15 years one-stop China custom CNC machining parts factory

Hey there I’m VMT Sam!

With 25 years of CNC machining experience we are committed to helping clients overcome 10000 complex part-processing challenges all to contribute to a better life through intelligent manufacturing. Contact us now

124 |

Published by VMT at Sep 23 2025

124 |

Published by VMT at Sep 23 2025

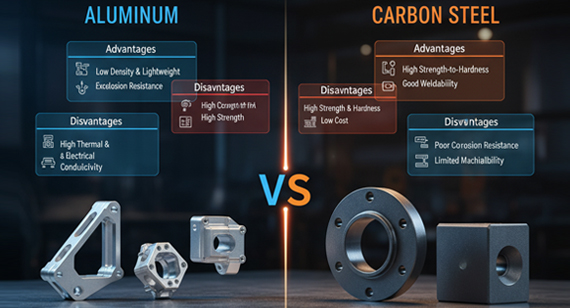

When selecting CNC Machining materials, the selection frequently comes down to 2 popular options: aluminum and carbon steel. Both are broadly utilised in industries along with automotive, aerospace, scientific devices, and consumer goods. But here’s the real query: Which one is higher on your undertaking?

In this article, you’ll see the important differences between aluminum and carbon steel. You’ll additionally learn how each material works in CNC machining so that you can make the proper choice for your elements.

Aluminum is a light-weight, silver-coloured metal recognised for its excellent power-to-weight ratio. You often pick aluminum when you want materials that face up to rust, are clean to machine, and nonetheless provide dependable strength.

Carbon steel is an alloy by and large, fabricated from iron and carbon. Depending on the carbon content, you may get low-carbon metallic (softer and extra ductile) or high-carbon steel (very strong and wear-resistant). If you want sturdiness and rigidity, carbon steel is regularly the go-to material.

Choosing the wrong material can result in high costs, negative overall performance, or components that don’t realistically match. That’s why it’s important to carefully examine aluminum CNC machining and carbon steel CNC machining before production starts.

1. Weight

Aluminum is one-third the weight of carbon steel. This makes it the preferred choice in industries like aerospace and cars, wherein reducing mass is essential. Carbon metallic, alternatively, is drastically heavier. The introduced weight does offer strength, but it’s not the best for applications in which lightweight designs are essential.

2. Strength

Carbon metal outperforms aluminum in terms of strength and hardness. For heavy-duty, high-stress, or structural initiatives, carbon steel is usually the more dependable alternative. Aluminum nonetheless affords solid power; however, it can not match carbon steel in terms of load-bearing potential.

3. Corrosion Resistance

Aluminum certainly resists corrosion by forming a thin oxide layer on its surface, making it ideal for outdoor or marine packages. Carbon steel rusts quickly without protection. To use it in moisture-susceptible environments, you need to use coatings, paints, or galvanisation.

4. Machinability

Aluminum is tender and clean to reduce, which makes CNC machining faster, more efficient, and much less costly. The tools are closing longer, and the fabric achieves easy finishes with fewer attempts. Carbon steel, with the aid of assessment, is an awful lot harder. Machining requires more powerful gear, slower speeds, and additional electricity, which will increase overall machining costs.

5. Cost

Raw aluminum generally costs more per kilogram than carbon steel. However, machining aluminum is commonly less expensive due to its high ease of machining. Carbon steel is less costly as a raw material, but the higher cost of machining and protective surface treatments could make it more costly in the long run.

Advantages

One of the primary benefits of aluminum is its machinability. It lets manufacturers create complicated shapes and excessive precision without excessive tools. Another major advantage is aluminum’s excellent corrosion resistance, which makes it appropriate for outside and marine environments without extra coatings. In addition, its light-weight nature combined with affordable power makes it a top choice for aerospace and car elements. Finally, aluminum regularly grants an appealing surface finish, even without heavy polishing.

Best Applications

Aluminum CNC machining is right for industries wherein reducing weight and ensuring corrosion resistance are priorities. Common applications include aerospace components, automotive components, consumer electronics casings, and medical equipment.

Limitations

The primary trouble with aluminum is its lower strength in comparison to carbon steel. For programs that require dealing with extremely heavy loads or consistent pressure, carbon steel remains the better choice.

Carbon Steel CNC Machining

Advantages

Carbon steel is known for its brilliant strength and hardness, making it a dependable choice for demanding programs. It plays nicely beneath heavy masses and affords sturdiness in business settings. Another benefit is its value-effectiveness as an uncooked cloth. Additionally, carbon metal can be heat-treated to enhance hardness, sturdiness, and wear resistance.

Best Applications

Carbon steel CNC machining is best for elements that have to bear heavy stress and wear. These encompass device tools, business equipment, car frames, and creation equipment.

Limitations

The downsides of carbon metal are its poor corrosion resistance and extra-hard machining requirements. Protective coatings or remedies are typically vital, which will increase costs. Its heaviness also makes it much less suitable for applications where lowering weight is critical.

For Aluminum

Anodising is one of the most common remedies for aluminum, improving corrosion resistance and developing a decorative finish. Powder coating is another option, which provides colour and a further protective layer. For parts wherein aesthetics depend, polishing aluminum produces an easy and reflective surface.

For Carbon Steel

Zinc coating, additionally referred to as galvanisation, presents awesome rust protection. Painting is another technique to create a shielding barrier against corrosion. Additionally, warmth treatment can drastically enhance carbon metal’s hardness and sturdiness.

When to Choose Aluminum

Select aluminum if your elements need to be lightweight, proof against moisture or chemical substances, and quick to assemble. It’s additionally the proper desire while natural corrosion resistance is desired.

When to Choose Carbon Steel

Choose carbon steel when most electricity and durability are required. It’s also suitable when uncooked material costs more than machining costs, or whilst defensive coatings may be carried out anyway.

Balanced Approach

Sometimes the best answer is a hybrid method. For instance, aluminum can be used for lightweight components, even as carbon steel presents durability for load-bearing structures.

So, Aluminum vs. Carbon Steel: Which is higher? The answer depends absolutely on your assignment. If you need lightweight, corrosion-resistant, and easy-to-machine elements, aluminum CNC machining is your quality wager. If your components must handle heavy masses, strain, and wear, carbon steel is the more potent choice.

By knowing the strengths and weaknesses of both materials, you may expectantly choose the right alternative to your CNC machining wishes.

1. Is aluminum more expensive than carbon steel?

Yes, aluminum typically costs more per kilogram, but it saves money throughout machining and calls for less upkeep over the years.

2. Which material has better corrosion resistance?

Aluminum obviously resists corrosion, at the same time as carbon steel ought to be coated or painted to avoid rusting.

3. Can carbon steel resist rust without coating?

No, carbon metallic rusts effortlessly without safety. It requires coatings, which include zinc plating or paint to prevent corrosion.

Ready To Start Your Next Project?

Get Instant Quote

Request a Free Quote

Send us a message if you have any questions or request a quote. We will get back to you ASAP!