excellent |

| Toughness |

High | Moderate |

| Hardness |

58-60 HRC | 59-61 HRC |

| Wear Resistance |

Very High | Good |

| Common Applications |

High-end knives, tools | Kitchen knives, outdoor knives |

VG10 offers excellent corrosion resistance, similar to CPM S30V, but S30V generally outperforms VG10 in terms of edge retention and wear resistance.

CPM S30V vs. D2 Steel

| Property |

CPM S30V |

D2 |

| Edge Retention |

Superior | Good |

| Corrosion Resistance |

Excellent | Fair |

| Toughness |

High | Moderate |

| Hardness |

58-60 HRC | 58-62 HRC |

| Wear Resistance |

Excellent | Good |

| Common Applications |

High-performance knives | Industrial tools, knives |

D2 is known for its toughness but lacks the corrosion resistance of CPM S30V. While D2 has high hardness, S30V provides better edge retention and is more suitable for harsh, corrosive environments.

CPM S30V vs. 1095 Steel

| Property |

CPM S30V |

1095 |

| Edge Retention |

Excellent | Moderate |

| Corrosion Resistance |

Excellent | Poor |

| Toughness |

High | High |

| Hardness |

58-60 HRC | 55-58 HRC |

| Wear Resistance |

Very High | Low |

| Common Applications |

Premium knives, tools | Budget knives, tools |

1095 steel is more affordable but lacks the corrosion resistance and edge retention of CPM S30V. It is more prone to rust and wear, making it less ideal for high-performance applications.

S30V Stainless Steel vs. 440C Stainless Steel

| Property |

S30V Stainless Steel |

440C Stainless Steel |

| Edge Retention |

Excellent | Good |

| Corrosion Resistance |

Excellent | Good |

| Toughness |

High | Moderate |

| Hardness |

58-60 HRC | 58-60 HRC |

| Wear Resistance |

Very High | Moderate |

| Common Applications |

Knives, aerospace tools | Bearings, knives |

Similar to the previous comparison, S30V excels in edge retention and wear resistance, while 440C remains a solid choice for less demanding applications.

S30V Steel vs. 420HC Stainless Steel

| Property | S30V Steel | 420HC Steel |

| Edge Retention | Excellent | Fair |

| Corrosion Resistance | Excellent | Good |

| Toughness | High | Moderate |

| Hardness | 58-60 HRC | 55-58 HRC |

| Wear Resistance | Very High | Low |

| Common Applications | High-end knives | Budget knives, tools |

420HC is a lower-cost alternative to S30V with less edge retention and wear resistance. S30V's enhanced properties make it ideal for high-performance knives and tools.

S30V vs. M390 Steel

| Property |

S30V |

M390 |

| Edge Retention |

Excellent | Excellent |

| Corrosion Resistance |

Excellent | Excellent |

| Toughness |

High | High |

| Hardness |

58-60 HRC | 60-62 HRC |

| Wear Resistance |

Very High | Very High |

| Common Applications |

Premium knives, tools | Premium knives, cutting tools |

M390 is a step above S30V in terms of hardness and wear resistance but can be more difficult to sharpen. It is often used for high-end knives where edge retention is critical.

CPM S30V vs. 3V Steel

| Property |

CPM S30V |

3V Steel |

| Edge Retention |

Excellent | Good |

| Corrosion Resistance |

Excellent | Fair |

| Toughness |

High | Very High |

| Hardness |

58-60 HRC | 59-61 HRC |

| Wear Resistance |

Very High | Good |

| Common Applications |

Knives, tools, aerospace | High-impact tools, knives |

3V offers superior toughness, making it a great choice for tools subjected to high impact, but it lacks the same level of corrosion resistance and edge retention as CPM S30V.

Maintaining CPM S30V stainless steel knives properly is essential for preserving their sharpness, corrosion resistance, and overall longevity. While CPM S30V is a high-performance steel known for its excellent wear resistance and edge retention, it still requires care to ensure it performs optimally. Here’s a guide on how to care for and maintain your CPM S30V knives:

1. Regular Cleaning

2. Proper Storage

3. Sharpening

4. Avoiding Impact and Excessive Force

5. Routine Oiling

6. Avoiding Harsh Chemicals

7. Honing Regularly

By following these simple yet effective care and maintenance steps, your CPM S30V stainless steel knife will remain sharp, durable, and corrosion-resistant for many years.

CPM S30V stainless steel is a high-performance material that offers outstanding edge retention, corrosion resistance, and wear resistance. However, whether it’s the right choice for your project depends on several key factors. Below, I’ll outline the considerations to help you determine if CPM S30V is a good fit for your needs.

1. Project Type

2. Budget Considerations

3. Material Properties and Durability

4. Machinability and Processing

5. End-Use Environment

In Summary:

To determine if CPM S30V is the best fit, you should assess the specific requirements of your project, including performance, cost, and environmental factors.

At VMT, we specialize in offering high-quality CPM S30V stainless steel CNC machined parts for a variety of industries, including aerospace, medical, tooling, and precision engineering. With our state-of-the-art machinery and experienced team of professionals, we provide precision machining services that ensure optimal performance, durability, and reliability for your projects.

Why Choose VMT for CPM S30V CNC Machining Parts?

Expertise in Hard-to-Machine Materials

Custom Solutions for Your Needs

Superior Material Properties

Fast Turnaround and On-Time Delivery

Competitive Pricing

Applications of CPM S30V CNC Machined Parts:

Our CNC Machining Services:

At VMT, we are committed to delivering top-tier CPM S30V stainless steel CNC machined parts that meet your project's specific needs. Our combination of expertise, cutting-edge technology, and commitment to quality makes us your trusted partner for precision machining.

For more information on how we can support your project, feel free to reach out for a quote or consultation!

In conclusion, CPM S30V stainless steel is a premium material known for its exceptional wear resistance, edge retention, and corrosion resistance, making it ideal for high-performance applications such as knives, cutting tools, aerospace components, and medical devices. While it’s a higher-cost option due to its advanced properties, the long-term benefits—such as durability and longevity—make it a worthy investment for projects that require precision, reliability, and toughness.

Whether you are looking for CNC machining services for CPM S30V stainless steel parts, or considering it for your next project, understanding its properties, advantages, and potential challenges is crucial. At VMT, we provide expert CNC machining services that ensure your CPM S30V parts are crafted to the highest standards of quality, meeting your specifications with precision and efficiency.

When selecting the right material for your project, always consider factors like cost, required performance, and environmental conditions. With proper care and maintenance, CPM S30V stainless steel can deliver outstanding performance and longevity for your cutting-edge applications.

If you are ready to move forward with your project or need professional guidance on CPM S30V parts, VMT is here to help you every step of the way. Contact us today to discuss your needs and how we can support your project with our expert CNC machining services.

1. CPM S30V Stainless Steel vs. 440C: Which is Better for Knives?

CPM S30V is generally considered superior to 440C for knives due to its better edge retention, wear resistance, and corrosion resistance. CPM S30V features a more advanced alloy composition with higher vanadium content, which contributes to its improved toughness and sharper edge. 440C, while a decent steel, tends to be less resistant to corrosion and may require more frequent sharpening than CPM S30V.

2. How Does CPM S30V Steel Compare in Strength to D2 Steel?

CPM S30V is harder and offers better wear resistance than D2, but D2 is tougher and more resistant to impact. CPM S30V excels in edge retention and is less prone to corrosion, making it ideal for precision tools and knives. D2 is often used for heavier-duty applications where impact resistance is more critical, though it is more prone to rusting than CPM S30V.

3. CPM S30V vs. 154CM Steel: Which Steel Holds an Edge Better?

CPM S30V holds an edge better than 154CM due to its higher vanadium content, which results in a finer grain structure and increased wear resistance. While 154CM is still a good steel for knives, CPM S30V is superior in edge retention, making it more suitable for premium knives that need to perform over extended periods without frequent sharpening.

4. Is CPM S30V Stainless Steel More Corrosion-Resistant than 440C?

Yes, CPM S30V has better corrosion resistance than 440C. This is largely due to its higher levels of chromium and its refined manufacturing process, which enhances the steel's resistance to rust and corrosion. 440C can be more prone to rust, especially in humid or salty environments, while CPM S30V maintains its integrity under harsh conditions.

5. CPM S30V vs. VG10: Which Steel is Better for Knife Making?

Both CPM S30V and VG10 are excellent for knife making, but CPM S30V offers better edge retention and wear resistance due to its higher vanadium content. VG10, however, is easier to sharpen and is often preferred for kitchen knives due to its balance of performance and ease of maintenance. For higher-end knives that need superior longevity and durability, CPM S30V is typically the better choice.

6. Why is CPM S30V Used in High-End Knives?

CPM S30V is used in high-end knives because of its excellent combination of hardness, wear resistance, corrosion resistance, and edge retention. These properties make it an ideal material for knives that need to maintain a sharp edge over time while performing well in harsh conditions. Its ability to retain sharpness even with heavy use makes it a favorite in premium hunting, tactical, and culinary knives.

7. Is S30V Better than 440C?

Yes, CPM S30V is generally considered better than 440C due to its superior edge retention, wear resistance, and corrosion resistance. While 440C is still a solid steel for certain applications, CPM S30V outperforms it in the key areas that matter for high-end knives and tools, particularly for those requiring long-lasting sharpness.

8. Is D2 or S30V Better?

CPM S30V is generally considered better than D2 for knives that require superior edge retention and corrosion resistance. D2 is a high-carbon tool steel with excellent toughness but tends to rust more easily than CPM S30V. For knives used in environments where corrosion resistance is critical, CPM S30V would be the better option. However, if your project requires a steel that can withstand more impact or bending, D2 might be more suitable.

9. What is the Hardest Steel for Knives?

The hardest steels for knives are often tool steels like CPM S110V, CPM 10V, and M390, which can achieve Rockwell hardness ratings above 60 HRC. However, CPM S30V is still among the hardest steels suitable for general knife making, typically reaching 58-60 HRC. While harder steels tend to hold an edge longer, they can also be more difficult to sharpen and may be more brittle.

10. What is the Best Steel for Pocket Knives?

The best steel for pocket knives depends on the intended use, but CPM S30V is often considered one of the top choices for premium pocket knives due to its outstanding edge retention, corrosion resistance, and overall performance. Other popular steels for pocket knives include VG10, 154CM, and S35VN, but CPM S30V remains a top contender in the high-performance category.

These FAQs should help you make an informed decision about whether CPM S30V is the right choice for your knives or tools, depending on your specific needs. If you have further questions or need personalized advice, feel free to reach out!